Modified starch compound mulching film

A starch and mulching film technology, applied in the field of polymer materials, can solve the problems of soil losing water and fertilizer retention properties, destroying the original structure of the soil, secondary soil salinization and the like, achieving low preparation cost, simple preparation process and easy operation. and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

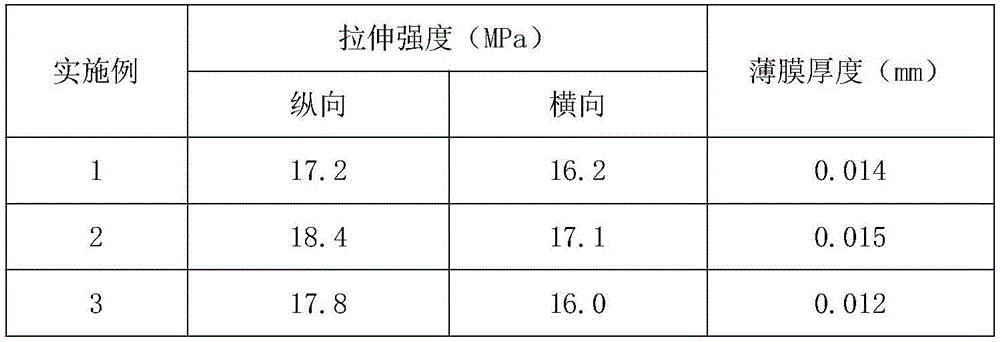

Examples

Embodiment 1

[0017] Raw materials are selected according to the following proportions:

[0018] 25 parts of polypropylene, 55 parts of acetate starch, 9 parts of polyvinyl alcohol, 7 parts of plasticizer, 2 parts of dispersant, 0.8 part of nano titanium dioxide;

[0019] Preparation steps:

[0020] 1) drying acetate starch at 80°C;

[0021] 2) Place polypropylene, acetate starch, plasticizer, dispersant, and nano-titanium dioxide in a high-speed mixer at a speed of 3000 rpm, stir for 6 minutes, and discharge;

[0022] 3) The mixture in step 2 is hot-melt extruded and blow-molded at 155°C to make a tubular mulch film, which is then cut and packaged.

Embodiment 2

[0024] Raw materials are selected according to the following proportions:

[0025] Polypropylene 22, acetate starch 58, polyvinyl alcohol 7, plasticizer 8 parts, dispersant 3 parts, nano titanium dioxide 1 part;

[0026] Preparation steps:

[0027] 1) drying acetate starch at 80°C;

[0028] 2) Place polypropylene, acetate starch, polyvinyl alcohol, plasticizer, dispersant, and nano-titanium dioxide in a high-speed mixer at a speed of 3500 rpm, stir for 5 minutes, and discharge;

[0029] 3) The mixture in step 2 is hot-melt extruded and blow-molded at 160°C to make a tubular mulch film, which is then cut and packaged.

Embodiment 3

[0031] Raw materials are selected according to the following proportions:

[0032] 30 parts of polypropylene, 52 parts of acetate starch, 5 parts of polyvinyl alcohol, 6 parts of plasticizer, 2 parts of dispersant, 0.8 part of nano titanium dioxide;

[0033] Preparation steps:

[0034] 1) drying acetate starch at 80°C;

[0035] 2) Place polypropylene, acetate starch, polyvinyl alcohol, plasticizer, dispersant, and nano-titanium dioxide in a high-speed mixer at a speed of 3800 rpm, stir for 6 minutes, and discharge;

[0036] 3) The mixture in step 2 is hot-melt extruded and blow-molded at 170°C to make a tubular mulch film, which is then cut and packaged.

[0037] The content provided above is only a preferred embodiment of the modified starch composite mulching film of the present invention and its manufacturing method. Of course, the scope of rights of the present invention cannot be limited by this. Therefore, the equivalent changes made according to the patent scope of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com