Drying control method of drying system

A drying control and drying system technology, applied in the field of clothing treatment, can solve the problems of high energy consumption and long drying time, and achieve the effects of improving applicability, improving drying effect, and reducing drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

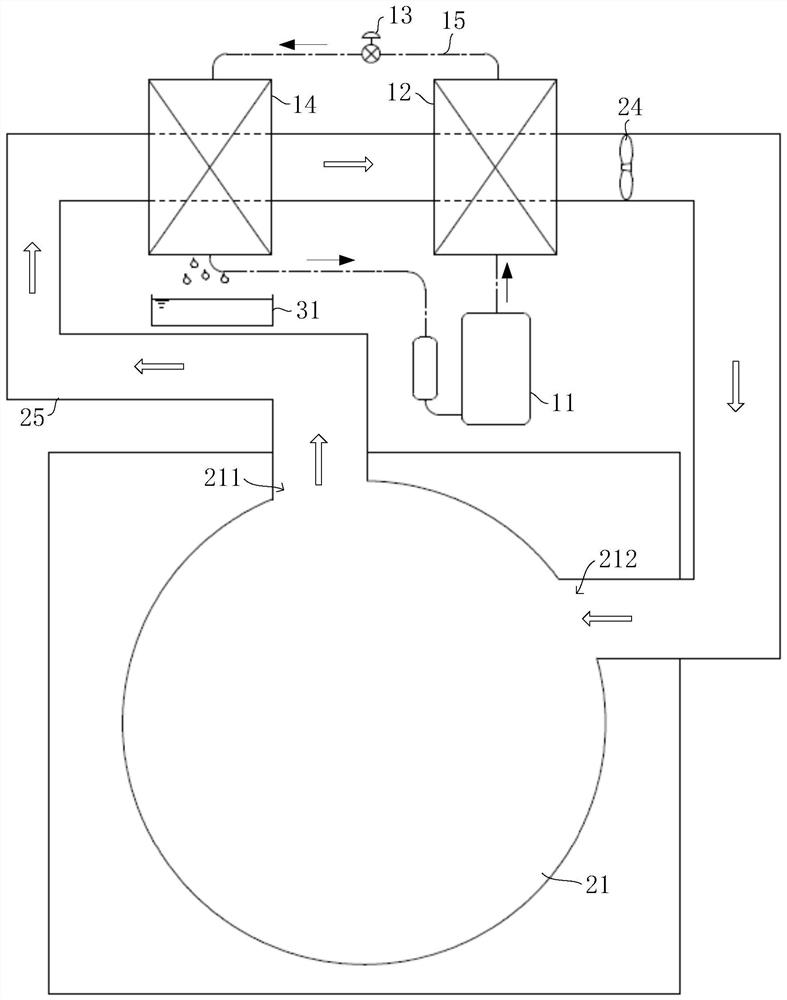

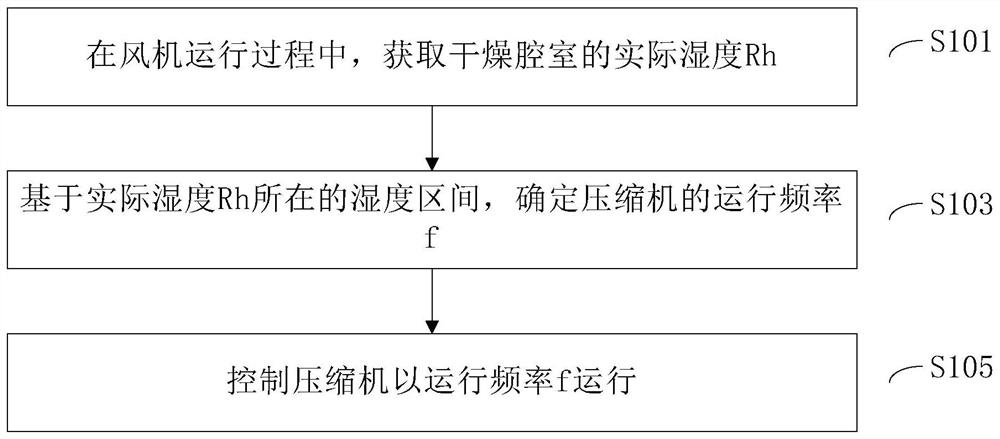

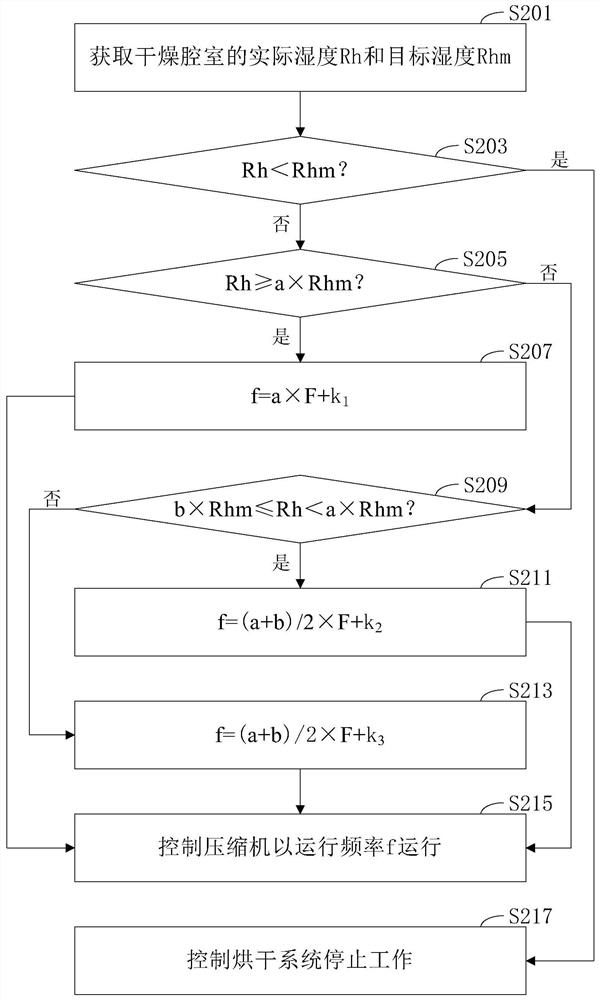

[0064] First refer to Figure 1-3 , to describe the first implementation manner of the drying control method of the present invention. in, figure 1 It is a system diagram of the drying system in the first embodiment of the present invention; figure 2 It is the main flowchart of the drying control method in the first embodiment of the present invention; image 3 It is a flowchart of a possible implementation of the drying control method in the first implementation of the present invention.

[0065] As mentioned in the background technology, in the existing drying system, as the moisture content of the clothes in the drying chamber gradually decreases, the relative humidity in the drying chamber is also getting smaller and smaller, and the air heated by the condenser is in the drying chamber The lowering range of the medium temperature also decreases, and the temperature of the air entering the evaporator and condenser continues to rise, which leads to the gradual weakening ...

Embodiment 2

[0086] Refer below Figure 4-5 , 9. Describe the second implementation manner of the drying control method of the present application. in, Figure 4 It is a system diagram of the drying system in the second embodiment of the present invention; Figure 5 It is the control flowchart of the water pump and the flow regulating valve in the second embodiment of the present invention; Figure 9 It is a structural diagram of a specific embodiment of the gas-liquid heat exchanger of the present invention.

[0087] Such as Figure 4 and Figure 9 As shown, in the second embodiment of the present application, on the basis of Example 1, the drying system further includes a gas-liquid heat exchanger 23 and a cooling circulation loop. The gas-liquid heat exchanger 23 has an air inlet 2311 , an air outlet 2312 , a liquid inlet 2313 and a liquid outlet 2314 , the air inlet 2311 communicates with the humid air outlet 211 , and the air outlet 2312 communicates with the inlet of the evapora...

Embodiment 3

[0104] Refer below Figure 6-7 , to describe the third implementation manner of the drying control method of the present application. in, image 3 It is a system diagram of the drying system in the second embodiment of the present invention. in, Figure 6 It is a system diagram of the drying system in the third embodiment of the present invention; Figure 7 It is the control flowchart of the first electric control valve and the second electric control valve in the third embodiment of the present invention.

[0105] Such as Figure 6As shown, in the third embodiment of the present application, on the basis of Embodiment 2, the water receiving tray 31 is further provided with a baffle 311, and the baffle 311 divides the water receiving tray 31 into a first part 312 and a second part 313 , the liquid inlet 2313 communicates with the first part 312, the liquid outlet 2314 communicates with the second part 313, and the first pipe section 151 and the second pipe section 152 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com