Engine

A technology of engine and line motion, applied in the direction of machines/engines, mechanisms for generating mechanical power, power devices, etc., can solve problems such as complex structure, high manufacturing cost, and troublesome maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

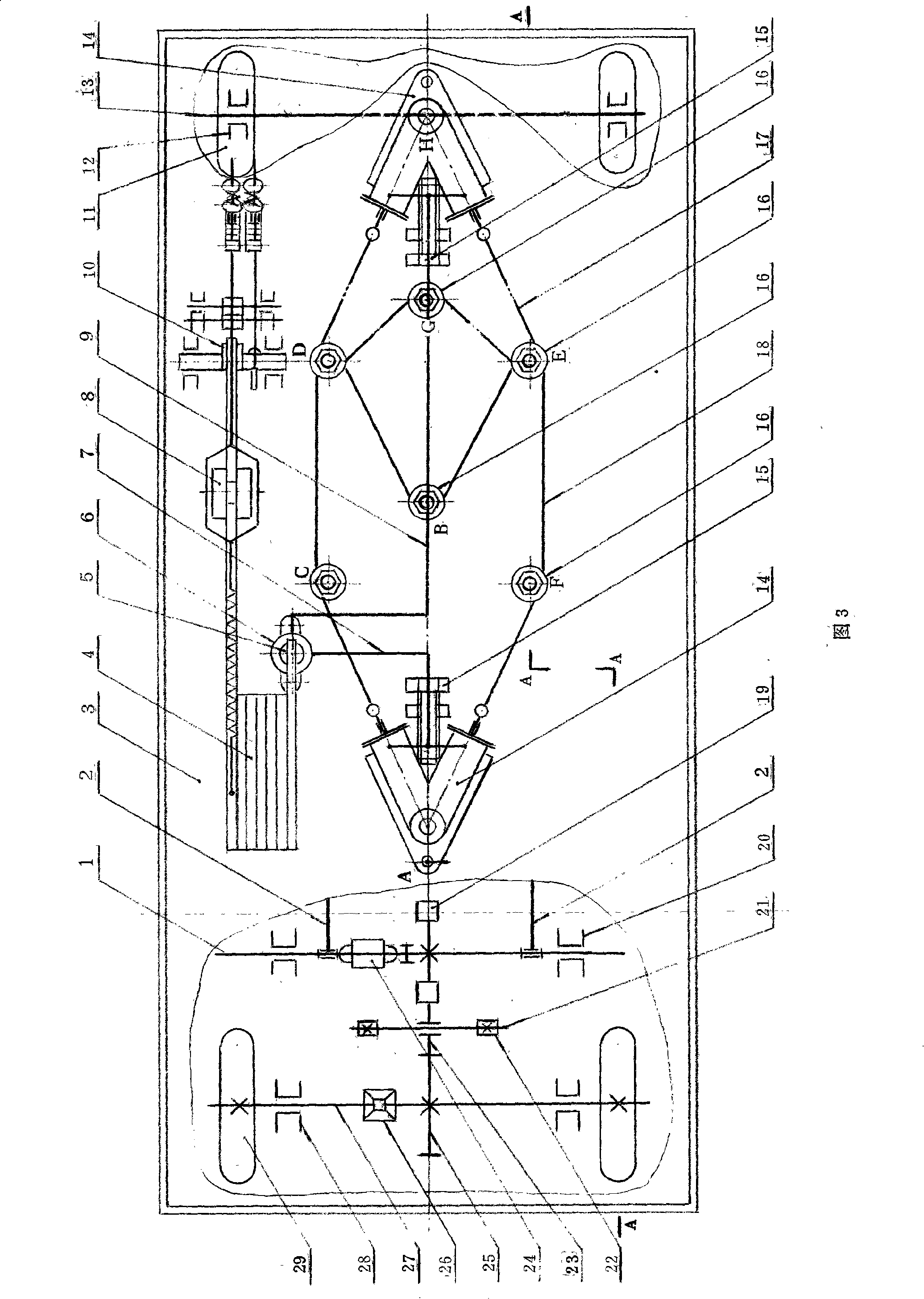

[0034] As shown in Figure 3 and Figure 4, it is a linear motion engine. On the car body (3), a group of nodes are evenly distributed in the horizontal direction: A, B, C, D, E, F, G, H, nodes B, C, F, G place, respectively have a special-purpose rolling bearing (16), be installed on the car body (3) with bearing pin (31), node D, E place, respectively have two stacked rolling bearings (16), Be installed on the piston (33) with bearing pin (36), and piston (33) is contained in the guide sleeve (32) that is fixed on the car body (3), the axis of two guide sleeves (32) and crankshaft (1) center The lines are in the same horizontal plane, and the former is located on the same side of the latter, the guide sleeve (32) has a longitudinal groove (37) through which the pin shaft (36) passes, and the piston (33) has an annular groove (35) on the outer surface of both ends. , embedded with balls (34), the piston (33) is connected to the connecting rod journal of the crankshaft (1) throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com