Polypropylene composition for spray-free bumpers and preparation method thereof

A technology of polypropylene composition and bumper, which is applied in the field of material chemistry, can solve the problems of bumper mechanical performance degradation, difficulty in meeting assembly requirements, and poor antistatic durability, so as to achieve dust absorption, low environmental dependence, and excellent performance. The effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

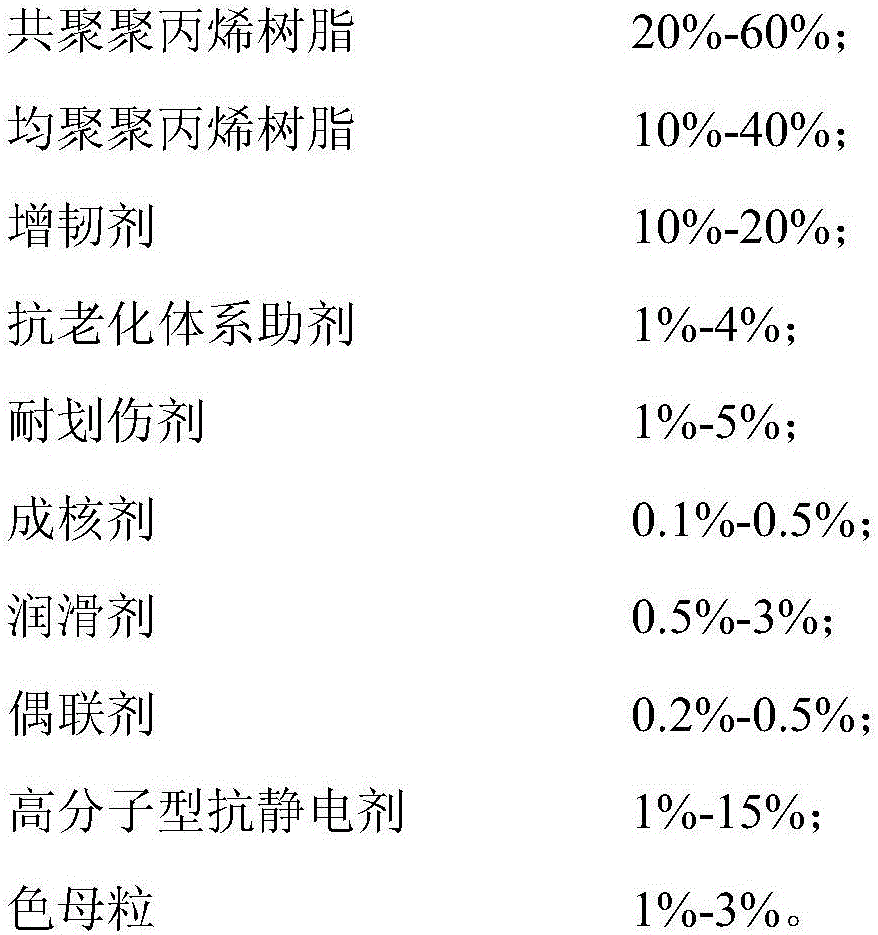

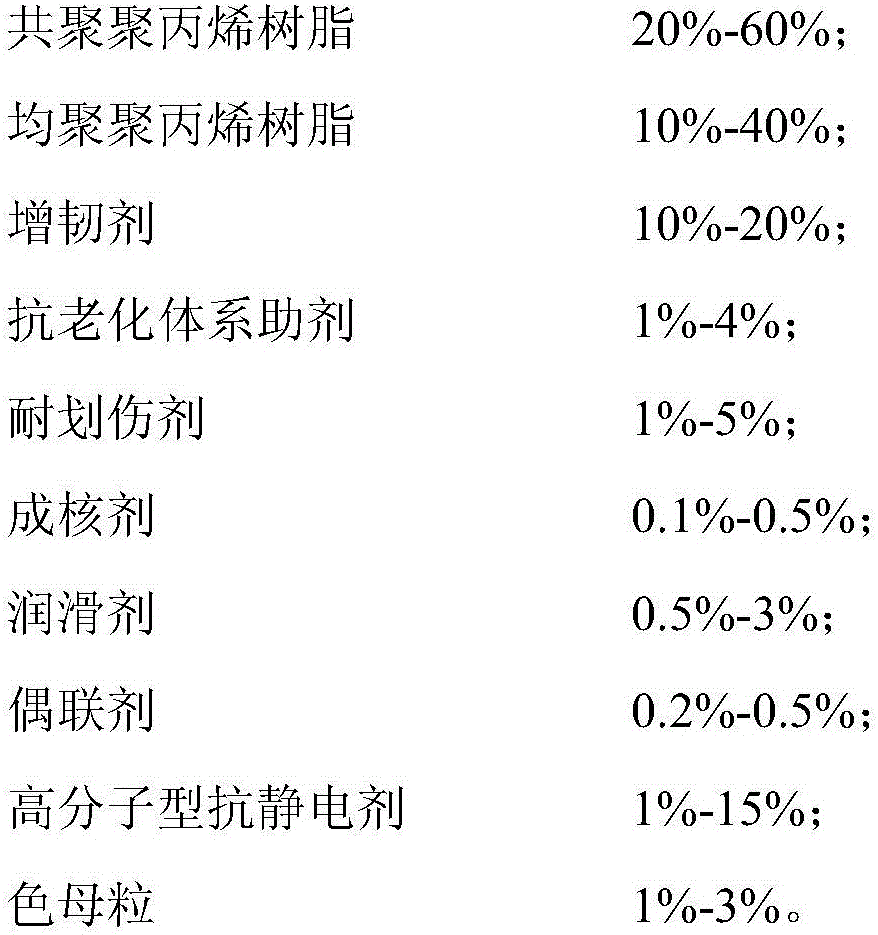

[0037] An embodiment of the polypropylene composition for spray-free bumper of the present invention and its preparation method, the polypropylene composition comprises the following components by weight percentage: 33.3% of copolymerized polypropylene, 32.5% of homopolypropylene, Toughening agent 13%, anti-aging system additive 1.2%, scratch resistance agent 2%, nucleating agent 0.2%, lubricant 0.5%, coupling agent 0.3%, polymer antistatic agent 5%, masterbatch 2 %, mineral filler 10%.

[0038] The preparation method of above-mentioned polypropylene composition, comprises the following steps:

[0039] (1) Weigh the following raw materials: melt index 20-40g / 10min, notched impact strength greater than 10KJ / m 2 33.3kg of copolymerized polypropylene resin, 32.5kg of homopolypropylene resin with a melt index greater than 10g / 10min, 10kg of ethylene-octene copolymer, 3kg of linear low-density polyethylene, 0.4kg of hindered amine light stabilizers, hindered phenols Heat stabiliz...

Embodiment 2

[0045] An embodiment of the polypropylene composition for spray-free bumper of the present invention and its preparation method, the raw materials of the polypropylene composition are calculated by weight percentage, including the following components: 28.3% of copolymerized polypropylene resin, 28.3% of homopolymerized polypropylene resin, Acrylic resin 22.5%, toughening agent 18%, anti-aging system additive 1.2%, scratch resistance agent 2%, nucleating agent 0.2%, lubricant 0.5%, coupling agent 0.3%, polymer antistatic agent 5 %, masterbatch 2%, mineral filler 20%.

[0046] The preparation method of above-mentioned polypropylene composition, comprises the following steps:

[0047] (1) Weigh the following raw materials: melt index 70-120g / 10min, notched impact strength greater than 5KJ / m 2 28.3kg of copolymerized polypropylene resin, 22.5kg of high crystalline homopolypropylene resin, 15kg of ethylene-butylene copolymer, 3kg of low-density polyethylene, 0.4kg of phenylacryli...

Embodiment 3

[0053] An embodiment of the polypropylene composition for spray-free bumpers of the present invention and its preparation method, the raw materials of the polypropylene composition are calculated by weight percentage, including the following components: 23.3% of copolymerized polypropylene resin, 23.3% of homopolymerized polypropylene resin, Acrylic resin 15.5%, toughening agent 20%, anti-aging system additive 1.2%, scratch resistance agent 2%, nucleating agent 0.2%, lubricant 0.5%, coupling agent 0.3%, polymer antistatic agent 5 %, masterbatch 2%, mineral filler 30%.

[0054] The preparation method of above-mentioned polypropylene composition, comprises the following steps:

[0055] (1) Weigh the following raw materials: melt index 20-40g / 10min, notched impact strength greater than 10KJ / m 2 Copolymerized polypropylene resin 3.3kg, melt index 70-120g / 10min, notched impact strength greater than 5KJ / m 2 20kg of copolymerized polypropylene resin, 5.5kg of homopolypropylene resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com