A modular low-rise assembled special-shaped column steel structure building system

A prefabricated, steel structure technology, applied in building construction, construction, etc., can solve problems such as low degree of specialization, environmental pollution around construction, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in detail below in conjunction with the accompanying drawings, but is not limited to the following embodiments.

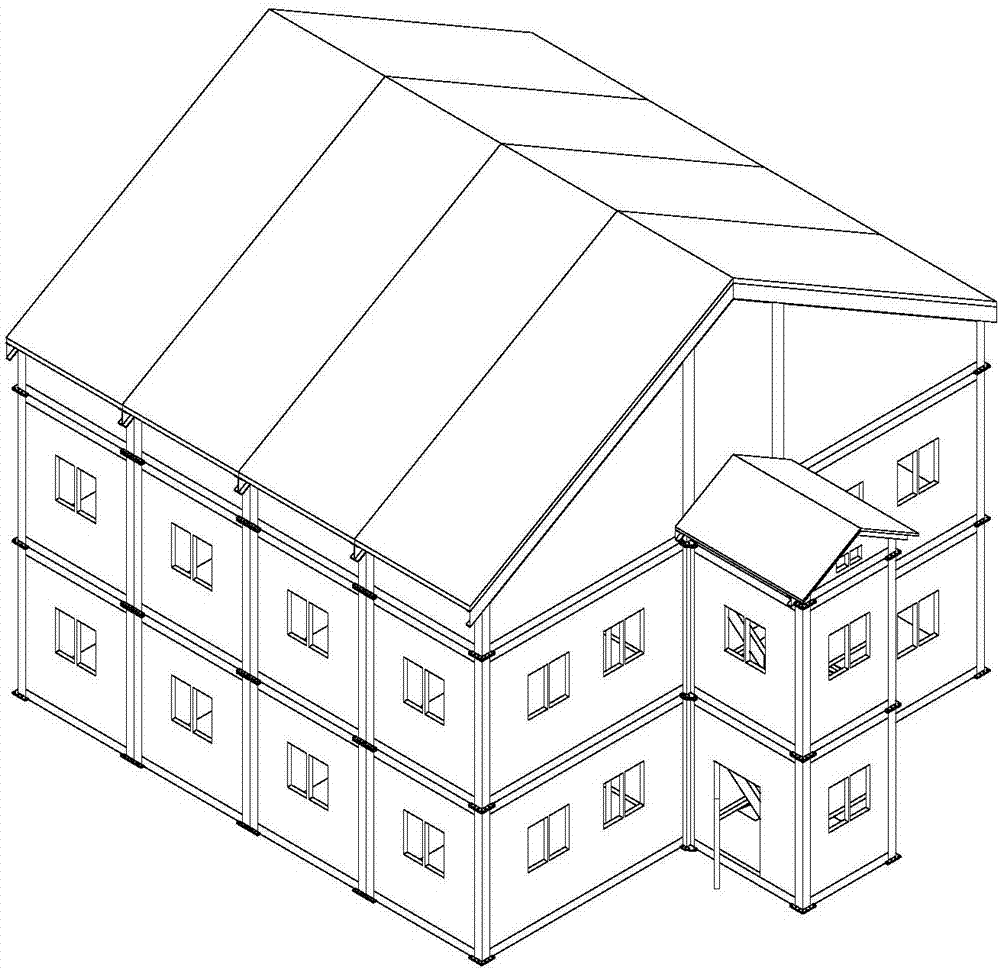

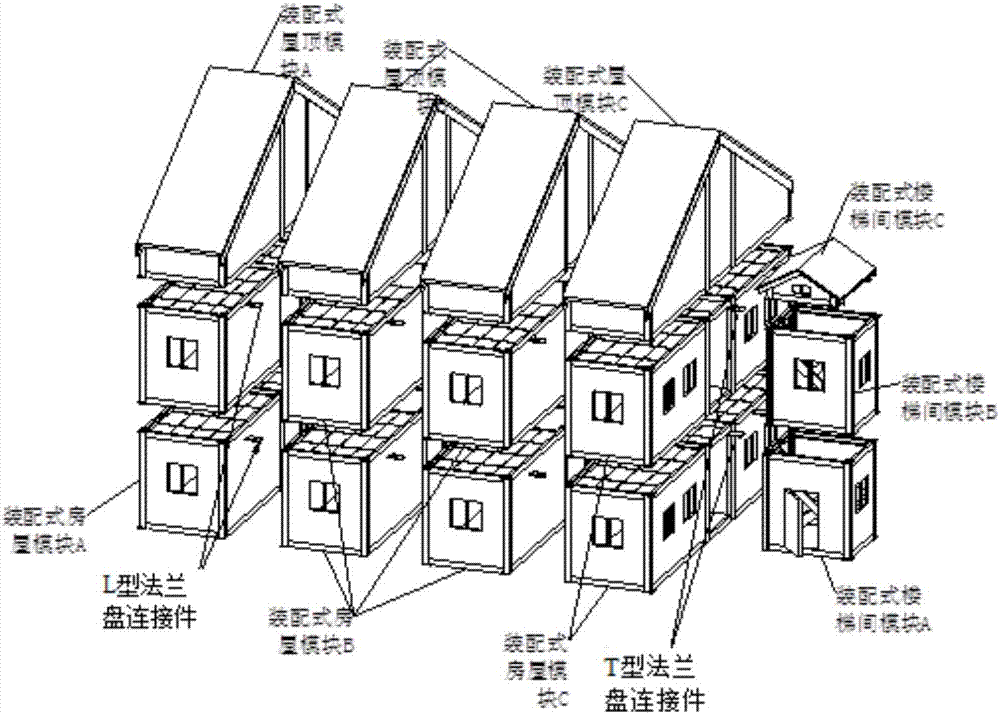

[0076] as attached figure 1 , 2 As shown, the present invention only needs to use high-strength bolts to complete the connection between the prefabricated house modules, prefabricated roof modules and prefabricated stairwell modules on site, and fix the plumbing pipes to complete the construction work of the steel structure house.

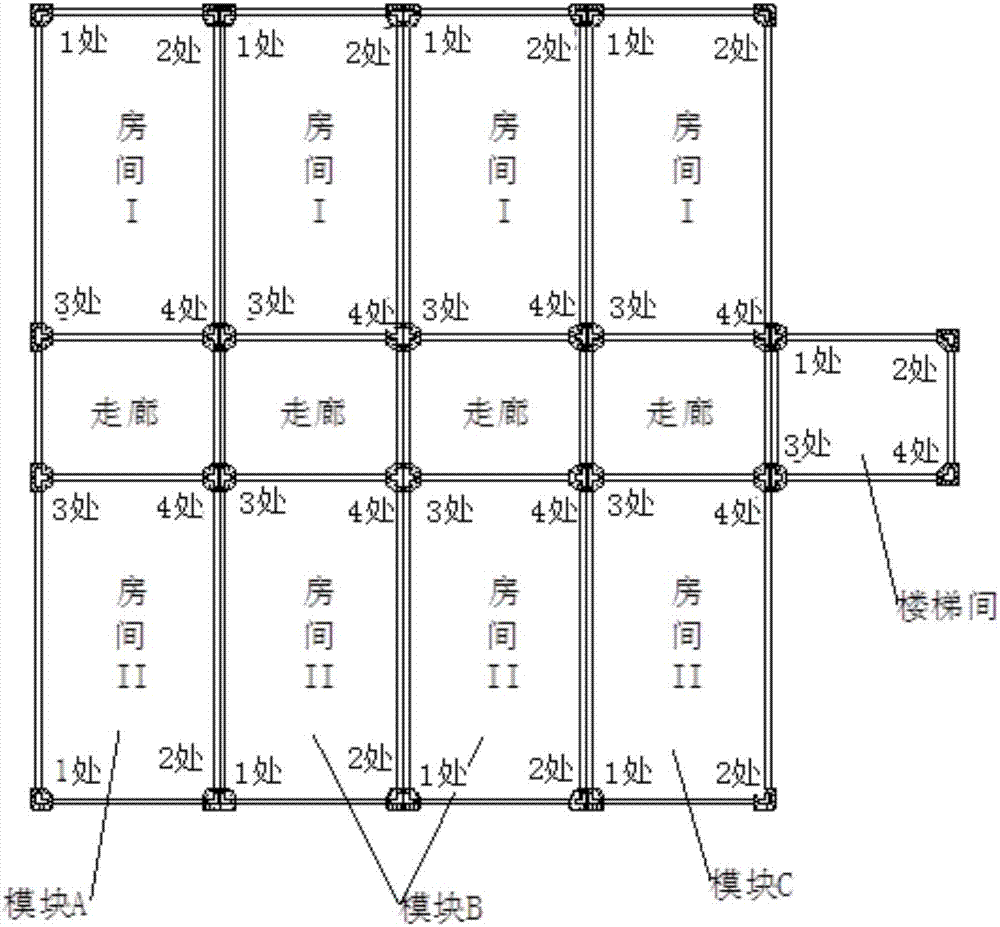

[0077] as attached image 3 As shown in -9, the prefabricated house module A in the present invention is a one-way connection, and its right side can be connected with the prefabricated house module B or the prefabricated house module C, and the left side of the corridor of the prefabricated house module A on the first floor The wall panel can choose to keep the door, which is convenient for travel. The prefabricated wall panel is not fixed on the right side of the corridor, and the corri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com