Method for producing compound microbial fertilizer from amino acid organic granules

A technology of composite microorganisms and organic particles, applied in the direction of organic fertilizers, fertilizer mixtures, applications, etc., can solve problems that affect product quality and effect, affect product use and promotion, and cannot meet market needs, etc., to simplify the drying steps , Expand the scope of product use, solve the effect of balling and dissolution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

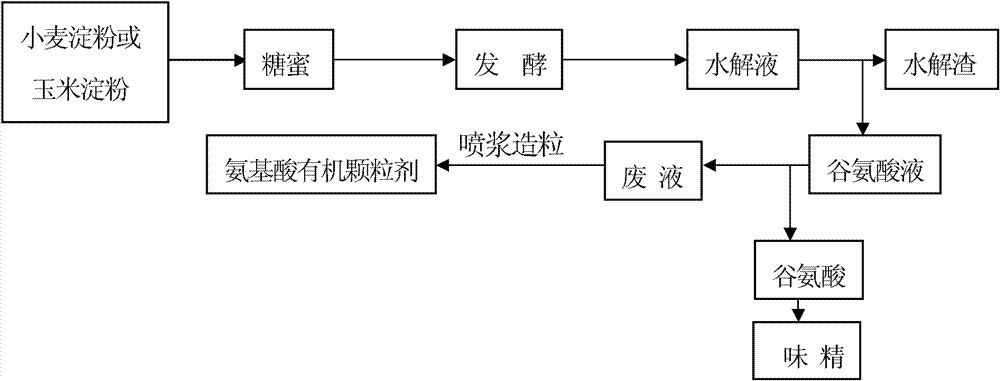

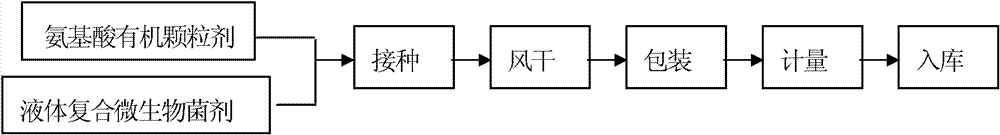

Method used

Image

Examples

Embodiment 1

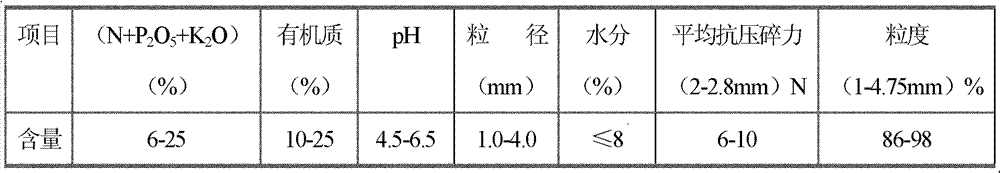

[0042] 1. Spray and granulate the waste amino acid liquid in the MSG production process into organic granules. The properties of the organic granules are shown in Table 2.

[0043] Table 2: Basic properties of amino acid organic granules

[0044]

[0045] Preparation of liquid inoculum: Bacillus subtilis, Bacillus megaterium and Bacillus mucilagimosus krassilm are separately fermented using fermentation equipment, and the three single bacterial liquids are produced according to 2:1 :1 ratio is mixed, so that the total number of effective viable bacteria of the liquid composite microbial inoculant mixed with the three bacteria liquid after mixing reaches 45.2×10 8 Pcs / g.

[0046] 2. Turn on the mixer, slowly and uniformly add organic granules to make the material flow continuously and uniformly. In the rotating mixer, use a plunger pump to spray the bacteria liquid on the surface of the organic granules at a ratio of 0.6% by weight. Spray 0.6 kg of bacterial liquid into 100 kg of org...

Embodiment 2

[0049] The amino acid waste liquid in the MSG production process is sprayed and granulated, and monoammonium phosphate, borax and humic acid are added in the granulation process.

[0050] 1. Preparation of liquid bacterial agents: Bacillus subtilis and Bacillus megaterium are separately fermented and produced by fermentation equipment, and the two single bacterial liquids are mixed at a ratio of 1:1 to make the two mixed bacteria The total number of effective viable bacteria of the mixed liquid compound microbial inoculants reaches 47.6×10 8 Pcs / g.

[0051] 2. Turn on the mixer, slowly and uniformly add organic granules to make the material flow continuously and uniformly. In the rotating mixer, use a plunger pump to evenly spray the bacteria liquid on the surface of the organic granules at a weight ratio of 0.8% (ie 100 kg Spray 0.8 kg of bacterial liquid in the organic granules).

[0052] 3. Transport the uniformly inoculated organic granules directly to the silo with a belt conve...

Embodiment 3

[0054] The amino acid waste liquid in the MSG production process is sprayed and granulated, and urea, potassium sulfate and ferrous sulfate are added during the granulation process.

[0055] 1. Preparation of liquid bacterial agents: Bacillus subtilis and Bacillus mucilagimosus krassilm are separately fermented using fermentation equipment, and the two single bacterial liquids are mixed in a ratio of 2:1 to make the mixture The total number of effective live bacteria of the liquid composite microbial inoculum mixed with the latter two bacteria liquids reaches 41.6×10 8 Pcs / g.

[0056] 2. Turn on the mixer, slowly and uniformly add organic granules to make the material flow continuously and uniformly. In the rotating mixer, use a plunger pump to evenly spray the bacteria liquid on the surface of the organic granules at a weight ratio of 0.8% (ie 100 kg Spray 0.8 kg of bacterial liquid in the organic granules).

[0057] 3. Transport the uniformly inoculated organic granules directly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com