Patents

Literature

130results about How to "Reduce the effects of aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for producing low viscosity octenylsuccinate starch by oxidation process

The invention discloses a technique for producing octenyl succinate starch ester with low viscosity by an oxidation method, which comprises steps as follows: waxy rice starch and water are prepared to be starch milk in a reaction vessel, then the starch milk is heated to 34 DEG C to 38 DEG C, and a sodium hydroxide solution is added for adjusting the PH value between 9.3 and 9.7; sodium hypochlorite is added to carry out oxidation reaction, and the PH value and the reaction temperature are kept; sodium pyrosulfite is added to carry out reduction reaction, and a hydrochloride solution is added in the reaction process to adjust the PH value of the starch milk between 8.5 and 9.0, and the temperature is cooled to 28 DEG C to 31 DEG C, and then octenyl succinic anhydride with 2 percent to 3 percent of the total mass of absolute dry starch is added to carry out esterification reaction; and after the esterification reaction, the hydrochloride solution is added to neutralize the PH value of the starch milk between 5.5 and 6.5, and the finished product can be obtained by washing and drying the neutralized starch milk. By adopting the technique for producing the octenyl succinate starch ester with low viscosity by the oxidation method, the product is high in esterification reaction efficiency, good in emulsifying properties and high in product quality.

Owner:诸城兴贸玉米开发有限公司

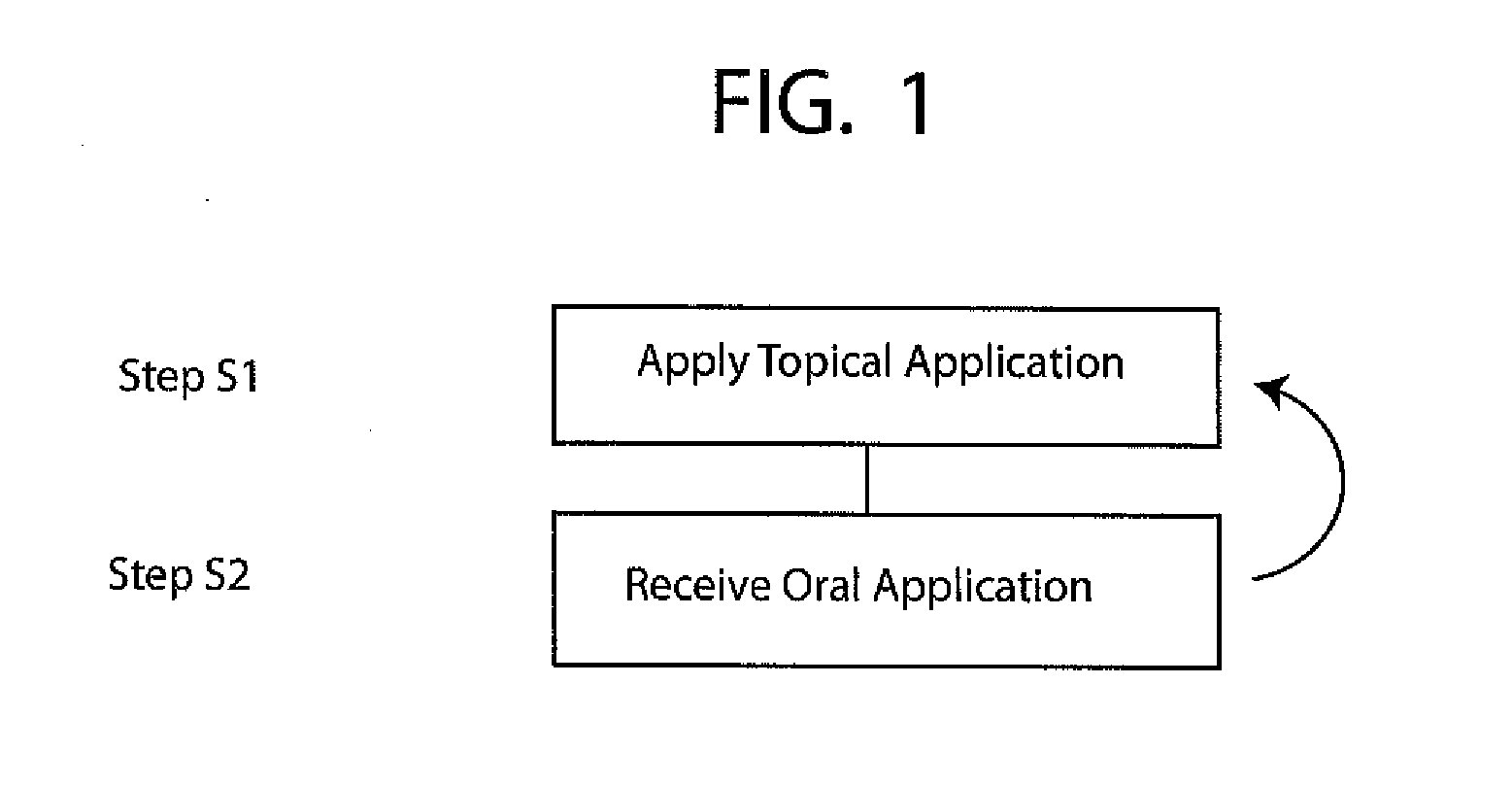

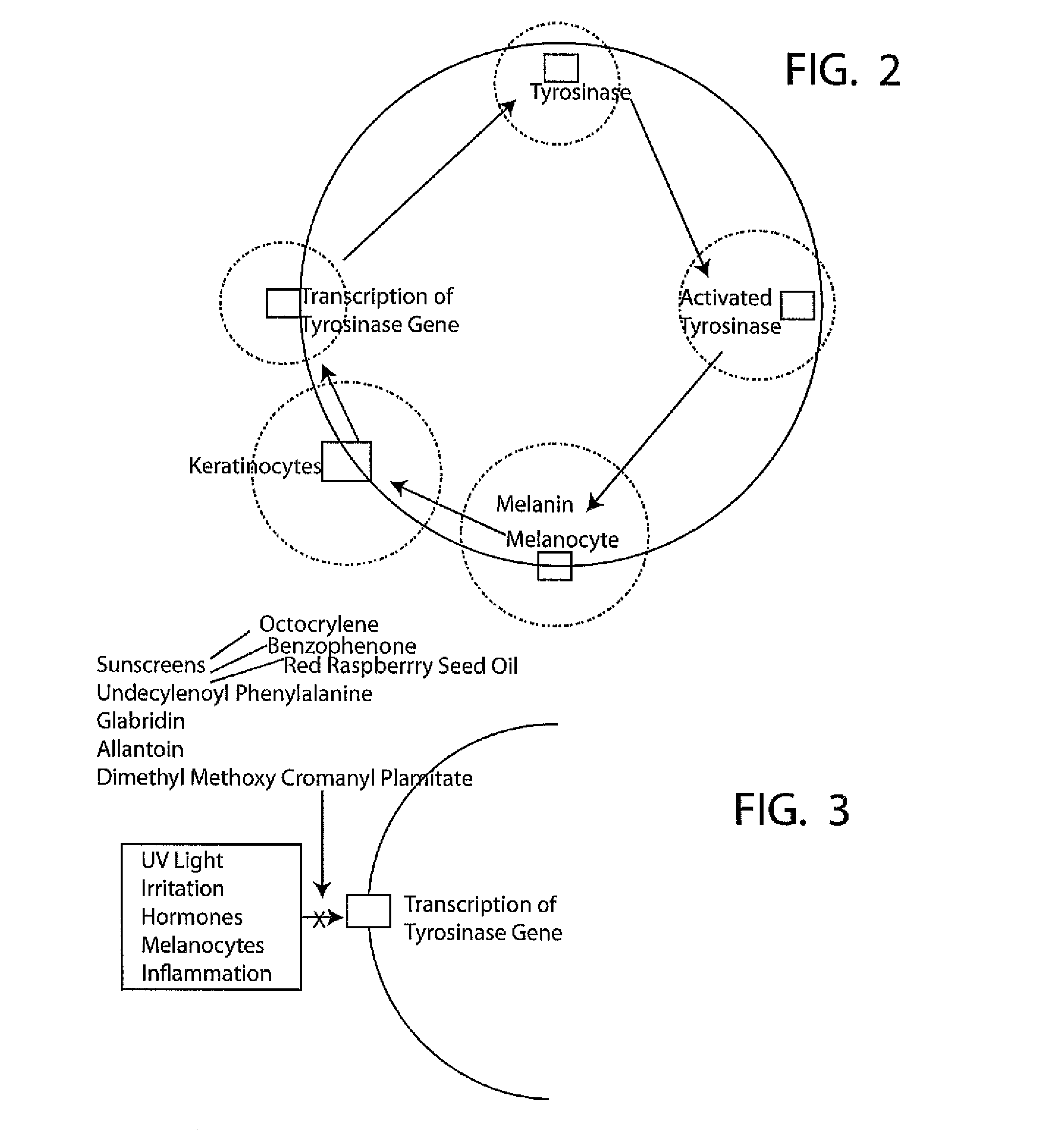

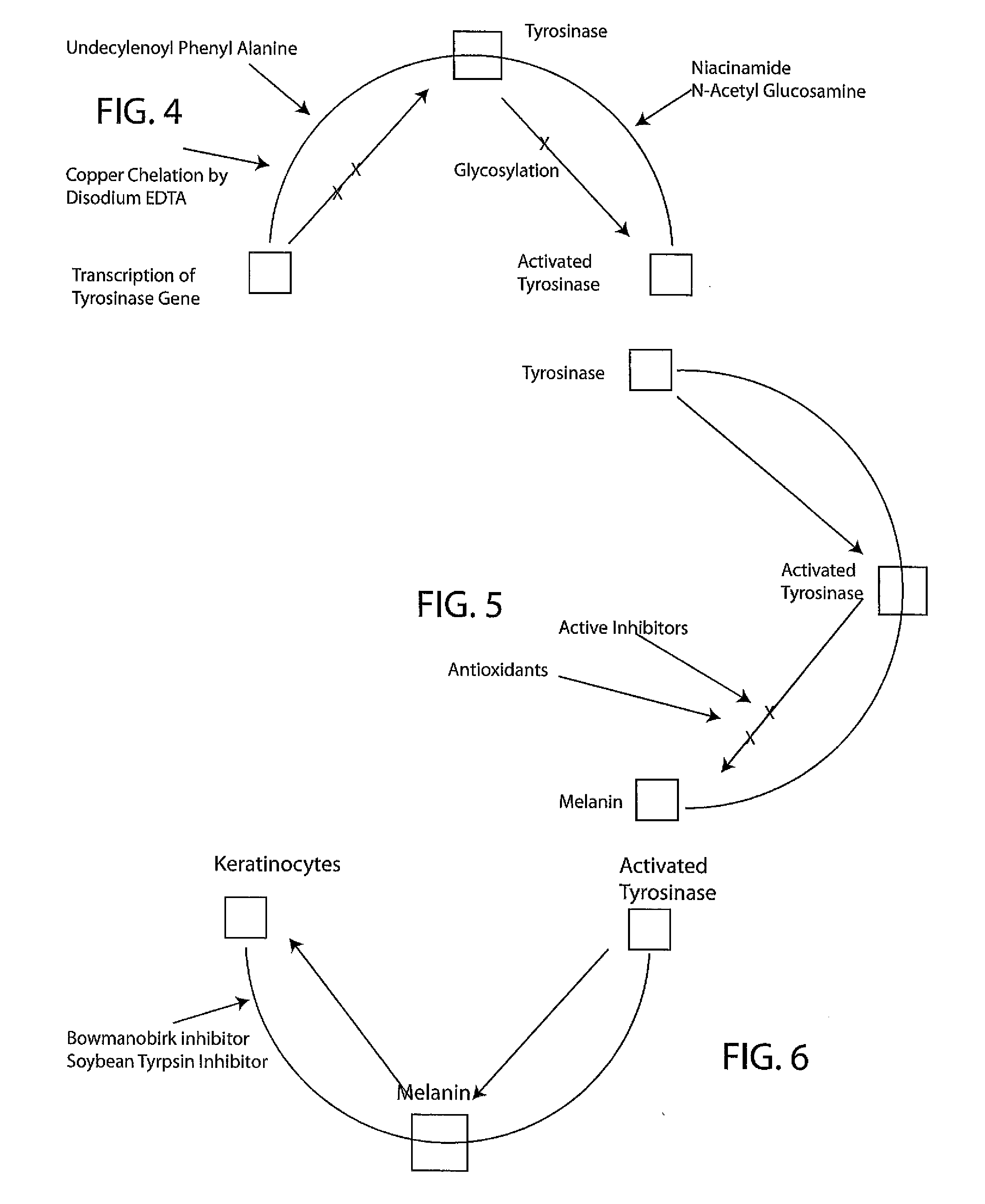

Anti aging application and method for treating aging

InactiveUS20130195925A1Reduce the effects of agingAlter and inhibit effect of agingOrganic active ingredientsCosmetic preparationsMelanocyteEmulsion

There is a topical anti-aging composition which is configured to interfere with the production of tyrosinase, as well as melanin by reacting with melanocytes as well as reacting with, or acting on keratinocytes. The anti-aging composition comprises an emulsion comprising a plurality of active ingredients comprising a plurality of pigmentation reducing elements which are configured to interrupt or prevent the production of tyrosinase and melanin. In addition there are a plurality of antioxidants a plurality of anti wrinkling agents a plurality of anti-inflammatory agents at least one additional agent comprising at least one of an emollient, a proactant and a conditioning agent.

Owner:VASKIN

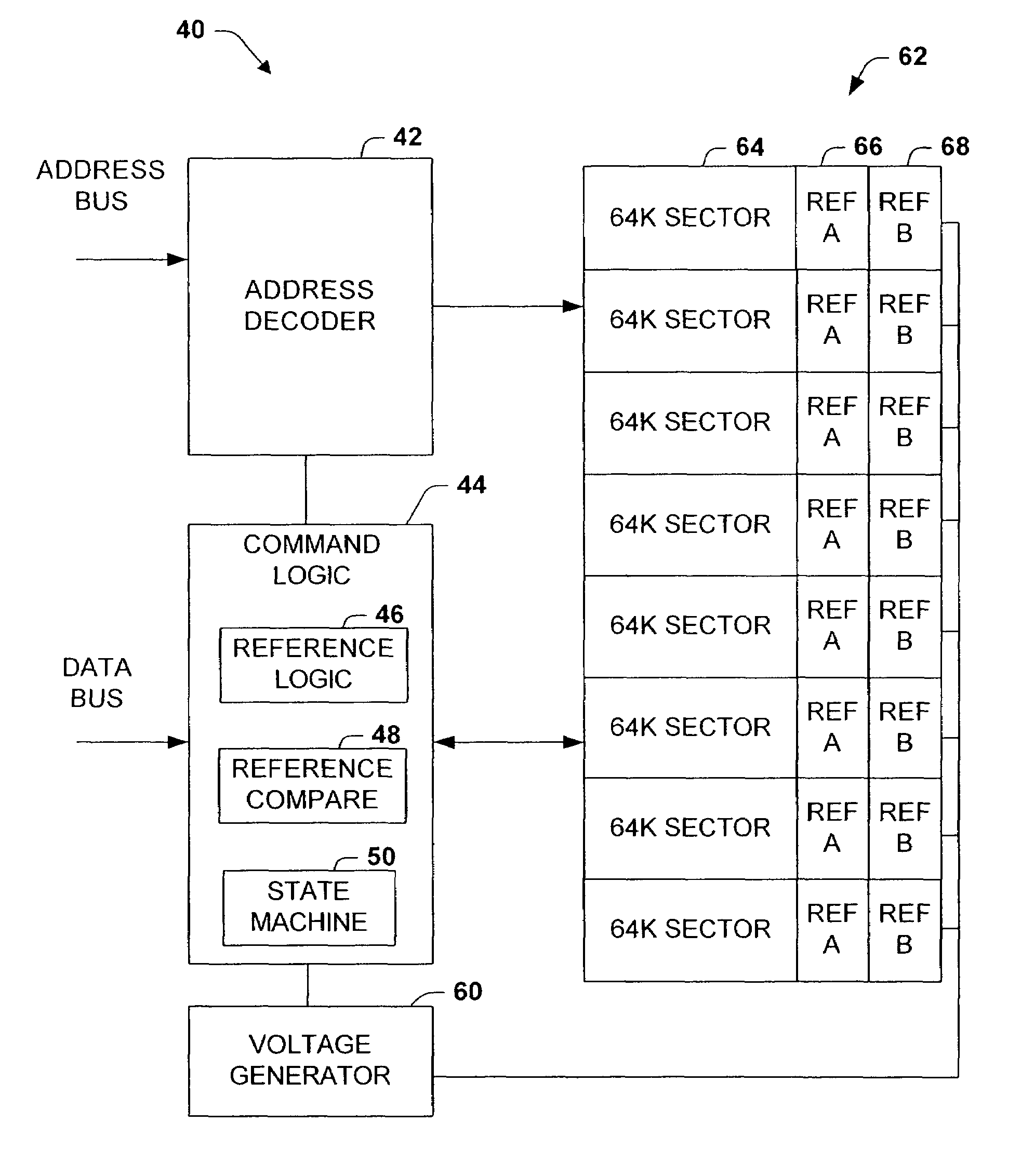

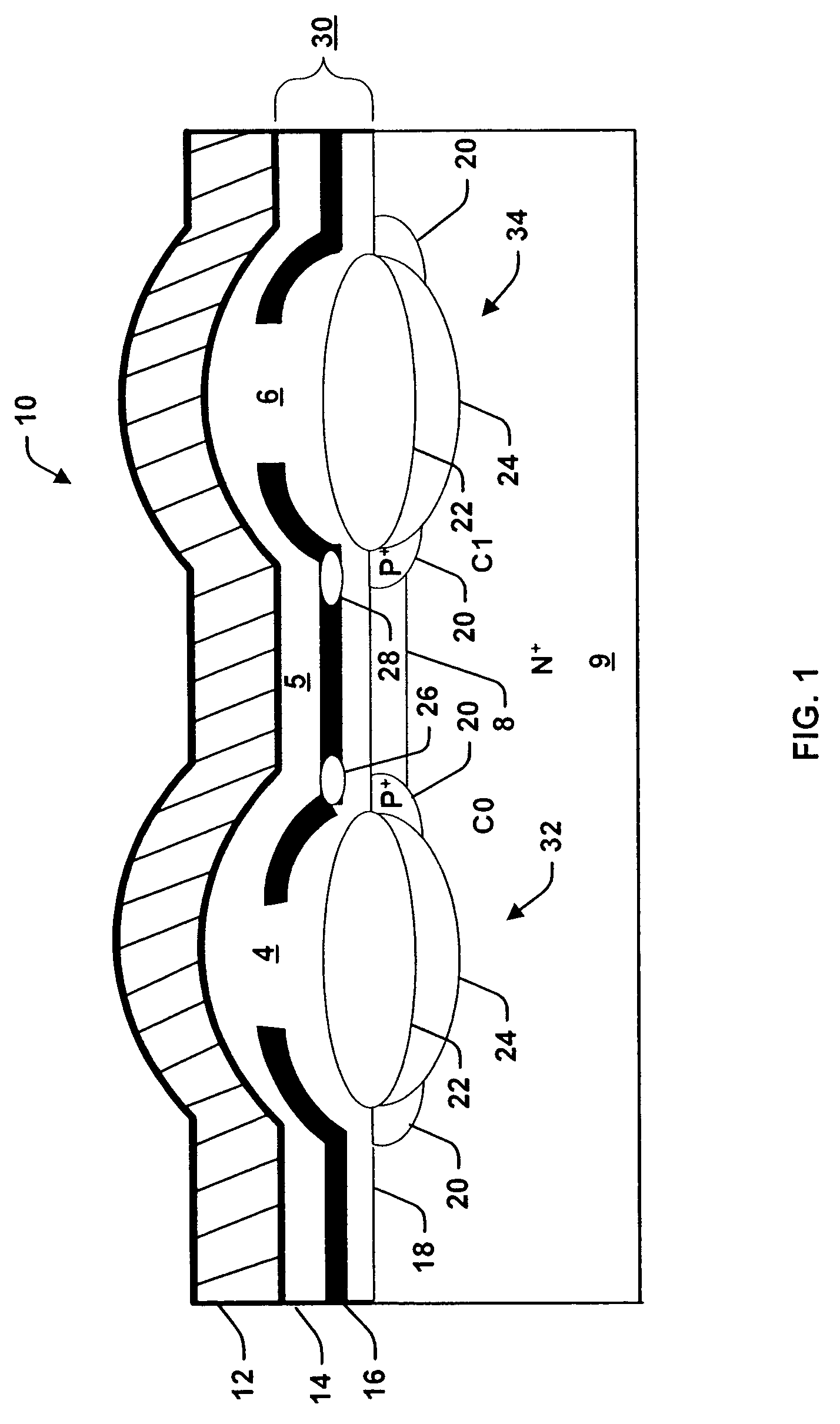

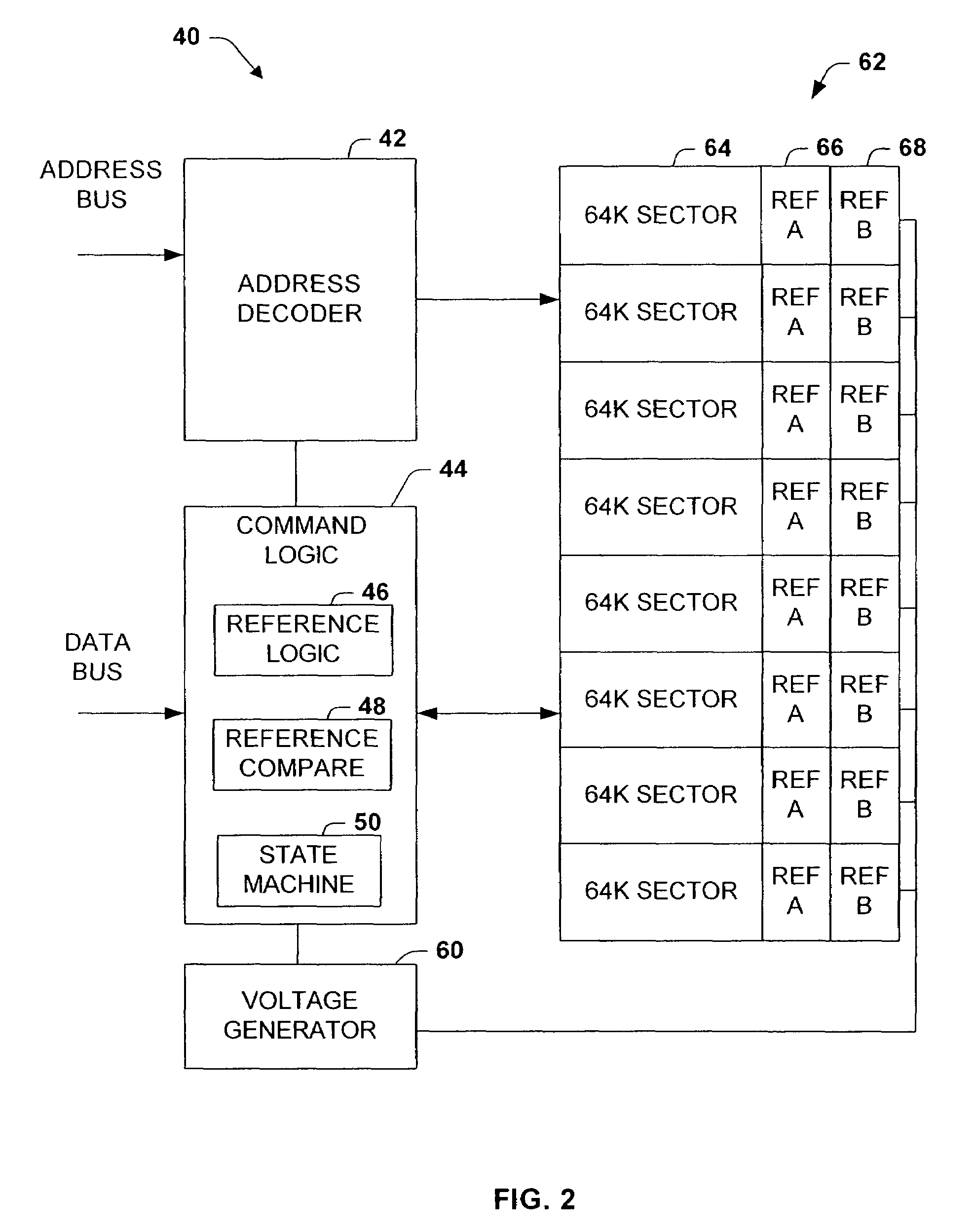

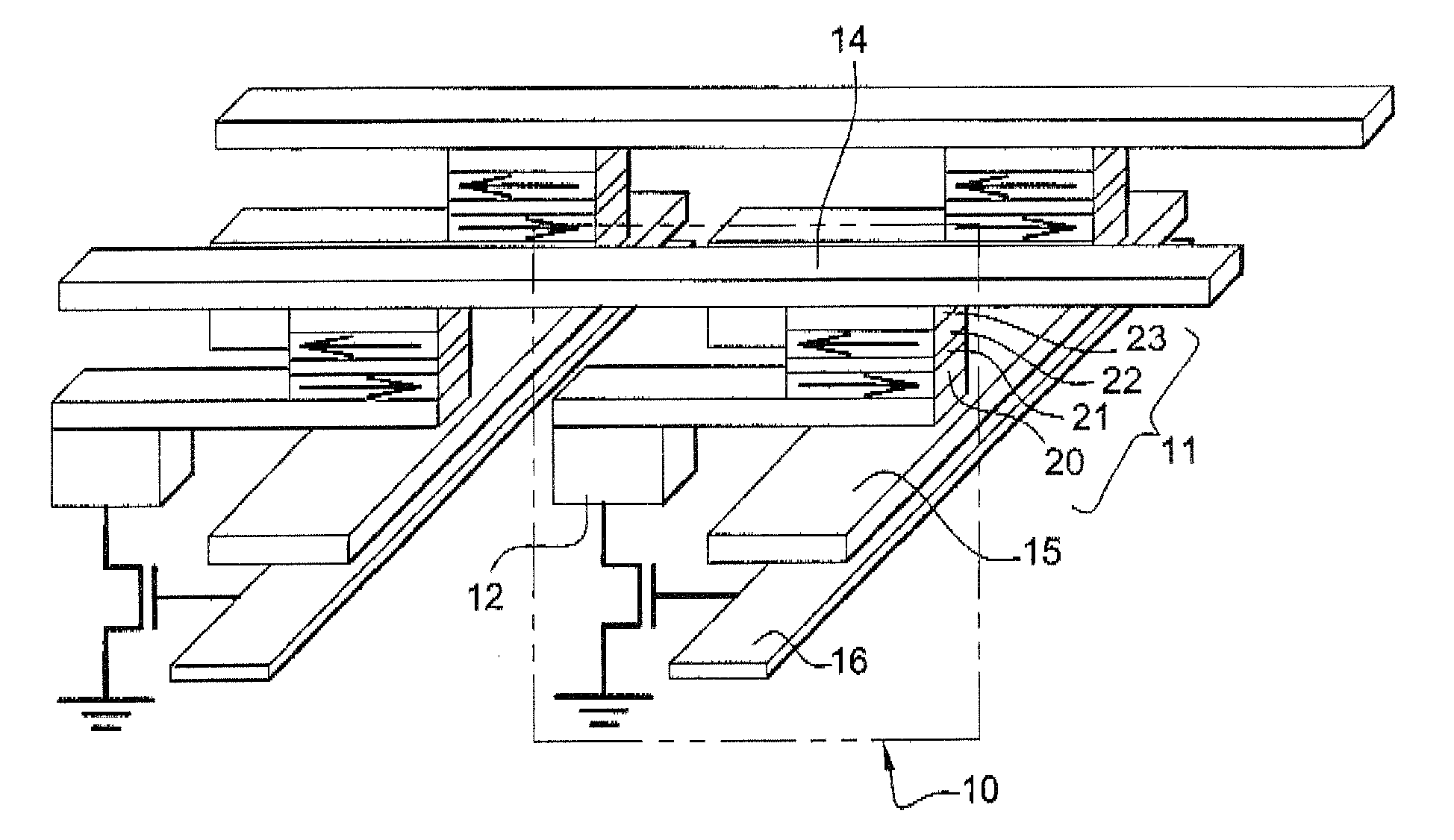

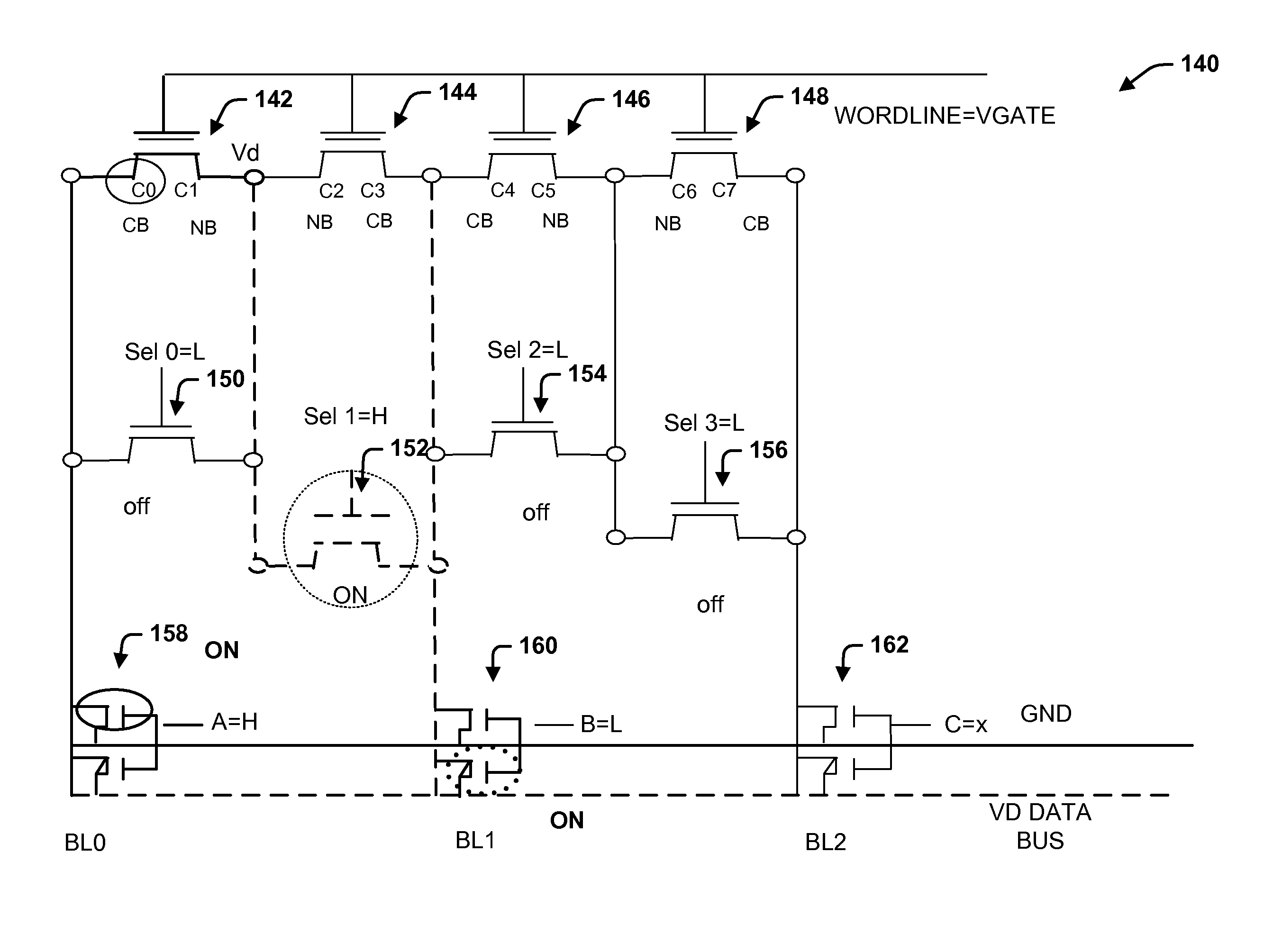

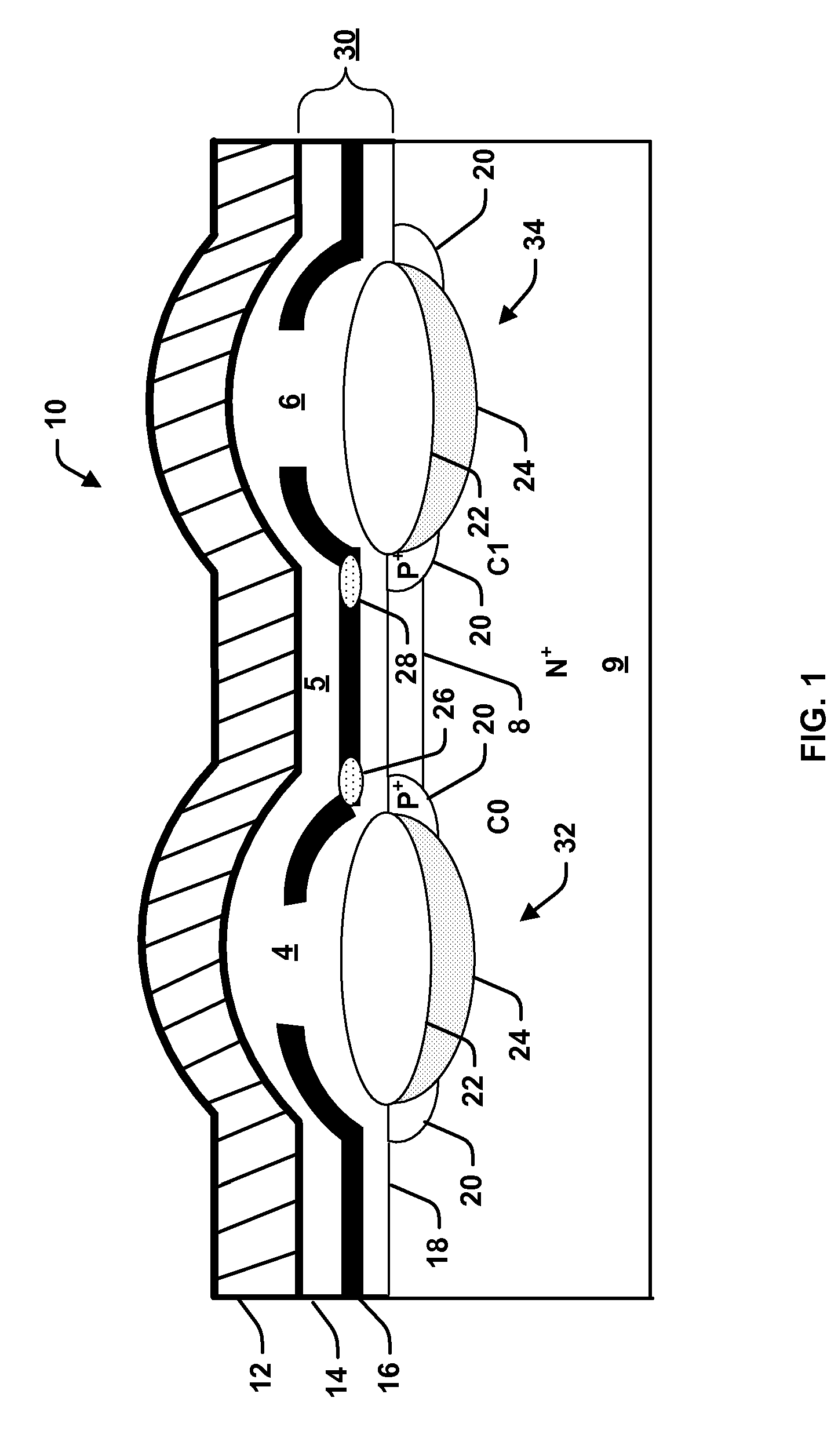

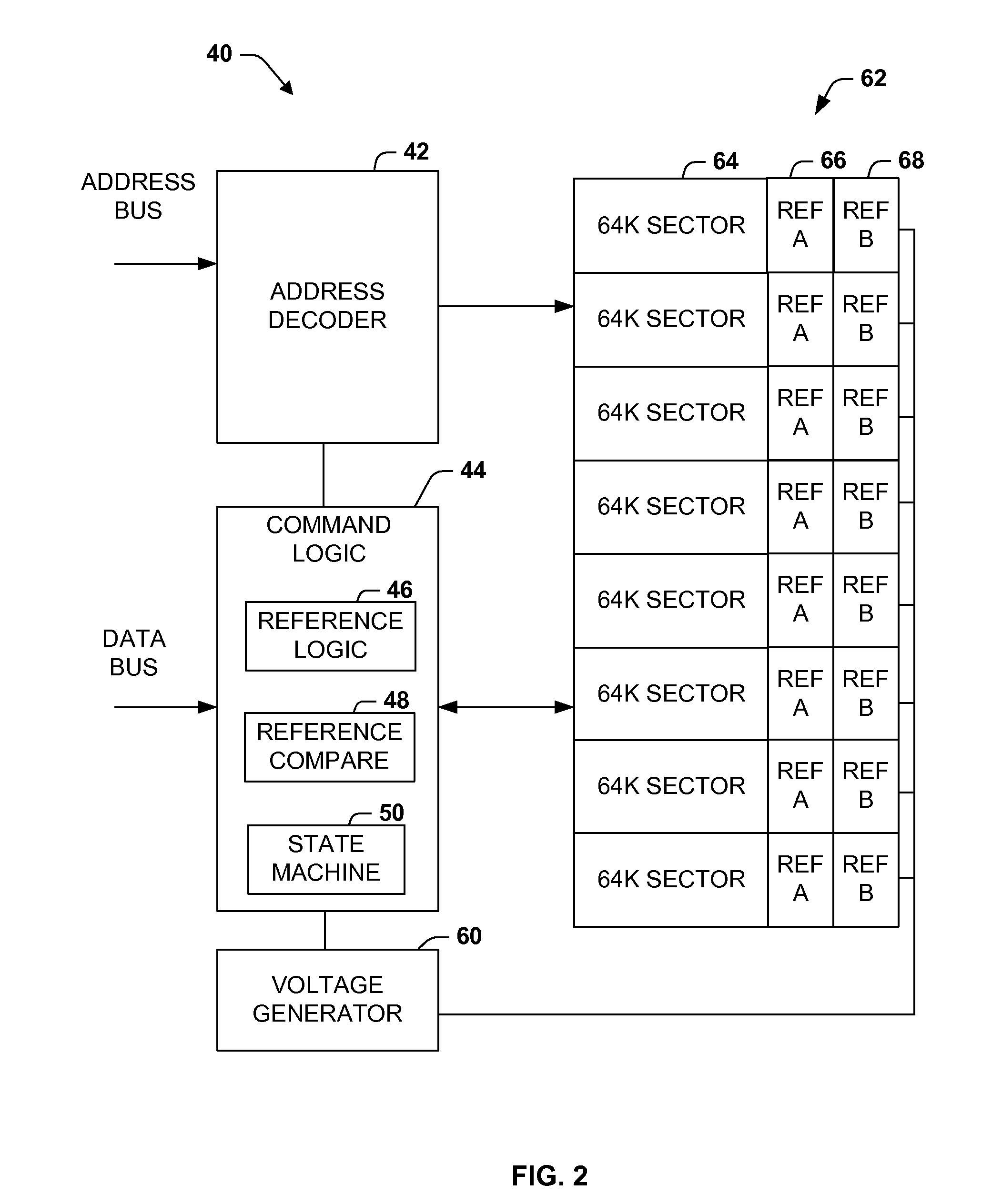

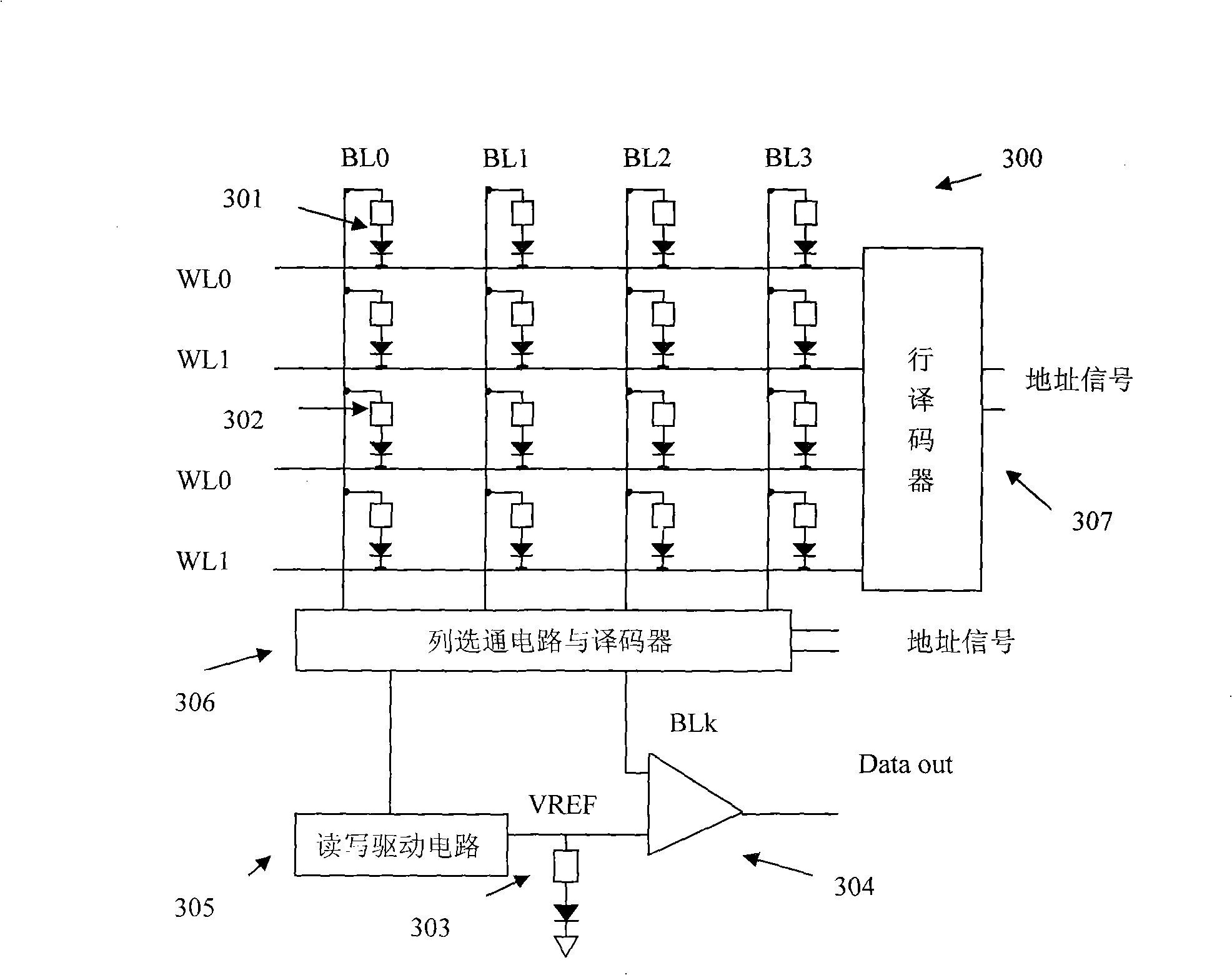

Memory with a core-based virtual ground and dynamic reference sensing scheme

ActiveUS7324374B2Reduce the effects of agingAccurate representationRead-only memoriesDigital storageVirtual groundVoltage reference

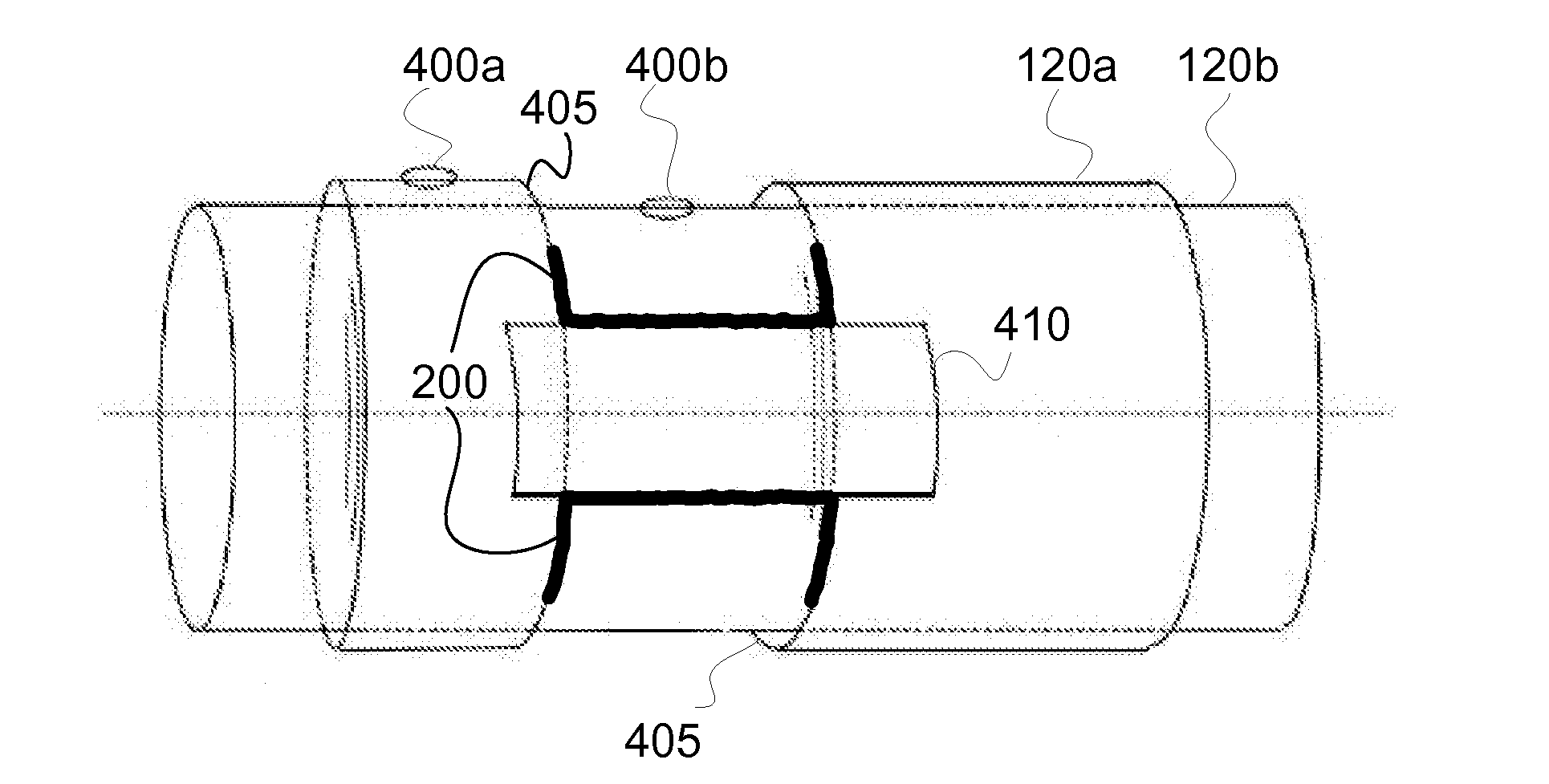

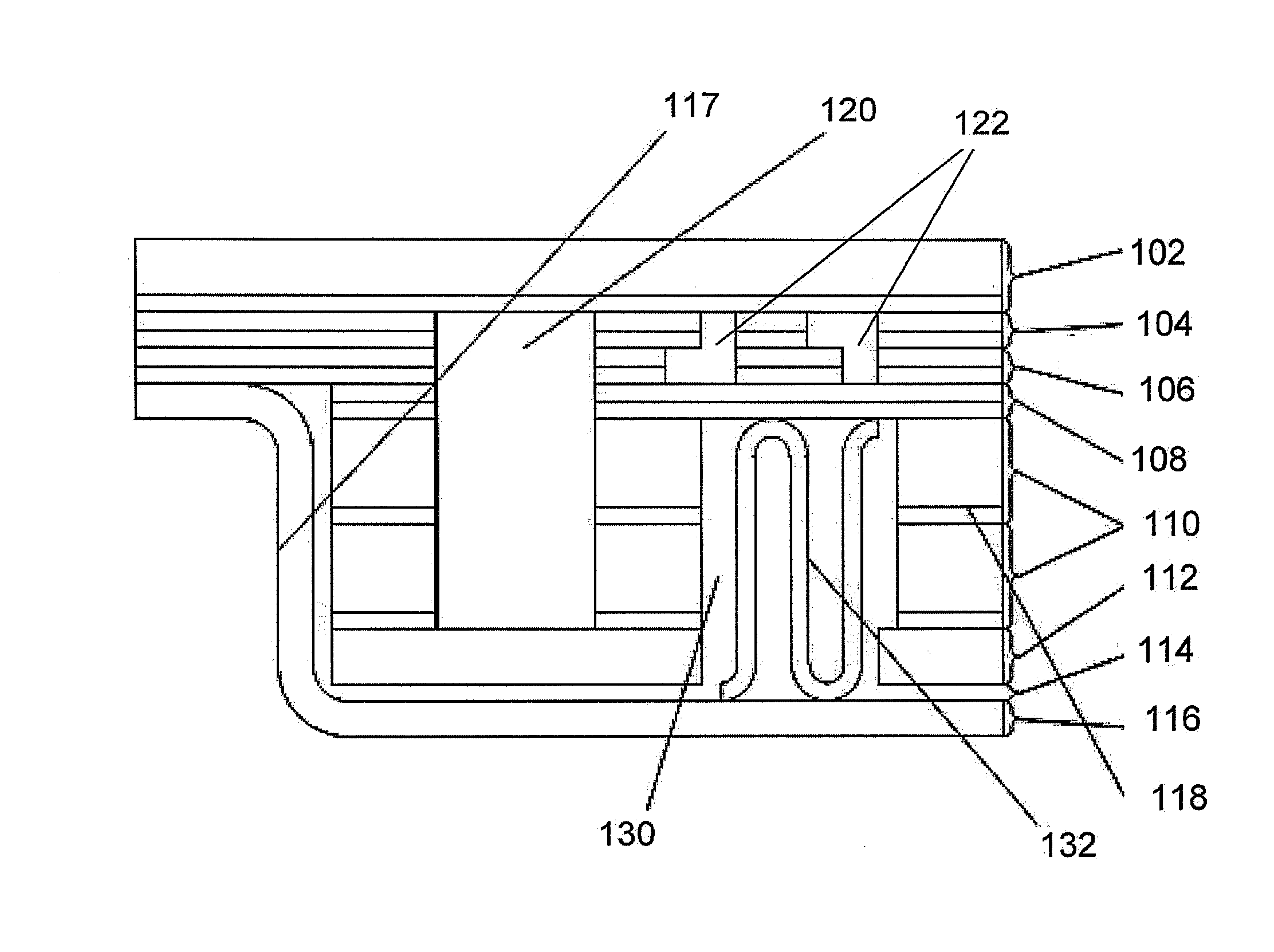

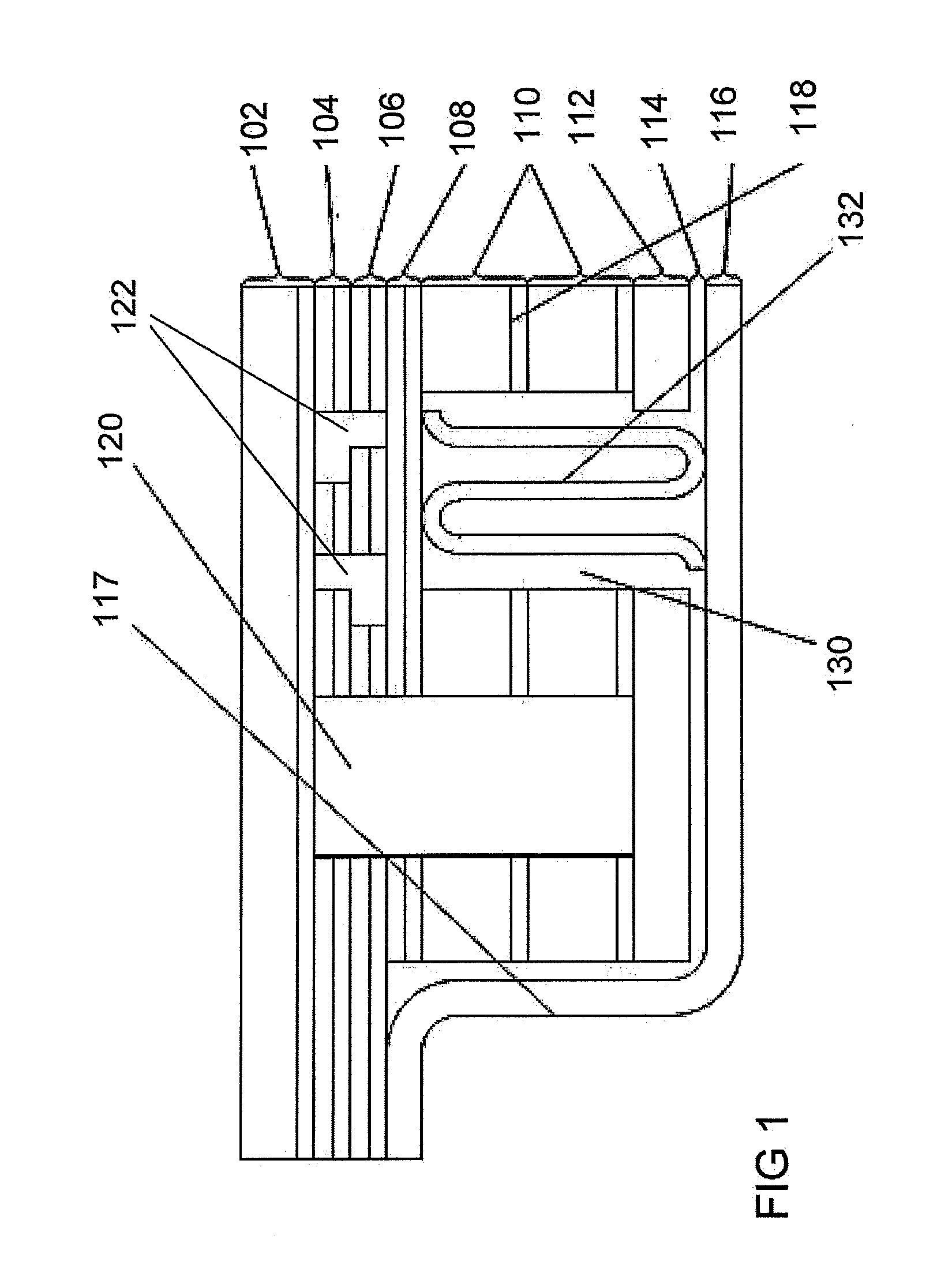

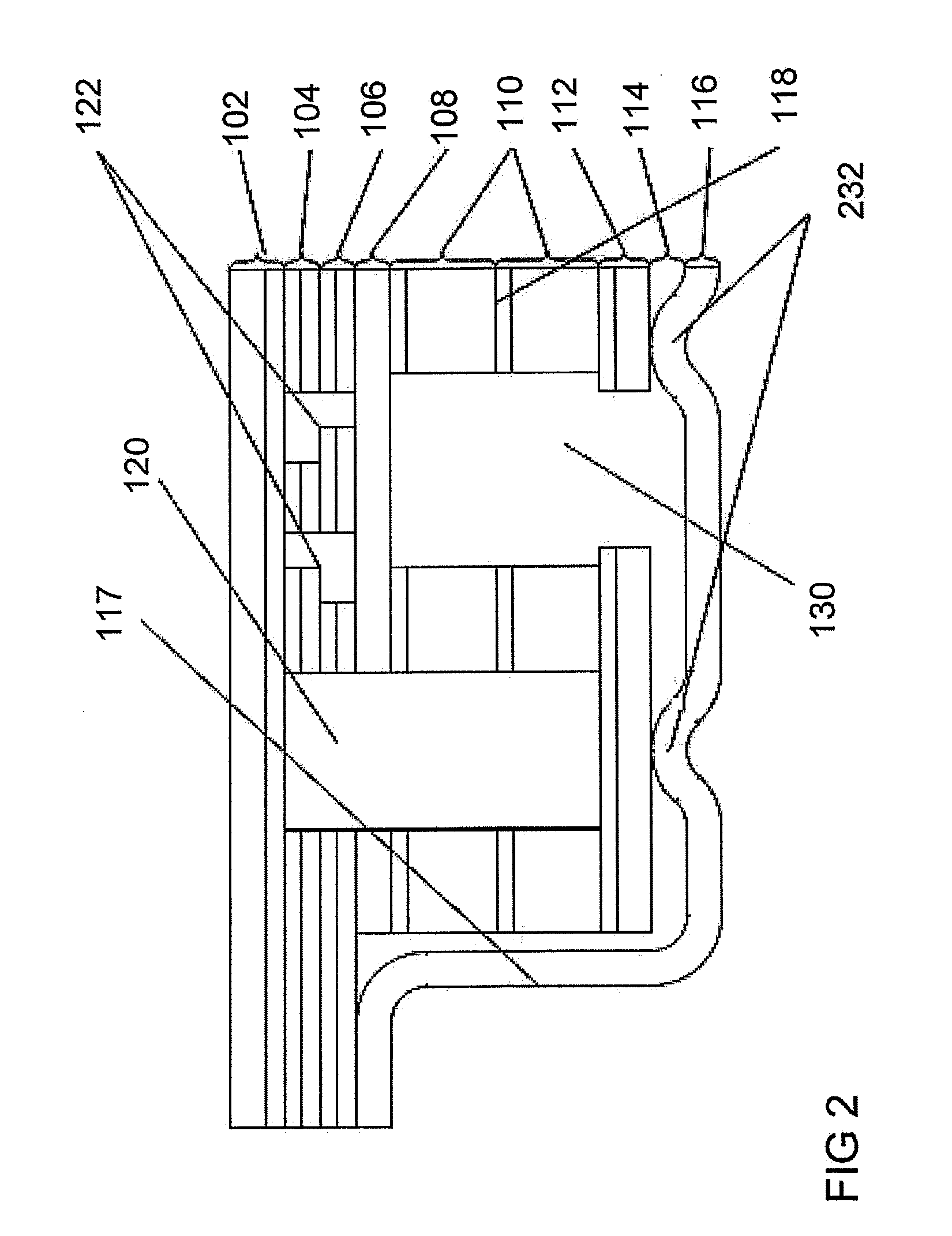

A core-based multi-bit memory (400) having a dual-bit dynamic referencing architecture (408, 410) fabricated on the memory core (401). A first reference array (408) and a second reference array (410) are fabricated on the memory core (401) such that a reference cell pair (185) comprising one cell (182) of the first reference array (408) and a corresponding cell (184) of the second reference array (410) are read and averaged to provide a reference voltage for reading a data array(s).

Owner:INFINEON TECH LLC

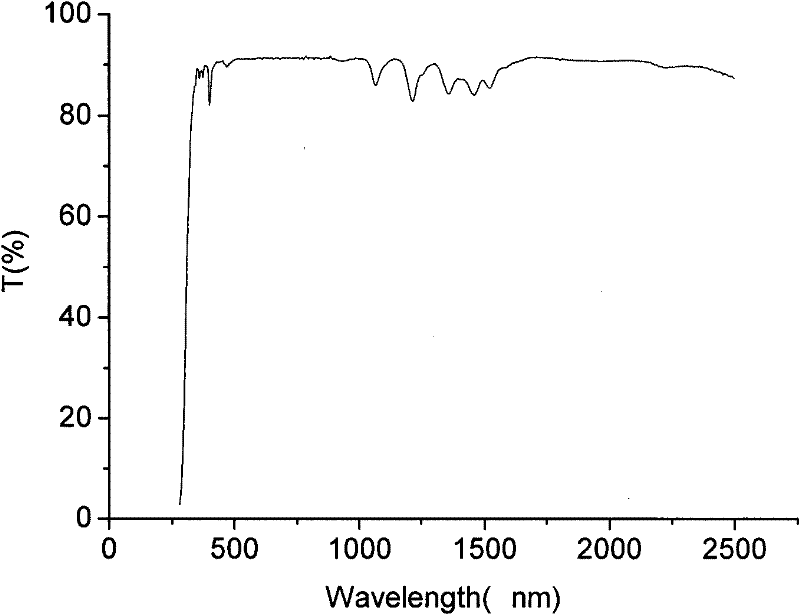

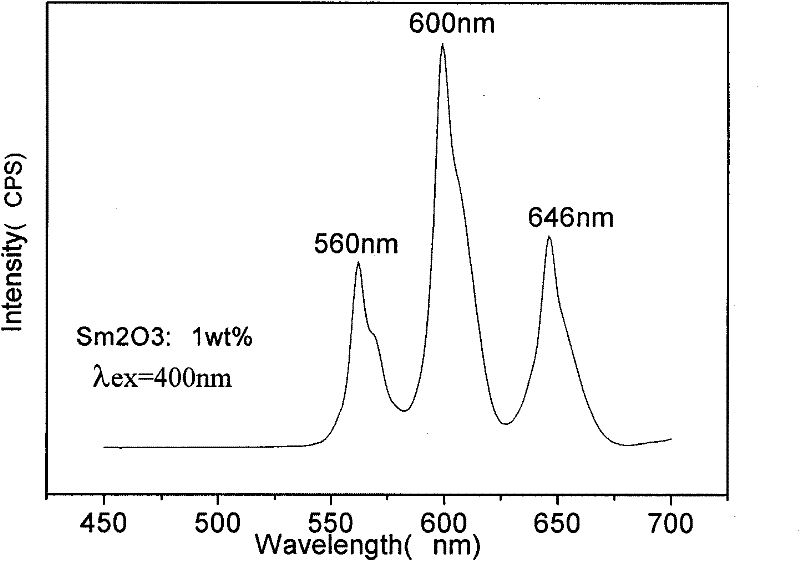

A kind of ultra-clear photovoltaic glass and its preparation method and application

ActiveCN102260041AImprove transmittanceImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesGlass coverTransmittance

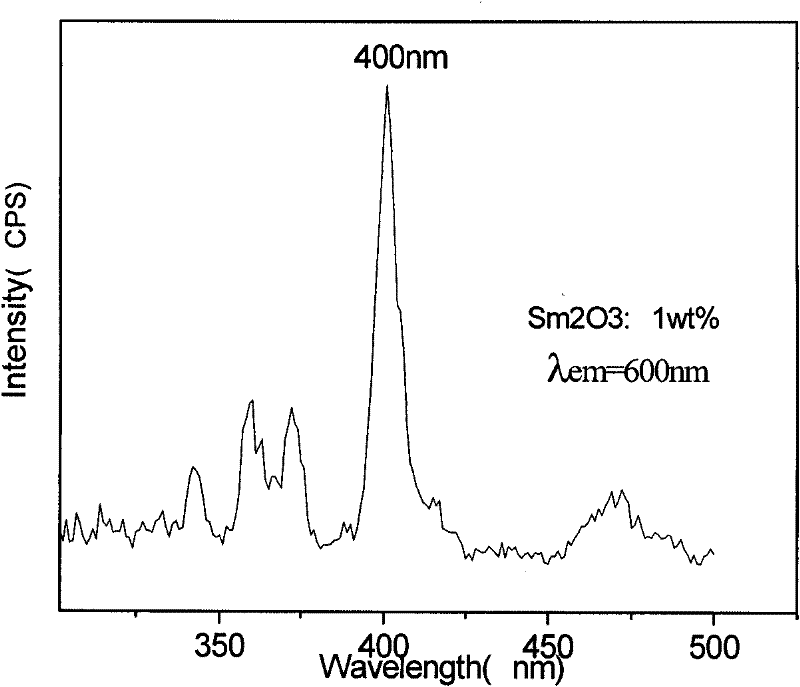

The invention provides super-white photovoltaic glass and a preparation method and application thereof. The super-white photovoltaic glass comprises substrate glass and a rare earth compound doped into the substrate glass, wherein the rare earth compound is rare earth oxide or rare earth-containing mineral; the rare earth oxide is at least one of CeO2, Sm2O3, Eu2O3, Tb2O3 and Dy2O3; and the rare earth-containing mineral comprises at least one element of Ce, Sm, Eu, Tb and Dy. The super-white photovoltaic glass can convert ultraviolet light into visible light, so that the transmittance of the visible light is enhanced; when the super-white photovoltaic glass is used for a glass cover plate of a solar cell, the conversion efficiency of the cell can be improved, generated energy is increased, and the aging of sealing materials such as ethylene-vinyl acetate (EVA) caused by the ultraviolet light can be reduced; and the preparation method of the super-white photovoltaic glass is simple, easy to operate and control and suitable for industrial production.

Owner:信义光伏产业(安徽)控股有限公司

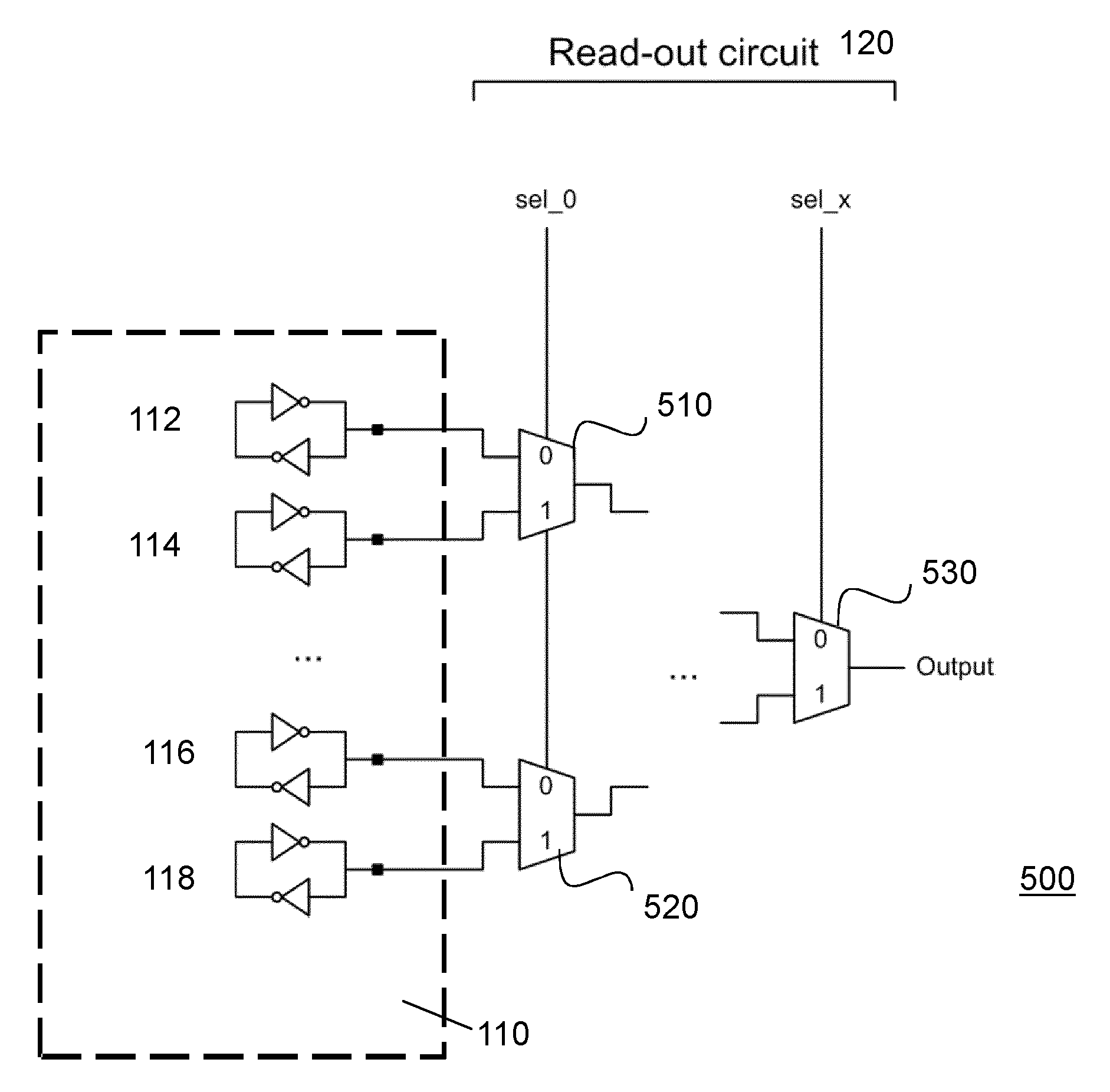

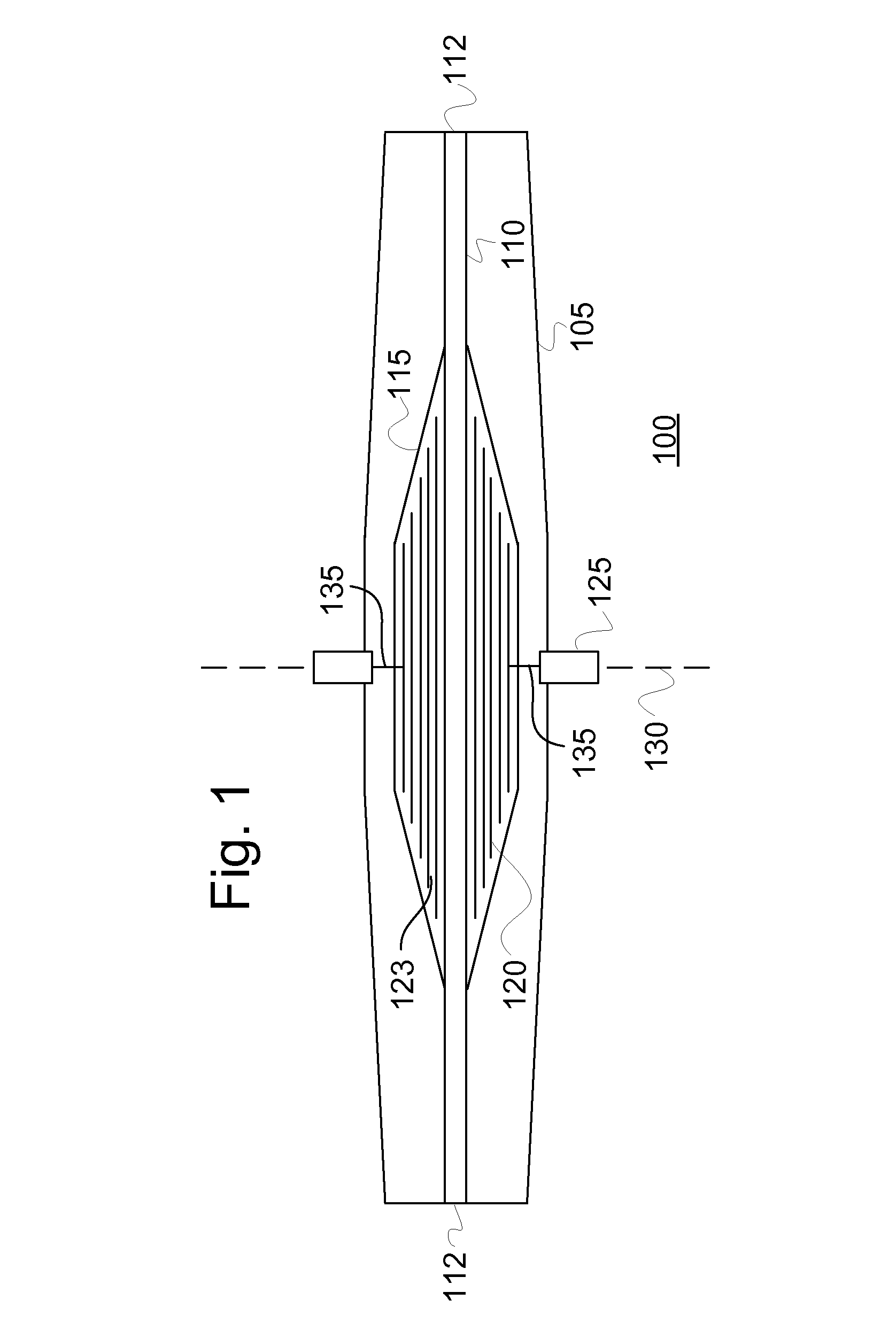

Physical unclonable function

ActiveUS20130234771A1Reduce the numberDesign economyDigital data processing detailsElectric pulse generatorComputer hardwarePhysical unclonable function

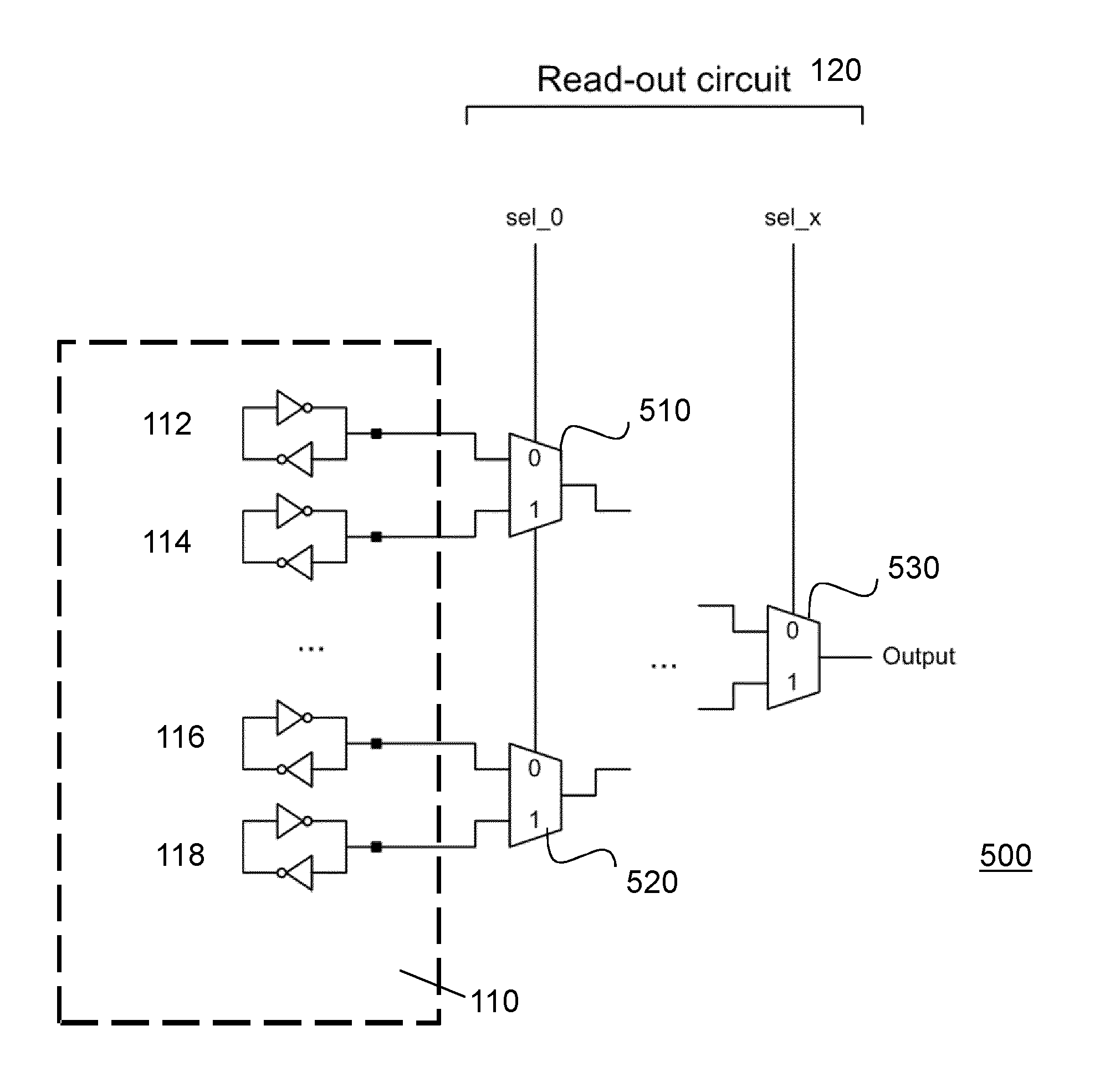

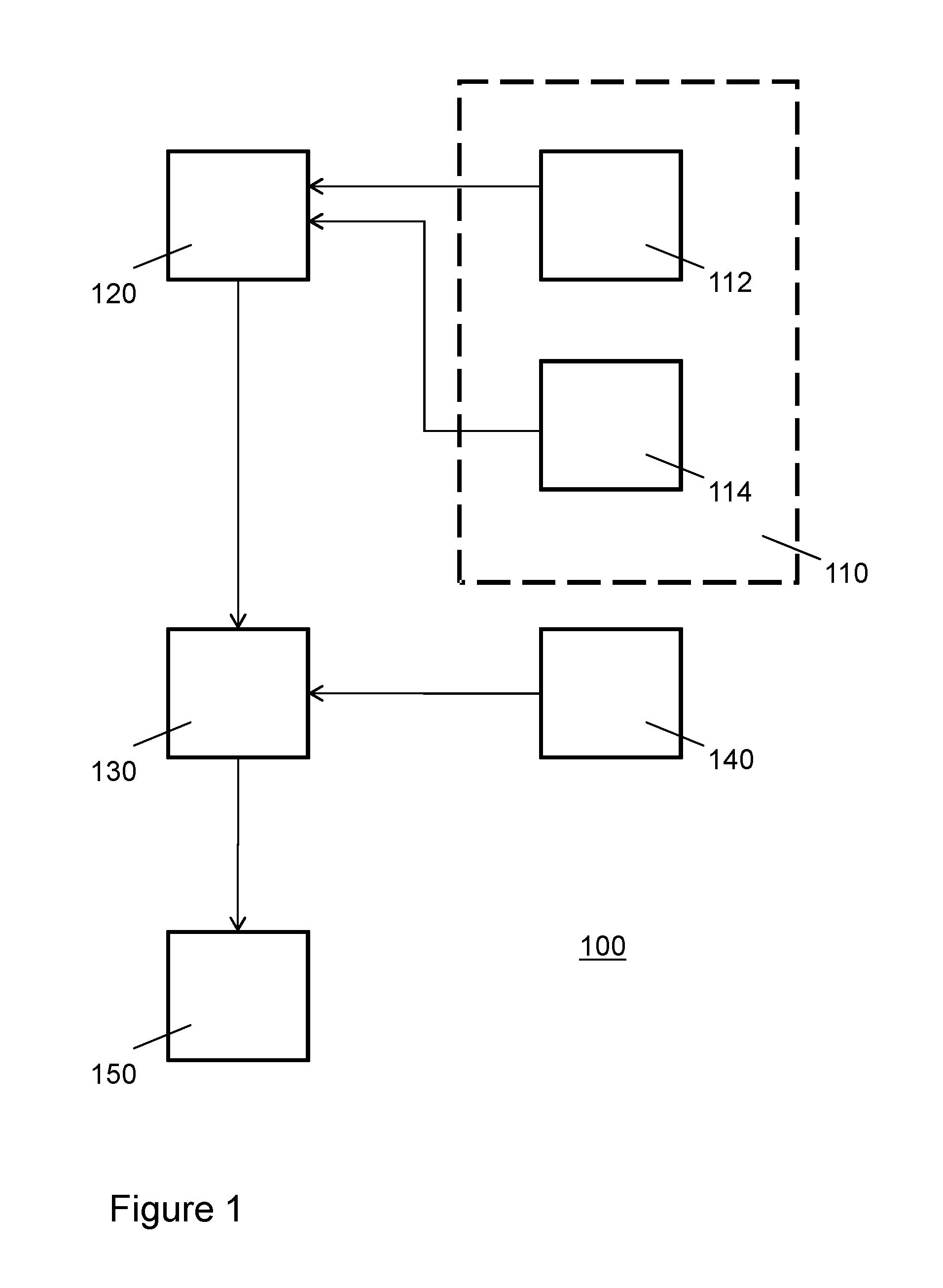

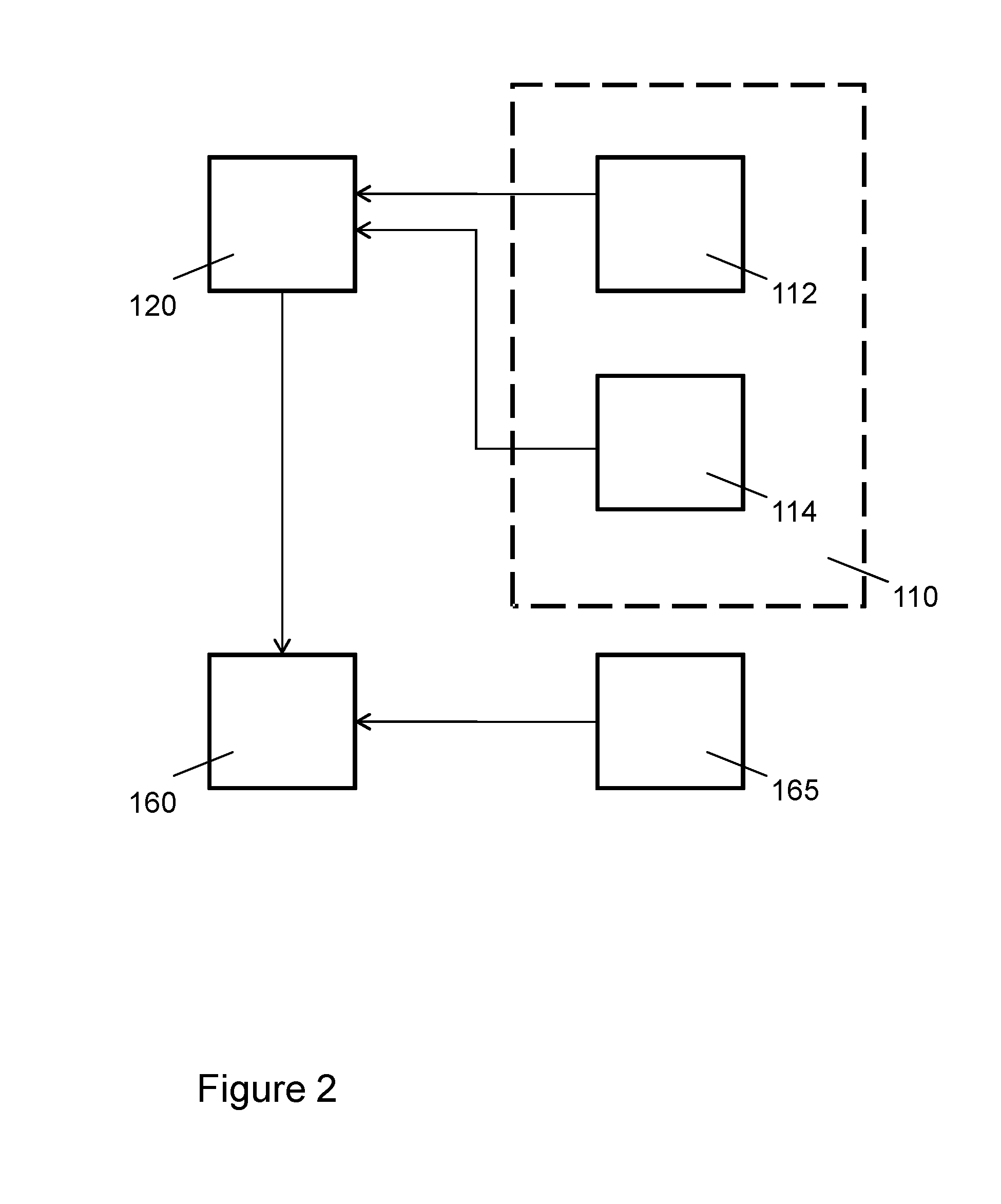

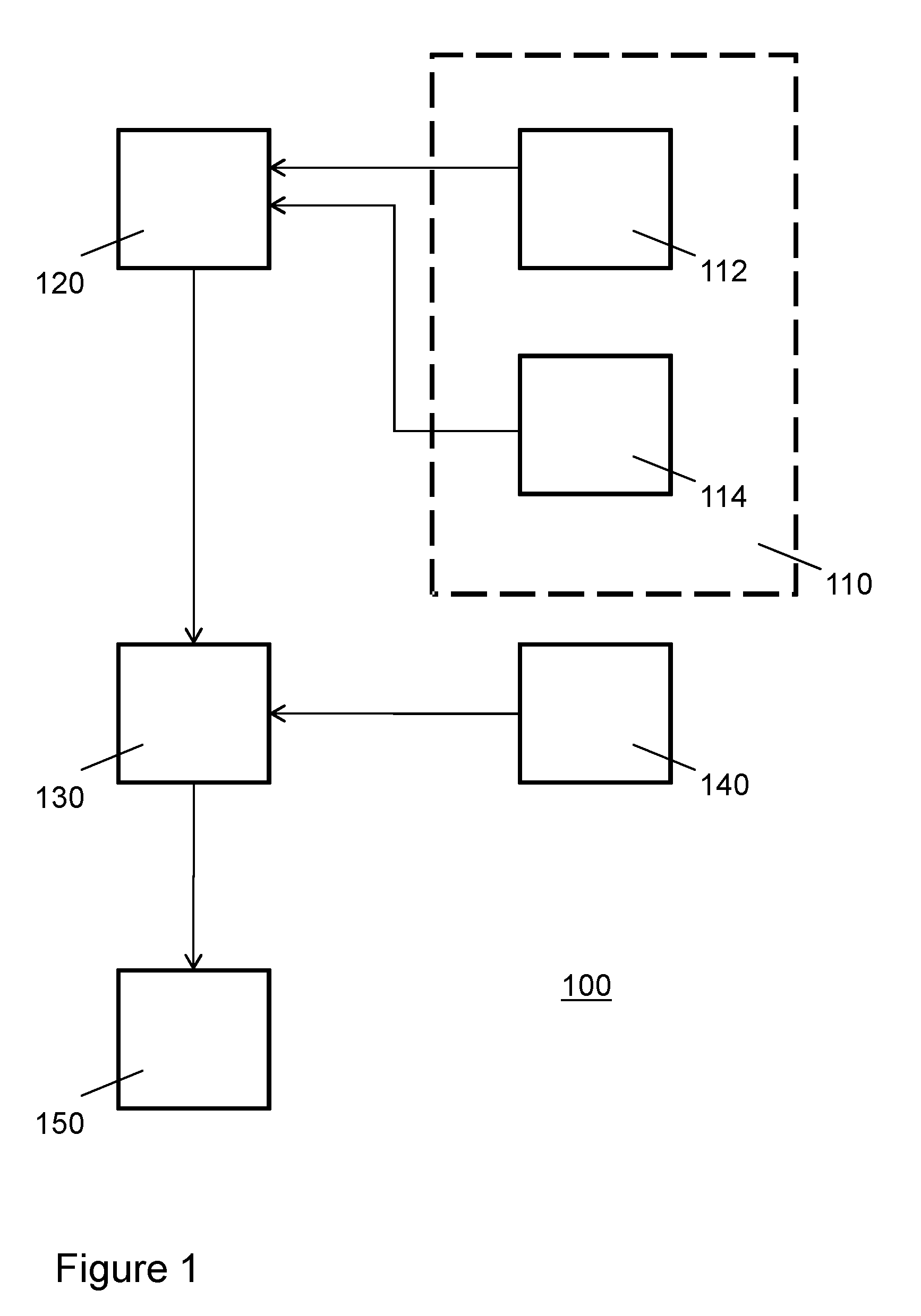

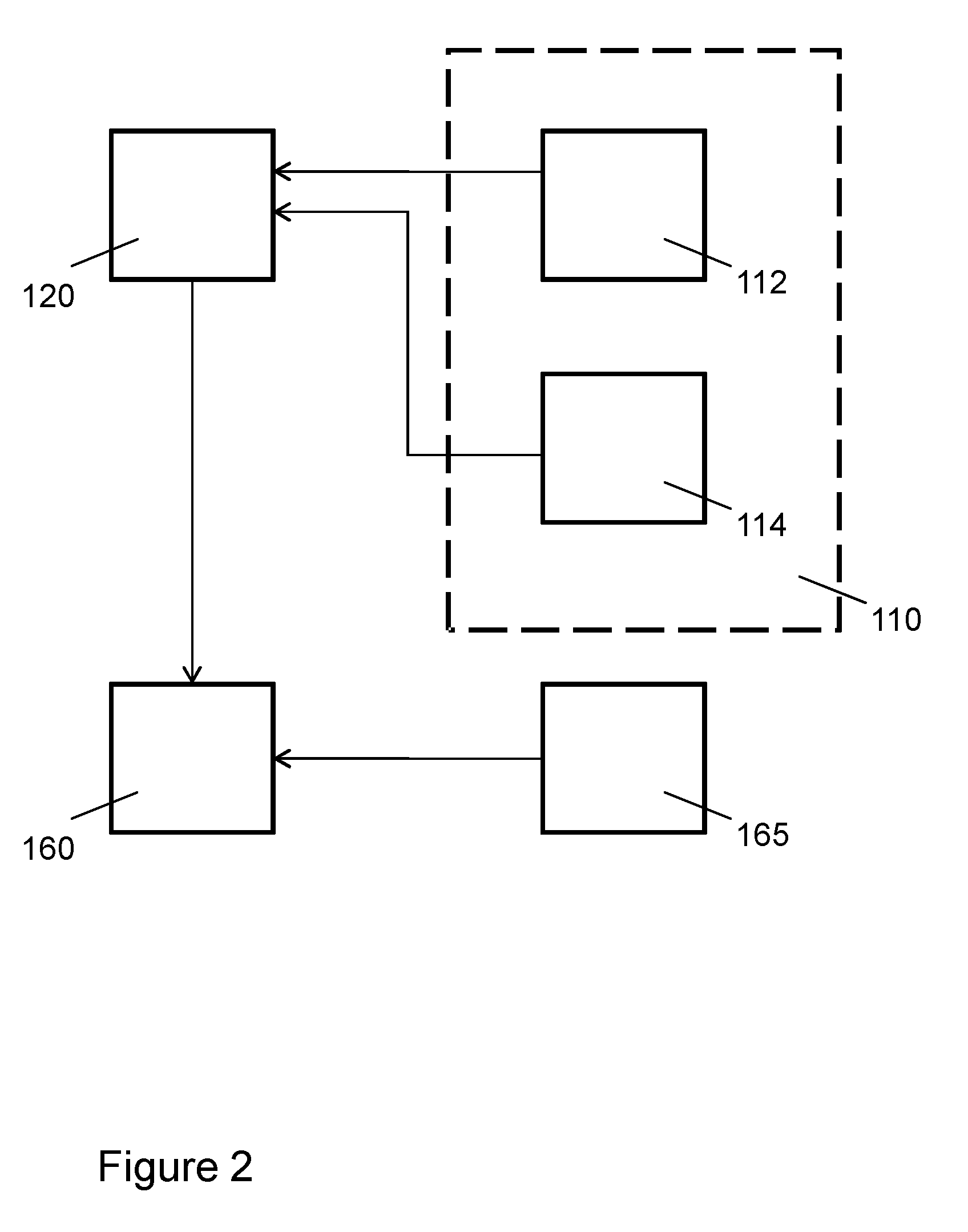

A physical unclonable function is provided 100, comprising a plurality of bus-keepers 110, each bus-keeper of the plurality of bus-keepers 110 being configured to settle into one of at least two different stable states upon power-up, the particular stable state into which a particular bus-keeper of the plurality of bus-keepers settles being dependent at least in part upon the at least partially random physical characteristics of the particular bus-keeper, and a reading circuit 120 for reading the plurality of stable states into which the plurality of bus-keepers settled after a power-up, the plurality of bus-keepers being read-only.

Owner:INTRINSIC ID

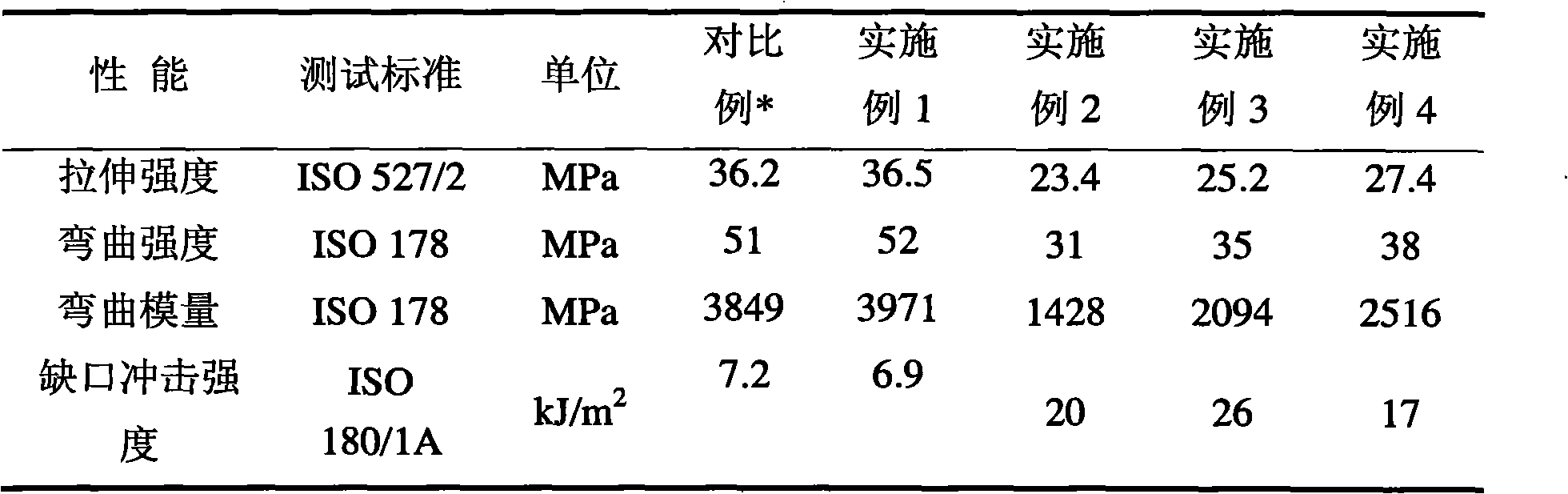

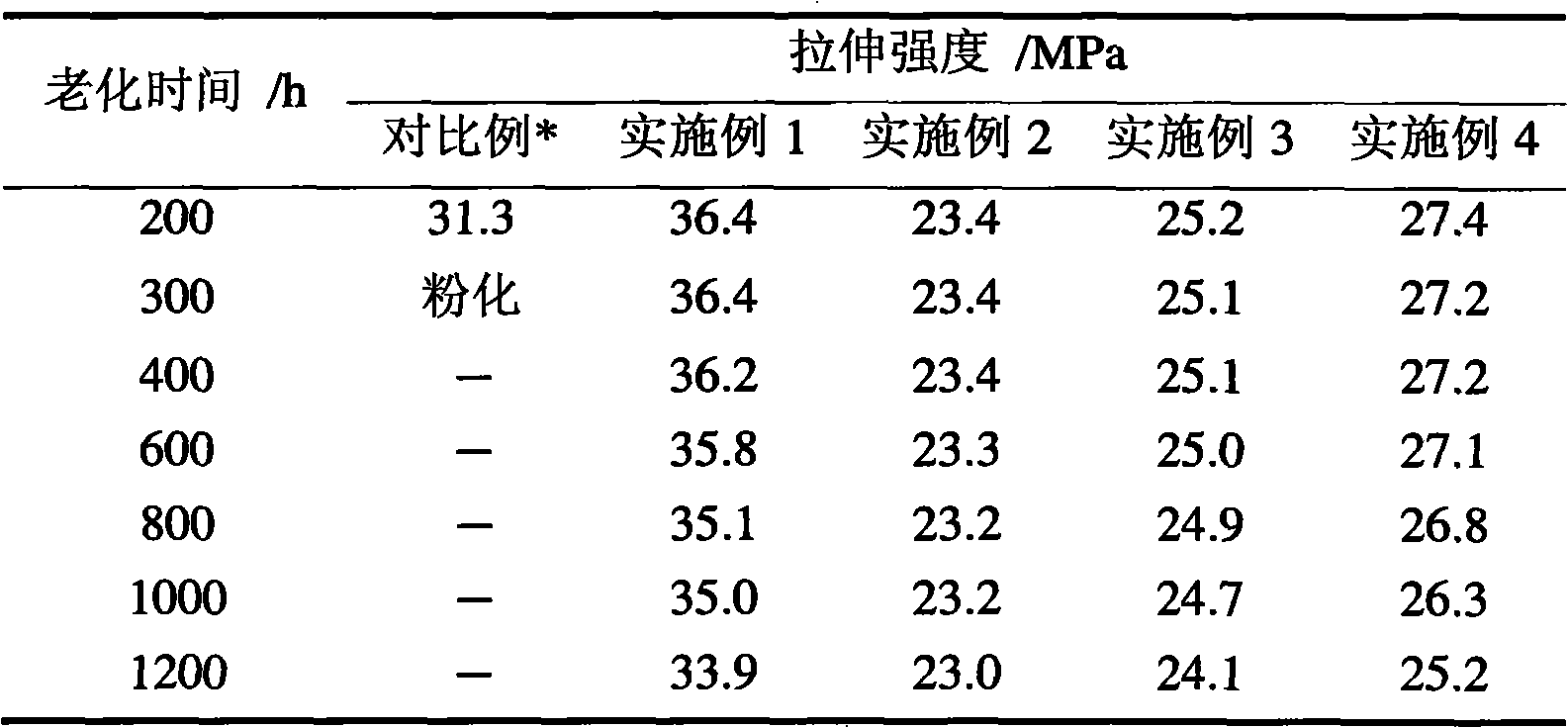

Thermo-oxidative ageing resistance black filling polypropylene composite material and preparation method thereof

The invention discloses a thermo-oxidative ageing resistance black filling polypropylene composite material and a preparation method thereof. The composite material consists of the following components in percentage by weight: 50 to 75 percent of polypropylene, 10 to 40 percent of filling, 0 to 15 percent of an elastomer, 0.5 to 2 percent of an acid acceptor, 0.7 to 1.5 percent of composite antioxidant, 0.2 to 0.6 percent of a processing aid, 0.4 to 0.8 percent of carbon black, and 0.2 to 0.8 percent of paraffin oil. In the composite material, the acid acceptor is added to adsorb acid substances on the carbon black surface, and the antioxidant containing a plurality of reactive functional groups is also added, so that the dissolubility of the antioxidant in the system is increased, the oxidation resistance of the antioxidant cannot be easily weakened by the carbon black, and the thermal-oxidative ageing resistance of a black high filling polypropylene system can be effectively improved. The acid acceptor in the polypropylene resin can eliminate halogen in the resin and the residual catalyst in the resin to prevent the halogen or the catalyst from reacting with the resin to generate gel, and can effectively prevent the halogen or the catalyst from corroding the equipment. The acid acceptor can effectively adsorb the acid substances of the PP filling system and impurities on the carbon black surface so as to improve the thermo-oxidative ageing resistance of the system.

Owner:KINGFA SCI & TECH CO LTD +3

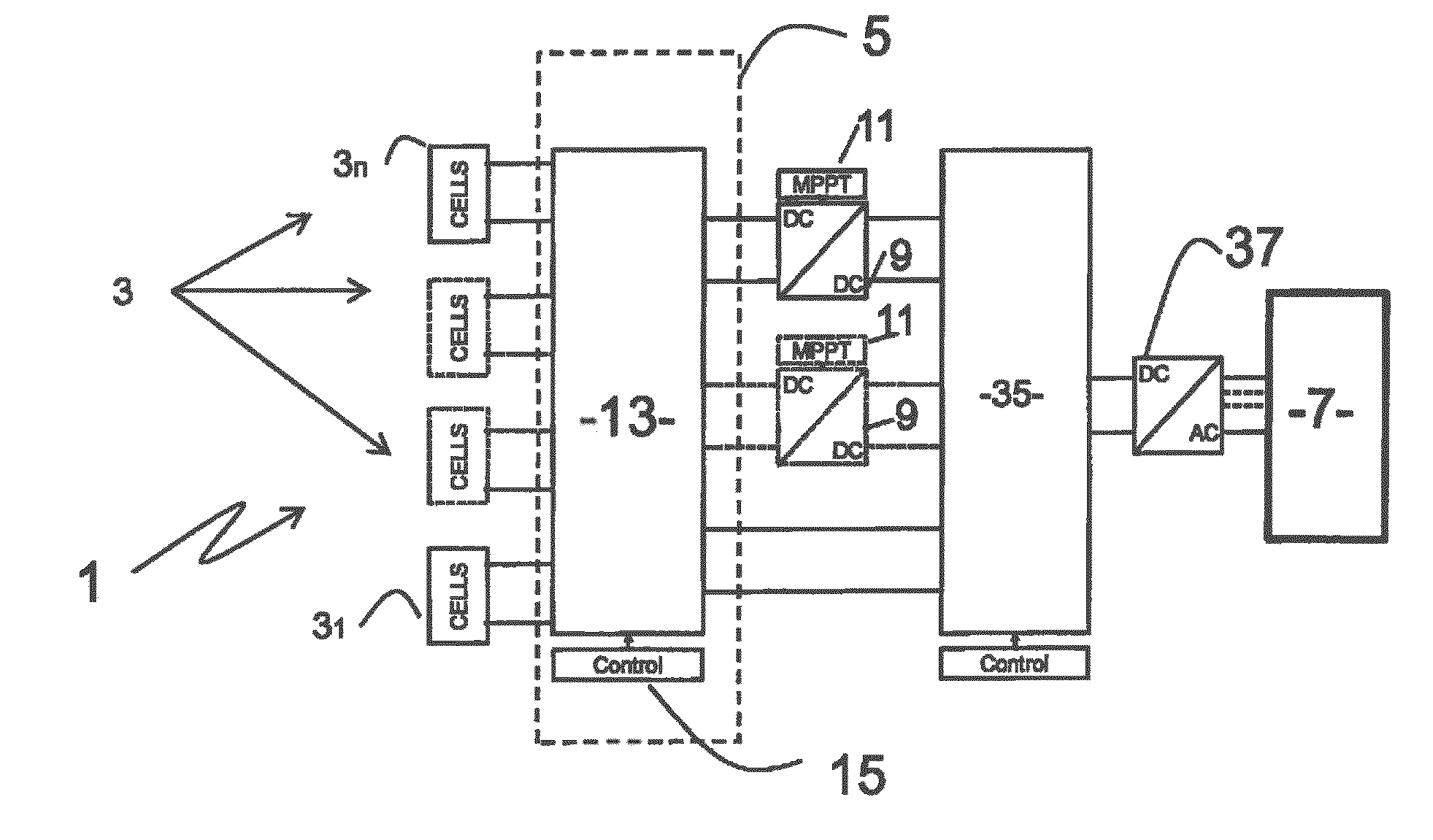

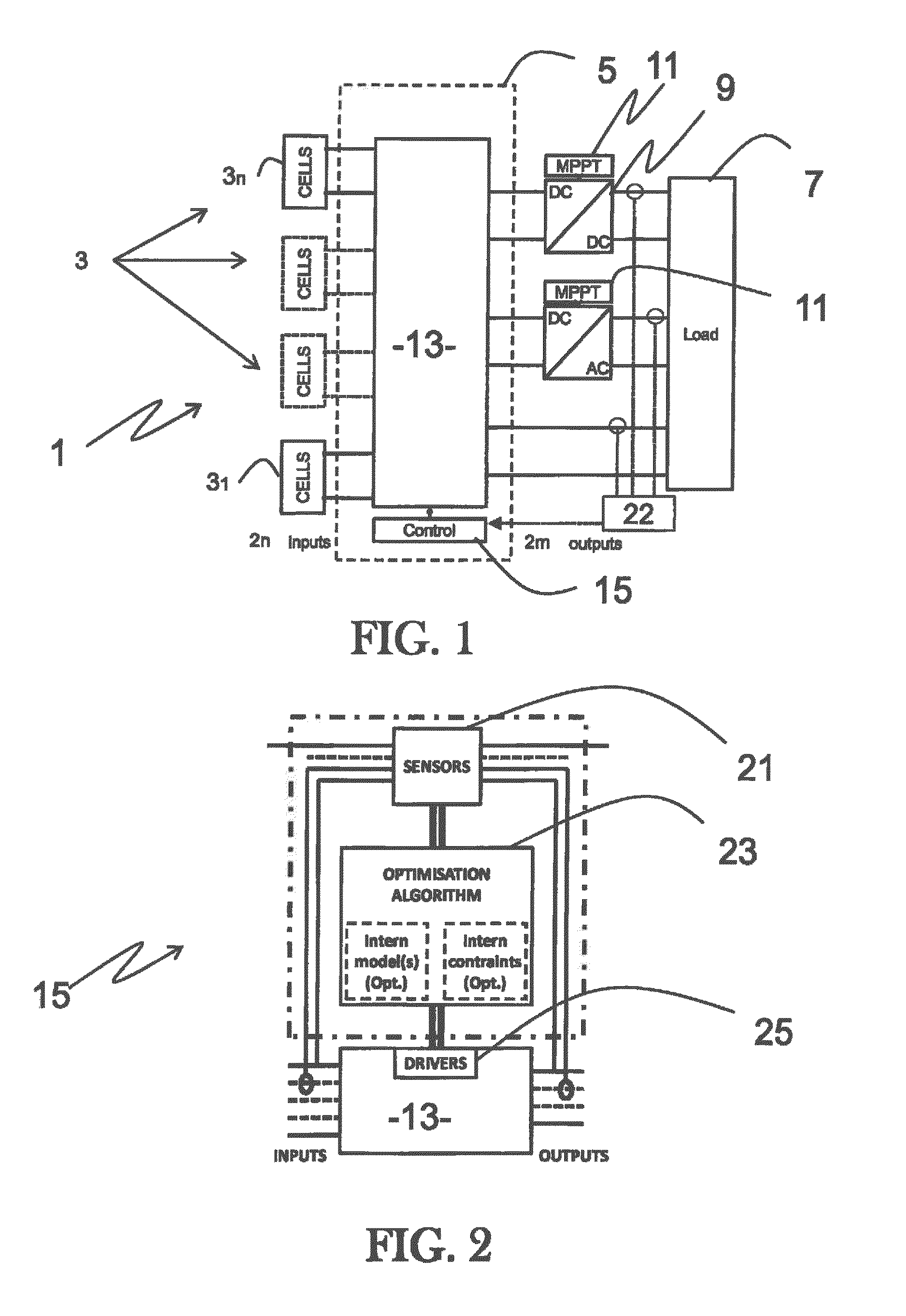

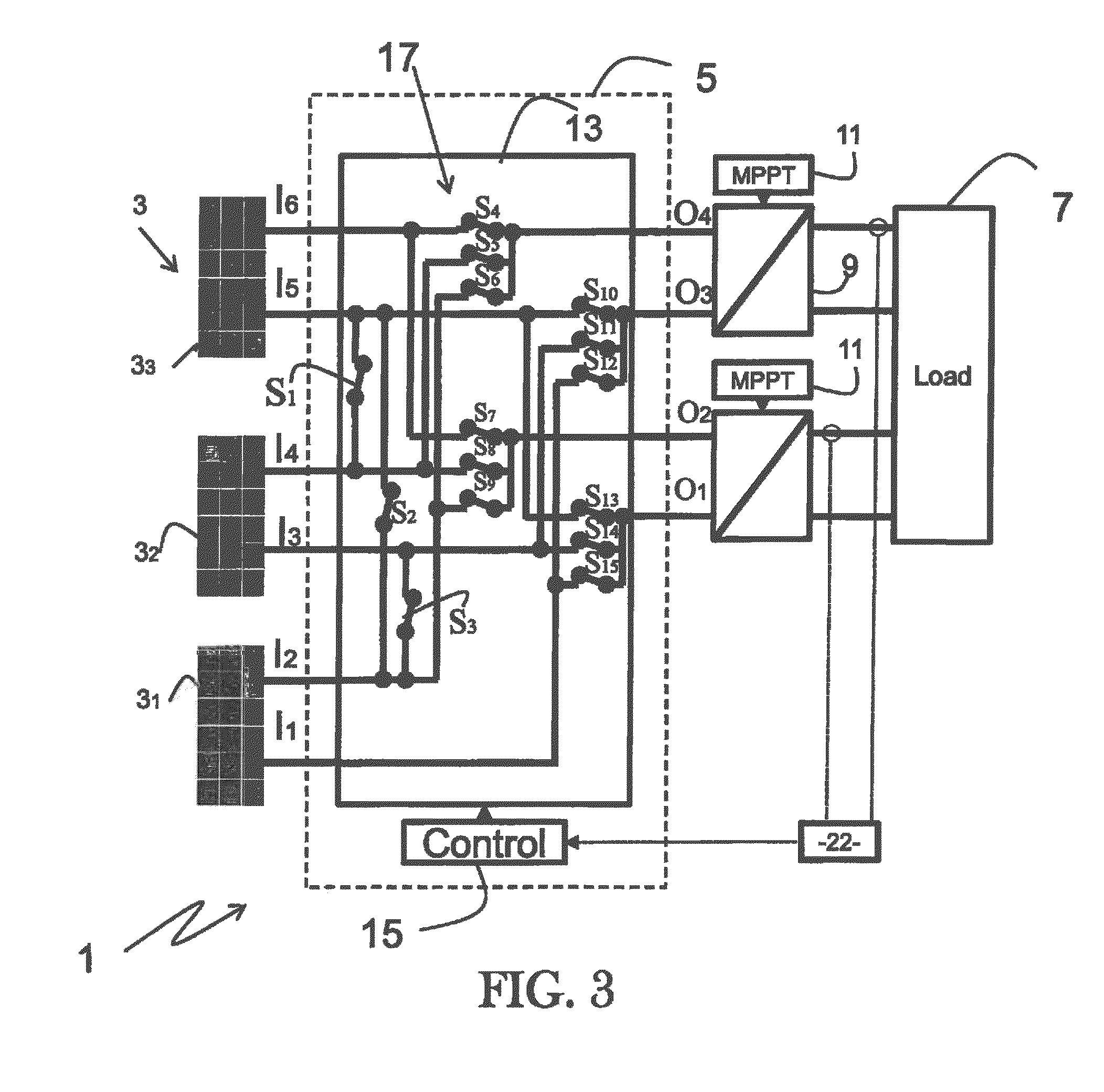

Electronic management system for electricity generating cells, electricity generating system and method for electronically managing energy flow

ActiveUS20160006250A1Power optimizationReduce the effects of agingDc network circuit arrangementsSingle network parallel feeding arrangementsConvertersElectrical battery

The invention relates to an electronic management system (5) for electricity generating cells (3), the system comprising:cell connection terminals to be connected to n associated electricity generating cells (3), n being a positive integer number,outputs to be connected to m associated static converters (9); m being a positive integer number and at least m=2,an energy routing module (13) adapted for routing energy flows from and between said cell connection terminals towards said outputs; andan electronic control unit (15) adapted for controlling dynamically the energy routing module (13).

Owner:TOTAL MARKETING SERVICES SA +1

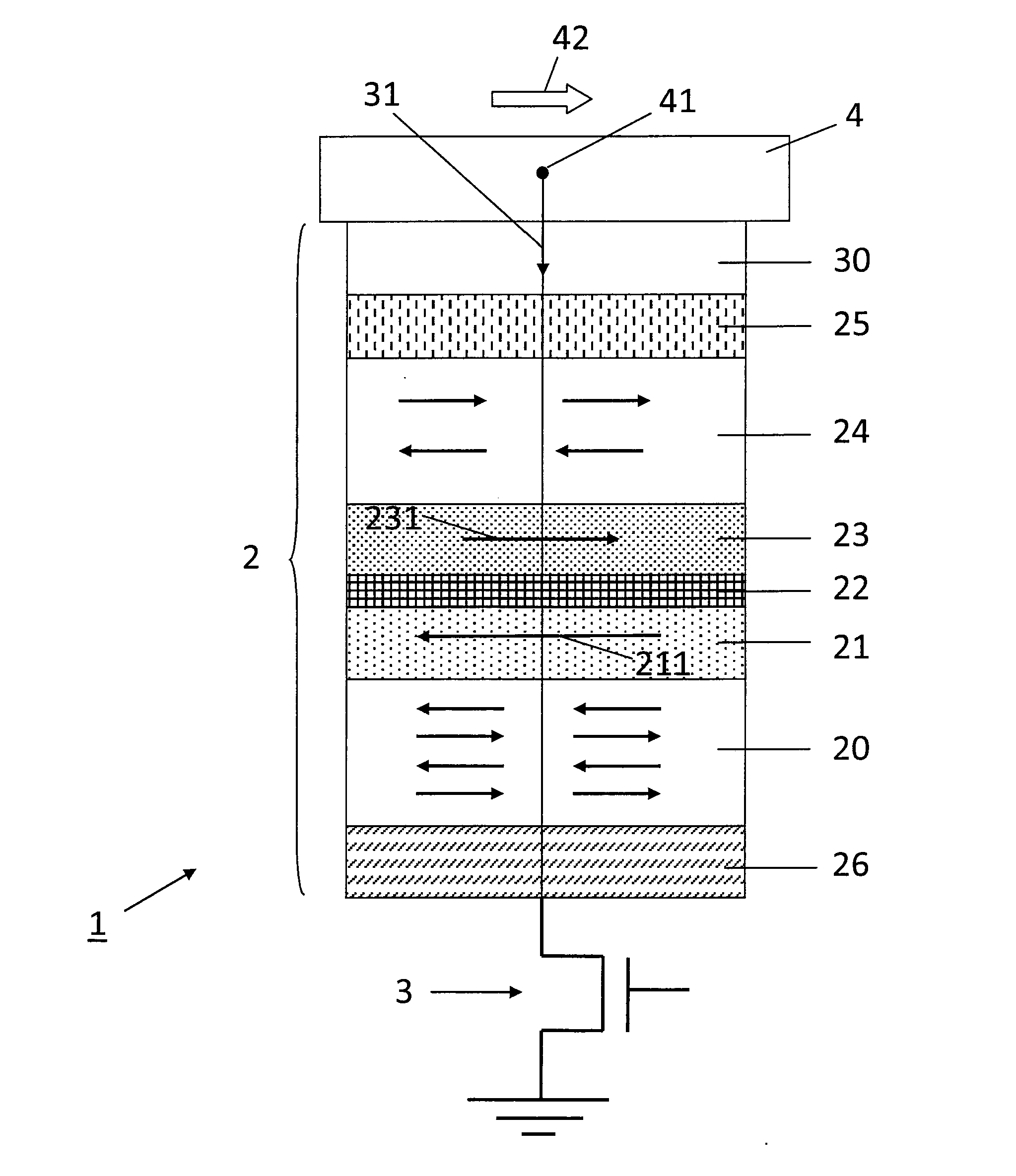

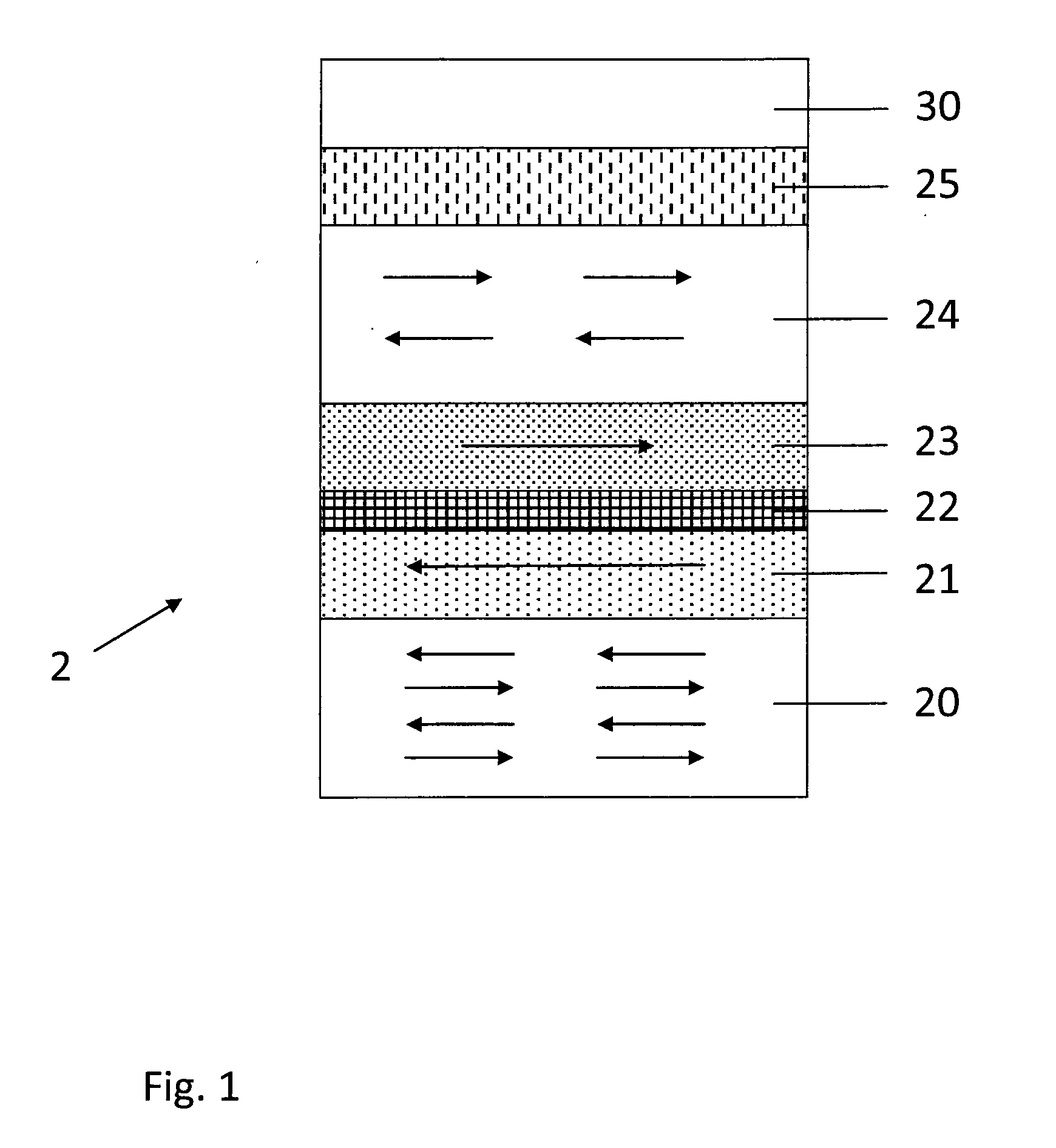

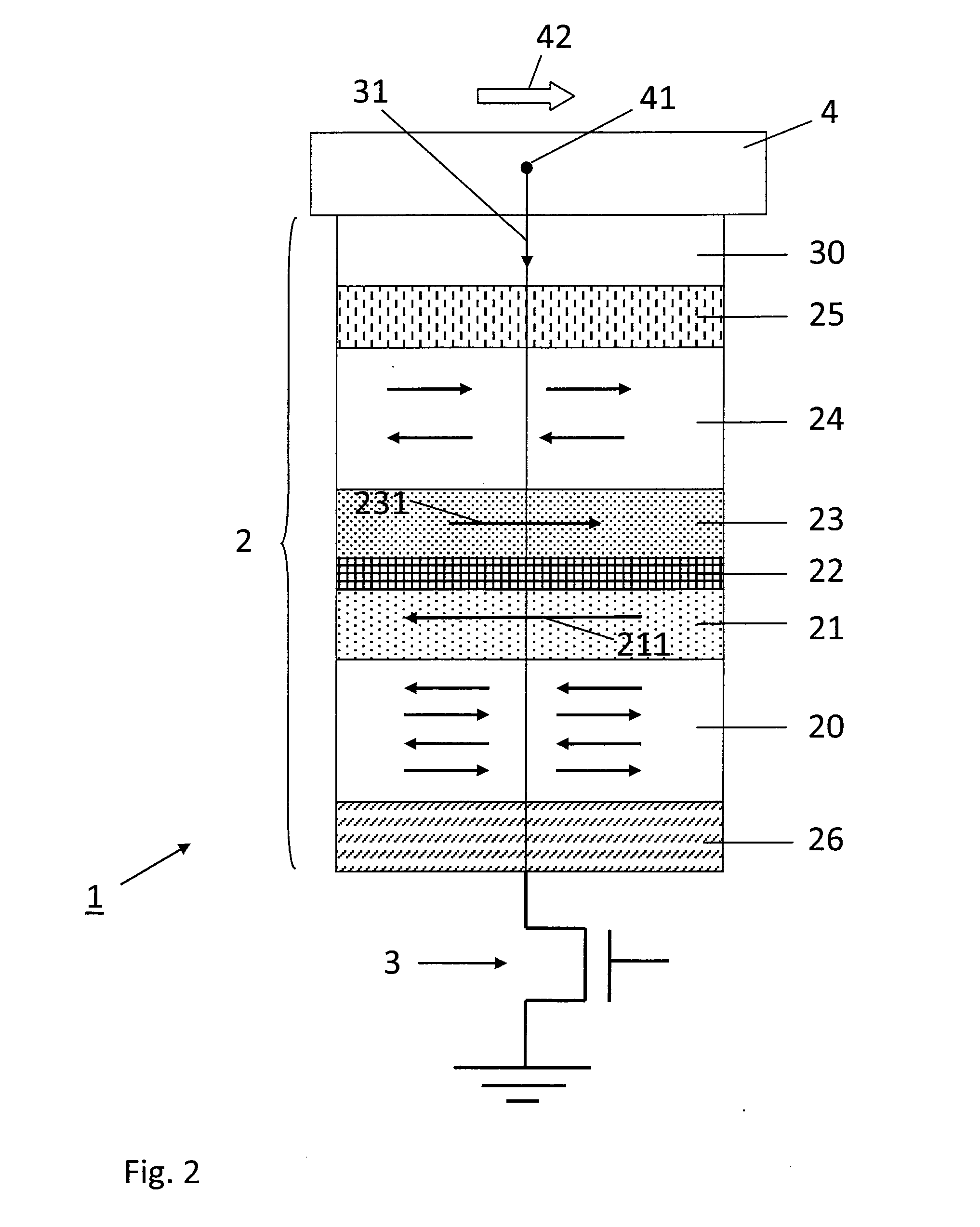

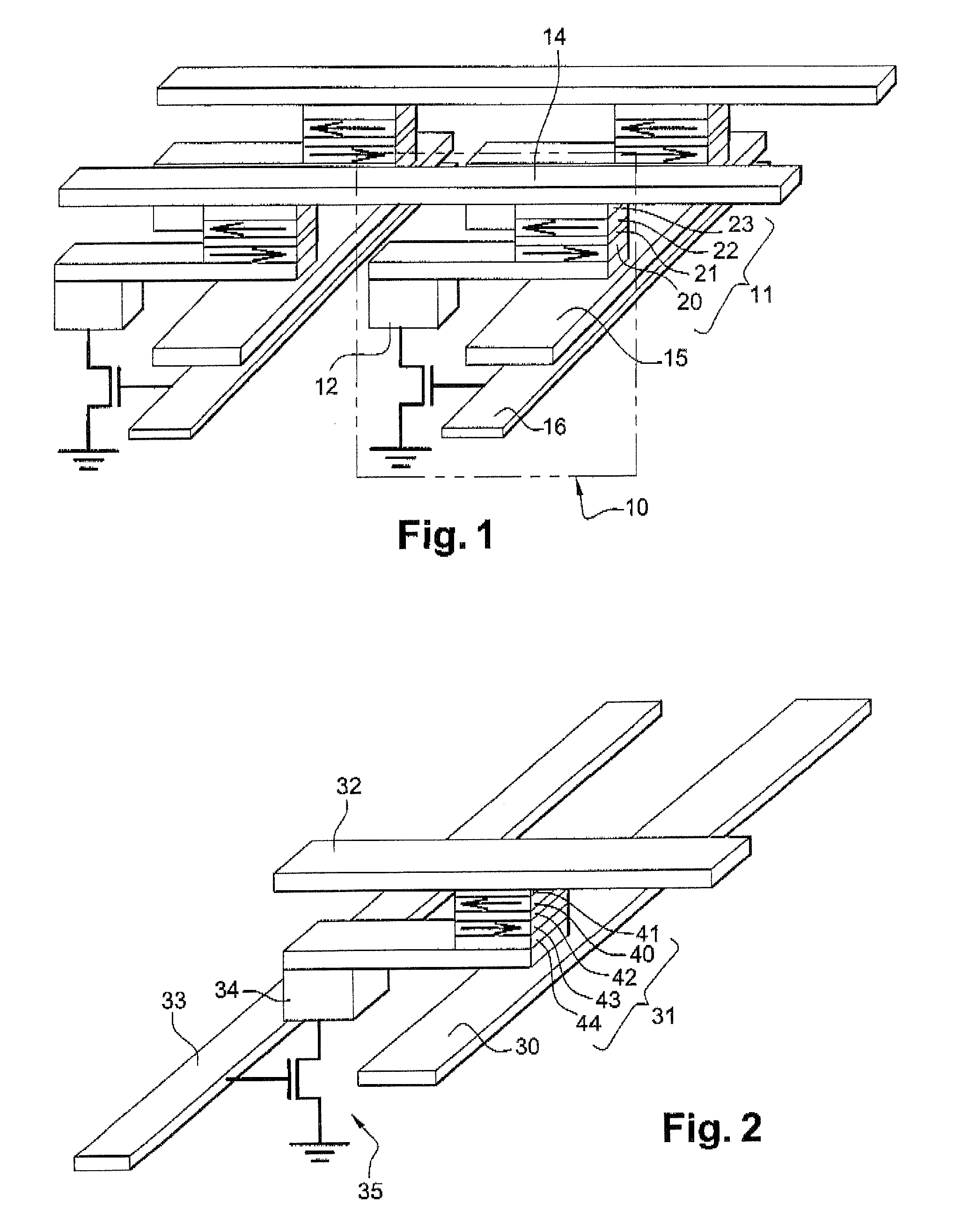

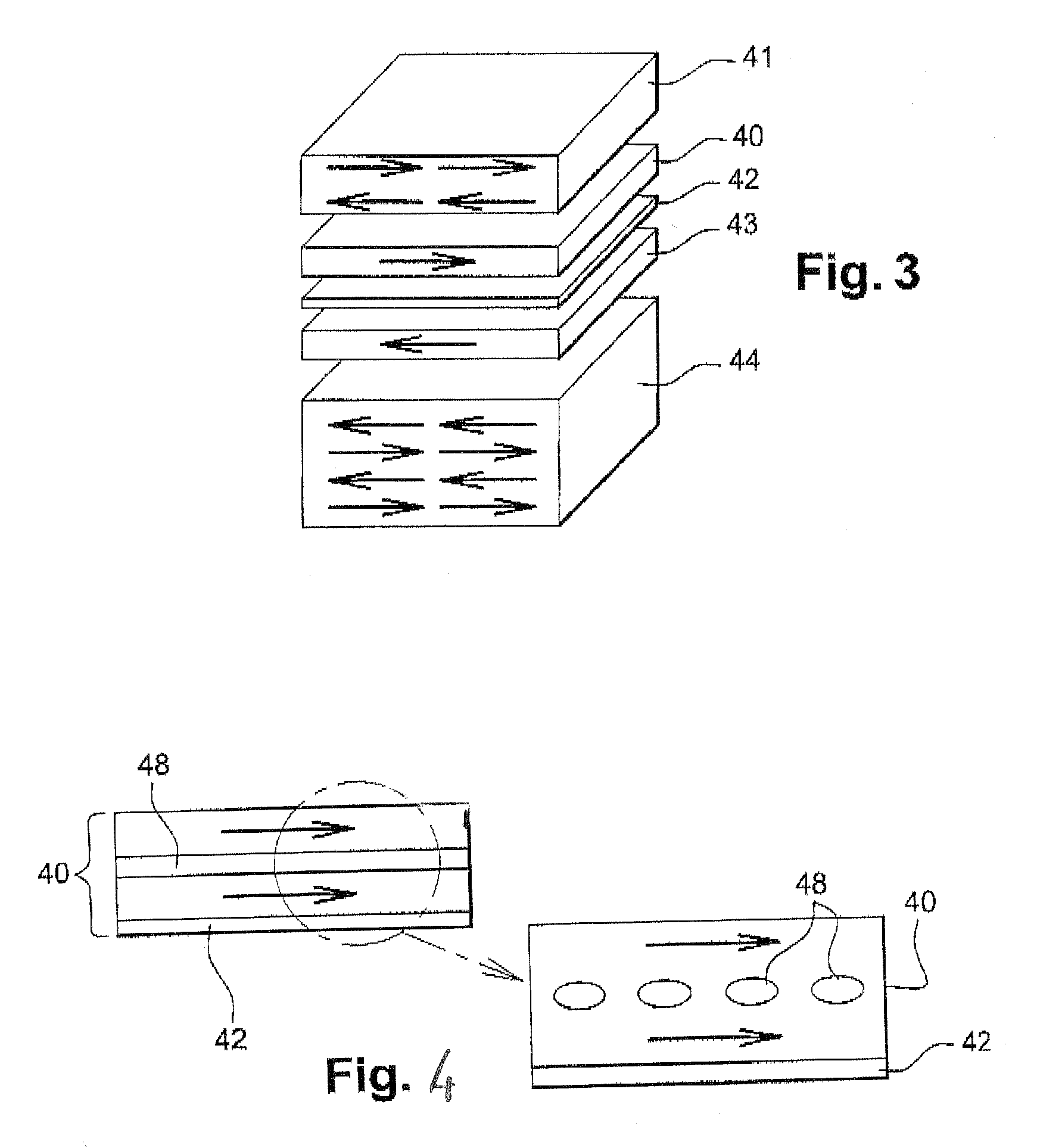

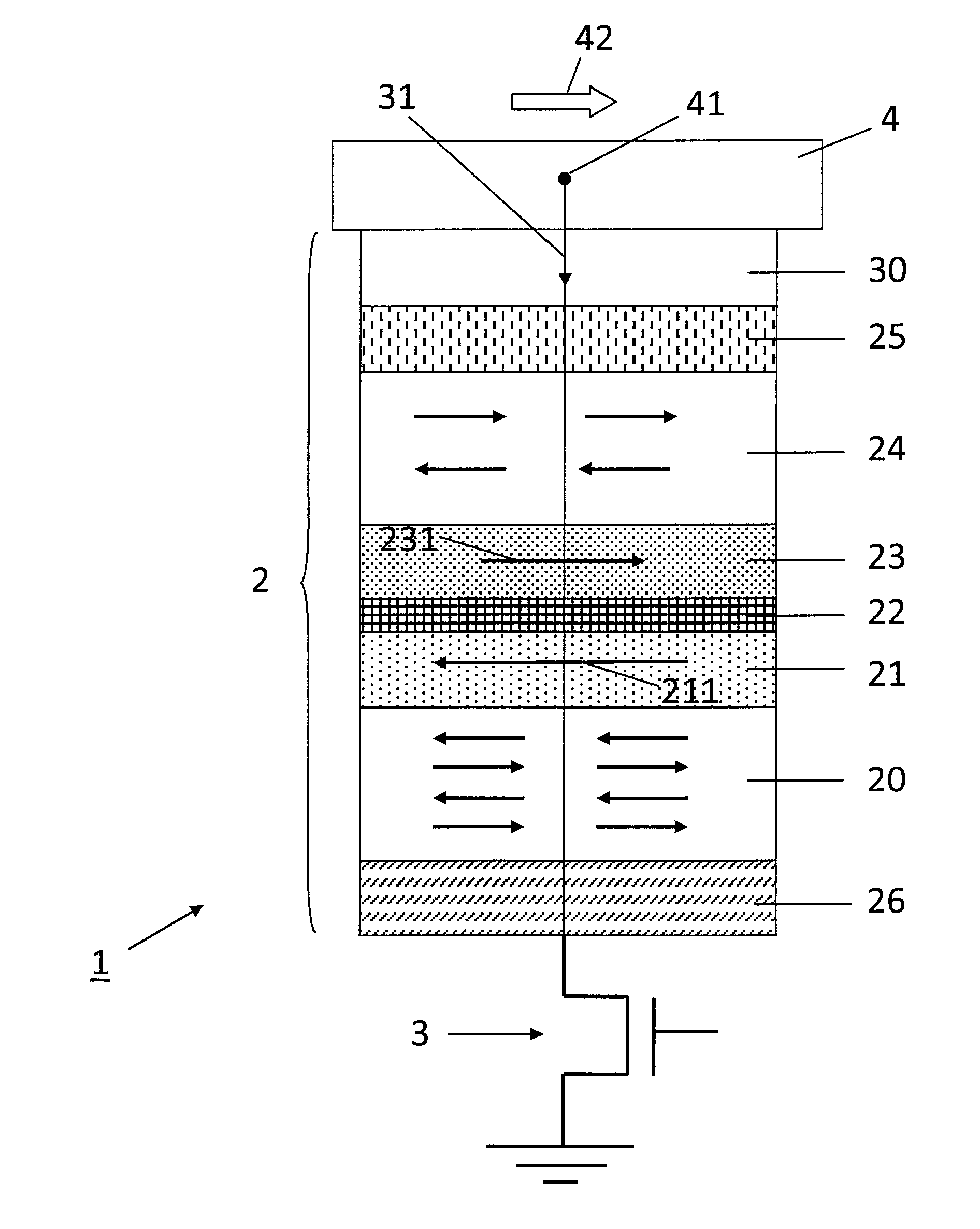

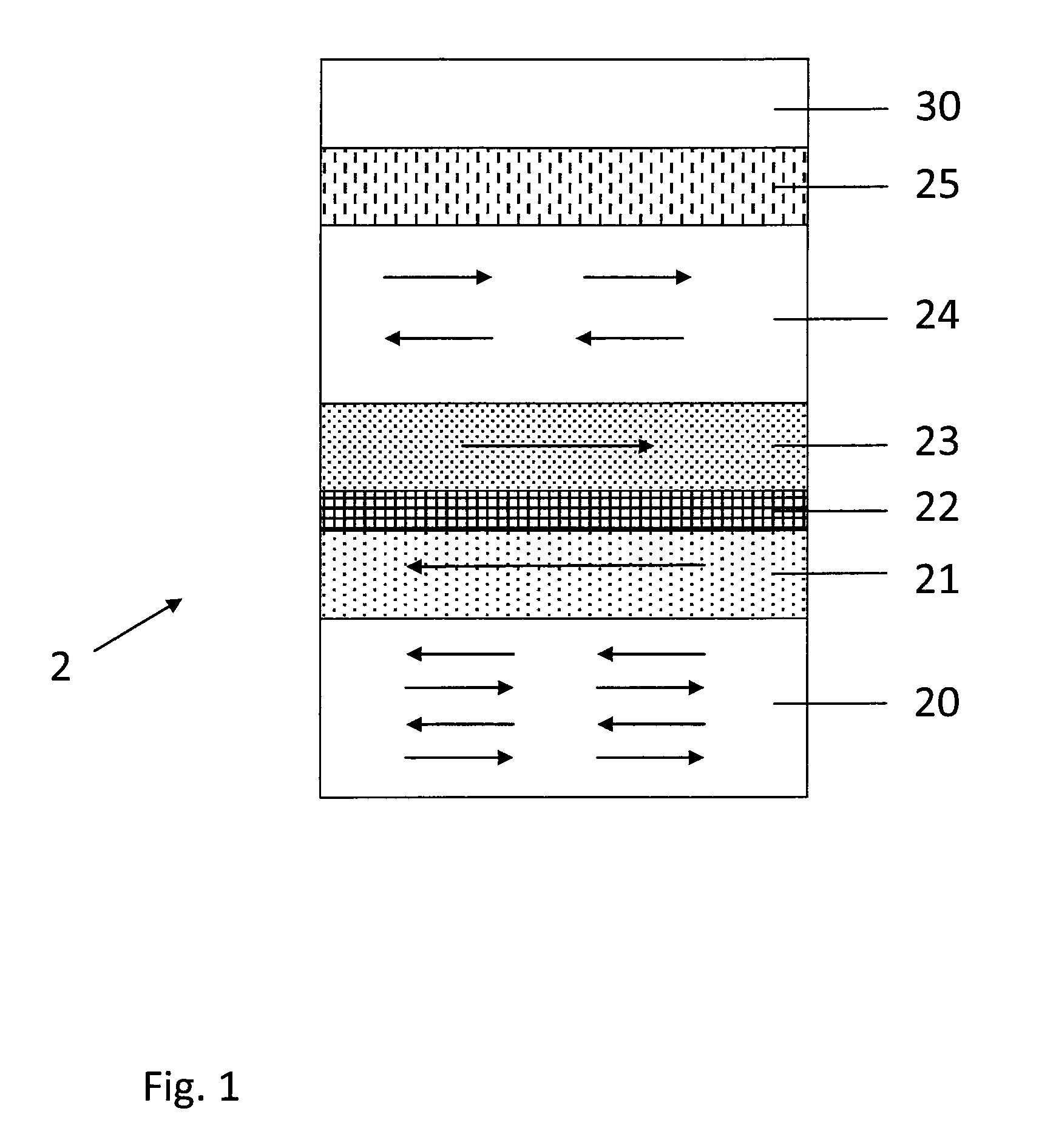

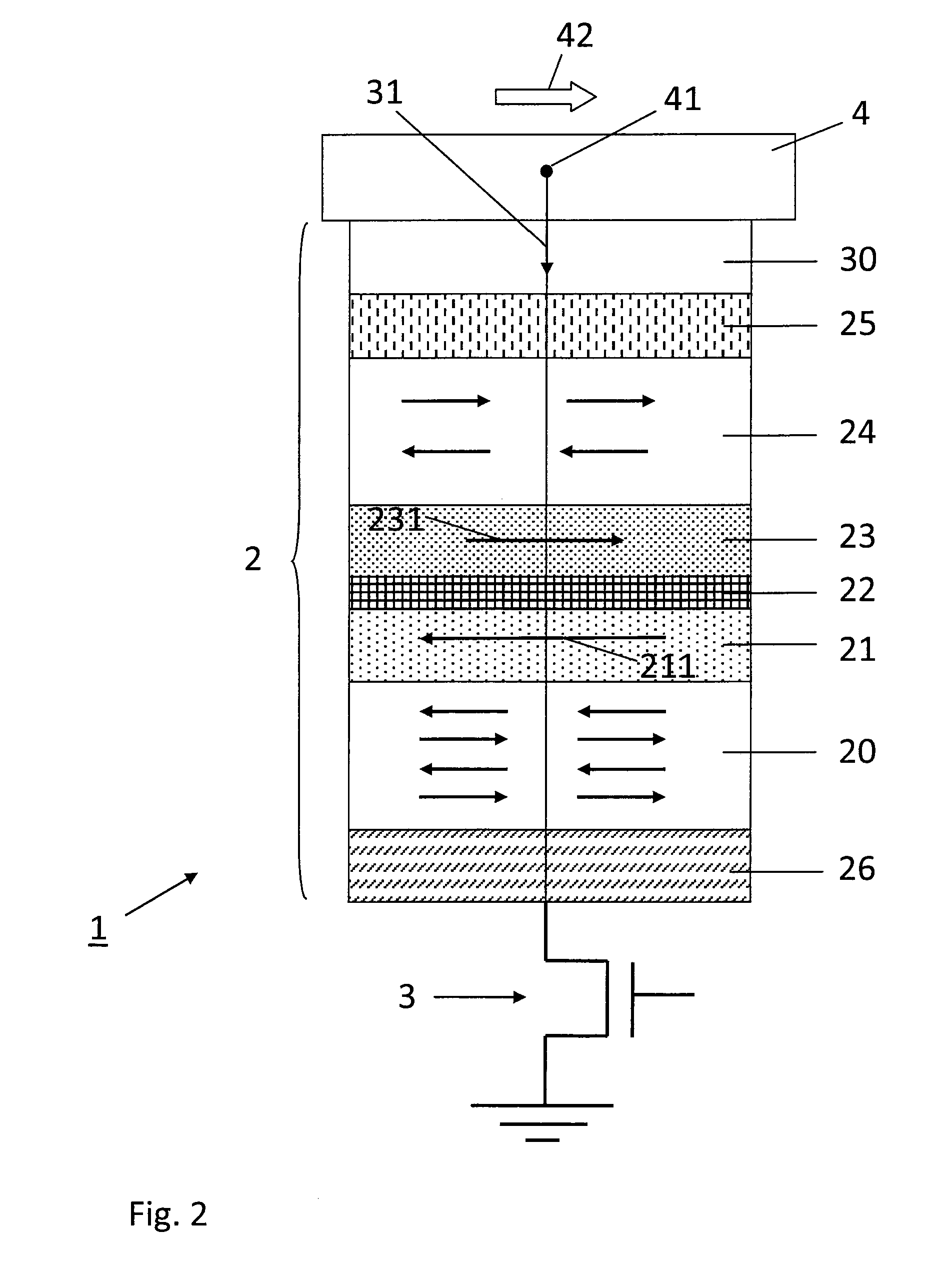

Thermally assisted magnetic random access memory element with improved endurance

ActiveUS20120106245A1Reduces induced stressReduce oxidative stressMagnetic-field-controlled resistorsNanotechnologyElectricityRandom access memory

The present disclosure concerns a magnetic memory element suitable for a thermally-assisted switching write operation, comprising a current line in electrical communication with one end of a magnetic tunnel junction, the magnetic tunnel junction comprising: a first ferromagnetic layer having a fixed magnetization; a second ferromagnetic layer having a magnetization that can be freely aligned at a predetermined high temperature threshold; and a tunnel barrier provided between the first and second ferromagnetic layer; the current line being adapted to pass a heating current through the magnetic tunnel junction during the write operation; wherein said magnetic tunnel junction further comprises at least one heating element being adapted to generate heat when the heating current is passed through the magnetic tunnel junction; and a thermal barrier in series with said at least one heating element, said thermal barrier being adapted to confine the heat generated by said at least one heating element within the magnetic tunnel junction.

Owner:CROCUS TECHNOLOGY

Modified polypropylene plastic and preparation method and use thereof

The invention discloses modified polypropylene (PP) plastic and a preparation method and use thereof. The modified polypropylene plastic is formed by melting and blending polypropylene with ZnO, ZnO / TiO2 or TiO2 / ZnO loaded molecular sieve activated powder. The preparation method of the modified plastic comprises: subjecting a precursor solution of ZnO or TiO2 and molecular sieve activated powder to reduced-pressure absorption reaction; loading the ZnO2 or TiO2 on a molecular sieve activated carrier by high-temperature firing; repeating the loading step to obtain ZnO / TiO2 or TiO2 / ZnO loaded molecular sieve activated powder; and melting and blending the ZnO / TiO2 or TiO2 / ZnO loaded molecular sieve activated powder with polypropylene. The modified polypropylene plastic disclosed by the invention has good killing effect on staphylococcus aureus, Escherichia coli and the like, has much obvious antibacterial effect in a dark environment than simple pure nano TiO2 modified PP under the same conditions, has much higher ultraviolet aging resistance than PP or PP inorganic particle composite material, and can be used for preparing all-weather antibacterial and anti-aging materials.

Owner:SUN YAT SEN UNIV

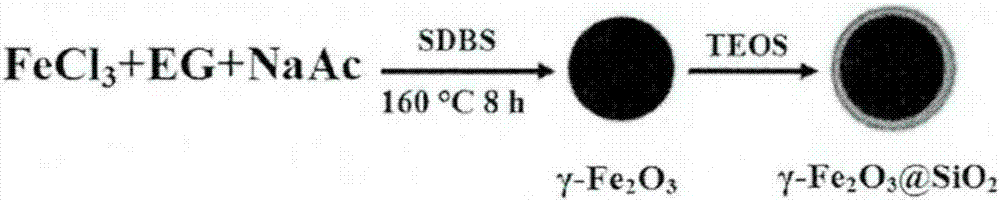

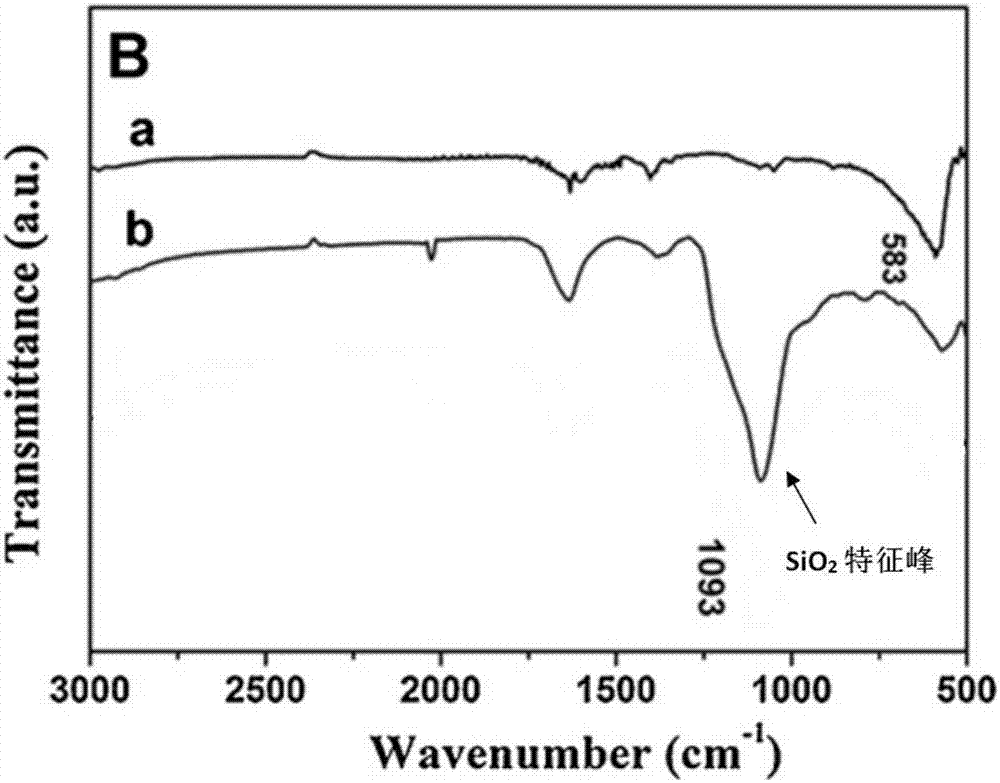

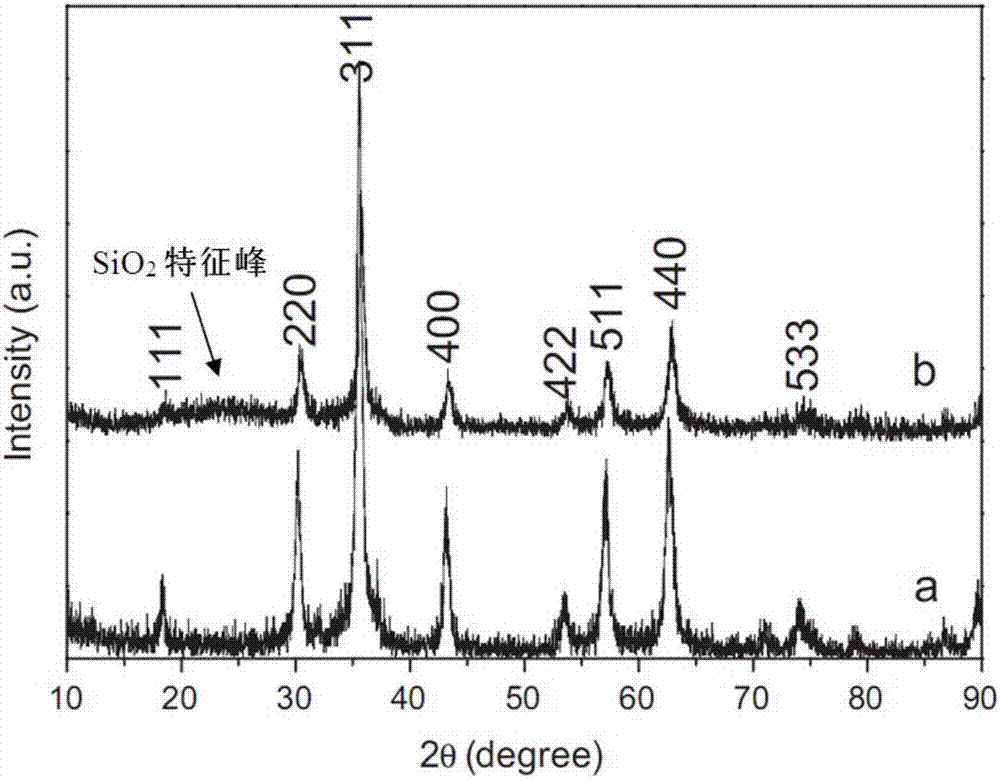

Nano inorganic composite pigment and preparation method thereof

ActiveCN107286705AImprove corrosion resistanceGood dispersionInorganic pigment treatmentSolventInorganic pigments

The invention provides a nano inorganic composite pigment. A nano inorganic pigment is used as a core, and silicon dioxide covers the nano inorganic pigment to form a shell layer, so that the obtained nano inorganic composite pigment is excellent in all properties such as corrosion resistance, dispersivity and compatibility; and furthermore, protection for a matrix substance below a pigment coating is obviously enhanced, and a good basis is provided for subsequent treatment of the pigment coating. The invention further provides a preparation method of the nano inorganic pigment. The preparation process is easy to operate; and no special solvent is used, so that the preparation method is environmentally-friendly and cost-effective, and has a remarkable economical value.

Owner:GREAT WALL MOTOR CO LTD

Physical unclonable function

ActiveUS9350330B2Reduce the numberDesign economyKey distribution for secure communicationRandom number generatorsElectricityStable state

A physical unclonable function is provided 100, comprising a plurality of bus-keepers 110, each bus-keeper of the plurality of bus-keepers 110 being configured to settle into one of at least two different stable states upon power-up, the particular stable state into which a particular bus-keeper of the plurality of bus-keepers settles being dependent at least in part upon the at least partially random physical characteristics of the particular bus-keeper, and a reading circuit 120 for reading the plurality of stable states into which the plurality of bus-keepers settled after a power-up, the plurality of bus-keepers being read-only.

Owner:INTRINSIC ID

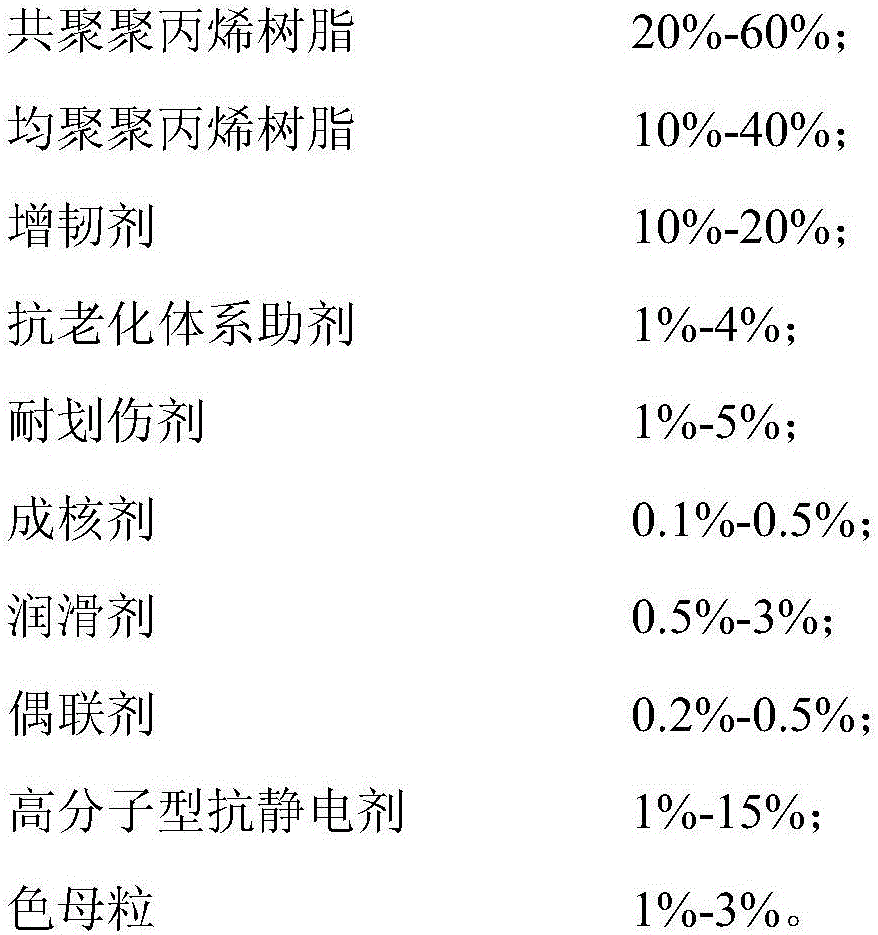

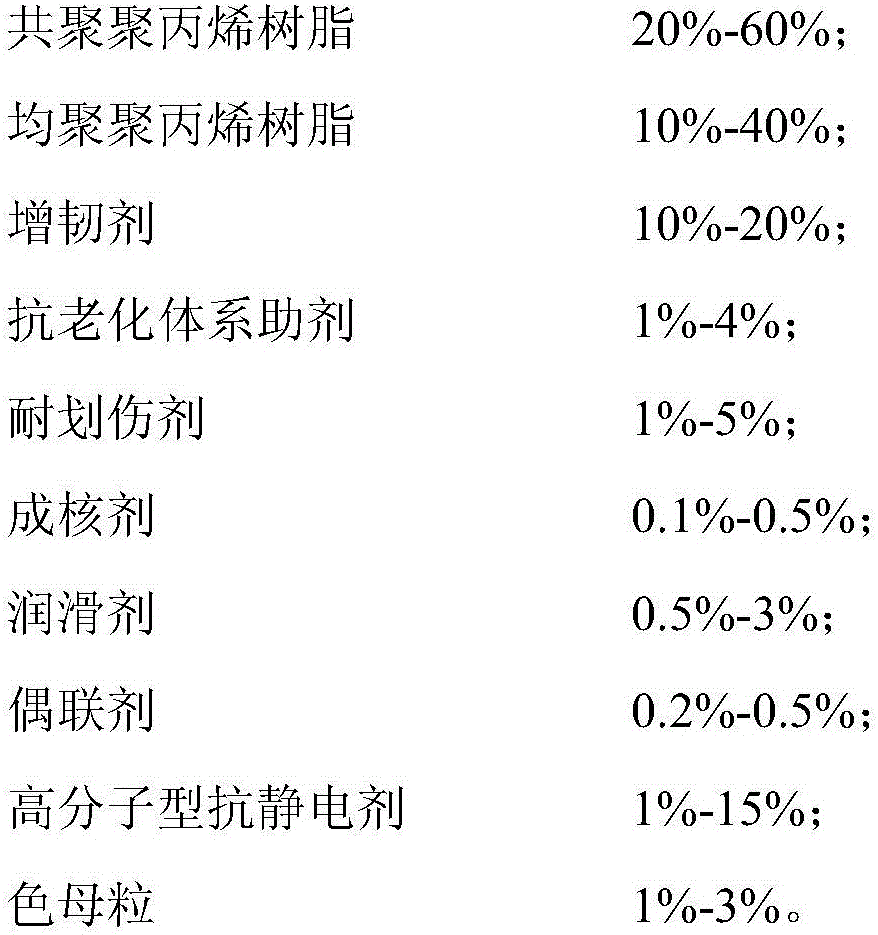

Polypropylene composition for spray-free bumpers and preparation method thereof

InactiveCN106380700AGood anti-aging propertiesInhibition of catalysisPolymer scienceAntistatic agent

The invention discloses a polypropylene composition for spray-free bumpers and a preparation method thereof. The polypropylene composition comprises the following components in percentage by weight: 20-60% of copolymer polypropylene resin, 10-40% of homopolymer polypropylene resin, 10-20% of toughener, 1-4% of antiaging system aid, 1-5% of scratch-resistant agent, 0.1-0.5% of nucleator, 0.5-3% of lubricant, 0.2-0.5% of coupling agent, 1-15% of high-polymer antistatic agent and 1-3% of master batch. The spray-free bumper prepared from the composition has the advantages of favorable washability, favorable permanent antistatic property, favorable long-term aging resistance and low dependence on the environment. The preparation method comprises the following steps: (1) weighing the materials in percentage by weight; (2) stirring and mixing the raw materials to obtain a premix; and (3) carrying out extrusion granulation on the premix to obtain the polypropylene composition. The method has the advantages of simple production technique and low cost.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

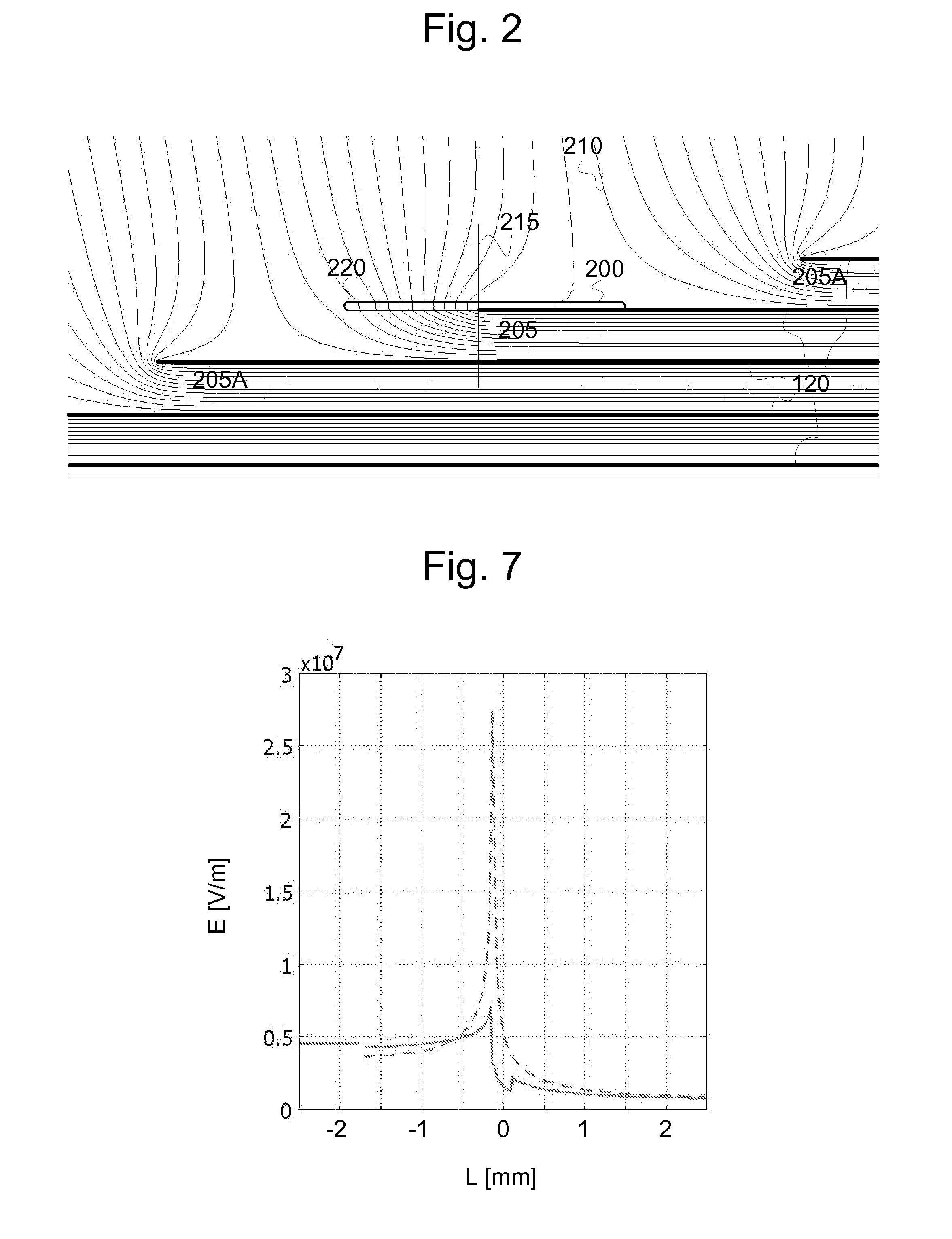

Electrical Bushing

ActiveUS20130025911A1Improve relationshipIncrease the electric field strengthTransformers/inductances detailsInsulating bodiesElectrical conductorElectrical contacts

Owner:HITACHI ENERGY SWITZERLAND AG

Method for preparing special oil for oil-in-water frozen dough

The invention relates to a method for preparing special oil for oil-in-water frozen dough, belonging to the technical field of oil preparation. The method comprises the following steps: adopting a product synthesized by ester exchanger of solid fat and liquid oil as base oil, adding a certain amount of sterilization water, and adding a small amount of emulsifier and stabilizer as well as trace amount of antioxidant and antiseptic. The production process comprises the steps of synthesizing the base oil by ester exchange, matching auxiliaries, emulsifying, quenching, kneading, packaging and ripening. The special oil for oil-in-water (O / W) frozen dough produced by adopting the invention has high quality and stable property and can be used when frozen dough is baked in different seasons.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

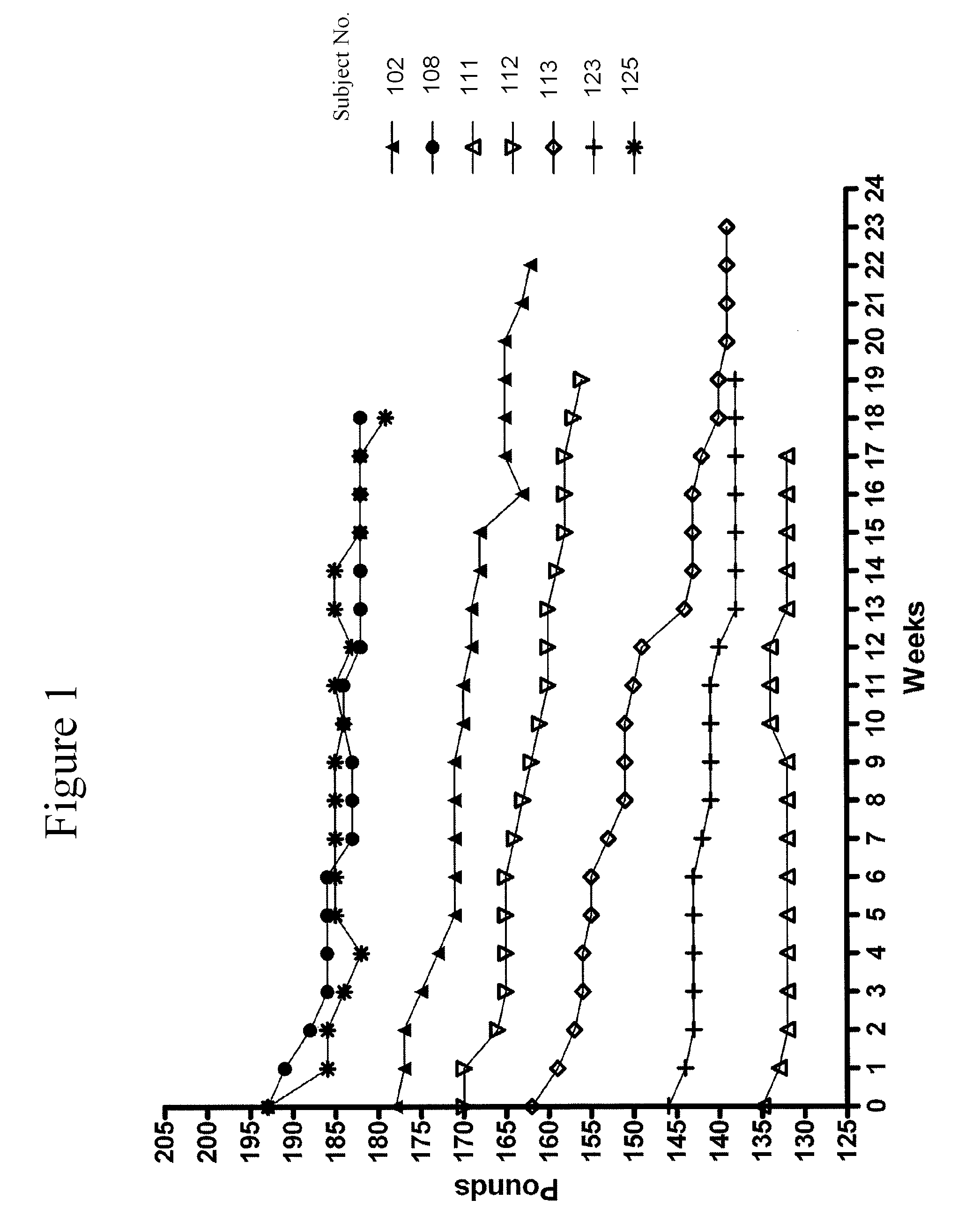

High protein supplement

ActiveUS7982066B2Prevention and improvementImbalance conditionOrganic active ingredientsNervous disorderProtein C deficiencyProtein

The present disclosure relates to high protein dietary supplements for treating various symptoms and diseases associated with protein deficiency including weight gain, obesity, catabolic diseases, fibromyalgia, anxiety reactions, posttraumatic stress and chronic fatigue syndrome. Embodiments of dietary supplements comprise combinations of proteins, essential and semi-essential amino acids including L-Lysine, L-Arginine, and / or L-Histidine.

Owner:SCHEELE GEORGE

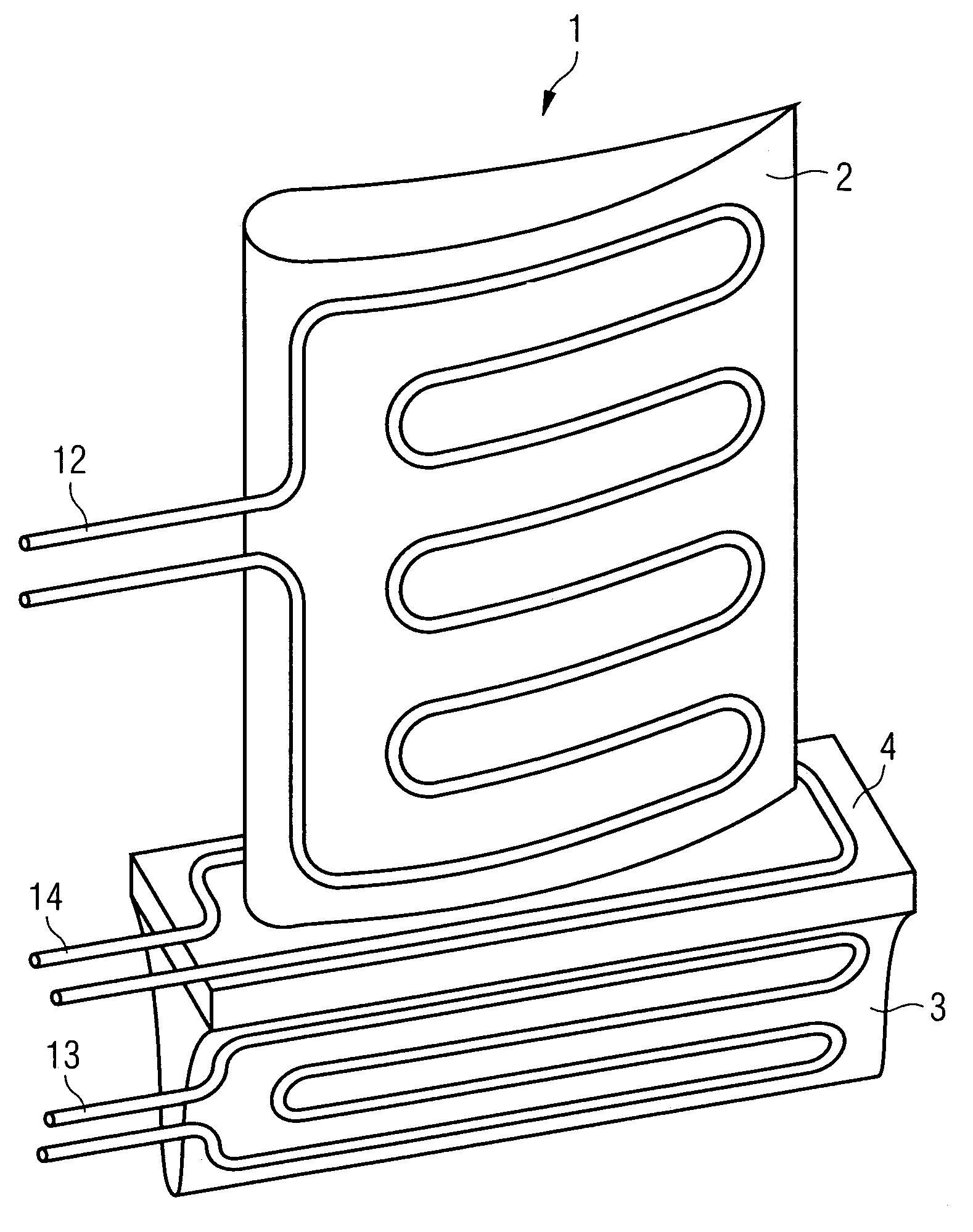

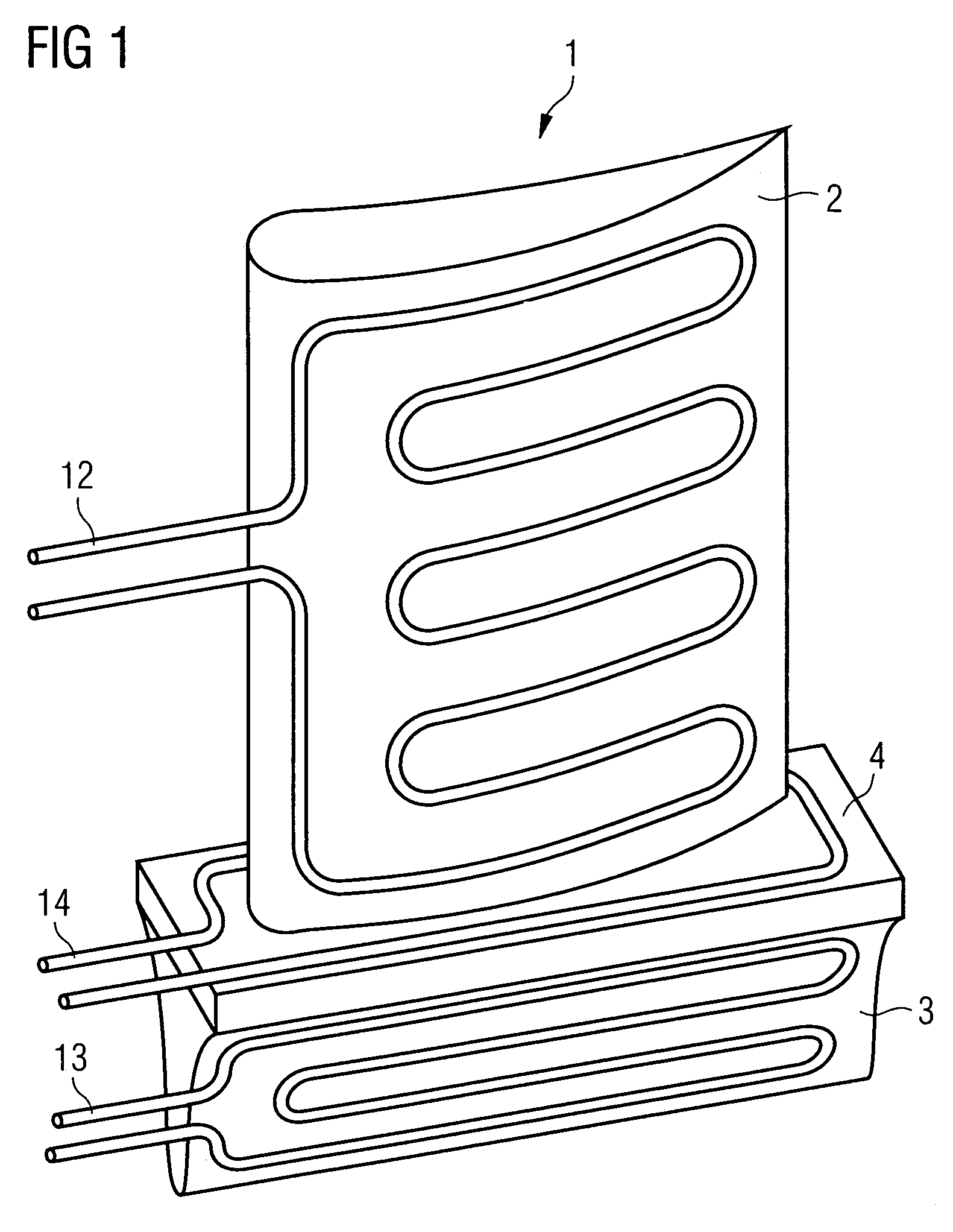

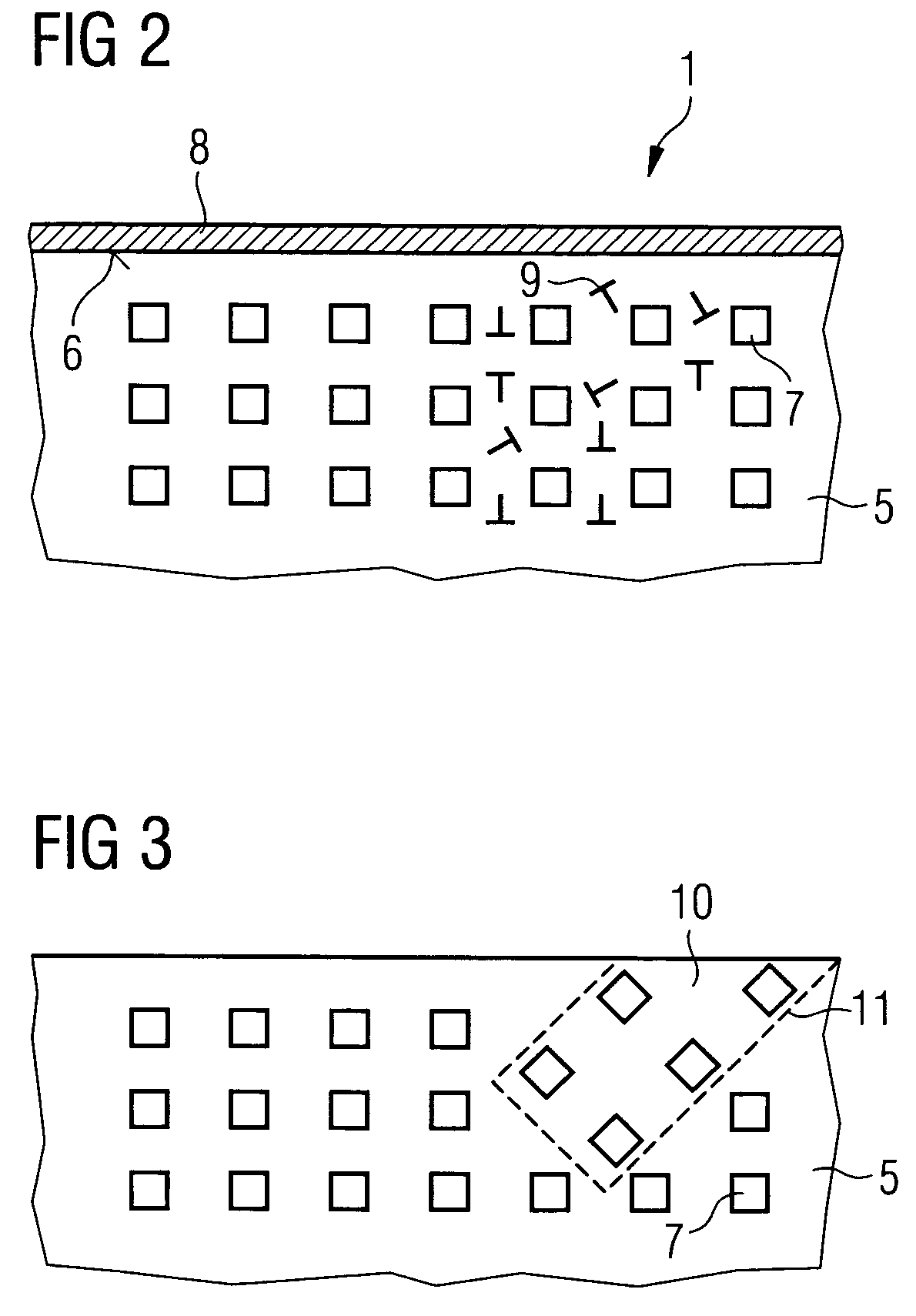

Device for controlling the temperature of an energy store and method for producing the device for controlling the temperature

InactiveUS20120107635A1High strengthAvoid contactEnvelopes/bags making machineryExtrusion containersContact elementBiomedical engineering

A device for controlling the temperature of an energy store is provided. The device includes a contact element having a contact area for providing a thermal coupling to the energy store, a fluid channel, which is arranged in the contact element, and an insulating apparatus, which is arranged in the contact element.

Owner:BEHR GMBH & CO KG

Magnetic element with thermally assisted writing

ActiveUS8228716B2Minimize risk of breakdownEffective temperatureDigital storageStress inducedMagnetic storage

Magnetic element with thermally-assisted magnetic-field writing or thermally-assisted spin-transfer writing, comprising: a reference magnetic layer having a fixed direction magnetization; a storage magnetic layer exchange-pinned with an antiferromagnetic layer, wherein the magnetization direction of the storage layer can vary when said element can be heated to a temperature at least higher than a critical temperature of the antiferromagnetic layer; a tunnel barrier, provided between the reference layer and the storage layer; wherein the magnetic reference layer, and / or the magnetic storage layer includes at least one electrically-resistive thin layer for heating the magnetic element. The magnetic element disclosed herein has a voltage gain of typically 10 to 50% compared to conventional magnetic elements and shows a reduction of the stress induced during a writing operation as well as a reduction of the aging.

Owner:CROCUS TECHNOLOGY

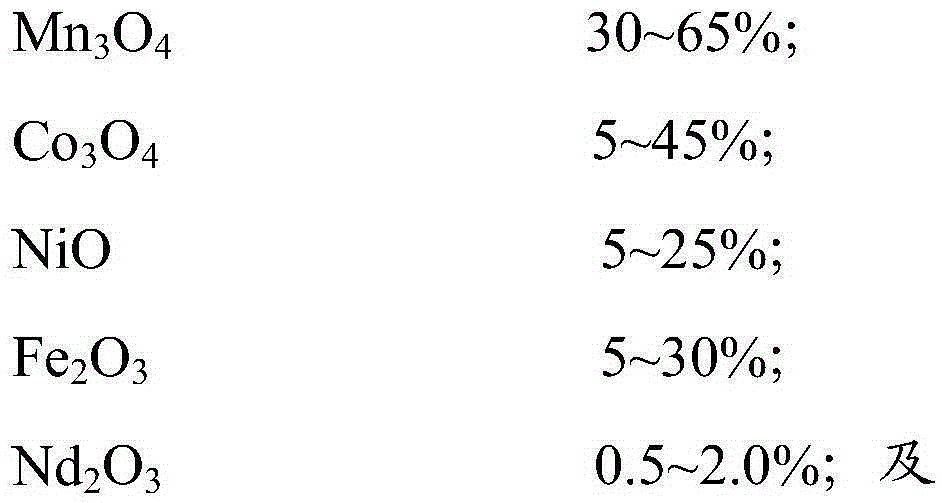

Negative temperature coefficient thermistor raw material composition and application thereof

The invention discloses a negative temperature coefficient thermistor raw material composition, a negative temperature coefficient thermosensitive composition, a preparation method of the negative temperature coefficient thermosensitive composition and a preparation method of a negative temperature coefficient thermistor chip. The negative temperature coefficient thermistor raw material composition is prepared from the following components in percentage by mass: 30 to 65 percent of Mn3O4, 5 to 45 percent of Co3O4, 5 to 25 percent of NiO, 5 to 30 percent of Fe2O3, 0.5 to 2.0 percent of Nd2O3 and 1 to 10 percent of Al(NO3)3.9H2O. Al<3+> is introduced into the negative temperature coefficient thermistor raw material composition in an aluminum nitrate form instead of an Al2O3 solid form; the aluminum nitrate is good in water solubility and is easily and uniformly distributed in the composition, so that the deviation between a resistance value and B value can be reduced, and electrical resistivity and B value precision are improved; in addition, by adding high-enthalpy rare earth oxide Nd2O3, the enthalpy of oxide is 1783KJ / mol, and the oxides do not easily generate chemical reaction at high temperature, so that the ageing influence caused by chemical changes is reduced, and further the electrical stability of the thermistor is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

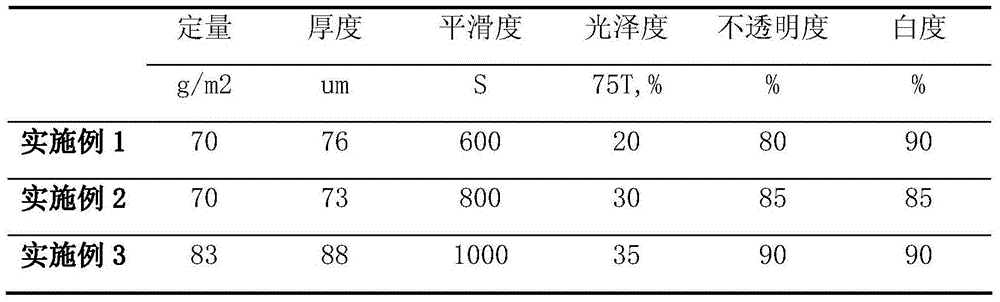

Surface paper with heat transfer label and production method thereof

ActiveCN104313940AImprove light scattering performanceReduce the effects of agingCoatings with pigmentsCalendersPaper sheetThermal insulation

A surface paper with a heat transfer label and a production method thereof are disclosed. The surface paper comprises a layer of original paper, at least a receiving layer is formed on one side or two sides of the original paper layer, and the receiving layer is composed of the following components in parts by weight: 100 parts of white pigment, 5 to 15 parts of adhesive agent, 10 to 20 parts of amorphous mat filling material, and 5 to 15 parts of paint made of hot-melt adhesive; wherein the solid content of the paint is 45% to 70%, the paint viscosity is 400 cps to 1000 cps, and the coating amount of the paint on the receiving layer is 1 g / m2 to 20 g / m2. Preferably, a thermal insulation layer is formed between the receiving layer and the original paper layer. The surface paper with a heat transfer label is obtained by preparing original paper and paint, coating paint on the surface of the original paper, and press-polishing the surface. The surface paper with a heat transfer label has the characteristics of simple preparation method and low cost.

Owner:MINFENG SPECIAL PAPER

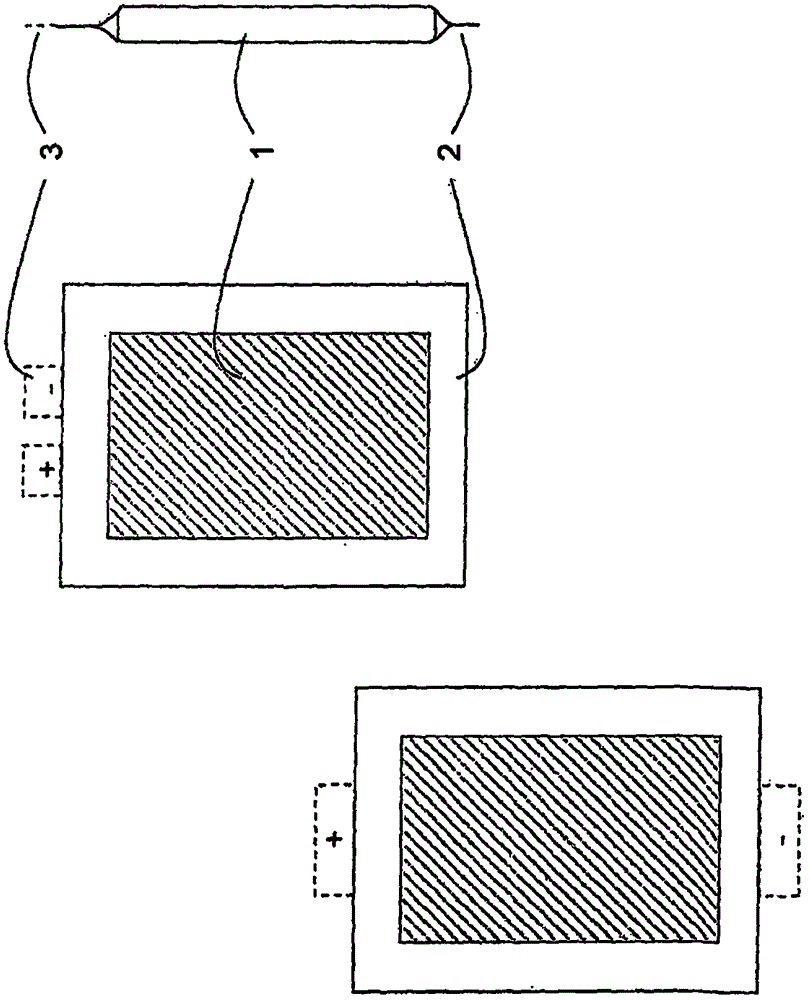

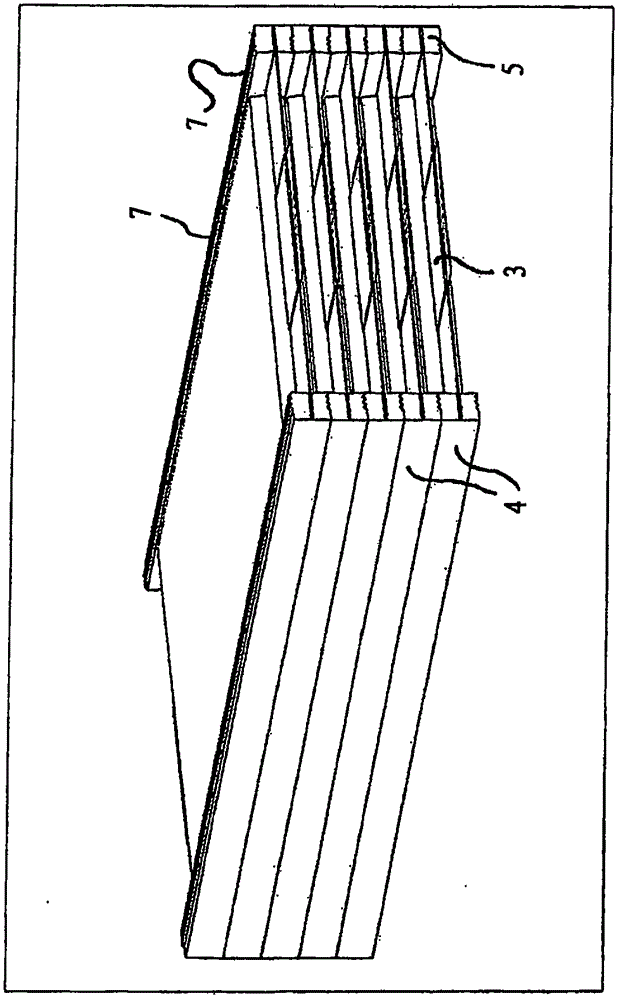

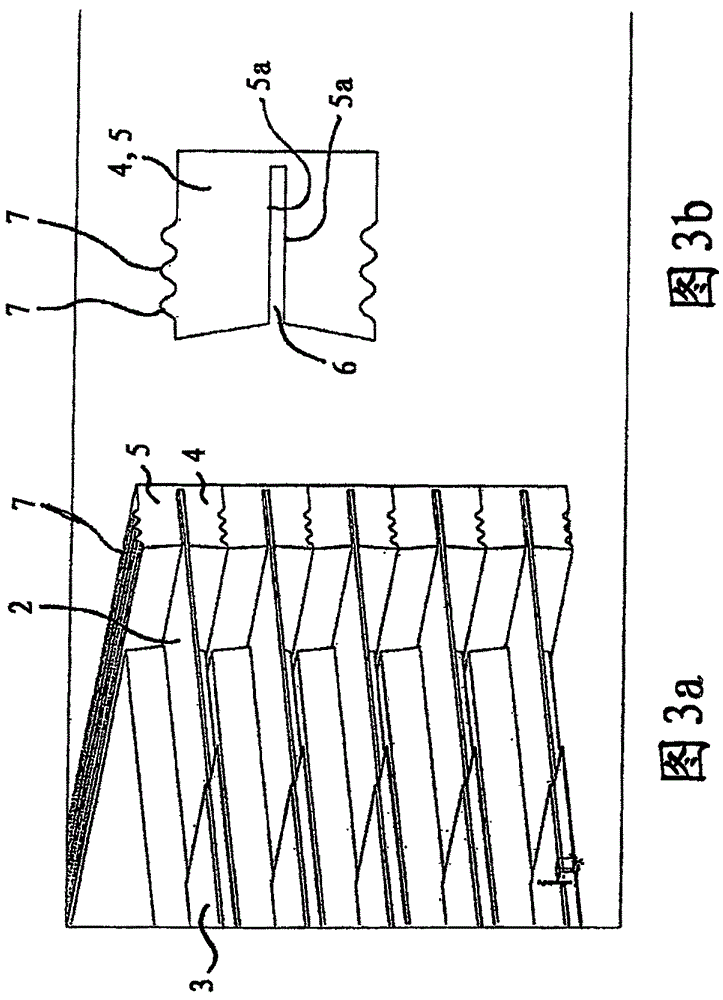

Receiving element for pouch cells

InactiveCN106384795AEasy to processNo penetrationFinal product manufactureBattery isolationEngineeringMechanical engineering

The invention relates to a receiving element (4) for mounting pouch cells, has a base body. The receiving element comprises a base body (5). With respect to an object of receiving the pouch cells securely and cost-effectively in a frame or housing, the receiving element is characterized in that the base body (5) is formed as a profile having a contact surface (5a) for contact against a sealing seam (2) of a pouch cell.

Owner:CARL FREUDENBERG KG

Heat treatment method for monocrystalline or directionally solidified structural components

InactiveUS7892370B2AdvantageousReduce formationPolycrystalline material growthAfter-treatment detailsSingle crystalDissolution

Owner:SIEMENS AG

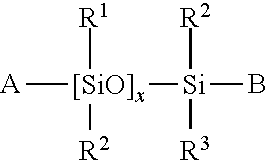

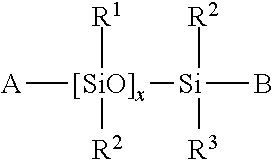

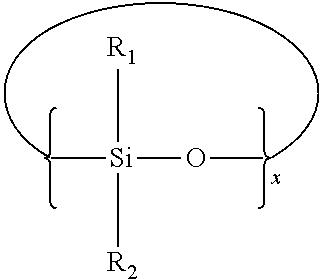

Organosiloxane Films for Gas Separations

ActiveUS20150306549A1Rapid fragmentationReduce volatilityNitrogen purification/separationMembranesPorous substrateHydrogen atom

A semipermeable gas separation membrane is plasma deposited from liquid organosiloxane monomer having at least three silicon atoms and an alpha hydrogen atom. The semipermeable membrane may be employed as a gas-selective membrane in combination with a porous substrate.

Owner:APPLIED MEMBRANE TECH

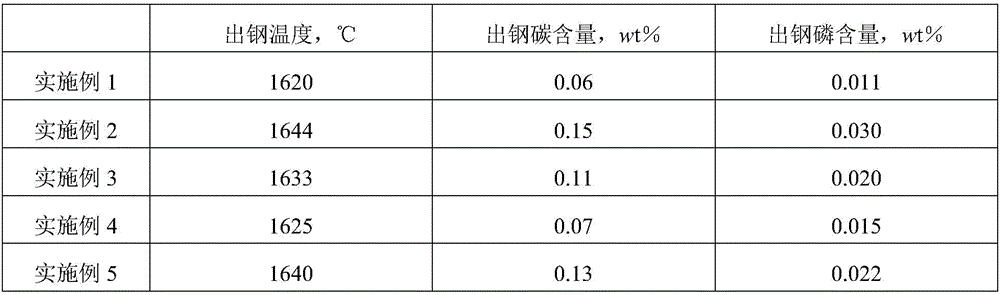

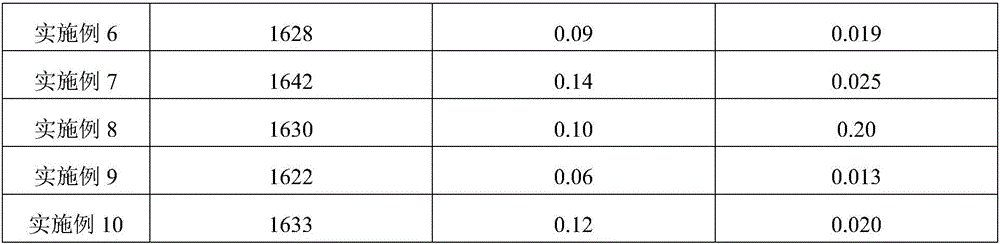

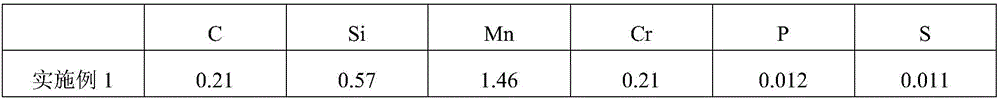

HRB400 rebar and production method thereof

The invention relates to the field of metallurgy, and particularly discloses an HRB400 rebar and a production method thereof. The HRB400 rebar is prepared from 0.19 wt%-0.25 wt% of C, 0.55 wt%-0.80 wt% of Si, 1.45 wt%-1.60 wt% of Mn, 0.20 wt%-0.30 wt% of Cr and the balance iron. The HRB400 rebar has the advantages of being excellent and stable in mechanical property and low in cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

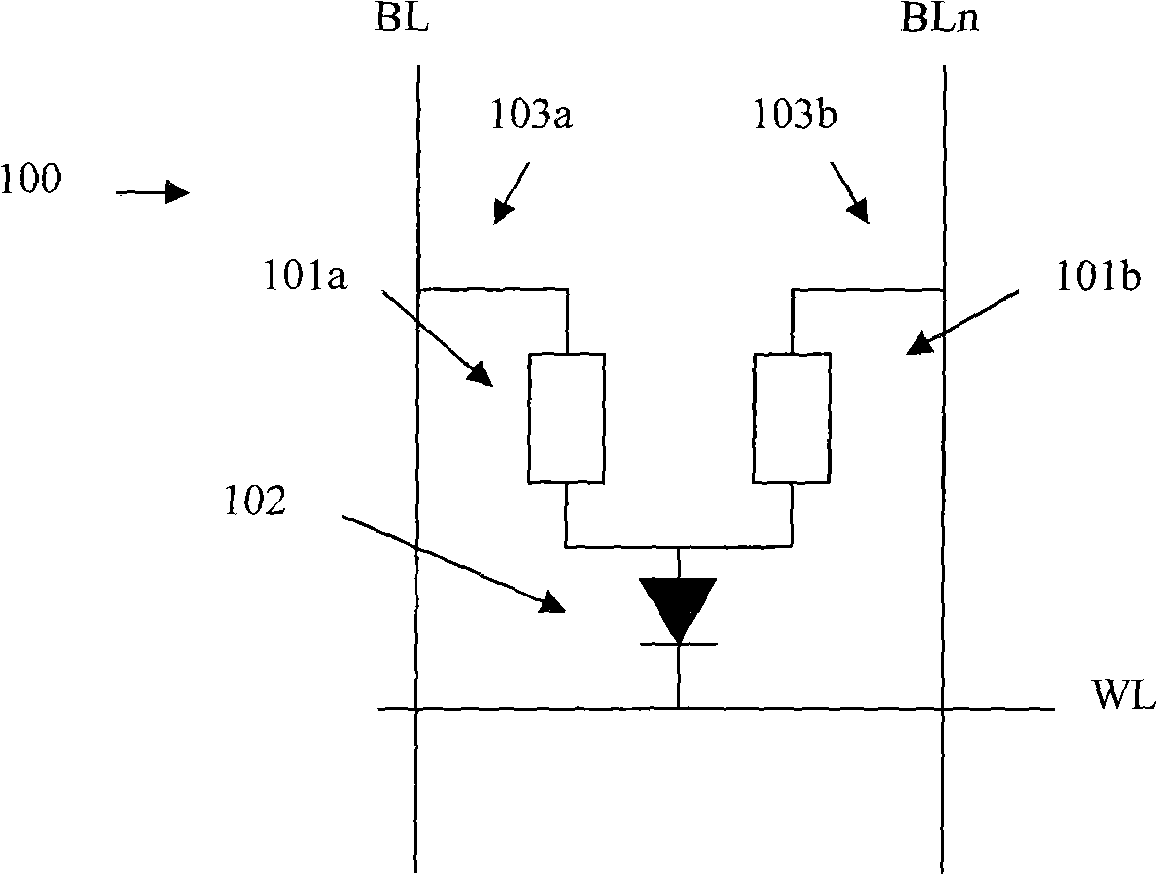

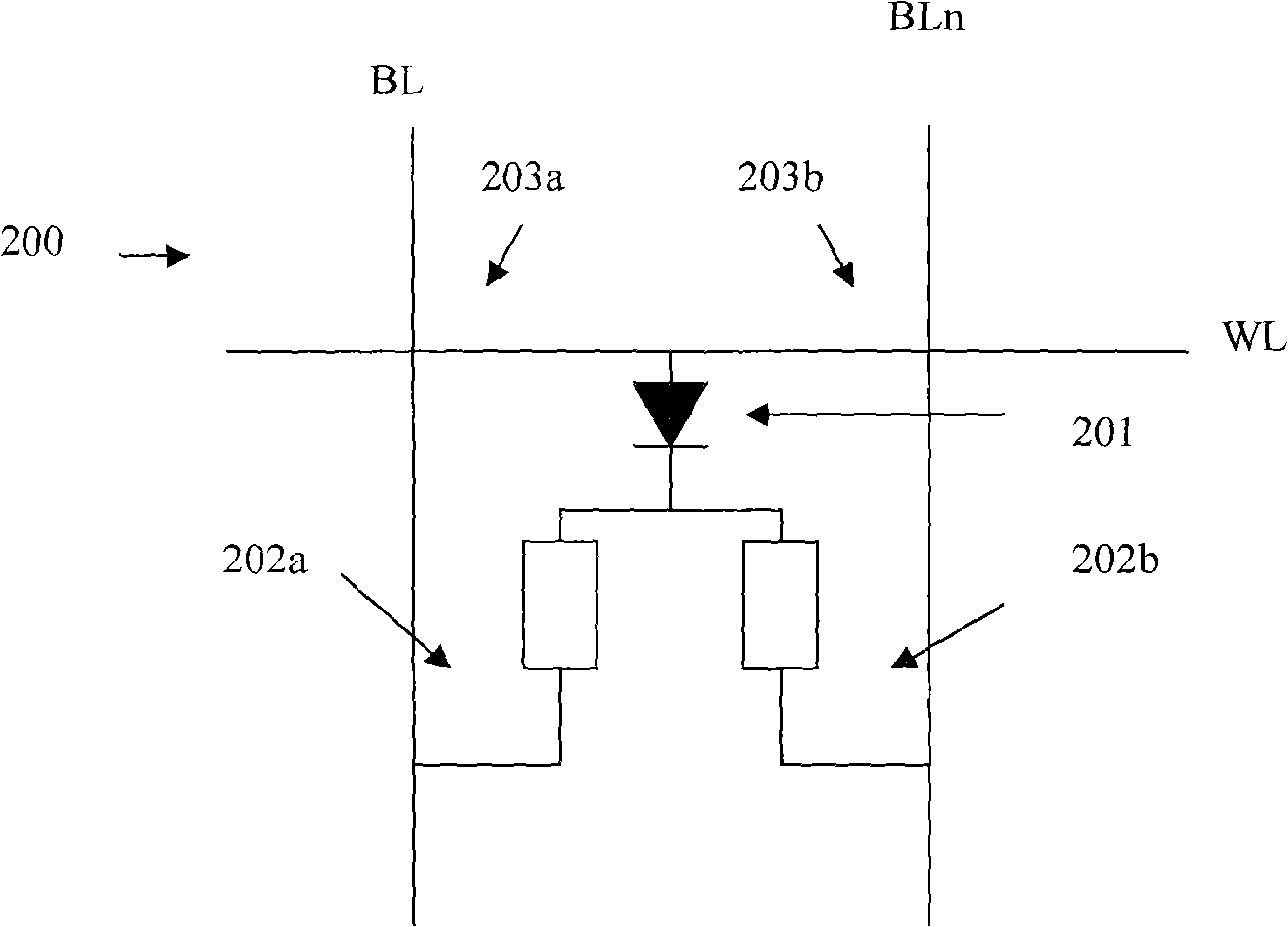

Memory with a core-based virtual ground and dynamic reference sensing scheme

InactiveUS20080117678A1Reduce the effects of agingAccurate representationRead-only memoriesDigital storageVoltage referenceComputer science

A core-based multi-bit memory (400) having a dual-bit dynamic referencing architecture (408, 410) fabricated on the memory core (401). A first reference array (408) and a second reference array (410) are fabricated on the memory core (401) such that a reference cell pair (185) comprising one cell (182) of the first reference array (408) and a corresponding cell (184) of the second reference array (410) are read and averaged to provide a reference voltage for reading a data array(s).

Owner:INFINEON TECH LLC

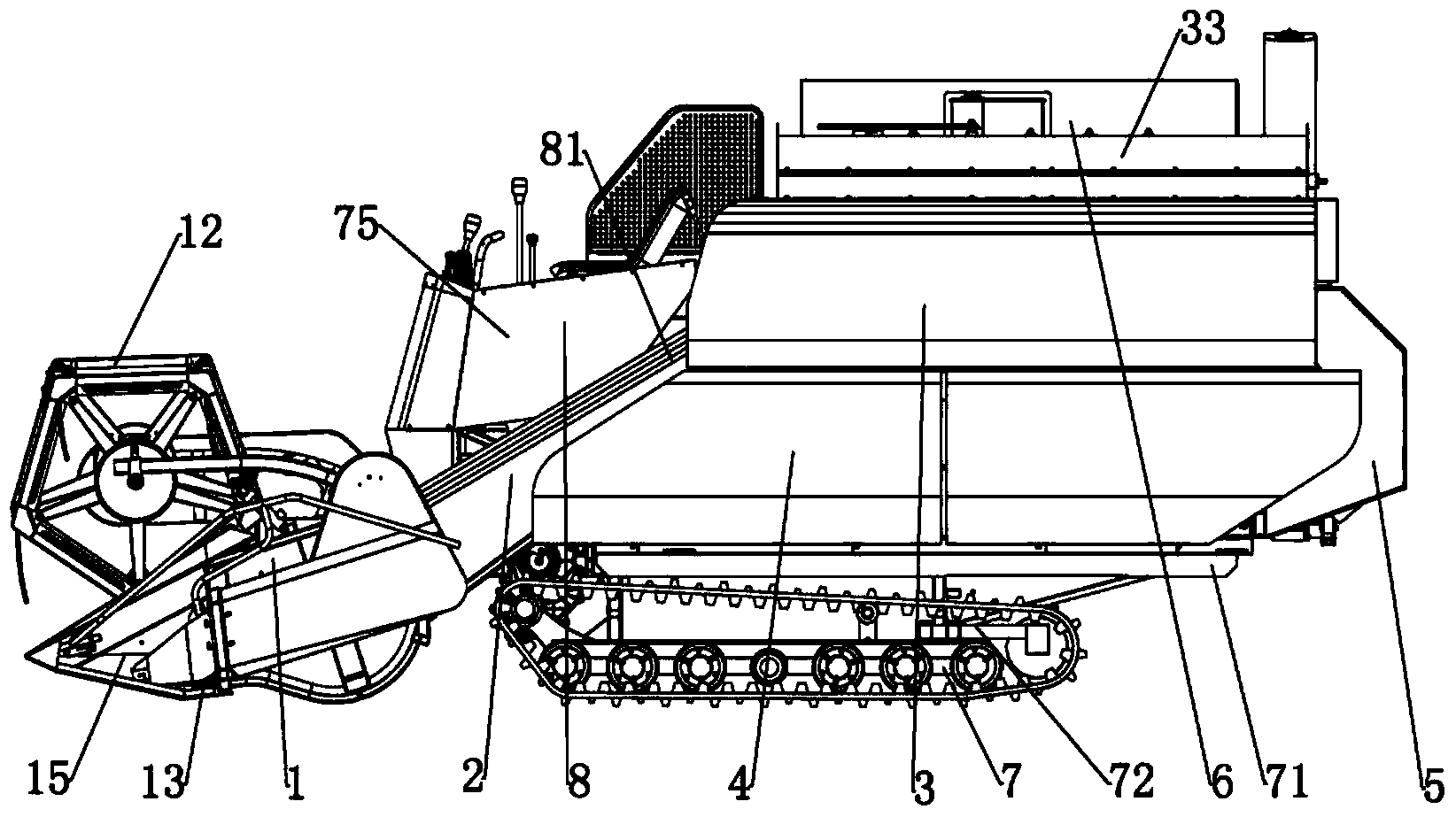

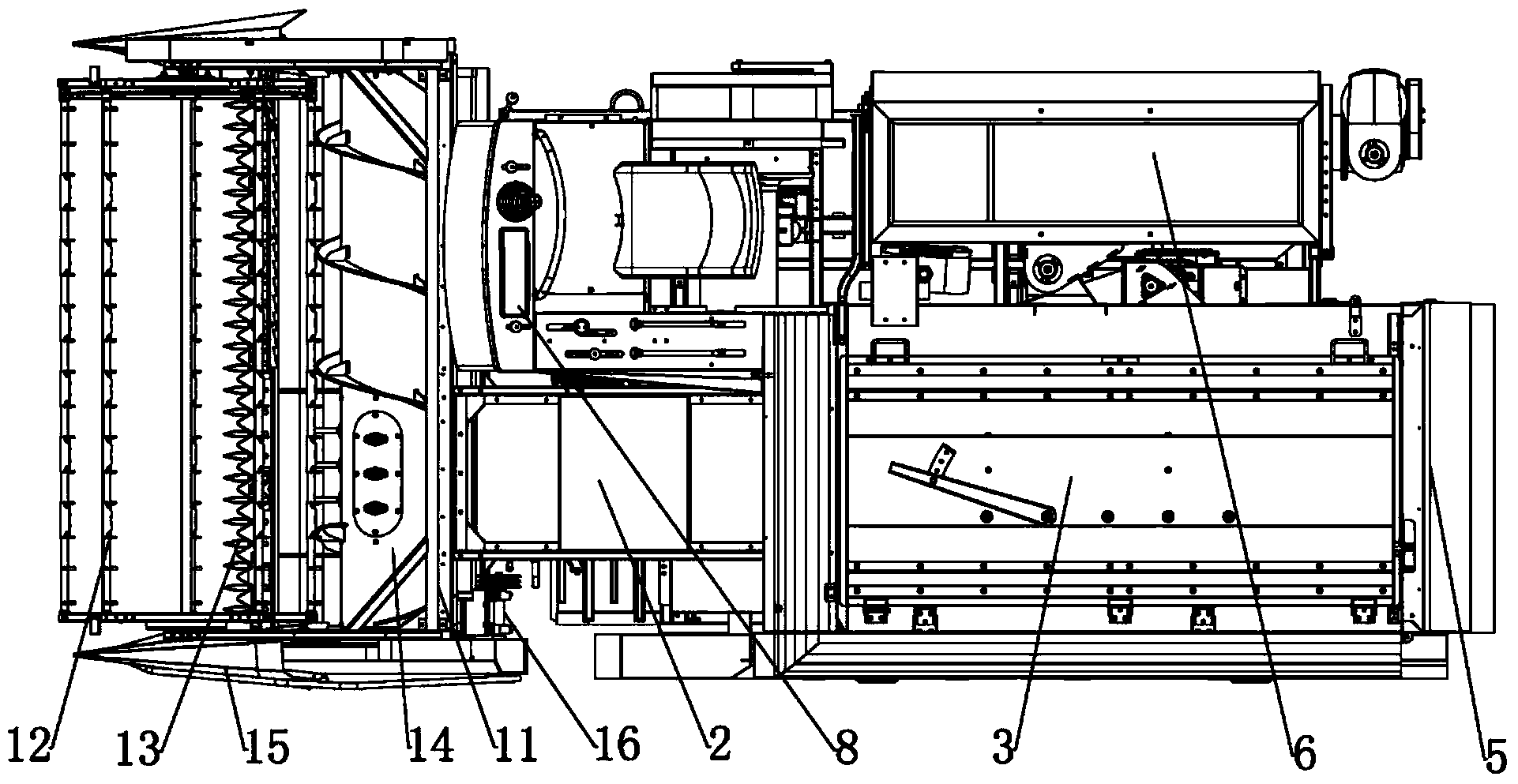

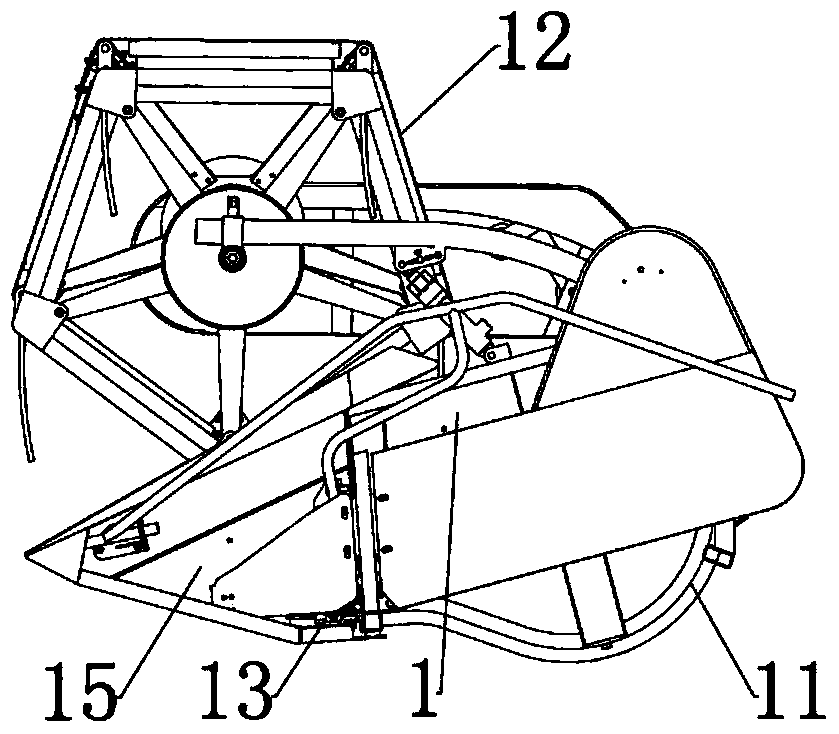

Combine harvester operating platform and combine harvester with same

The invention relates to a combine harvester operating platform. The combine harvester operating platform comprises a main operation panel, a side operation panel, an instrument panel, a reel lifting rod, a main operating rod, a throttle cable handle, a flameout cable switch, a main speed change lever, a vice speed change lever, a work clutch lever and a grain discharging auger lifting handle, wherein the instrument panel is located in the middle of the main operation panel and comprises an outer frame, a rubber pad, a main screen, an oil pressure path identifier, an engine revolving speed path identifier, a water temperature path identifier, a power supply path identifier, an oil pressure rotating axis, a revolving speed rotating axis, a water temperature rotating axis, a power supply rotating axis, a left turn indicating lamp, a right turn indicating lamp, a power supply indicating lamp, a charge indicating lamp, a valley full warning indicating lamp, a liquid-crystal timer, an oil pressure pointer, a revolving speed pointer, a water temperature pointer and a power supply pointer. The invention relates to a combine harvester with the operating platform. The operating platform provided by the invention is attractive and generous, is good in transparency and difficult in water accumulation and is more beneficial to operator observation.

Owner:XINGGUANG AGRI MACHINERY

Phase-change memory

ActiveCN101335046AReduce areaReduce the effects of agingRead-only memoriesDigital storageDriver circuitBit line

The invention discloses a phase-change memory which comprises a plurality of memory units, a column gating circuit, a decoder, a comparative readout resistor, a sensitive amplifier, a read-write drive circuit and a row decoder; bit lines of all the memory units are connected to the column gating circuit and the decoder; the word lines of all the memory units are connected to the row decoder; the column gating circuit and the decoder are connected with the read-write drive circuit and the sensitive amplifier; the read-write drive circuit is connected with the sensitive amplifier by the comparative readout resistance; the memory unit comprises a gating diode and at least two phase-change memory units; after being parallel, the phase-change memory units are connected with the gating diode. The phase-change memory of the invention adopts a 1DnR memory unit structure, thus reducing the chip area occupied by the gating diode.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Thermally assisted magnetic random access memory element with improved endurance

ActiveUS8717812B2Minimizing of breakdownMinimizing of agingMagnetic-field-controlled resistorsNanotechnologyElectricityPower flow

Owner:CROCUS TECHNOLOGY

Organosiloxane Films for Gas Separations

InactiveUS20150135957A1Increased gas fluxReduce the effects of agingSemi-permeable membranesGas treatmentPorous substrateHydrogen atom

A semipermeable gas separation membrane is plasma deposited from liquid organosiloxane monomer having at least three silicon atoms and an alpha hydrogen atom. The semipermeable membrane may be employed as a gas-selective membrane in combination with a porous substrate.

Owner:APPLIED MEMBRANE TECH

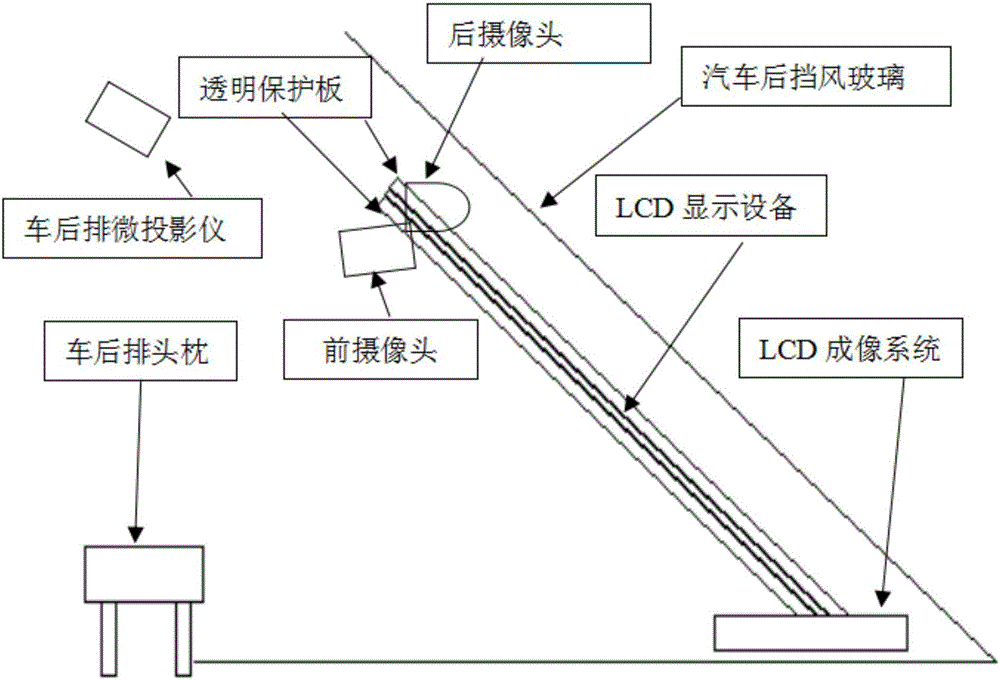

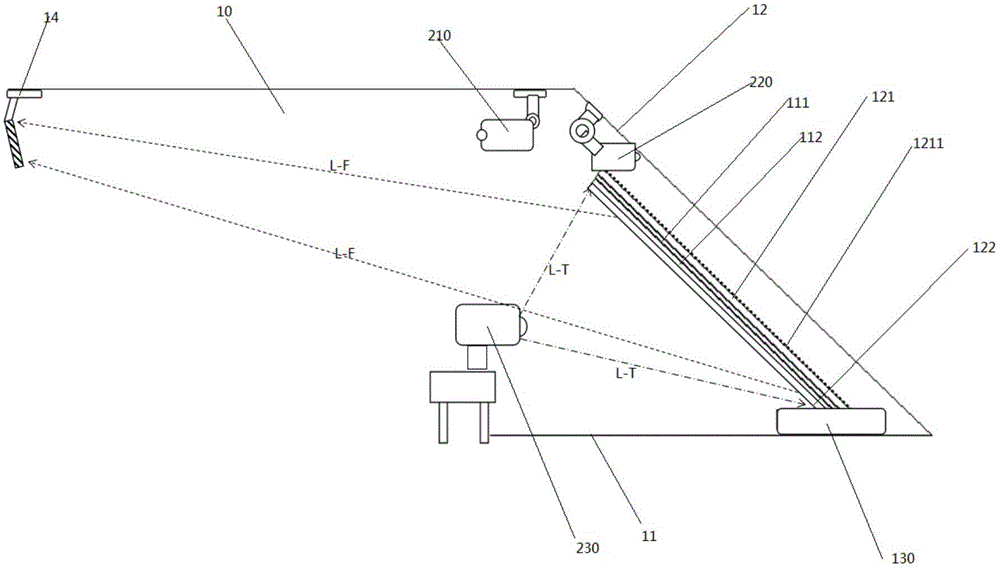

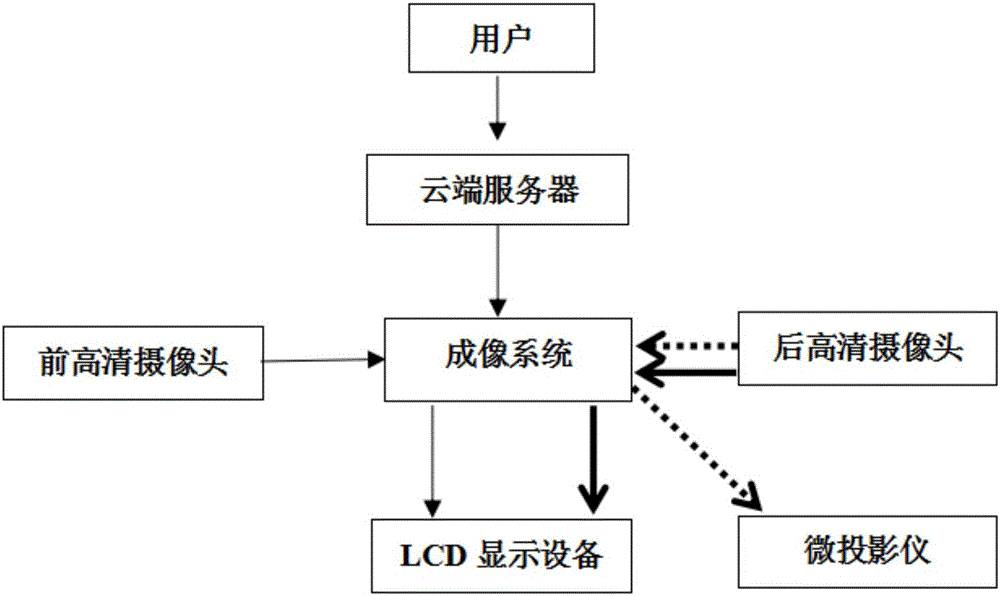

Vehicle load virtual transparent imaging display method and display system

InactiveCN106494310AAvoid interferenceImprove accuracyOptical viewingImagery techniqueComputer science

The invention provides a vehicle load virtual transparent imaging display method, being characterized by comprising the steps of conducting real time gathering of the images of the vehicles in front, conducting a projection or playing of the images in front within a viewable scope of the rear side vehicles; and / or after conducting the real time gathering of the images of the rear side vehicles, conducting the projection or playing of the images in rear side inside current vehicle; and / or through a remote server obtaining multimedia data, then conducting the projection or playing of the multimedia data within the viewable scope of the rear side vehicles. The system can be used as a backup system for transparently backing the vehicle in a rear side panorama, when adopting the projection technique to back a vehicle the rear carriage is turned 'transparent', thus enabling the driver completely sees the environment of the rear side of the vehicle when backing the vehicle, and increasing the accuracy and safety of vehicle backing. The driver also can through the real time imaging technology carry out observations of the dead angles of the vehicle rear side road situations.

Owner:SHANGHAI BIHU NETWORK TECH CO LTD

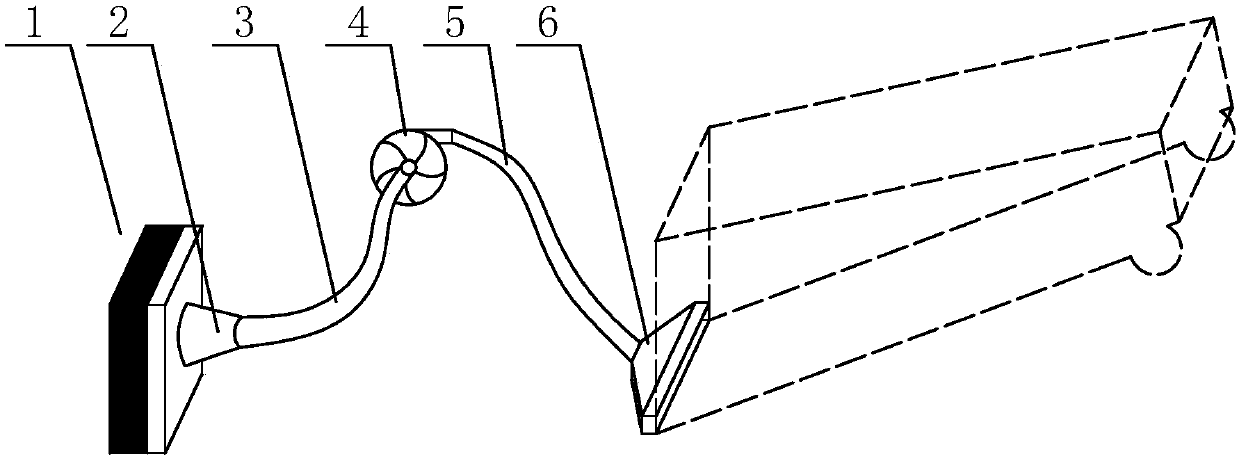

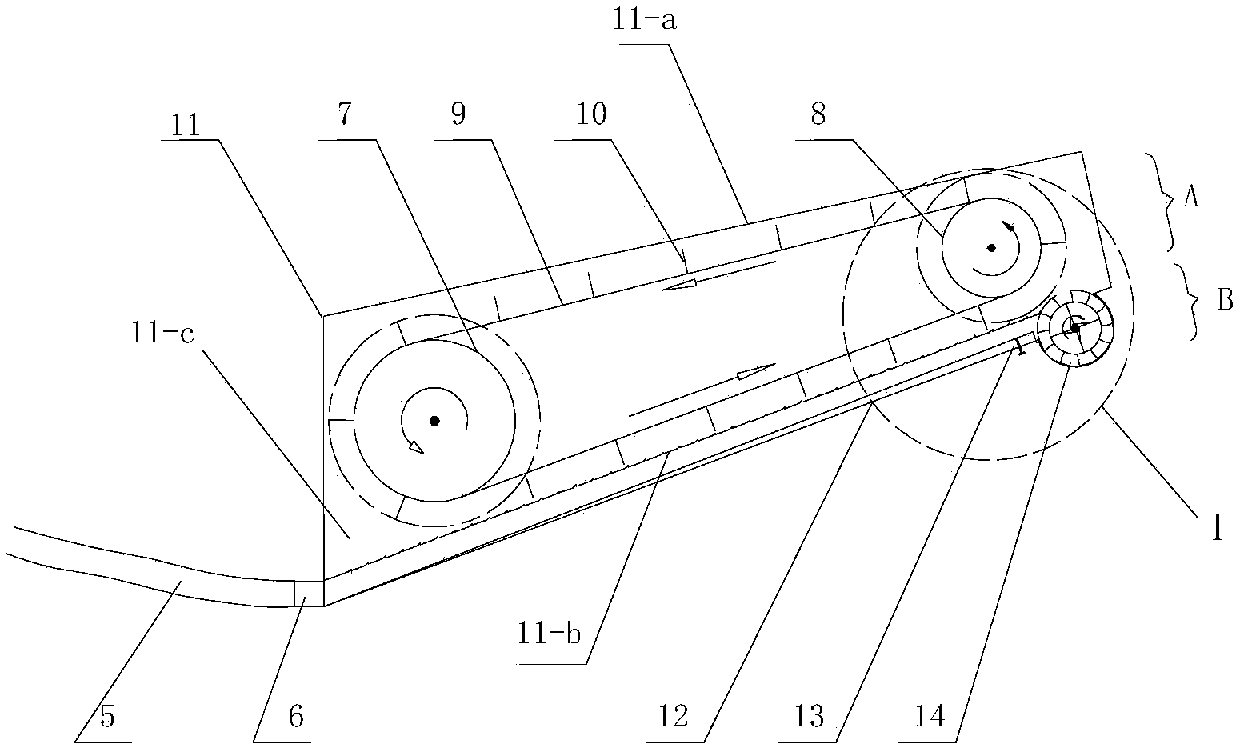

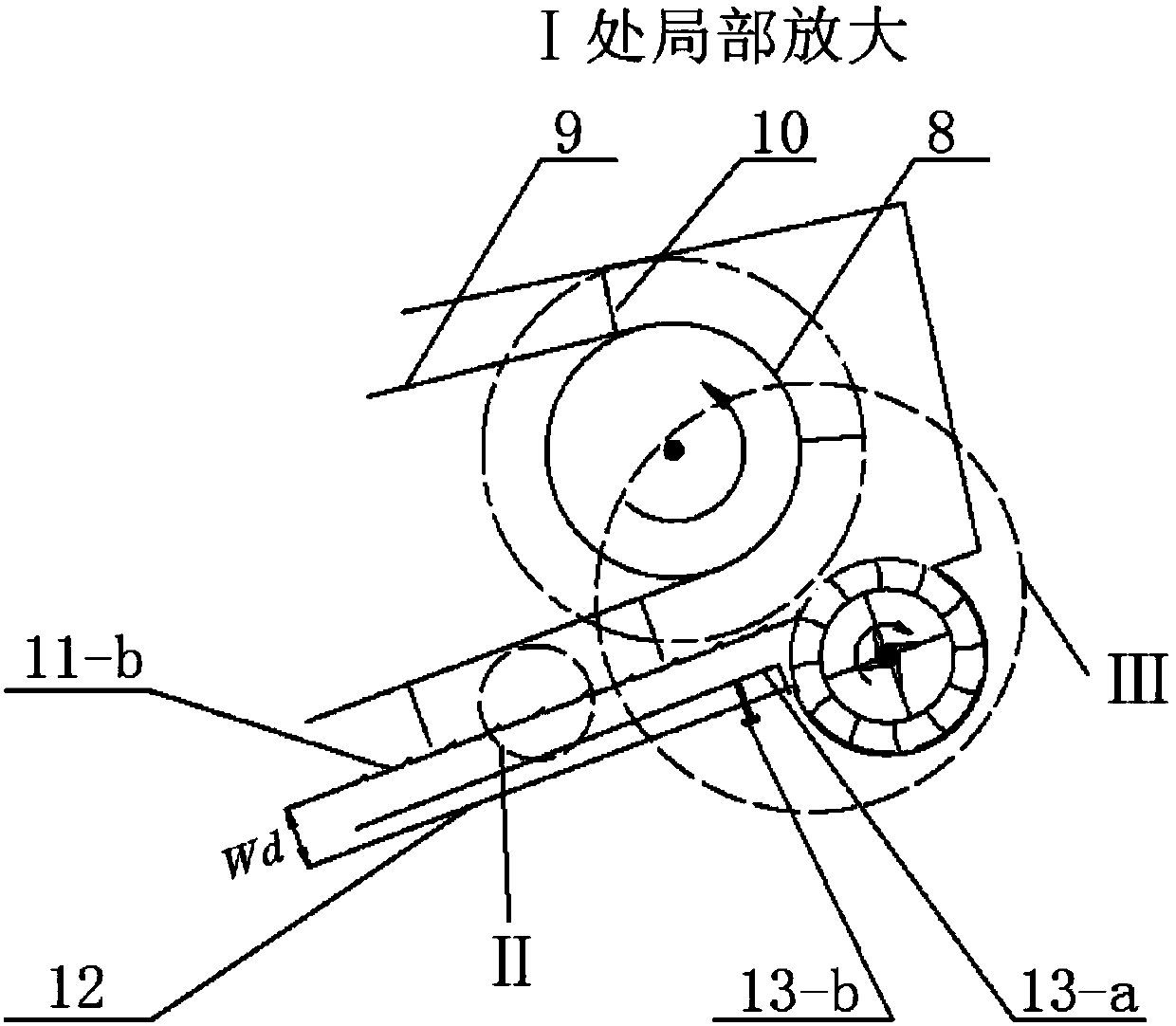

Cross-flow hot-air type combine harvester humid material conveying feeding device

InactiveCN107926291AFlow fastImprove conveying smoothnessDrying solid materials with heatMowersAir pumpWorking temperature

The invention discloses a cross-flow hot-air type combine harvester humid material conveying feeding device. The device is composed of a hot-air pumping component and a material conveying component. According to the hot-air pumping component, an air pump is used for extracting waste hot airflow from an engine radiator of a combine harvester through a pipeline, and the hot airflow is provided for the material conveying feeding device. The material conveying component is composed of a chain harrow type conveying groove structure A and a cross flow wind room structure B, the chain harrow type conveying groove structure A is located at the upper portion of the cross flow wind room structure B, forced conveying and feeding of materials are achieved, and the cross flow wind room structure B utilizes hot air for flow guiding drying, blowing auxiliary feeding and cross flow wind wheel forced feeding. Waste heat generated by the combine harvester engine is sufficiently utilized for performing auxiliary blowing and drying in the humid material conveying feeding process, the working temperature of the engine can be lowered, the heat radiation and aging effects of engine high temperature on peripheral devices are lowered, the water content of humid agricultural materials can be remarkably lowered, and blockage caused by humidity is avoided.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com