Pulverized coal gasification device and process method for blending combustion of organic wastewater

A technology for coal gasification and waste water, which is applied in the gasification process, details of gasification devices, combustion methods, etc., can solve problems such as inability to be directly applied, and achieve the effect of reducing the amount of steam used, adapting to a wide range, and reducing the environmental protection pressure of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

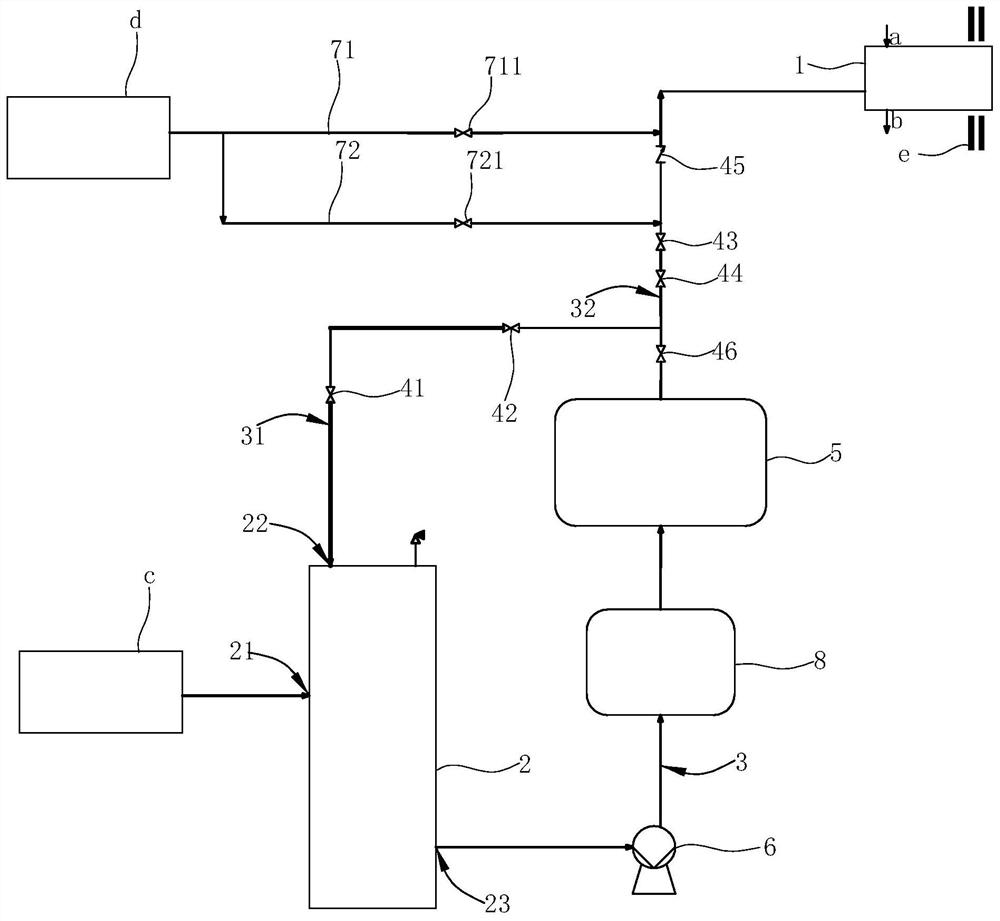

[0042]Such asfigure 1As shown, the pulverized coal gasification device of this preferred embodiment includes a gasifier, a waste water nozzle 1, a waste water buffer tank 2, a liquid feeding pipe 3, a heat exchanger 5, a booster pump 6, a filter 8, an air inlet pipe, etc. ,figure 1Middle e is the gasifier shell and water wall.

[0043]The gasification furnace has an ignition burner, a start-up burner, a process burner, and an interface for installing the aforementioned burners respectively, and the aforementioned burners are independently configured.

[0044]In this embodiment, the start-up burner is made to realize the combined functions of ignition and start-up, and the wastewater nozzle 1 is installed on the interface of the original ignition burner, that is, the ignition burner is no longer installed on the interface, and the interface is used to install the wastew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com