Positioned full-automatic concrete paving finisher

A concrete, fully automatic technology, applied in the field of positioning type automatic concrete paving and leveling machine, can solve the problems of high price, restricted after-sales service, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

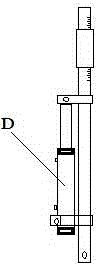

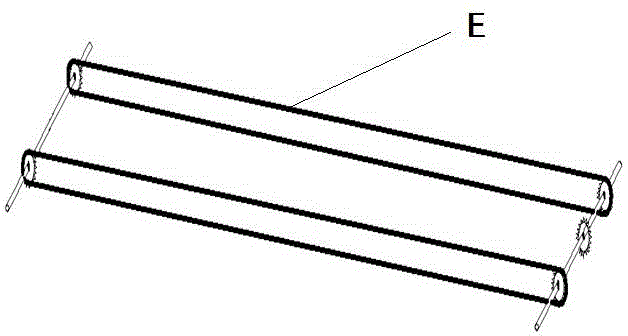

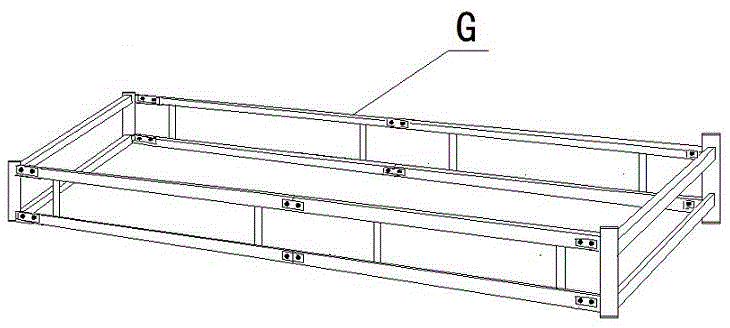

[0027] as attached figure 1 , 2 , 3, the positioning type fully automatic concrete paving and leveling machine, including the main console, automatic material conveying system, shifting walking system, hydraulic adjustment system, chain components, paving and leveling system, disassembly and assembly frame, power Assembly and main console, mobile frame, laser transceiver components.

[0028] The positioning type automatic concrete paving and leveling machine is to determine the elevation size of the laser transmitter according to a fixed horizontal point in the entire working area, and then according to the specific requirements of the project (horizontal plane or slope surface and thickness), positioning The height of the laser receiver is adjusted by the hydraulic adjustment system to adjust the scraper on the paving and leveling system to control the level of the concrete layer. The slurry disperses the concrete material to the base surface, the power system drives the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com