Patents

Literature

32results about How to "Excellent and stable mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process and application of moderately strong 7-series aluminum alloy profile

ActiveCN107513678AImprove mechanical propertiesIncrease productivityRoom temperatureThermal treatment

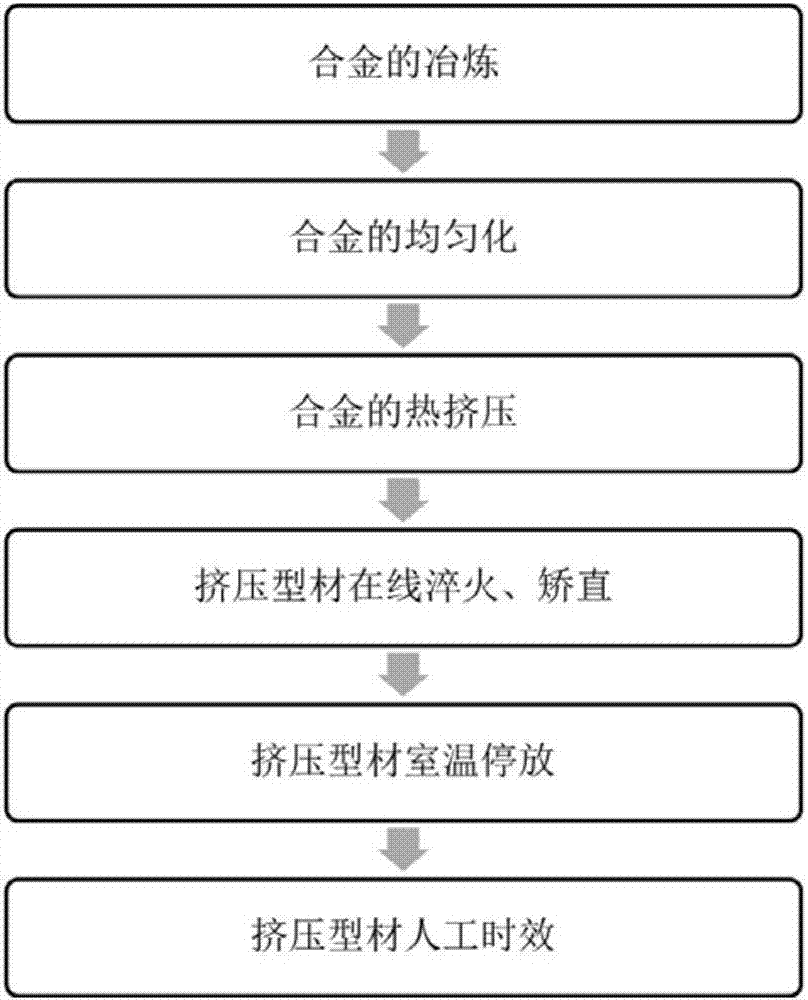

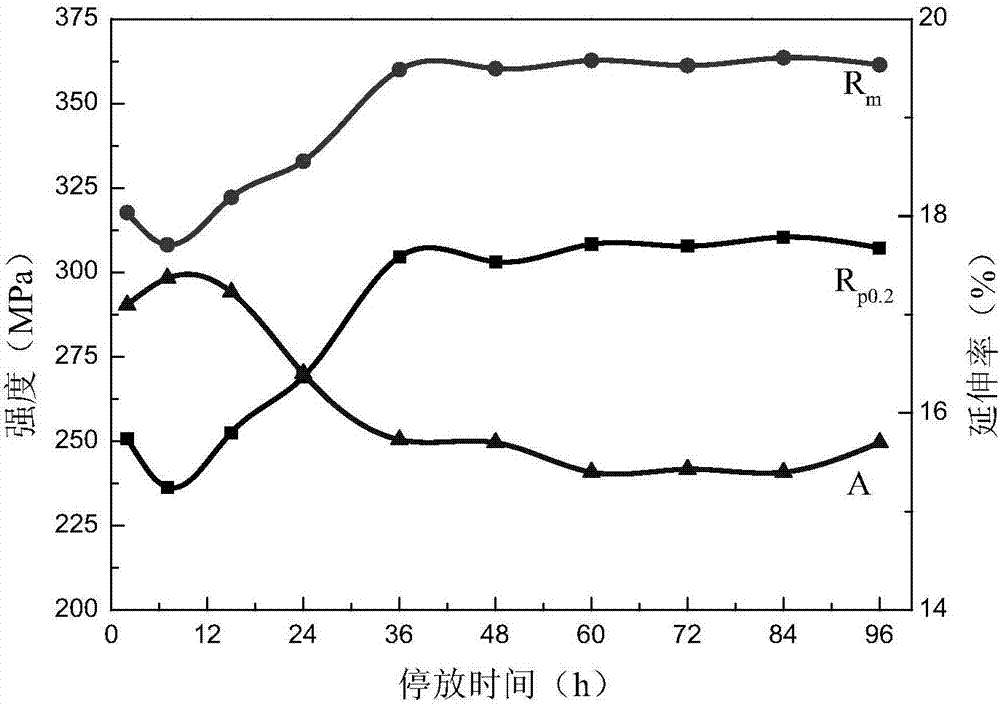

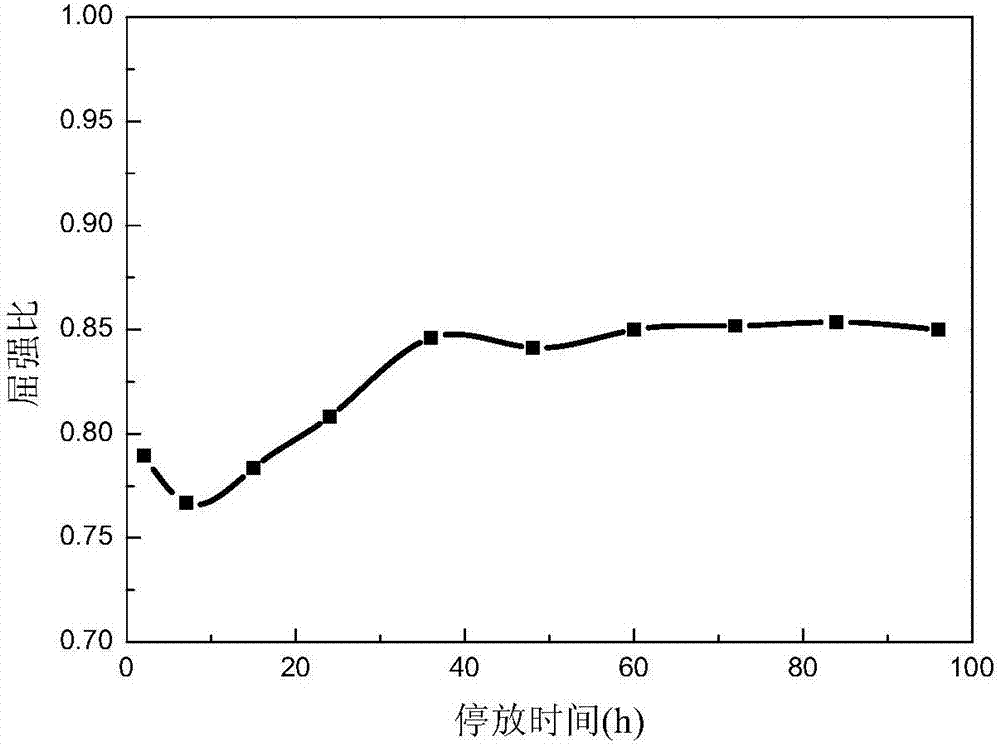

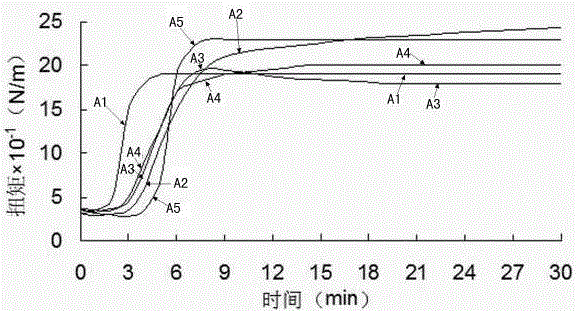

The invention relates to a production process and application of a moderately strong 7-series aluminum alloy profile, and belongs to the technical field of production and manufacturing of aluminum alloys. The production process comprises processes of natural standing, thermal treatment and the like of an aluminum alloy hot-extruded profile. According to the production process, a moderately strong 7-series aluminum alloy is thermally extruded, then is subject natural standing under a room temperature condition for 36 hours to 60 hours, and is subjected to artificial aging, so that high and stable mechanical property can be obtained. The moderately strong 7-series aluminum alloy profile disclosed by the invention is prepared from the following components in percentage by mass of 4.0% to 5.0% of Zn, 1.0% to 2.0% of Mg, 0.2% to 0.7% of Mn, less than or equal to 0.30% of Cr, less than or equal to 0.25% of Zr, less than or equal to 0.20% of Ti, and the balance aluminum and unavoidable impurities. According to the production process, the natural standing time is greatly shortened; and on the basis of guaranteeing the property, the production efficiency of the aluminum alloy profile is obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

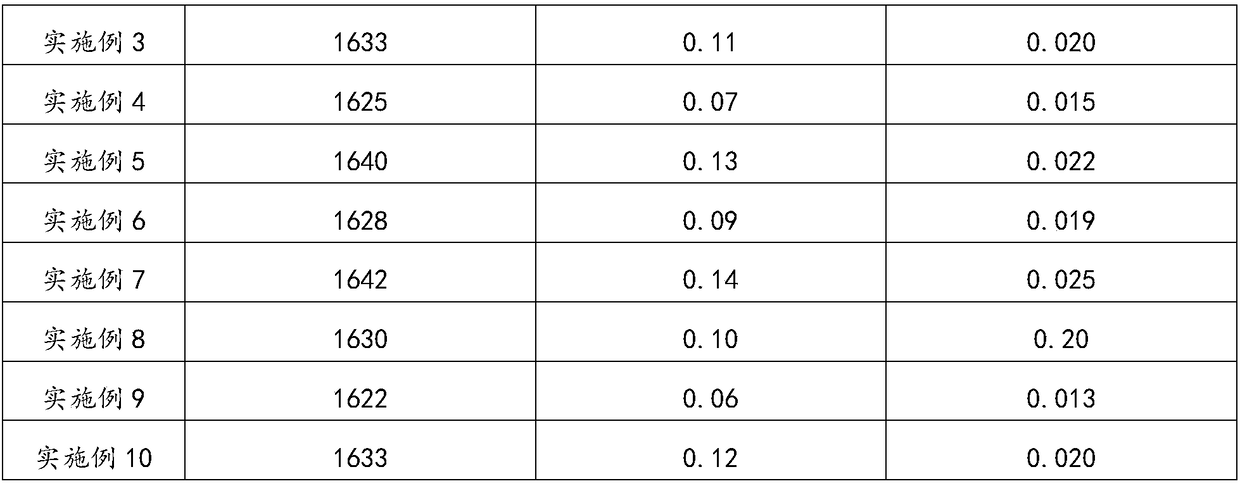

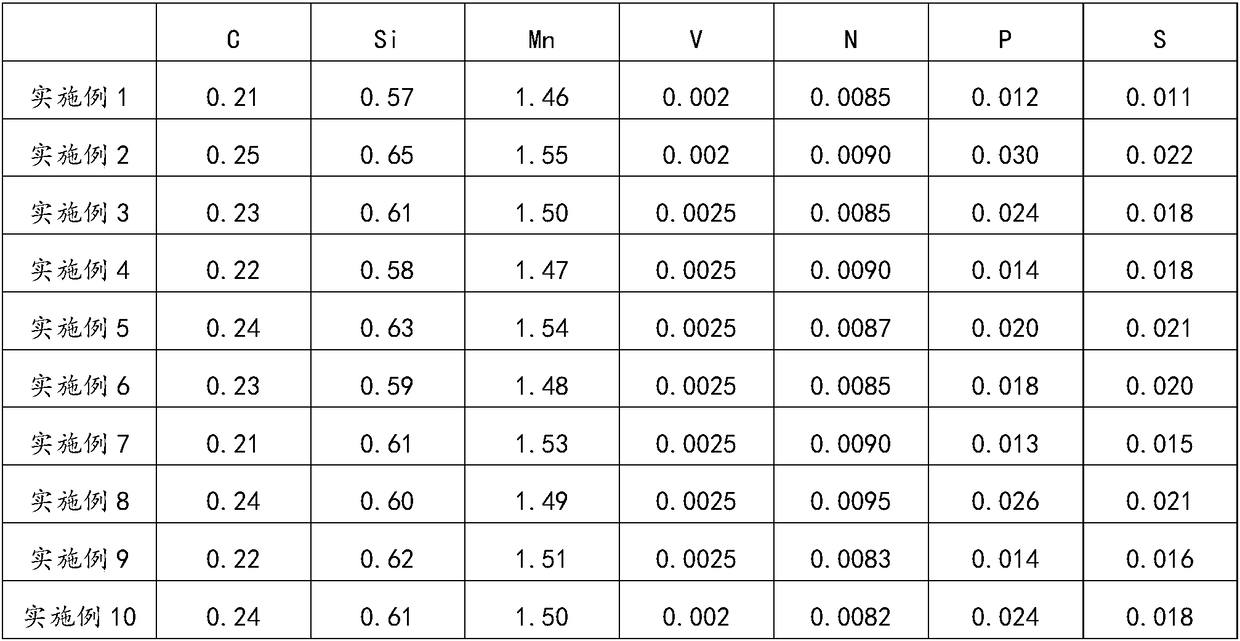

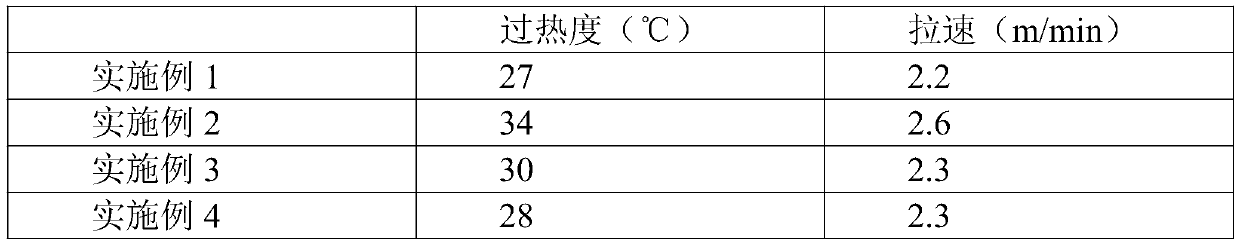

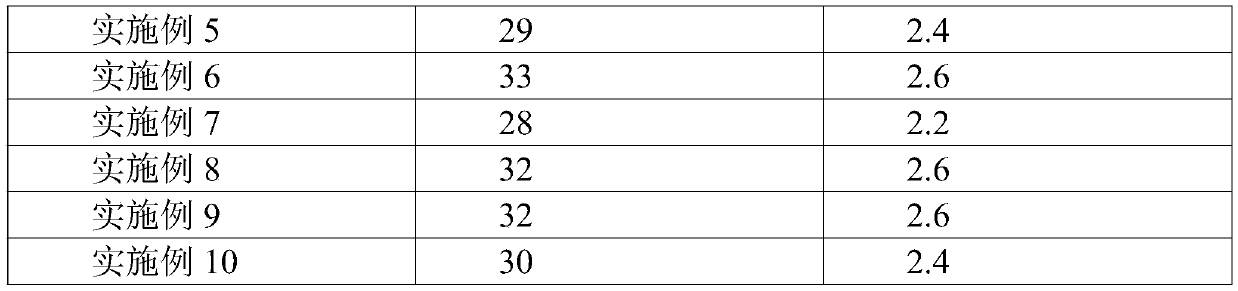

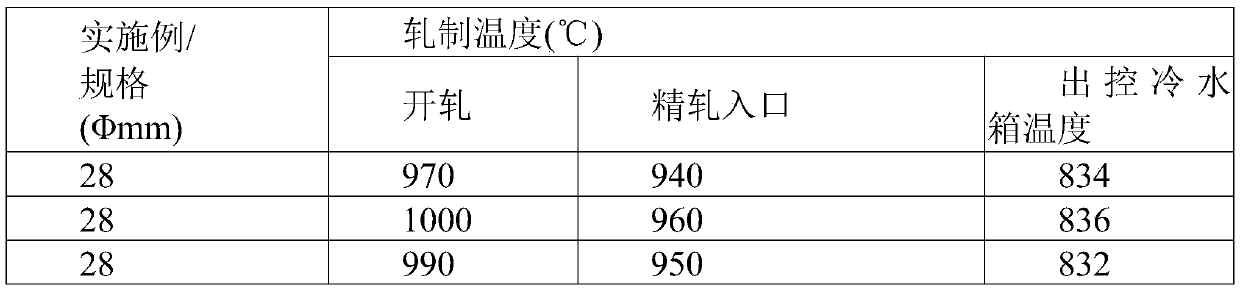

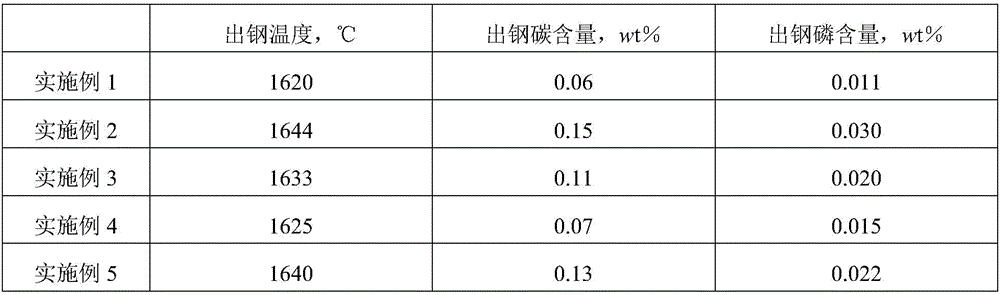

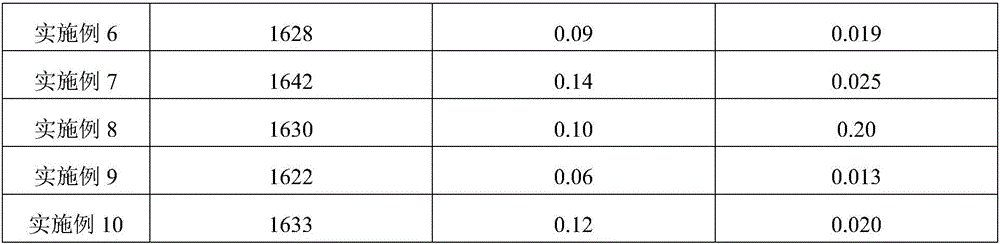

HRB400 steel bar and production method of HRB400 steel bar

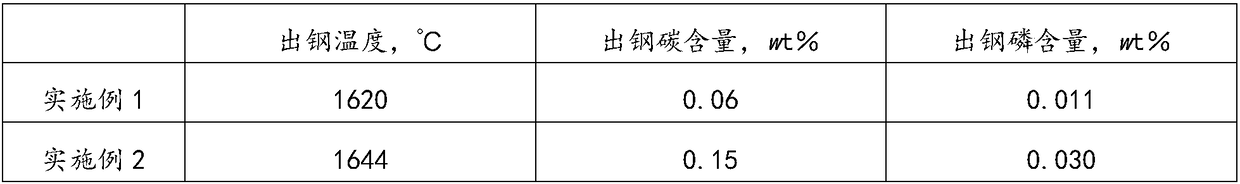

InactiveCN108950135ALow costExcellent and stable mechanical propertiesMetal rolling arrangementsChemical compositionRebar

The invention provides an HRB400 steel bar and a production method of the HRB400 steel bar. The HRB400 steel bar comprises, by mass, 0.19-0.25% of C, 0.55-0.80% of Si, 1.45-1.60% of Mn, 0.02-0.04% ofV, 0.008-0.010% of N, and the balance Fe and unavoidable impurities. According to the technical scheme, vanadium nitrogen microalloying is used for improving the strength, compared with ferrovanadiummicroalloying, the aim of reducing the cost is achieved, and the HRB400 steel bar has the advantages that mechanical properties are excellent and stable, and the cost is low.

Owner:BAOTOU IRON & STEEL GRP

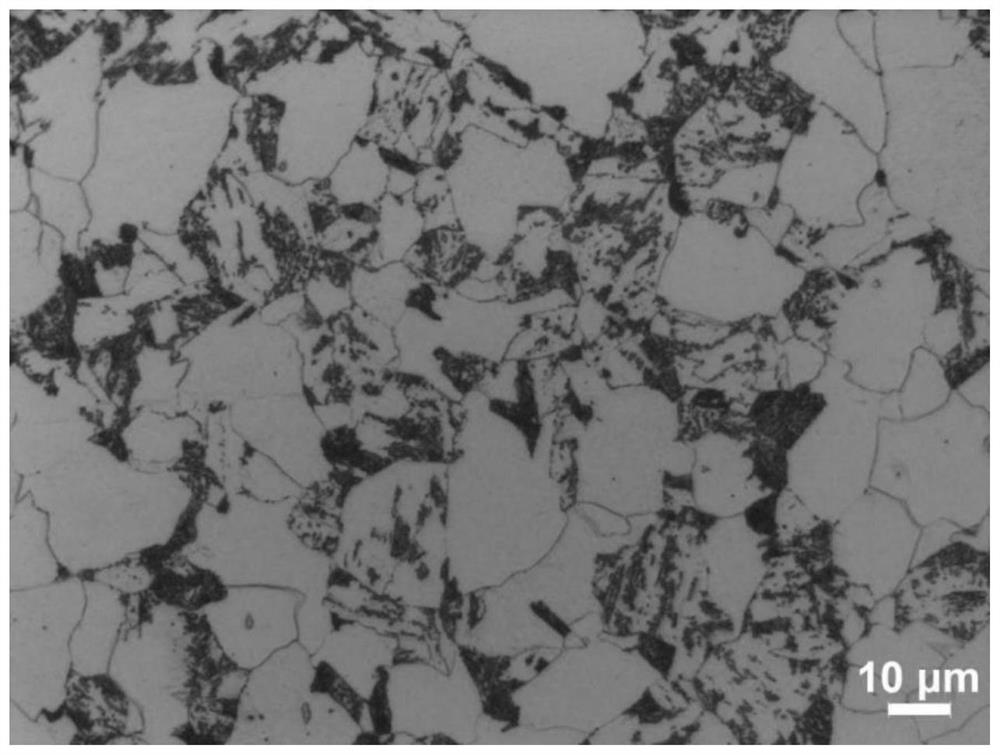

Niobium microalloyed fine grain HRB400 rebar and preparation method thereof

The invention discloses a niobium microalloyed fine grain HRB400 rebar. The niobium microalloyed fine grain HRB400 rebar is prepared from, by mass, 0.22% to 0.25% of C, 0.40% to 0.50% of Si, 1.35% to1.45% of Mn, 0.025% to 0.035% of Nb and the balance Fe and inevitable impurities. The invention further discloses a preparation method of the niobium microalloyed fine grain HRB400 rebar. According tothe niobium microalloyed fine grain HRB400 rebar, the strength of the rebar is improved, and the production cost is reduced.

Owner:BAOTOU IRON & STEEL GRP

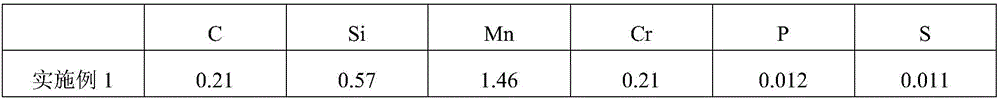

HRB400 rebar and production method thereof

The invention relates to the field of metallurgy, and particularly discloses an HRB400 rebar and a production method thereof. The HRB400 rebar is prepared from 0.19 wt%-0.25 wt% of C, 0.55 wt%-0.80 wt% of Si, 1.45 wt%-1.60 wt% of Mn, 0.20 wt%-0.30 wt% of Cr and the balance iron. The HRB400 rebar has the advantages of being excellent and stable in mechanical property and low in cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

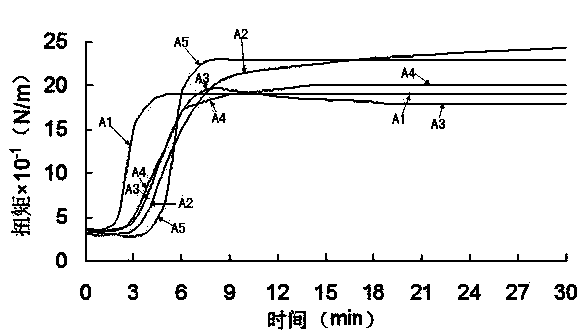

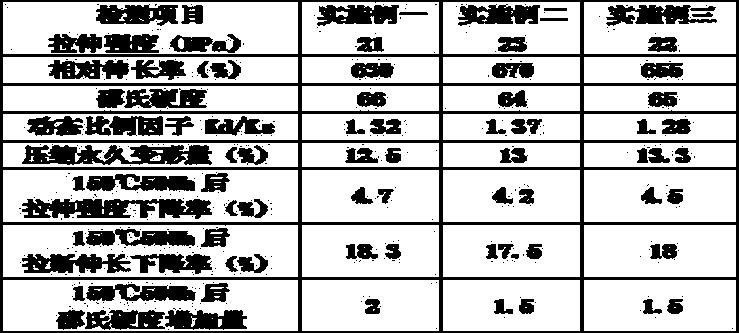

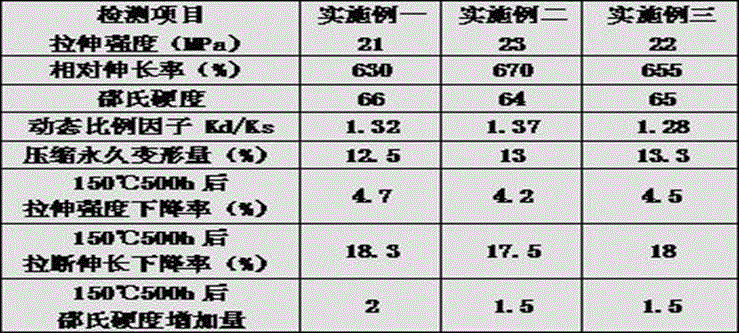

Preparation method of rubber shock pad for engine

The invention discloses a preparation method of a rubber shock pad for an engine, and relates to the technical field of rubber products. The preparation method comprises the following steps: weighing the following raw materials in parts by weight: 40-60 parts of deproteinization natural rubber, 20-40 parts of ethylene propylene diene monomer, 20-30 parts of carbon fibers, 20-25 parts of white carbon black, 2-3 parts of stearic acid, 4-6 parts of zinc oxide, 2-4 parts of sulfur, 1.5-2.5 parts of accelerant and 3-5 parts of anti-aging agent; steeping the carbon fibers in a silane coupling agent, and then drying; adding the two types of rubber to an open mill, mixing, after covering rollers with a sizing material, adding the carbon fibers, the white carbon black, the stearic acid, the zinc oxide and the anti-aging agent at twice, finally adding the sulfur and the accelerant for mixing, and standing for 24 hours after forming sheets; and putting a rubber compound on a plate vulcanizing machine so as to vulcanize, and then trimming to obtain the required product. The preparation method can be used for solving the problem that the traditional rubber shock pad for the engine is likely to fatigue and has poor impact resistance and tear resistance.

Owner:LIUZHOU CITY QIANYANG MACHINERY & ELECTRIC

High-performance rubber for generator shock pad and preparation process thereof

ActiveCN103627043AIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

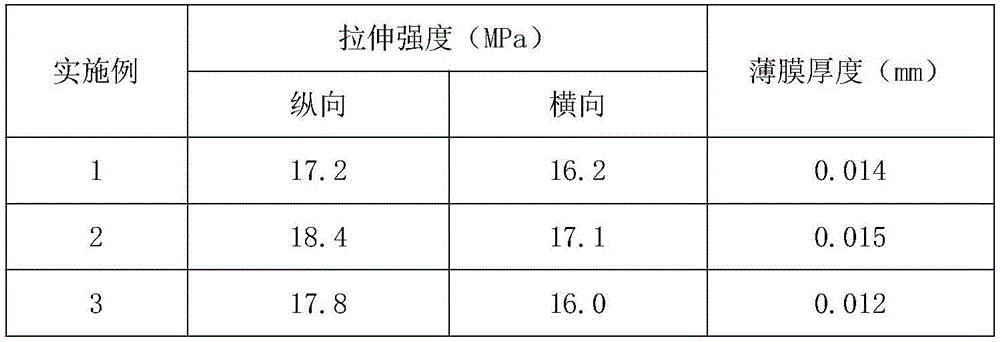

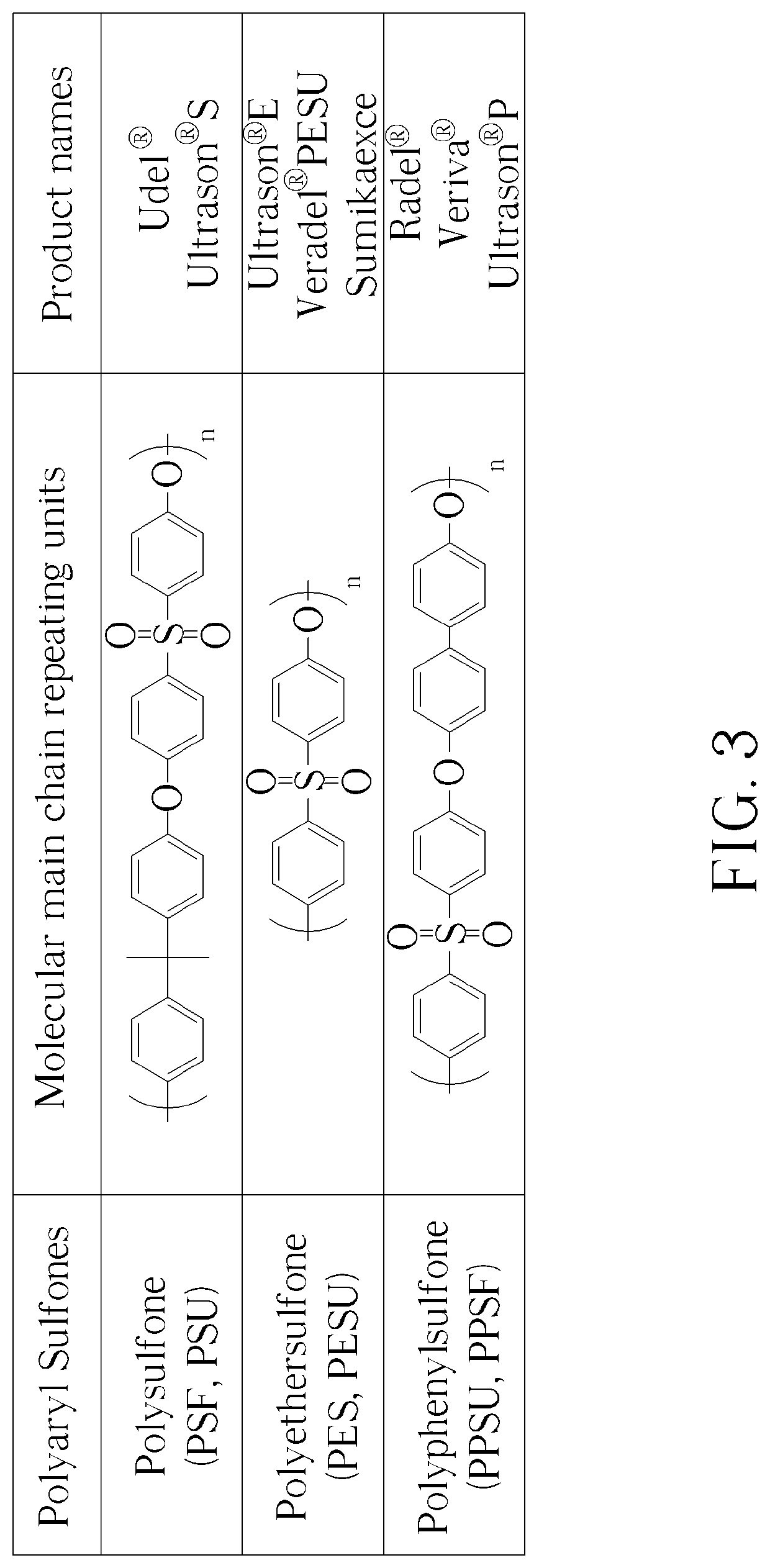

Graphene-loaded polyimide high-dielectric-permittivity composite film doped with microcrystal glass powder and used for capacitor and preparing method of composite film

InactiveCN105085948AImprove Dispersion and UtilizationGood interface compatibilityThin/thick film capacitorFixed capacitor electrodesCvd graphenePolyvinyl alcohol

The invention discloses a graphene-loaded polyimide high-dielectric-permittivity composite film doped with microcrystal glass powder and used for a capacitor. According to the composite film, the microcrystal glass powder, graphene and other filler are doped in the polyimide film preparing process, and the graphene is loaded on the microcrystal glass powder to improve the dispersity and the utilization rate of the microcrystal glass powder. A powder body is covered with a polyvinyl alcohol film good in stability in an organic solvent, and the composite powder body with the surface modified and processed by a silane coupling agent is good in compatibility with an polyamic acid organic glue solution interface and can be evenly dispersed more easily, so that the dielectric permittivity of a material is stably and efficiently improved, and loss is reduced. The dielectric properties of the finally prepared polyimide film pure in composite film material are greatly improved, good mechanical properties and processability are still maintained, heat stability is better, and application prospects are good.

Owner:TONGLING SHENGDA ELECTRONICS DEVICE

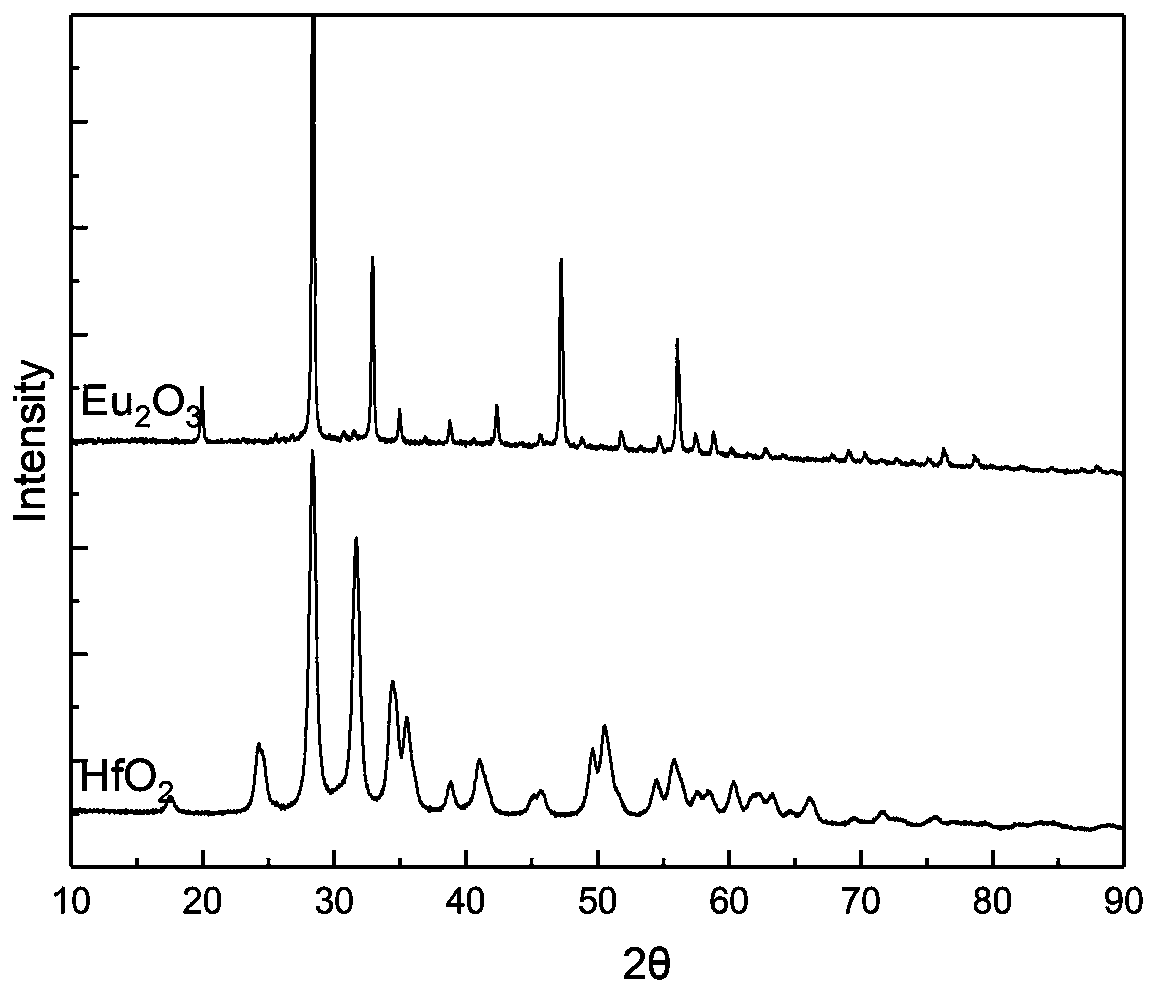

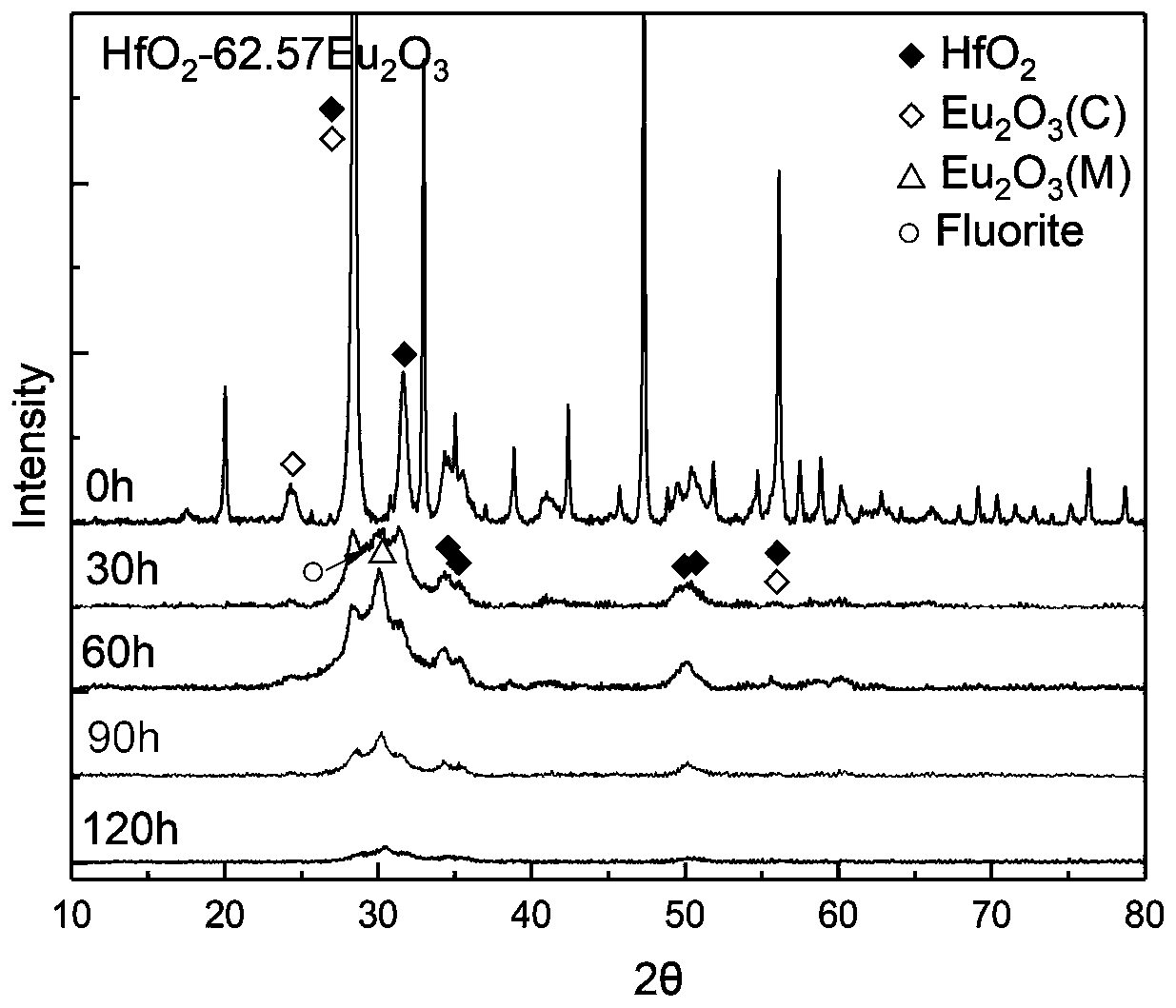

Europium hafnate neutron absorbing material and application thereof

InactiveCN110818414ALong-term stabilityExcellent and stable heat conductionNuclear energy generationShieldingCrystal structureEuropium

The invention discloses a europium hafnate neutron absorbing material and application thereof. The europium hafnate neutron absorbing material is prepared through a ball milling-isostatic cool pressing-sintering or ball milling-hot pressed sintering technological process by adopting raw materials including hafnium oxide powder and europium oxide powder; the europium hafnate neutron absorbing material always keeps a single fluorite crystal structure within the range from the room temperature to 2200 DEG C; the mass percentage of europium oxide is 55.78 percent by weight to 65.34 percent by weight; and the mass percentage of hafnium oxide is 34.66 percent by weight to 44.22 percent by weight. The europium hafnate neutron absorbing material provided by the invention has excellent and stable combination properties such as neutron absorption, heat conduction, mechanical property and radiation resistance; the transformation of the crystal structure and the decomposition of a phase cannot occur along with the temperature change; and a mixed phase with different crystal structures and a mixed phases with different phases cannot occur in the material.

Owner:XIAMEN UNIV

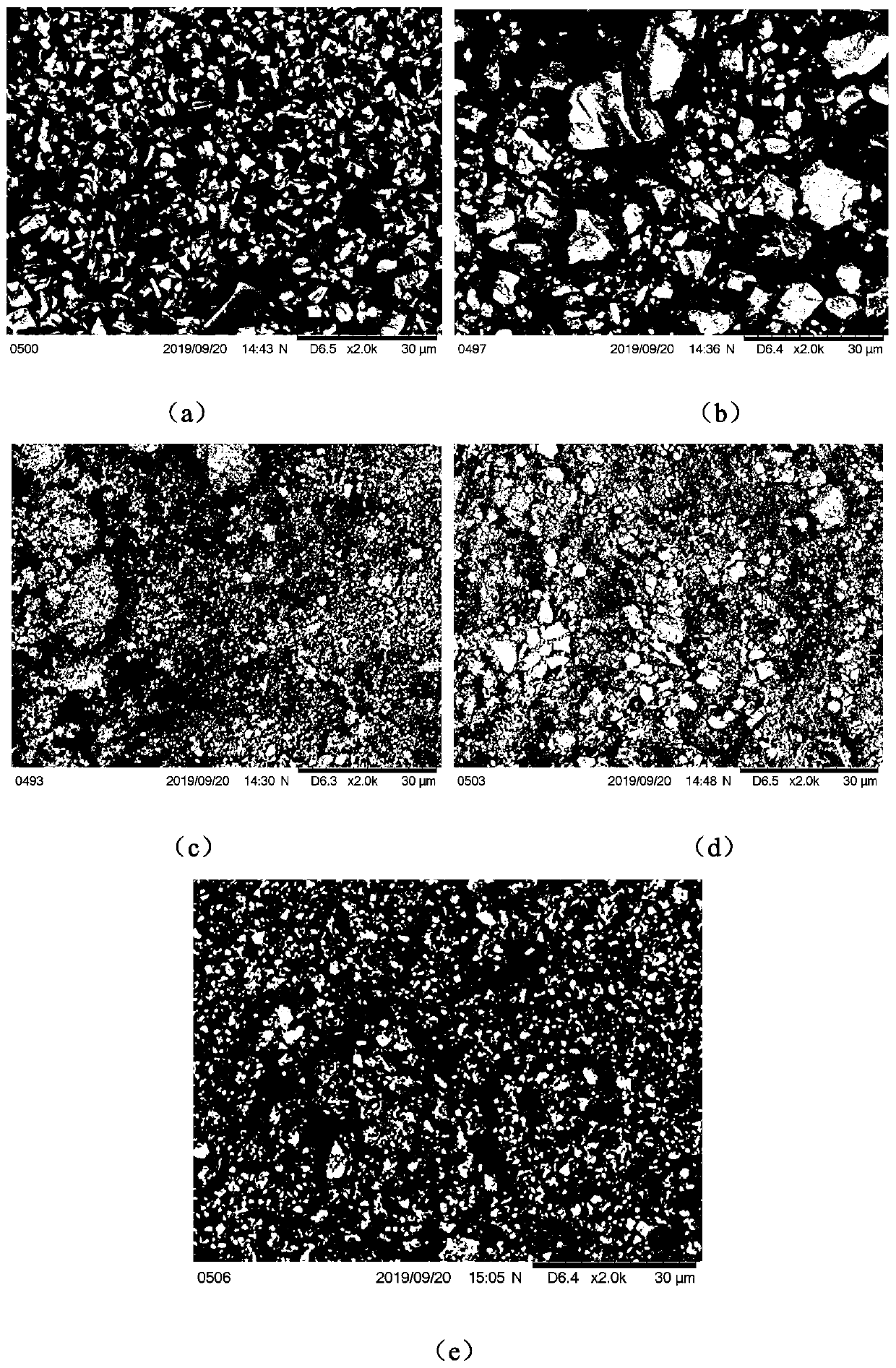

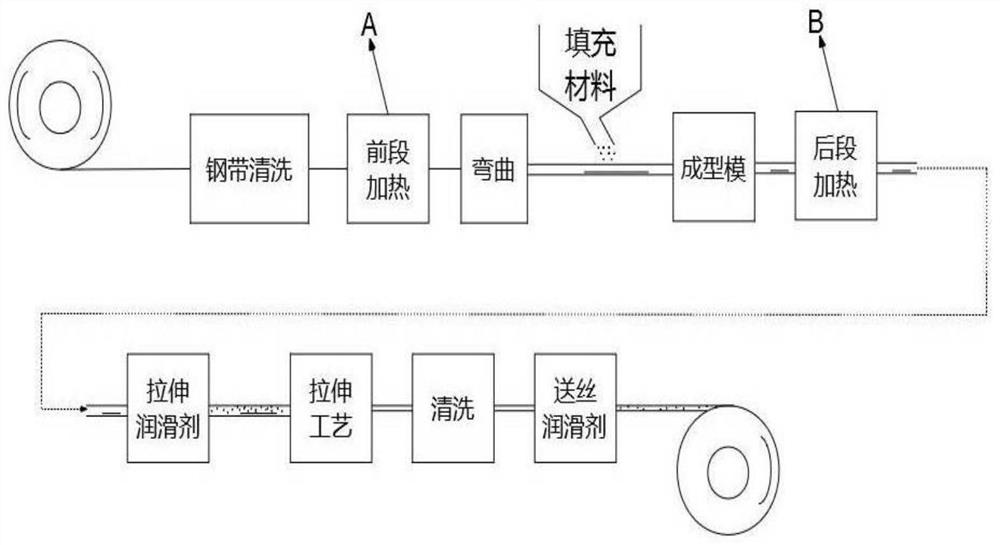

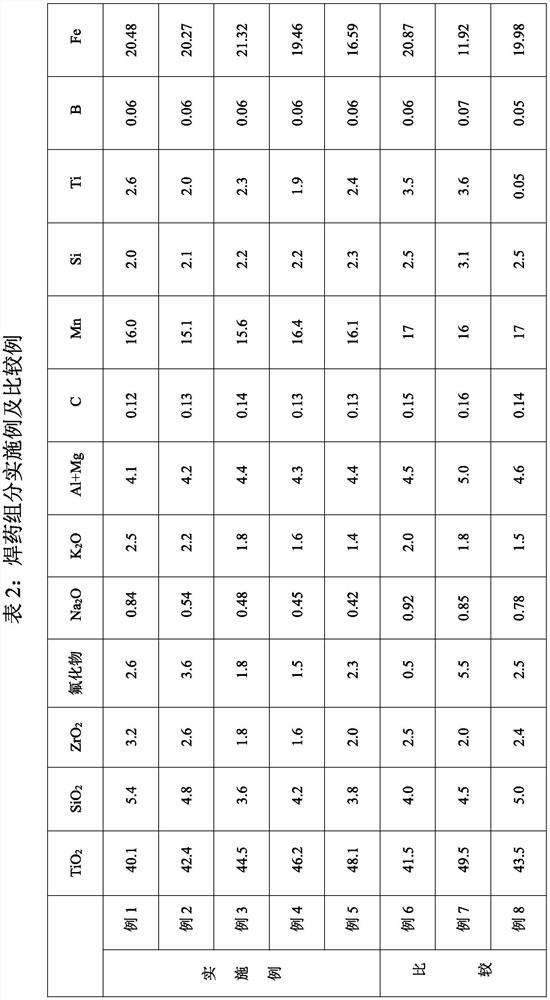

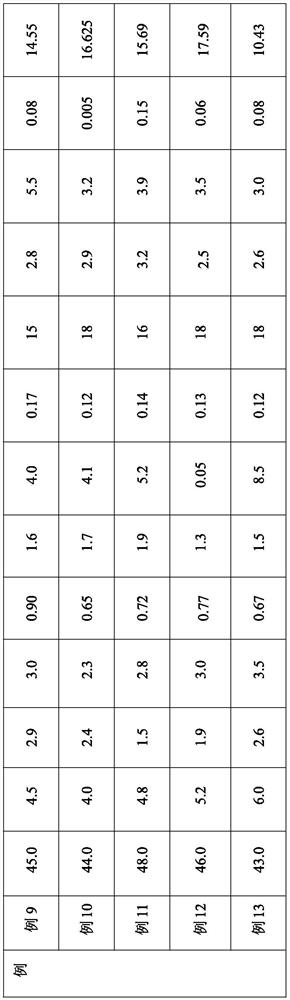

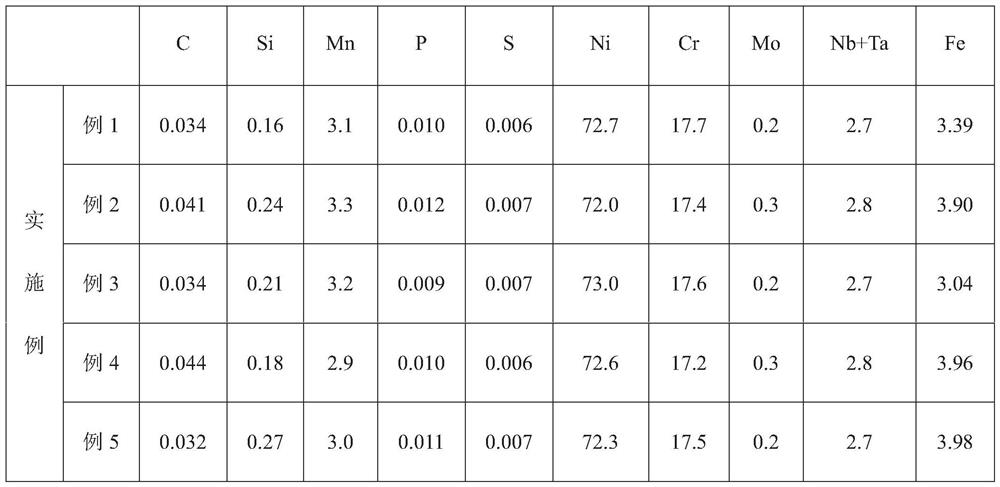

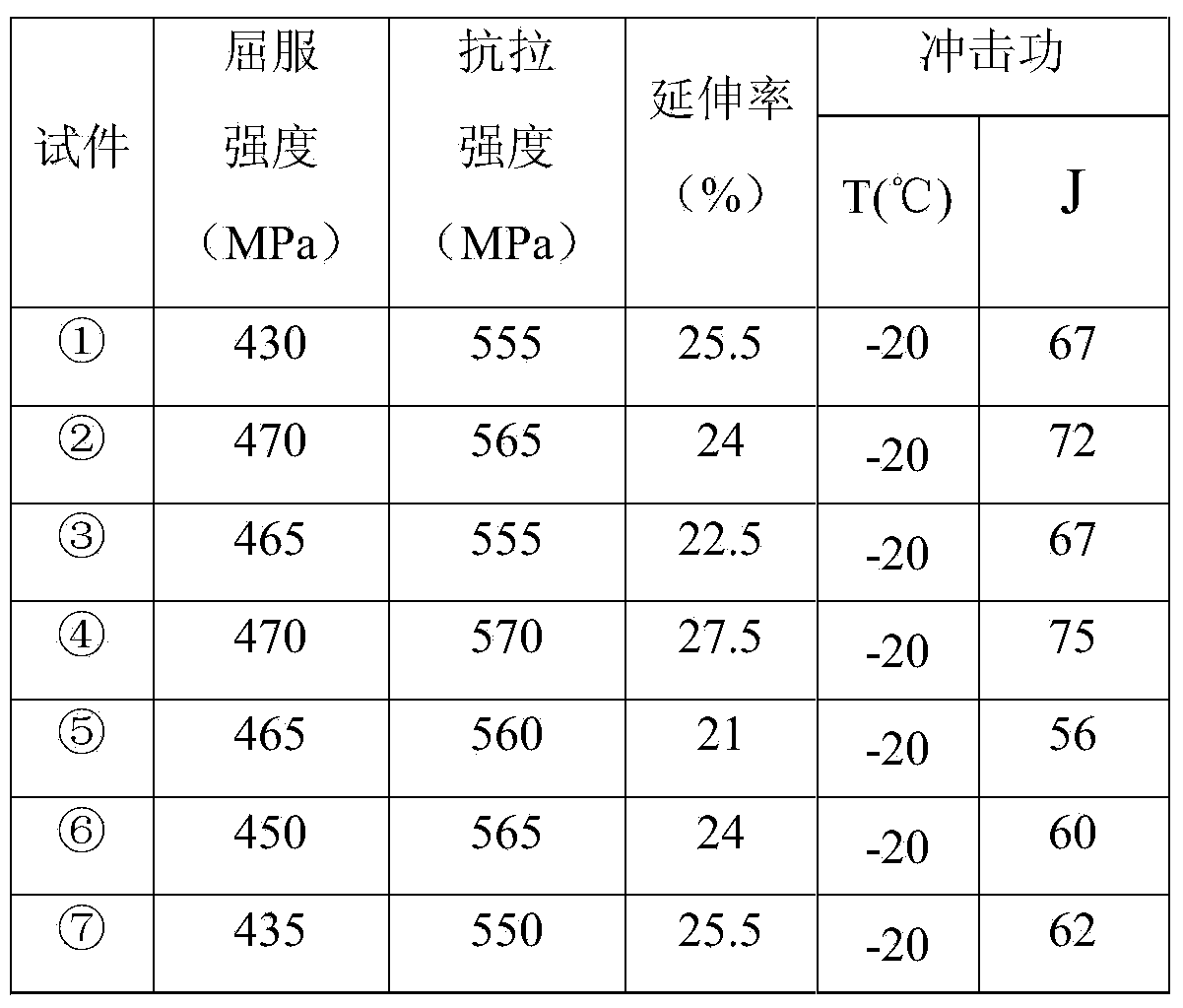

Ultra-low hydrogen type acid flux-cored wire and production method thereof

InactiveCN111702371ABeautiful weld appearanceSimple welding processWelding/cutting media/materialsSoldering mediaCrack resistanceHydrogen content

Owner:KUSN GINTUNE WELDING

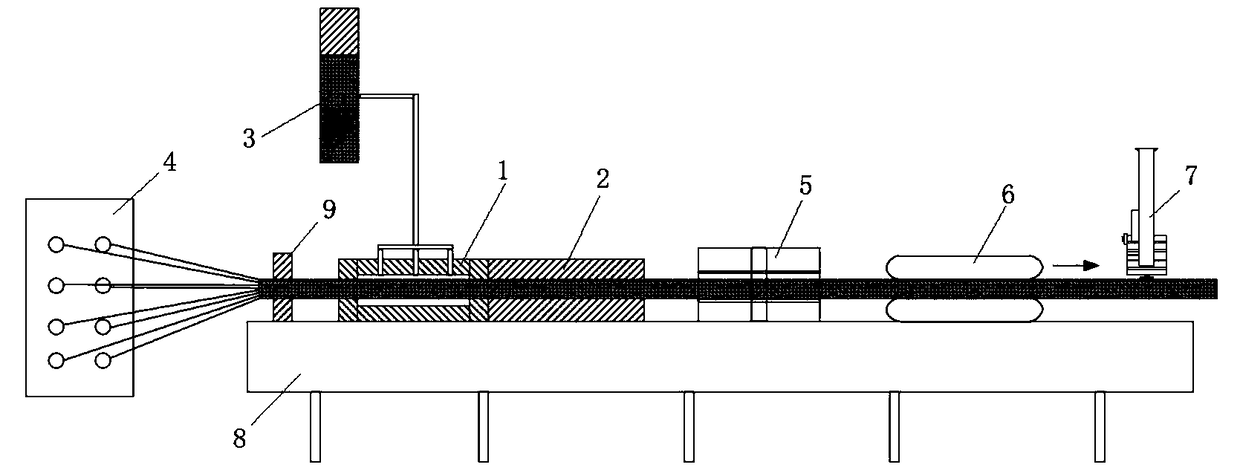

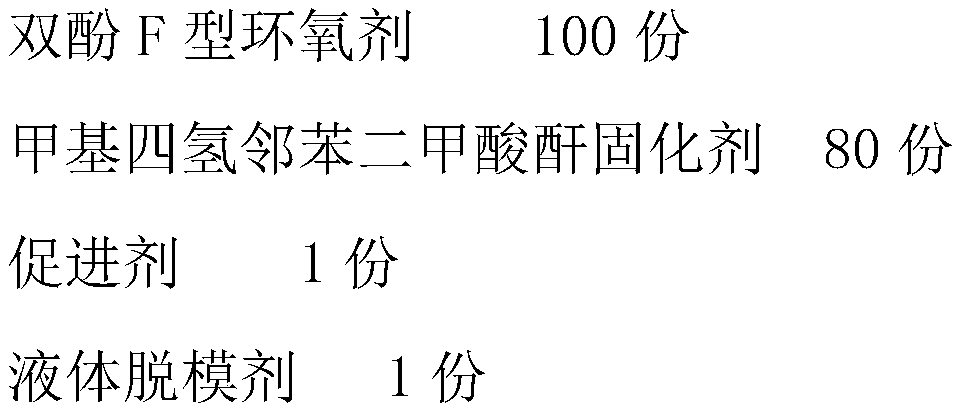

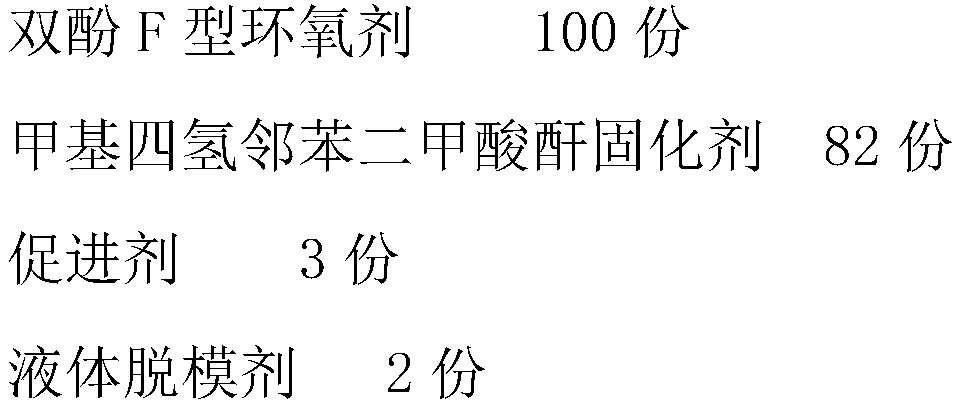

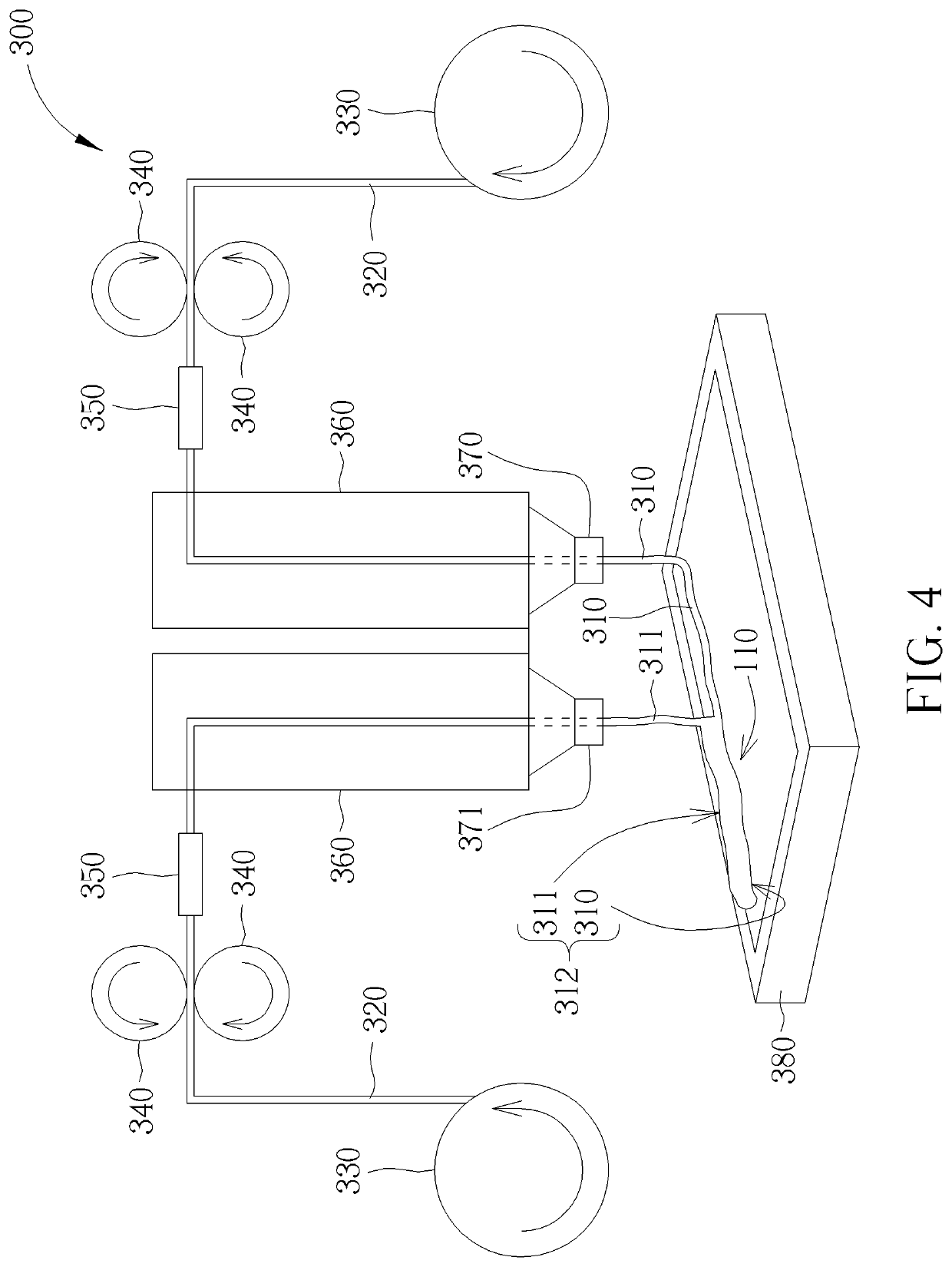

Glass fiber reinforced epoxy resin base profile for electric power system, production method and device

A glass fiber reinforced epoxy resin base profile for an electric power system is prepared from glass fiber and epoxy resin glue through injection-pultrusion, wherein the profile has a T-shape, an L-shape, an H-shape or a U-shape structure, and is characterized in that by setting the T-shape, L-shape, H-shape or U-shape profile, the weight of the insulating core rod made of the profile is effectively reduced, meanwhile the use of a hollow material is avoided, namely the internal insulation problem of the insulating core rod is avoided, and the insulation performance of the insulating core rodis improved, and the structural stability of the profile is effectively improved by arranging one or more preset curvature circular arc structures on the outer surface of the profile. The glass fiberand the epoxy resin are injected into one body by the injection-pultrusion process, so that the glass fiber can be fully impregnated, and the produced profile has less bubbles, excellent electrical and mechanical properties and stability are realized.

Owner:STATE GRID CORP OF CHINA +2

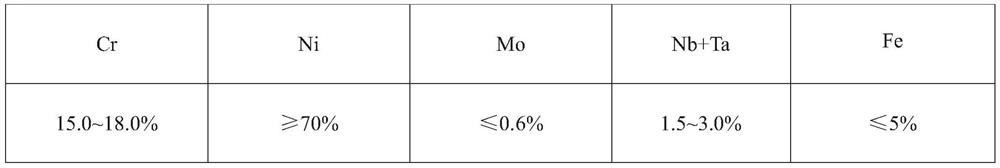

9% Ni steel matched nickel-based welding rod special for overhead welding

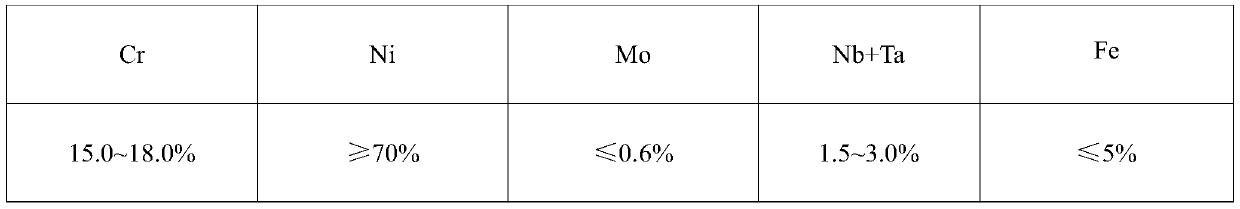

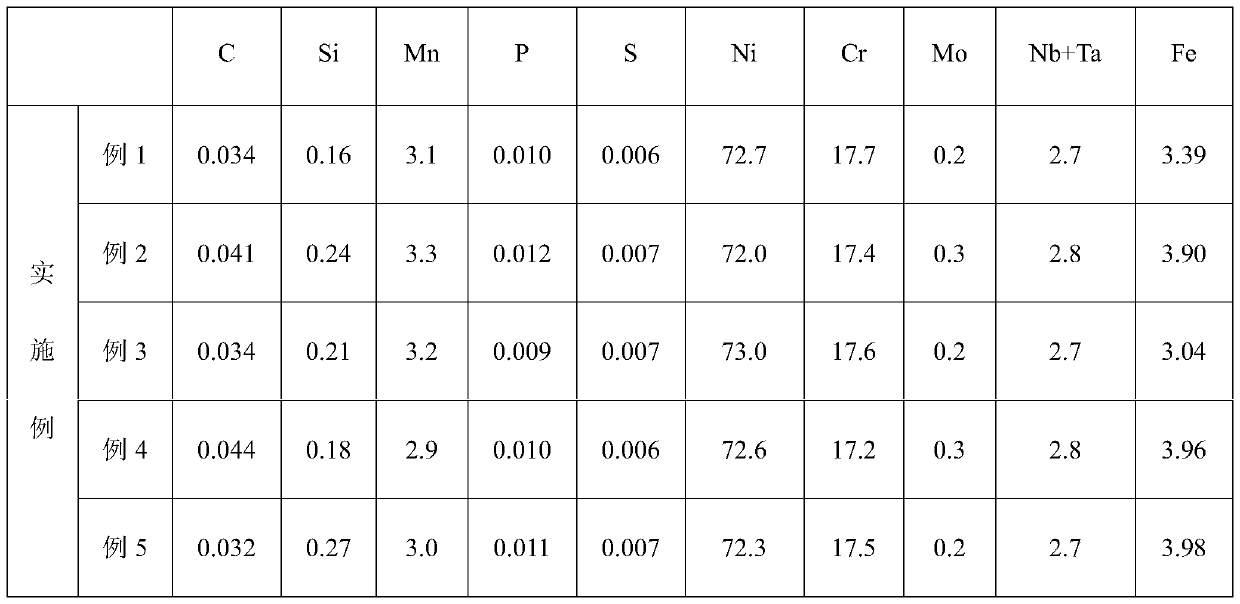

ActiveCN111590240AReduce distractionsReduce porosityWelding/cutting media/materialsSoldering mediaSlag (welding)Nichrome

The invention discloses a 9% Ni steel matched nickel-based welding rod special for overhead welding. The welding rod is composed of a welding core and a coating, wherein the outer wall of the weldingcore is coated with the coating, the coating accounts for 0.3-0.5% of the total weight coefficient of the welding rod, the welding core is a nickel-chromium-iron welding core, and the coating is composed of a CaCO3-MgCO3-CaF2 low-hydrogen slag system with high alkalinity. The welding rod has excellent all-position weldability, especially overhead welding position weldability, and extremely low overhead welding shooting porosity; and the welding rod has excellent overhead welding property, stable electric arc, excellent deslagging property and excellent weld joint forming property, the weldingrod has extremely low overhead welding porosity, and the overhead welding high-definition radiographic inspection TOFD shooting qualification rate can reach 99.5% or above.

Owner:KUSN GINTUNE WELDING

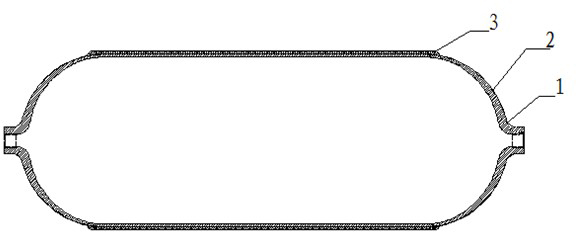

High-pressure gas cylinder for gas transportation vehicle

InactiveCN102434776AImprove fatigue performanceImprove impact resistancePressure vesselsEpoxyGlass fiber

The invention provides a high-pressure gas cylinder for a gas transportation vehicle. The high-pressure gas cylinder comprises a barrel body section which is positioned in the middle, two cylinder openings which are positioned at two ends respectively, and end sockets which are connected with the barrel body section and the cylinder openings, wherein the wall of the high-pressure gas cylinder sequentially comprises an inner container which is made of steel, a combined coating layer which is made of a polyurethane material, a composite material layer which is made of a glass fiber-epoxy composite material, and an outer protection film from inside to outside. The high-pressure gas cylinder has the advantages that: by adopting the steel inner container and the composite material layer with a glass fiber-epoxy system, the fatigue property and the impact resistance are high, and a special requirement of the high-pressure gas cylinder for the gas transportation vehicle can be met; and the outer protection film is wrapped outside the composite material layer, so that a phenomenon that the wet air in the air and corrosive substances corrode the outer surface of the compound material layer, and thus the property of the gas cylinder is influenced can be avoided.

Owner:SINOMA SCI & TECHSUZHOU

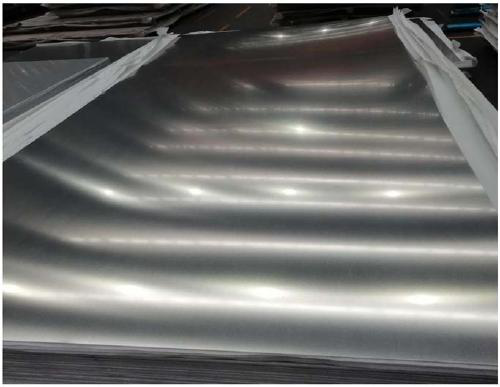

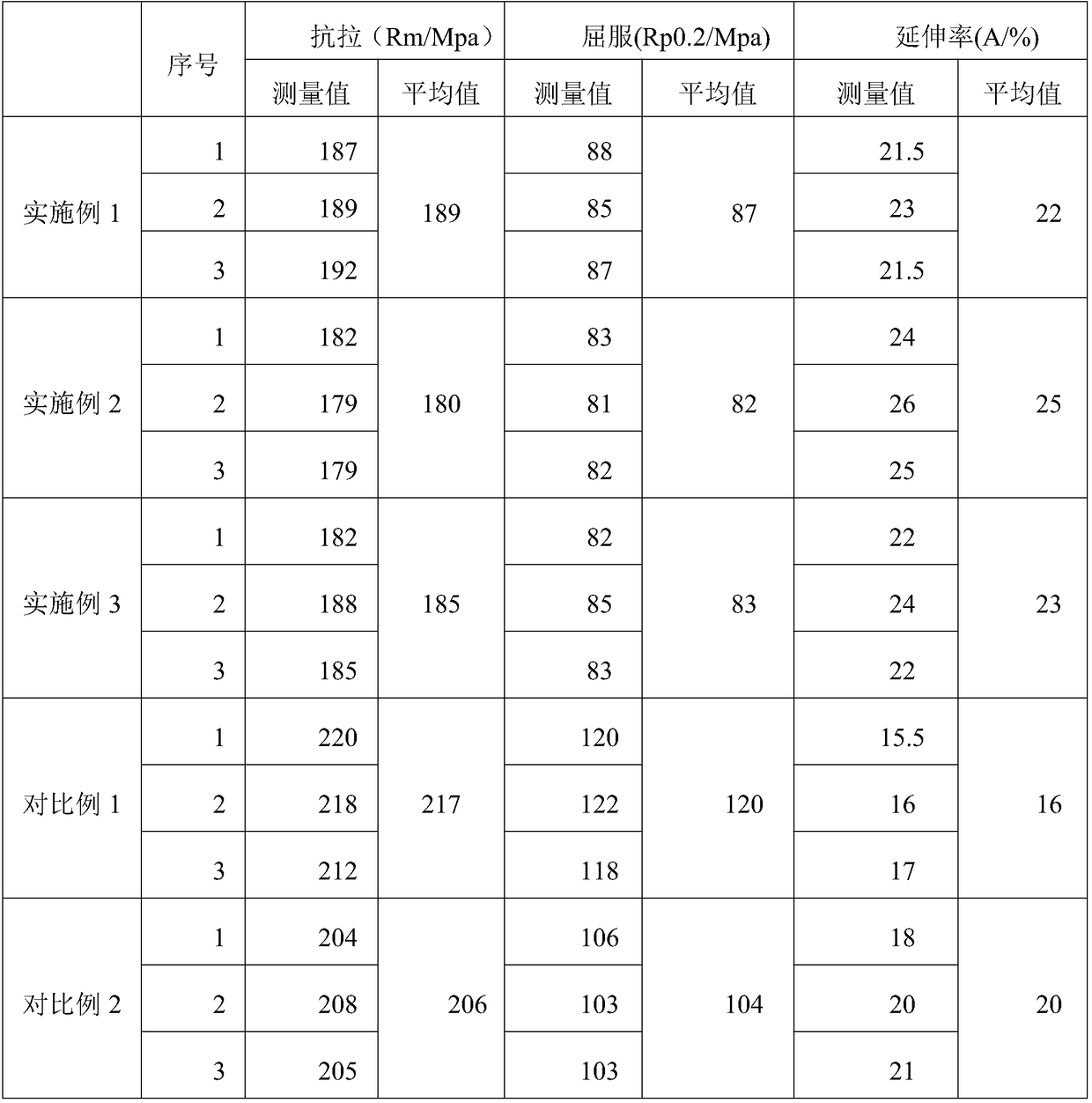

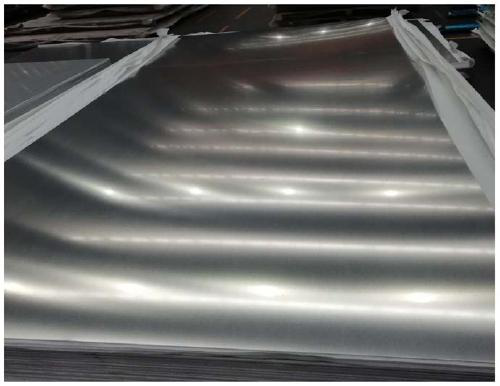

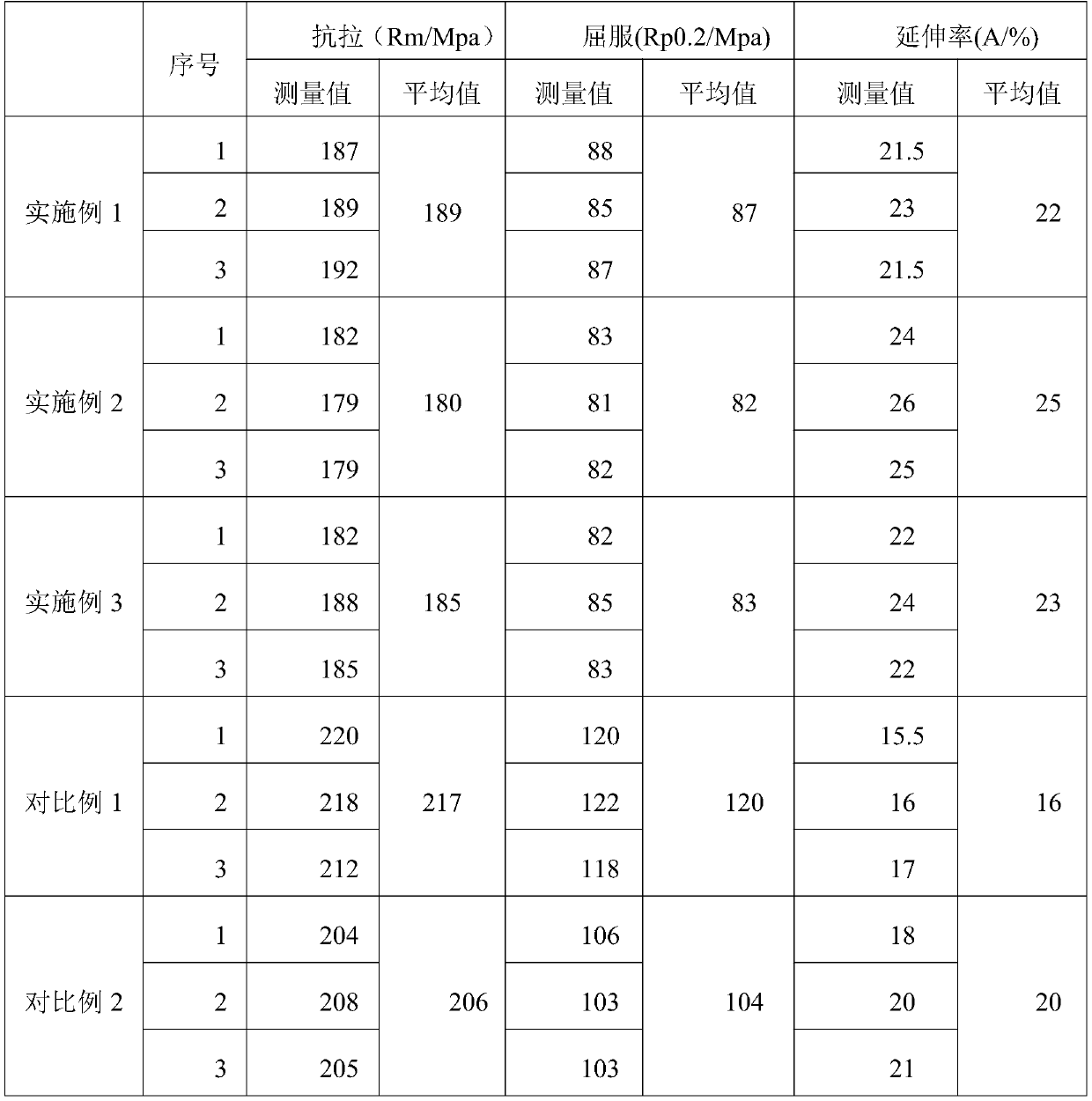

Production method for Al-Zn-Mg-Cu series aluminum alloy panel for safety shoe box toes

The invention relates to the technical field of aluminum alloys, in particular to a production method for an Al-Zn-Mg-Cu series aluminum alloy panel for safety shoe box toes. According to the production method for the Al-Zn-Mg-Cu series aluminum alloy panel for the safety shoe box toes, chemical components including Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al are adopted for casting an aluminum alloy casting ingot, the aluminum alloy casting ingot is subjected to the steps of preheating, hot rolling, cold rolling, cleaning and three-level annealing, and the aluminum alloy panel is manufactured. The obtained product has excellent and stable mechanical performance and meanwhile has high punching performance, high electric conductivity and good surface quality, and the punching using requirement for safety shoe toepiece materials can be met.

Owner:广西南南铝加工有限公司

A kind of high-performance rubber for generator shock absorber and its preparation process

ActiveCN103627043BIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

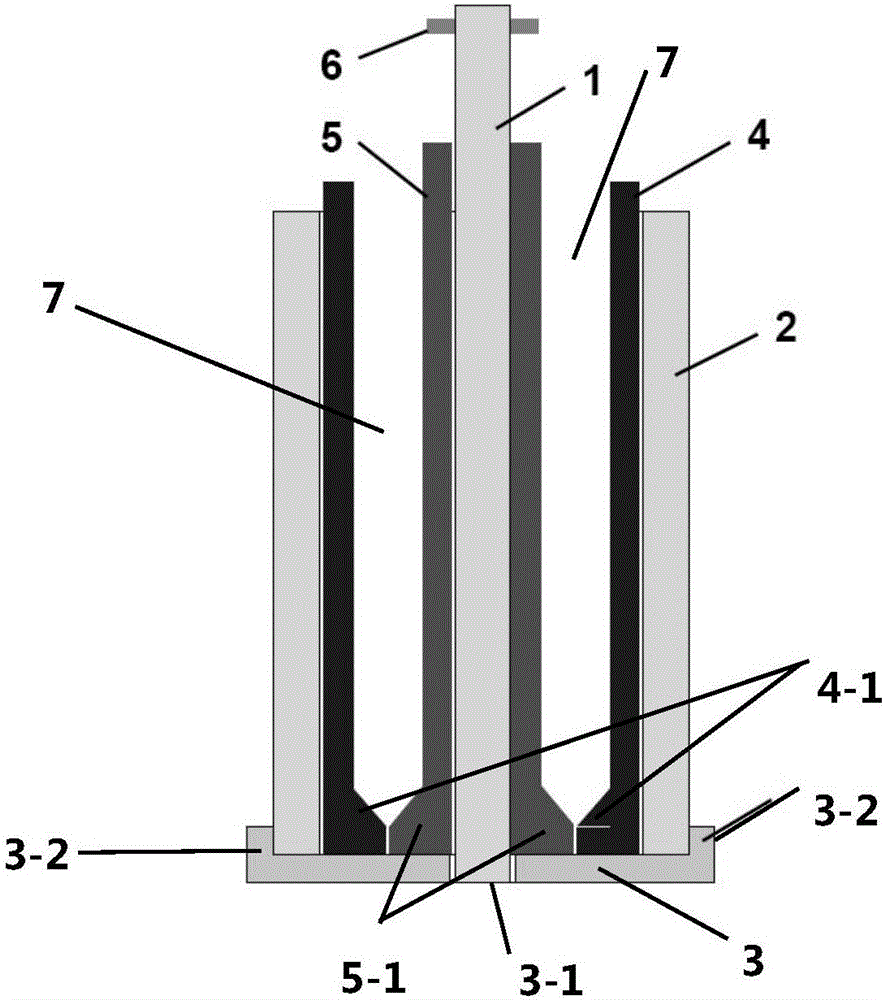

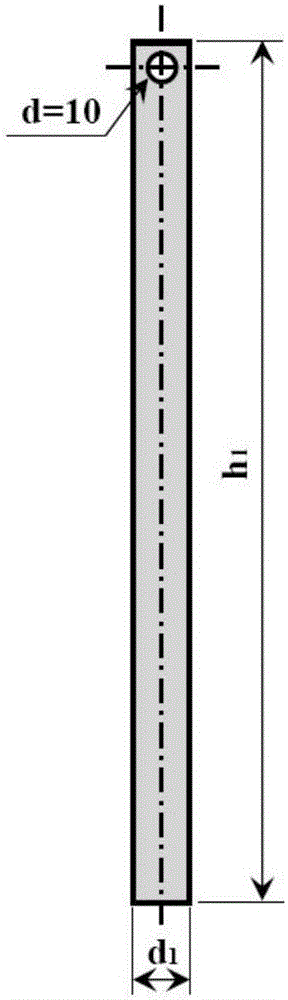

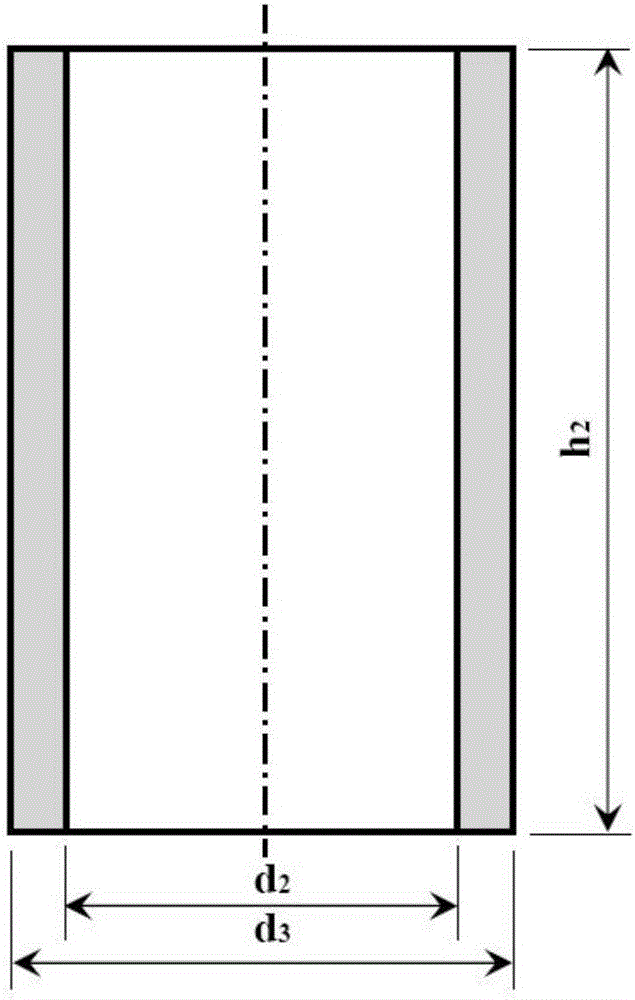

Method and die for preparing long and thin ceramic pipe blank through alternated die pressing

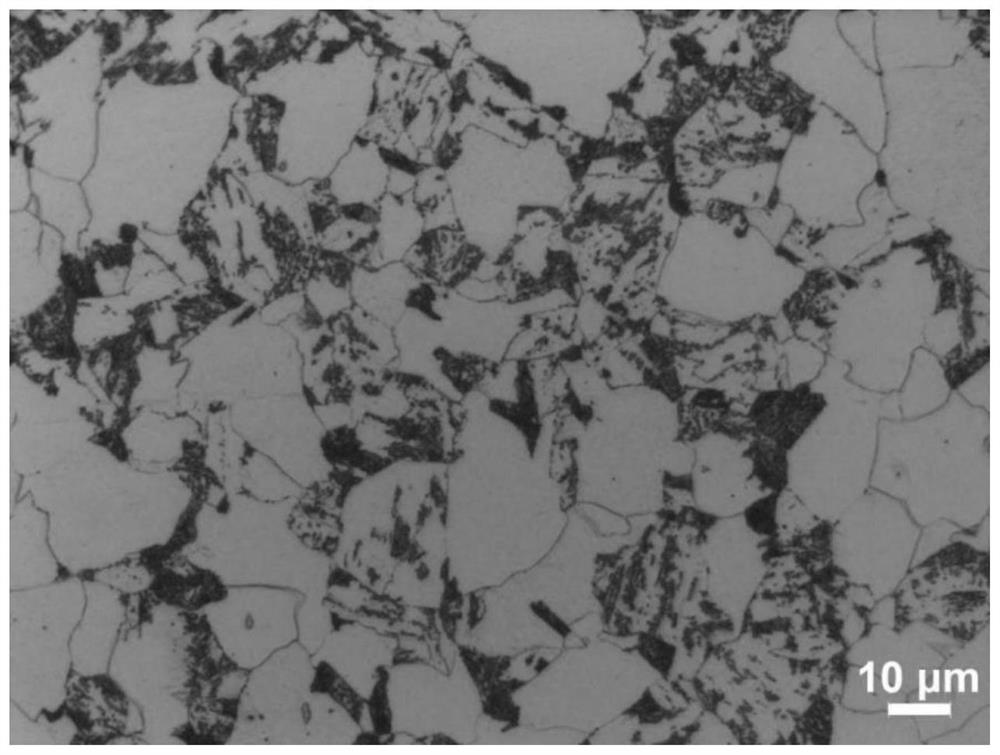

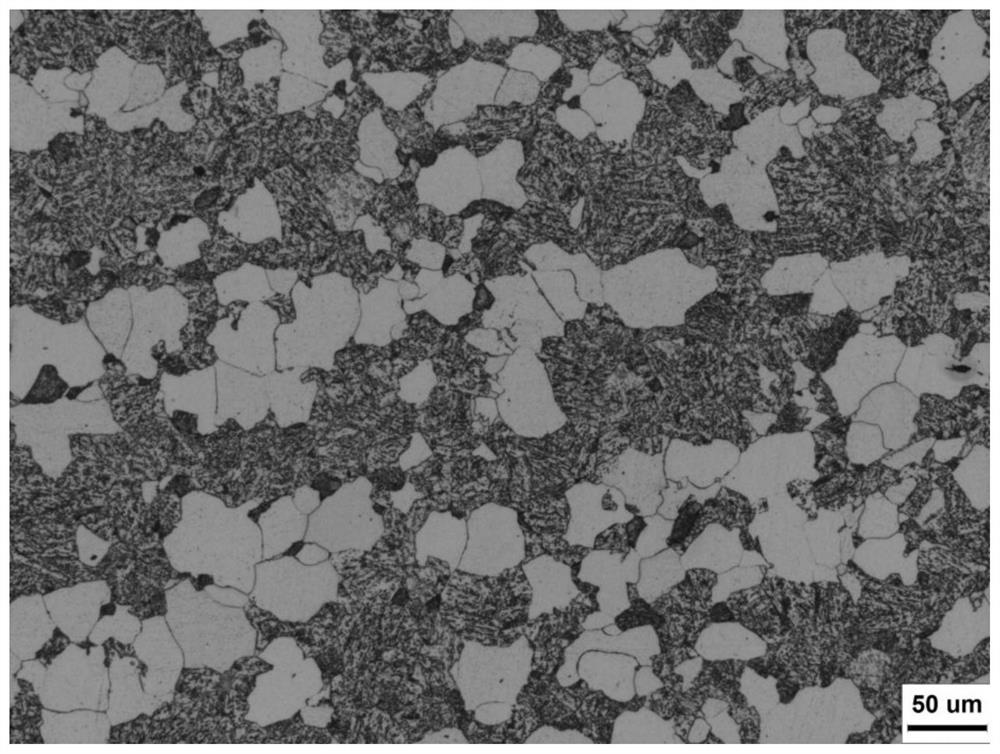

ActiveCN106671266AUniform microstructureExcellent and stable mechanical propertiesMouldsCeramic shaping coresMicrostructureSintered ceramic

The invention provides a die for preparing a long and thin ceramic pipe blank through alternated die pressing and an application method of the die. The problems existing in preparing of long and thin ceramic pipes through a conventional die pressing manner in the prior art are solved; and in other words, the problem that the long and thin ceramic pipes are hard to prepare through one-way die pressing and both-way die pressing is solved, and the problems of the complex technology, the long period, the high cost and the like in static pressure preparing of the long and thin ceramic pipes are solved. The method adopted for preparing the long and thin ceramic pipe blank has the beneficial effects of being simple in technology, short in period, low in cost and the like, and a sintered ceramic pipe component is uniform in microstructure and excellent and stable in mechanical performance.

Owner:YANTAI UNIV

Modified starch compound mulching film

The invention provides a modified starch compound mulching film. The modified starch compound mulching film is prepared from, by weight, 20-30 parts of polypropylene, 50-60 parts of starch acetate, 5-10 parts of polyvinyl alcohol, 5-10 parts of plasticizer, 1-5 parts of dispersant and 0.5-1.5 parts of nano-titanium dioxide. The modified starch compound mulching film is easy to prepare, low in cost, degradable and safe in modified starch compounding.

Owner:欧小宇

Brazing flux-free brazed aluminum alloy composite strip and manufacturing method thereof

InactiveCN112338386AExcellent and stable mechanical propertiesUniform and fine brazing structureWelding/cutting media/materialsSoldering mediaIngot castingSilicon alloy

The invention discloses a brazing flux-free brazed aluminum alloy composite strip and a manufacturing method thereof. The brazing flux-free brazed aluminum alloy composite strip comprises a core layerand brazing layers, wherein the brazing layers are arranged on the two sides of the core layer. The brazing layers are made of aluminum-silicon alloy, and the aluminum-silicon alloy is prepared from,in percent by weight: smaller than or equal to 0.25% of Fe, 7.8-8.2% of Si, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.05% of Mn, smaller than or equal to 0.01% of Mg, smaller than or equal to 0.001% of Sr, smaller than or equal to 0.05% of Ti, smaller than or equal to 0.05% of each of other elements and the balance Al. Alloy components and structures are controlled throughformula adjustment and ingot casting procedures, then the rolling procedure is conducted, the composite strip has excellent and stable mechanical properties, the tensile strength and yield strength ofthe prepared finished strip are high, the brazing structure is uniform and fine, and the brazing strength is high; and brazing flux is not contained, the brazing performance is stable, the brazing quality is good, the service life of a heat transfer material is prolonged, the production efficiency is improved, and therefore the cost is reduced.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Low-carbon low-alloy chromium-molybdenum steel plate for pressure vessel and heat treatment method for steel plate

The invention discloses a low-carbon low-alloy chromium-molybdenum steel plate for a pressure vessel and a heat treatment method for the steel plate. The thickness and components of the steel plate are dynamically controlled on the basis of using a heat treatment process, of normalizing and tempering, which is simple in procedures and low in cost, the finally obtained steel plate can meet the performance requirements, the production procedures are simplified, and the production cost is reduced. According to the steel plate and the heat treatment method, based on the simple heat treatment process of normalizing and tempering, a dynamic regulation and control thought for controlling a dynamic structure through dynamic components and obtaining good performance is provided. The invention mainly relates to the low-carbon low-alloy chromium-molybdenum steel plate for the pressure vessel and comprises the heat treatment process for dynamic structure and component control of 15CrMoR and 14Cr1MoR steel.

Owner:CENT SOUTH UNIV +1

Drying method for Typha angustifolia

InactiveCN106217531AAvoid performance degradation issues such as strengthStrength and other performance improvementsRadiation/waves wood treatmentPressure wood treatmentBulrushEngineering

The invention discloses a drying method for Typha angustifolia. The drying method comprises the following steps: (1) first-stage drying; (2) second-stage drying; and (3) third-stage drying. Each stage of the method is carried out on the basis of the characteristics of drying of Typha angustifolia; through the steps, the drying time for Typha angustifolia in the invention is shortened by 30% or more compared with conventional methods, the loss rate of Typha angustifolia is reduced by about 3%, the mechanical properties like flexibility and strength of Typha angustifolia are excellent and stable, and dried Typha angustifolia has a uniform and consistent color as a whole and is not prone to mildew or color changing after long-term storage; and high-quality and detailed technical support is provided for drying of Typha angustifolia, and the method has good promotion value.

Owner:FUNAN NATURE ARTS & CRAFTS

Chemically modified silicone rubber and preparation method thereof

The invention relates to chemically modified silicone rubber and a preparation method thereof. The product developed by the invention comprises silicone rubber, petroleum resin and linear silicone oil, the petroleum resin is aminopropyltriethoxysilane modified petroleum resin, and the silicone rubber and the aminopropyltriethoxysilane modified petroleum resin are crosslinked to form a three-dimensional network structure; and gaps of the three-dimensional cross-linked network structure are filled with the linear silicone oil. The preparation method of the chemically modified silicone rubber comprises the following steps: reacting hydrogenated petroleum resin with epoxy chloropropane to obtain hydrogenated petroleum resin glycidyl ester; heating the hydrogenated petroleum resin glycidyl ester and aminopropyltriethoxysilane, stirring and reacting under the protection of inert gas, and obtaining aminopropyltriethoxysilane modified petroleum resin; then mixing the silicone rubber, the aminopropyltriethoxysilane modified petroleum resin and an organic tin catalyst, heating and stirring for reaction, and then carrying out hot-pressing curing to obtain the product.

Owner:合盛硅业(上海)有限公司 +1

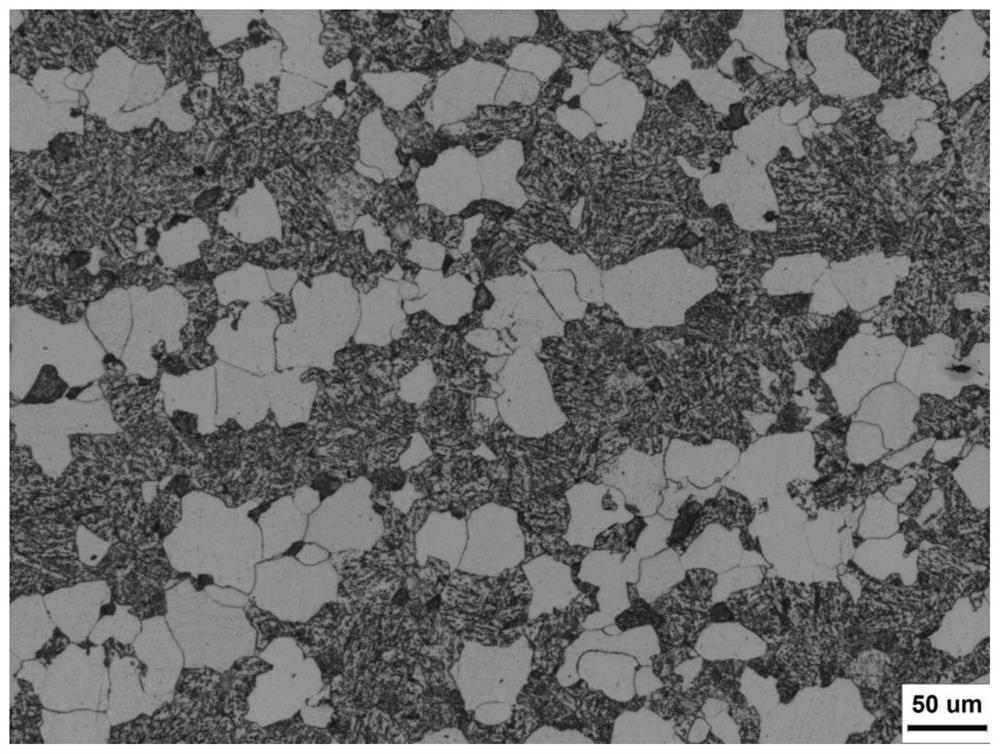

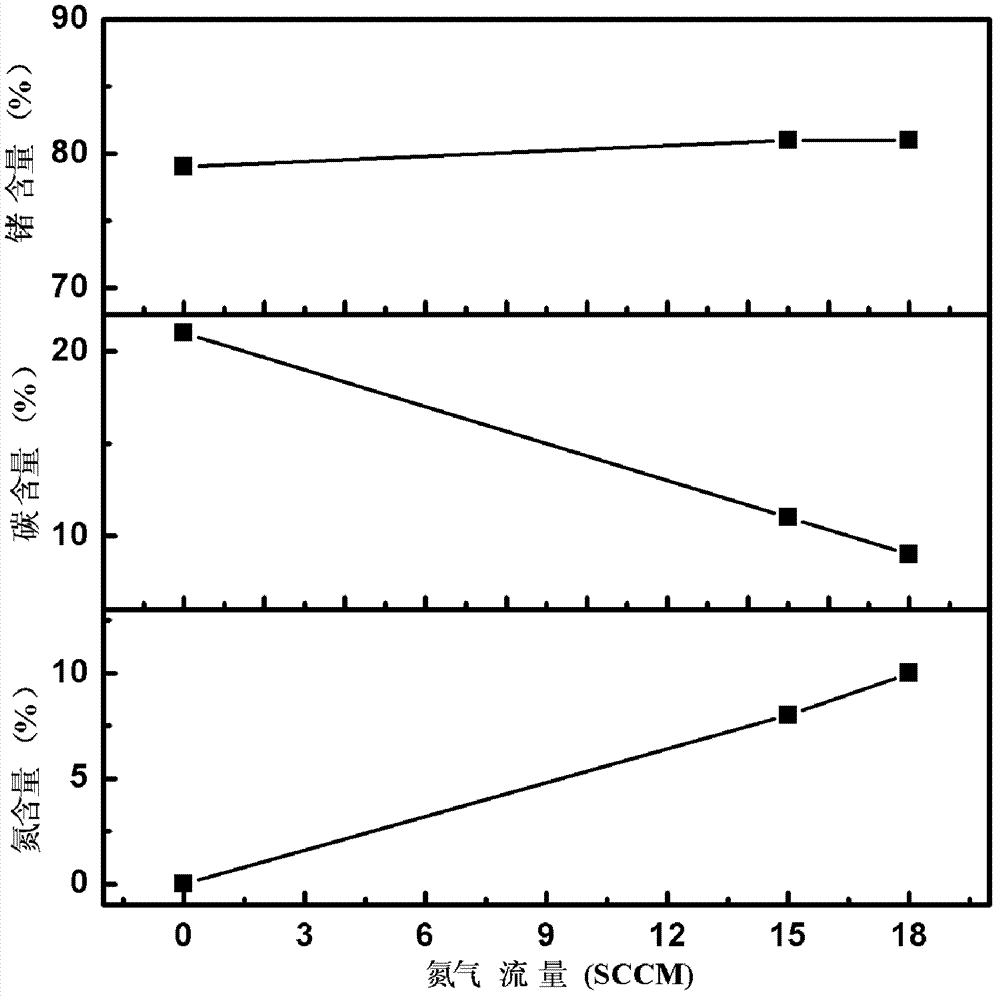

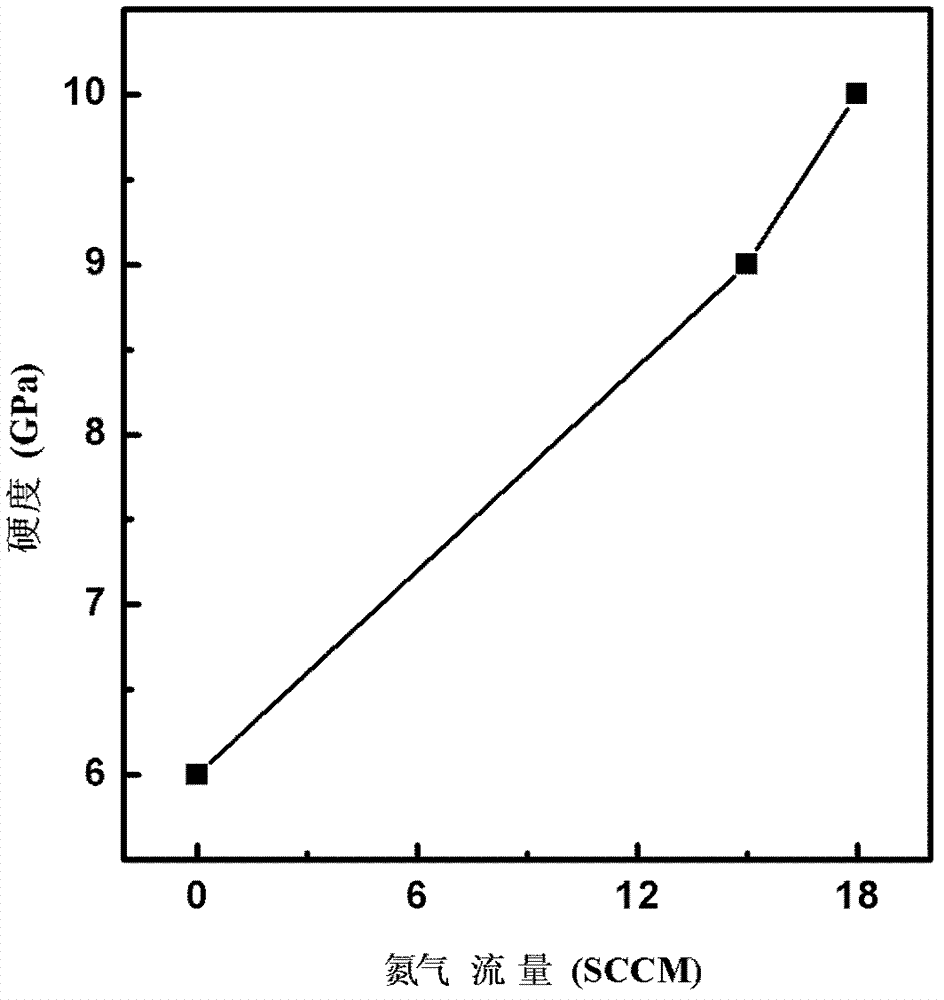

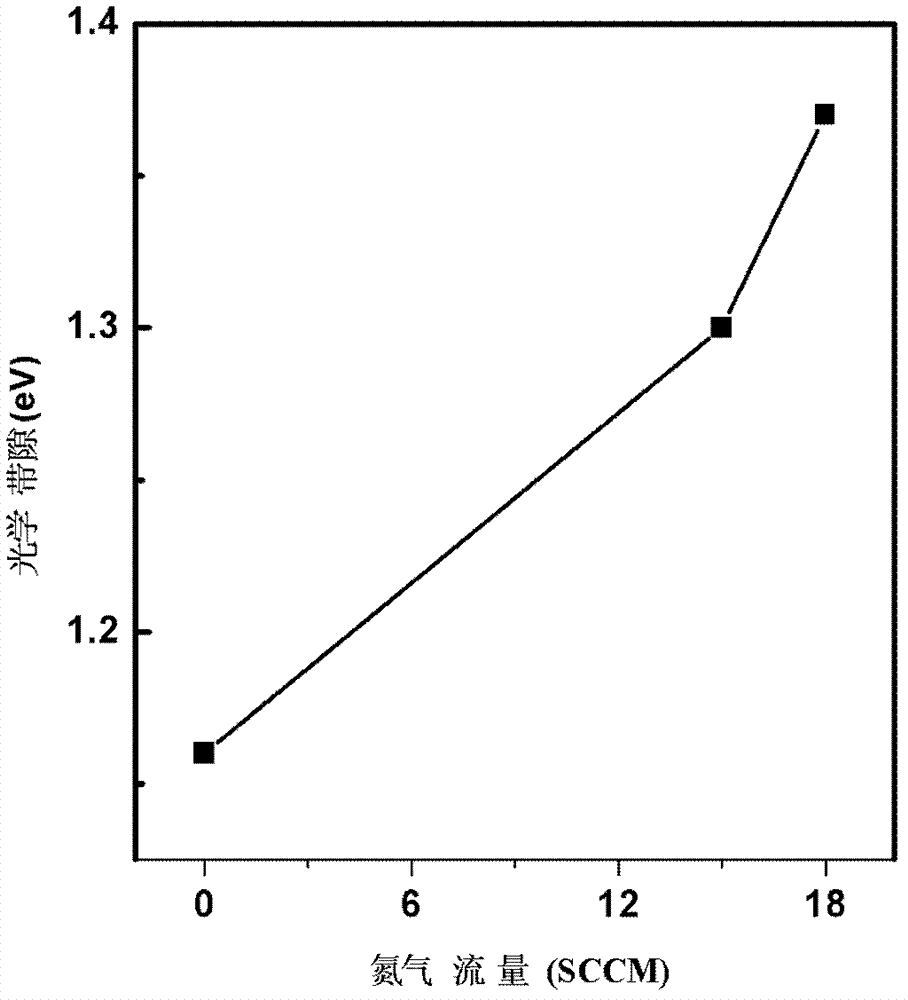

Nitrogen-containing germanium carbon alloy membrane material and preparation method thereof

InactiveCN102400026BHigh hardnessCompact structureVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSingle crystal

Owner:JILIN UNIV

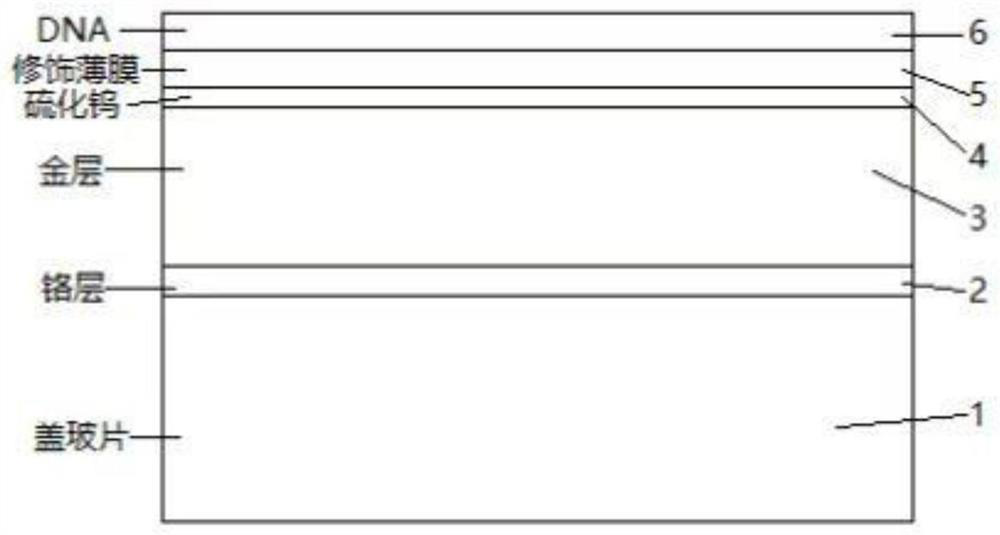

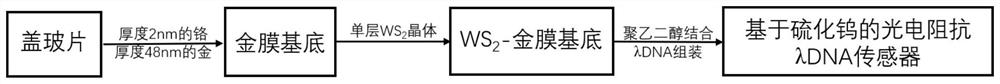

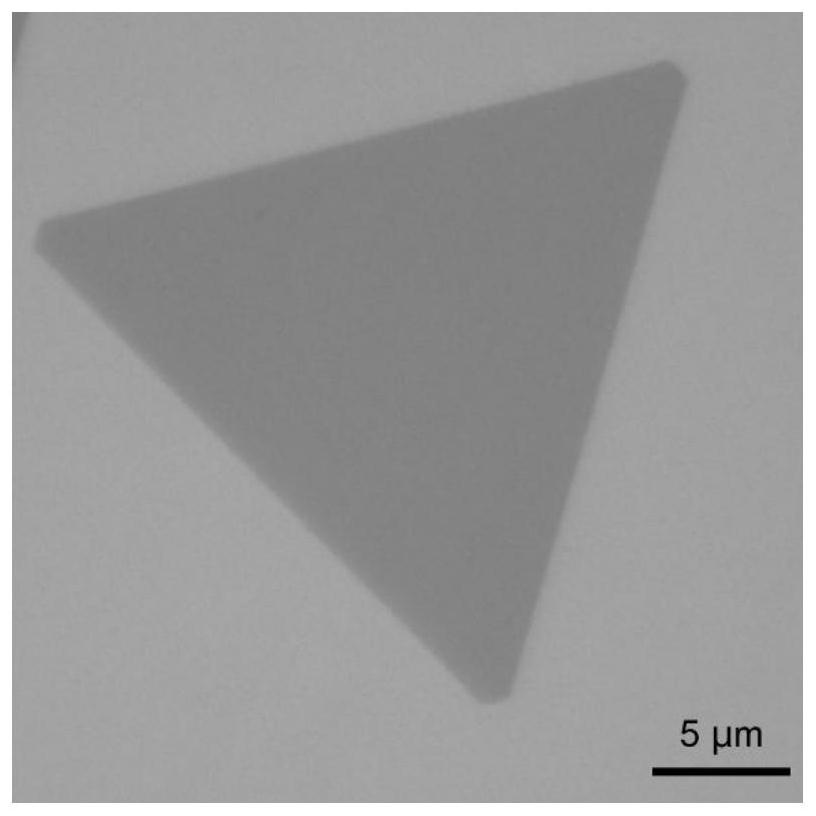

Biosensor as well as preparation method and application thereof

PendingCN114755276AHigh sensitivityImprove performanceMaterial electrochemical variablesResonance angleThin membrane

The invention belongs to the technical field of biological detection, and particularly relates to a biosensor and a preparation method and application thereof. An existing biosensor is complex in operation, low in sensitivity and unstable in performance. The invention provides a biosensor which comprises a carrier film, a modified film and a to-be-observed DNA layer which are sequentially stacked in a first direction, and the first direction is that the carrier film points to the to-be-observed DNA layer; the carrier film comprises a gold film substrate layer and a tungsten sulfide layer which are sequentially stacked in the first direction. By adding a single-layer tungsten sulfide crystal which is a charge sensitive material, on the basis of original pure gold film surface plasmon resonance angle imaging, modulation of different potential amplitude frequencies is added, and the effect of observing lambda DNA more clearly and sensitively is achieved. Operation is simple, sensitivity is high, and performance is stable.

Owner:YANSHAN UNIV

A Ni-based welding rod for 9% Ni steel for overhead welding

ActiveCN111590240BSolve the problem of stomataReduce purityWelding/cutting media/materialsSoldering mediaSlag (welding)Nichrome

The invention discloses a nickel-based electrode for overhead welding with 9% Ni steel, which is composed of a welding core and a coating, the coating is coated on the outer wall of the welding core, and the coating accounts for 0.3 to 0.5 of the total weight coefficient of the welding rod; The welding core adopts nickel-chromium-iron welding core; the composition of the coating adopts high alkalinity CaCO 3 ‑MgCO 3 ‑CaF 2 Low hydrogen residue system. The invention has excellent weldability in all positions, especially in the overhead welding position, and extremely low porosity of the overhead welding film. The welding rod of the invention has excellent welding performance for overhead welding, stable arc, excellent slag removal and excellent weld formation; the welding rod has extremely low welding porosity for overhead welding, and the pass rate of high-definition radiographic flaw detection TOFD filming for overhead welding can reach more than 99.5%.

Owner:KUSN GINTUNE WELDING

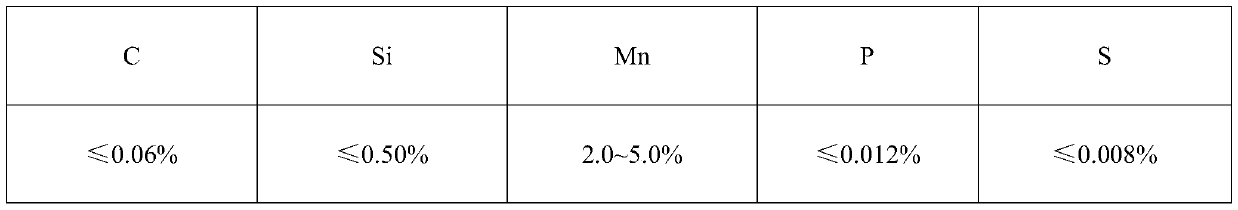

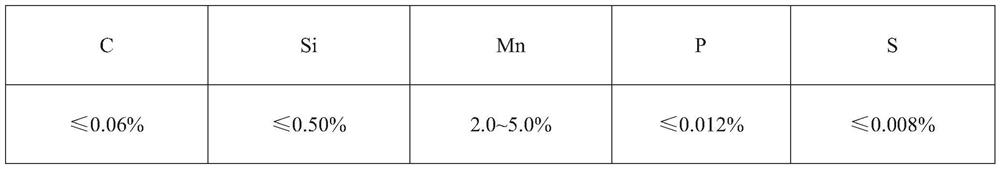

Flux-cored wire for electrogas welding

ActiveCN102528317BHigh purity of weld seamArc stabilizationArc welding apparatusWelding/cutting media/materialsWeight coefficientManganese

The invention discloses a flux-cored wire for electrogas welding, which comprises a steel strip and welding flux wrapped in the steel strip. The weight coefficient of the welding flux in the overall weight of the wire ranges from 0.2 to 0.3. By weight percentage, the steel strip comprises 0.010-0.055% of C (carbon), 0.01-0.03% of Si (silicon), 0.10-0.30% of Mn (manganese), 0.005-0.060% of Al (aluminum), 0.007-0.012% of P (phosphorus), 0.007-0.012% of S (sulfur) and the balance Fe (ferrum). By the overall weight of the wire, the welding flux comprises 0.2-2.0% of fluoride, 0.2-1.0% of oxide, 1.0-3.0% of Mn, 0.2-1.0% of Si, 0.4-1.2% of Ni (nickel), 0.1-1.0% of Mg (magnesium), 0.002-0.16% of Ti (titanium), 0.002-0.010% of B (boron) and the balance Fe. The flux-cored wire matched with electrogas welding is used for welding, so that welding efficiency is greatly improved, and excellent and stable mechanical performance is also obtained.

Owner:KUSN GINTUNE WELDING

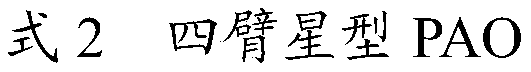

A composite solid propellant with low burning rate, high energy and high mechanical properties

ActiveCN107867963BHigh molecular weightExcellent burning speedExplosivesPressure gas generationPlasticizerHigh energy

The invention relates to a compound solid propellant with a low burning rate, high energy and high mechanical property. The compound solid propellant is prepared from components in parts by weight asfollows: 6-7 parts of an adhesive, 17-19 parts of a plasticizer, 10-15 parts of an oxidizing agent, 42-47 parts of energy-containing explosive, 15-18 parts of metal fuel, 0.15-0.25 parts of a curing agent, 0.05 parts of a curing catalyst, 0.3 parts of a stabilizing agent and 0.2 parts of a bonding agent. The minimum burning rate under the pressure of 6.686 MPa can reach 7 mm / s, the standard specific impulse is stably larger than 255 s according to actual testing, the technical problems that the burning rate of a high-energy propellant is further reduced and the energy of the propellant is substantially reduced are solved, and the technical requirements of existing propellants for weapon models for high energy, lower burning rate and high mechanical property are met.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

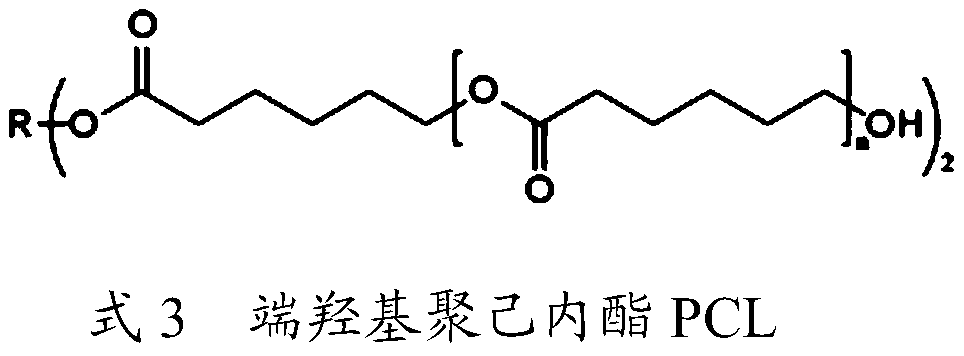

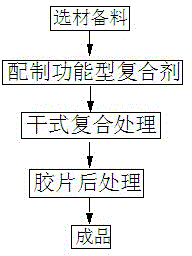

Method for preparing uvioresistant APET composite film

InactiveCN104309258AImprove practicalityHigh bonding strengthLaminationLamination apparatusAfter treatmentComposite film

The invention discloses a method for preparing an uvioresistant APET composite film. The method comprises the following steps: a) selecting and preparing materials; 2) preparing a functional composite agent; c) performing dry compounding treatment; and d) performing after treatment on the film. The invention discloses a method for preparing the uvioresistant APET composite film. The method is reasonable in procedure arrangement, scientific in application process and moderate in cost; the prepared composite film is high in interlayer combination strength and excellent and stable in mechanical property and has an outstanding and long-lasting uvioresistant function, and the practicability of the APET film is effectively improved.

Owner:JIN BAOLI TECH SUZHOU

A kind of production method of al-zn-mg-cu series aluminum alloy sheet material for inner toe cap of safety shoes

The invention relates to the technical field of aluminum alloys, in particular to a production method for an Al-Zn-Mg-Cu series aluminum alloy panel for safety shoe box toes. According to the production method for the Al-Zn-Mg-Cu series aluminum alloy panel for the safety shoe box toes, chemical components including Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al are adopted for casting an aluminum alloy casting ingot, the aluminum alloy casting ingot is subjected to the steps of preheating, hot rolling, cold rolling, cleaning and three-level annealing, and the aluminum alloy panel is manufactured. The obtained product has excellent and stable mechanical performance and meanwhile has high punching performance, high electric conductivity and good surface quality, and the punching using requirement for safety shoe toepiece materials can be met.

Owner:广西南南铝加工有限公司

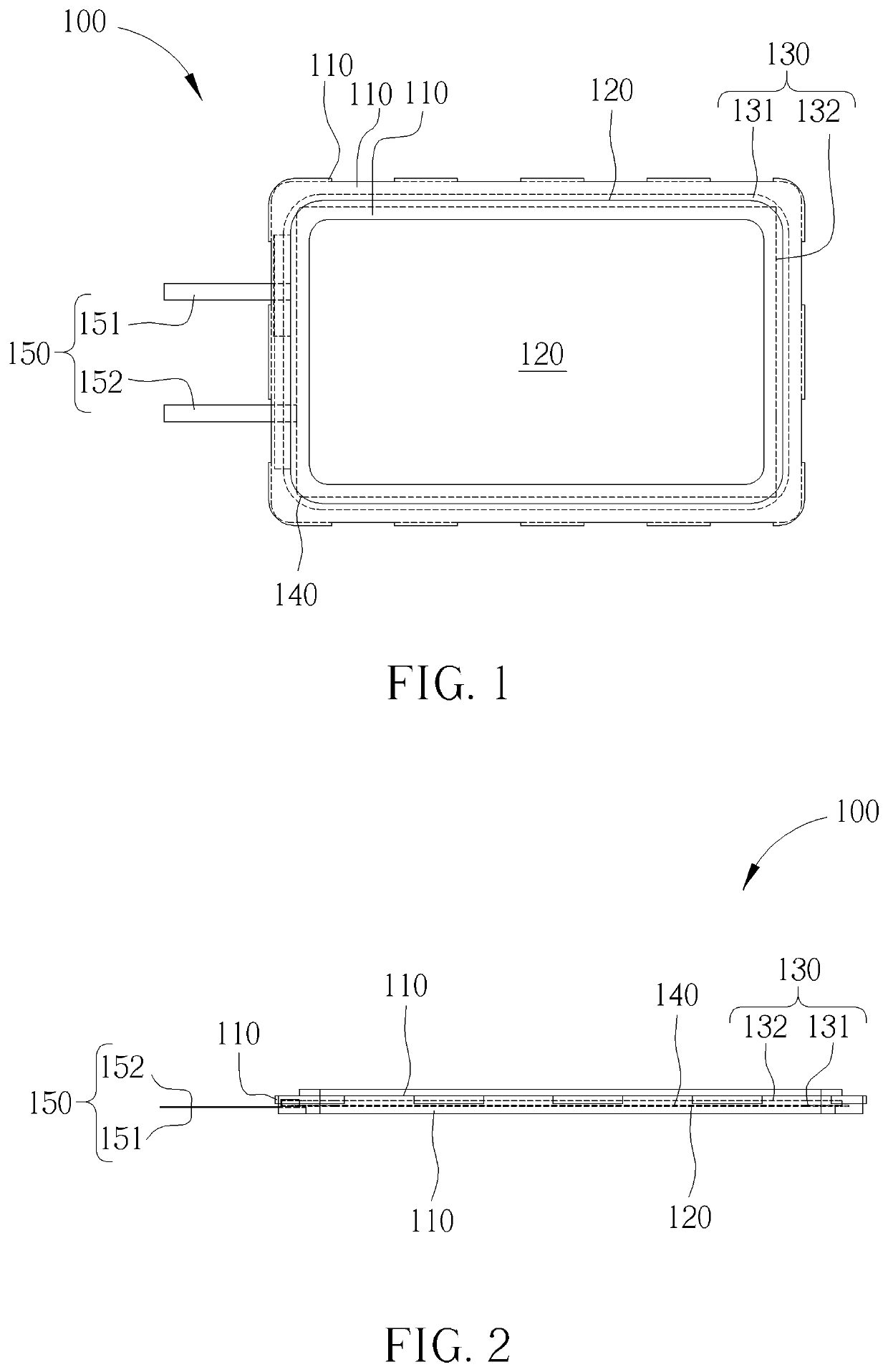

Box-in-box structure comprising thermal clay, use of the same and method to form the same

PendingUS20210218039A1High mechanical strengthExcellent and stable mechanical propertiesAdditive manufacturing apparatus3D object support structuresClassical mechanicsMechanical engineering

Owner:THUNDERZEE IND CO LTD

Low-carbon low-alloy chromium-molybdenum pressure vessel steel plate and its heat treatment method

The invention discloses a low-carbon low-alloy chromium-molybdenum pressure vessel steel plate and a heat treatment method thereof. On the basis of using a simple and low-cost heat treatment process such as normalizing + tempering, the thickness and composition of the steel plate are dynamically controlled to finally obtain The high-quality steel plate can not only meet the performance requirements, but also simplify the production process and reduce the production cost. The invention is based on a simple heat treatment process: normalizing + tempering, and provides a dynamic control idea to control the dynamic structure through dynamic components and obtain good performance. The invention mainly relates to steel plates for low-carbon and low-alloy chromium-molybdenum pressure vessels, including the dynamic structure and component-controlled heat treatment process of 15CrMoR and 14Cr1MoR steels.

Owner:CENT SOUTH UNIV +1

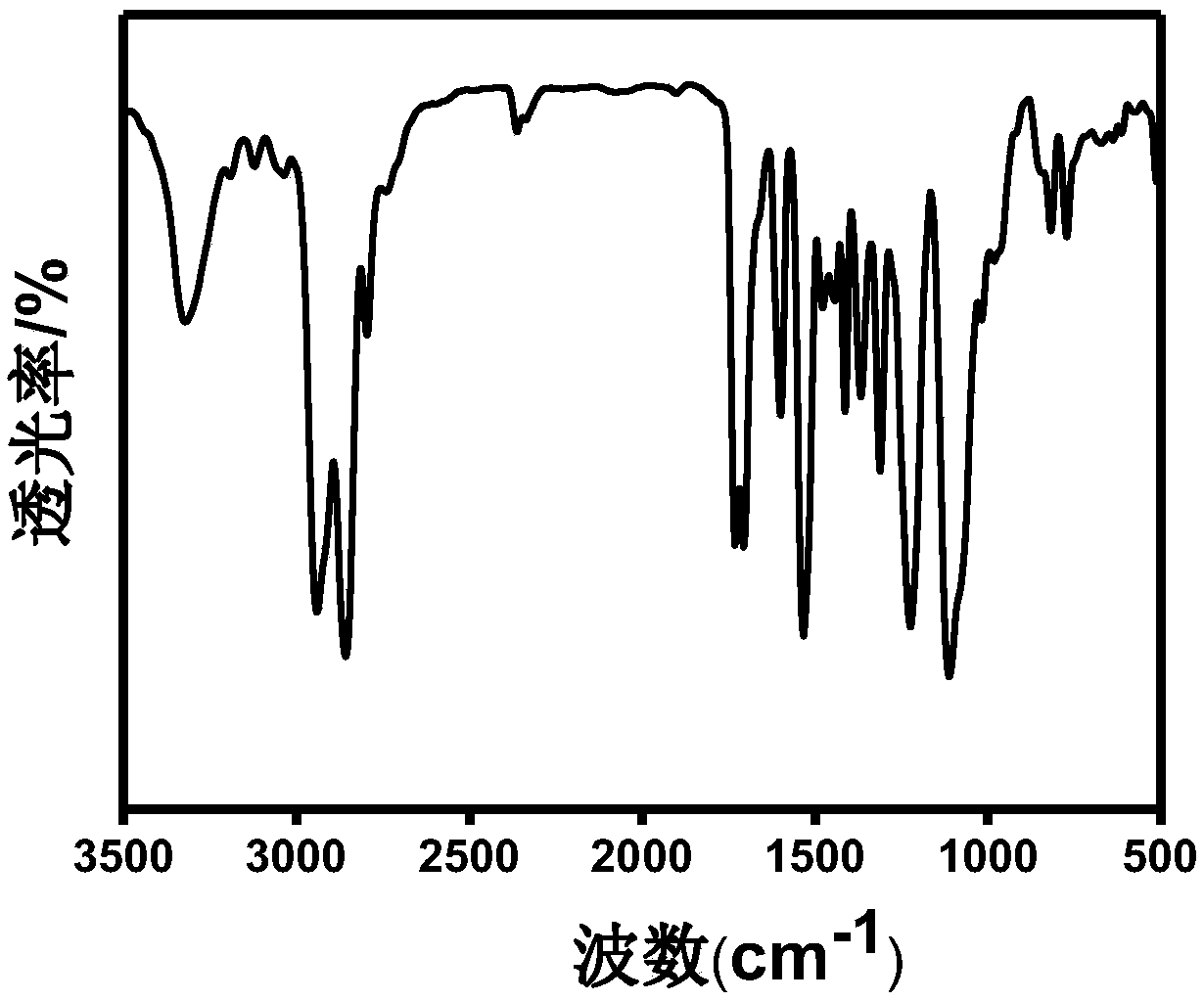

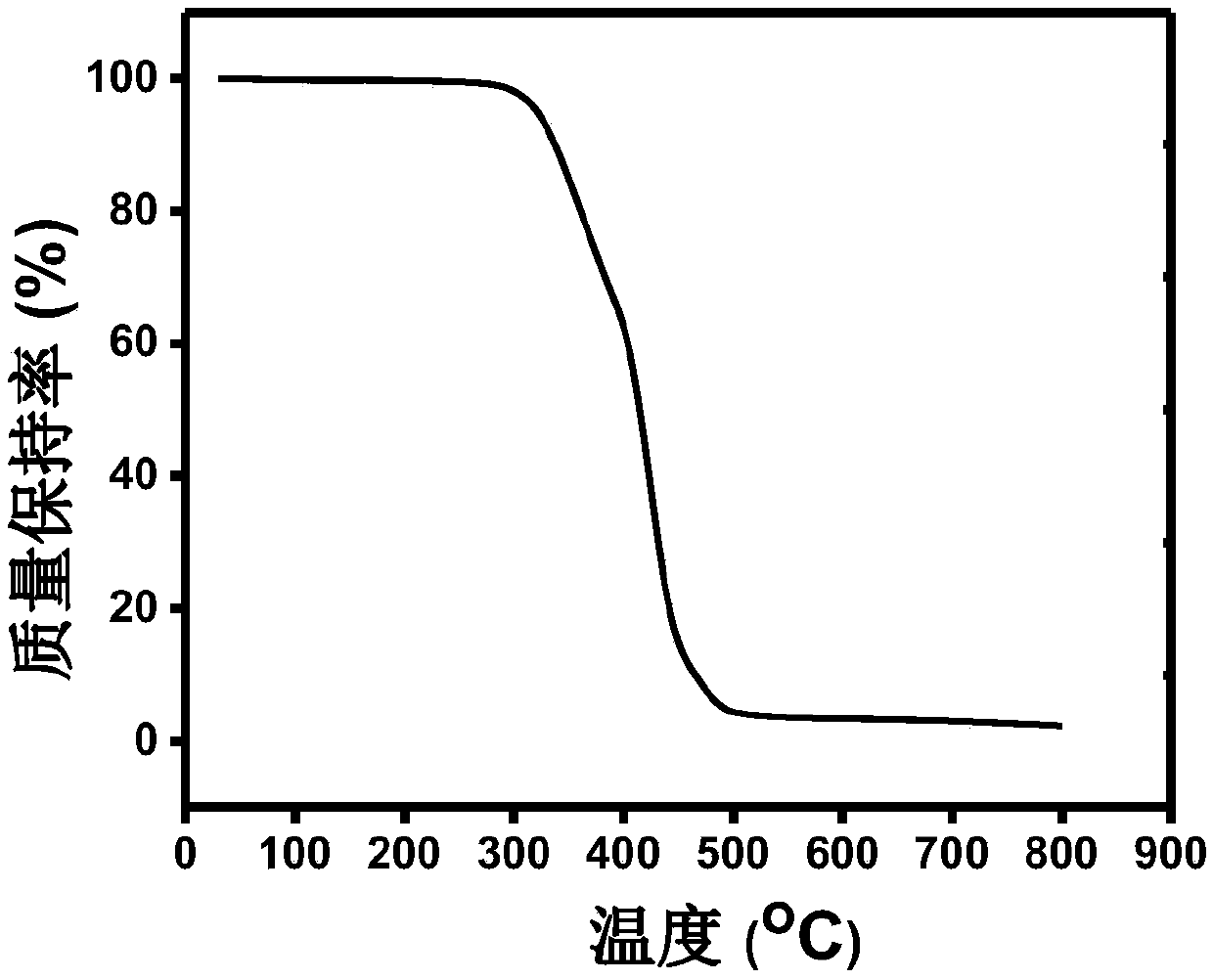

High temperature-resistant solvent-based polyurethane material with monomer structure containing biphenylphthalazine structure, and preparation method thereof

InactiveCN109651580AImprove solubilityExcellent and stable mechanical propertiesChemistryRadiation resistance

The invention discloses a high temperature-resistant solvent-based polyurethane material with the monomer structure containing a biphenylphthalazine structure, and a preparation method thereof. The defects of poor high temperature resistance and poor radiation resistance of traditional solvent-based polyurethane materials are overcome from the perspective of the design of the molecular structure of a polymer. The polyurethane material designed in the invention is prepared by polymerizing diisocyanate, polyether or polyester polyol, a chain extender, a catalyst, an end capping agent, and a monomer containing the biphenylphthalazine structure. The polyurethane material not only improves the heat resistance and the radiation resistance of the polyurethane material, and also maintains excellent mechanical properties, and cured products of the polyurethane material can be used for a long period under a high temperature (200 DEG C) condition.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com