Sodium alginate/starch-based enteric-coated hollow capsule and its one-time molding preparation method

A technology of sodium alginate and hollow capsule, applied in the direction of capsule transportation, can solve the problems of complex production process, etc., and achieve the effects of high transparency, good film-forming property and good film-forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

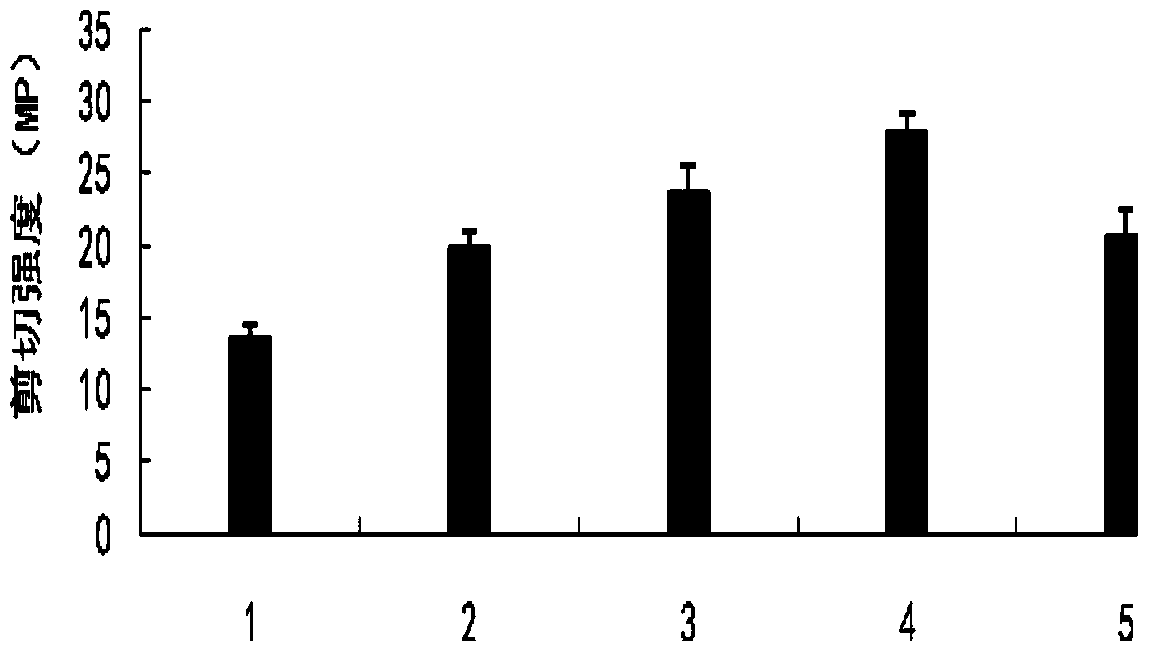

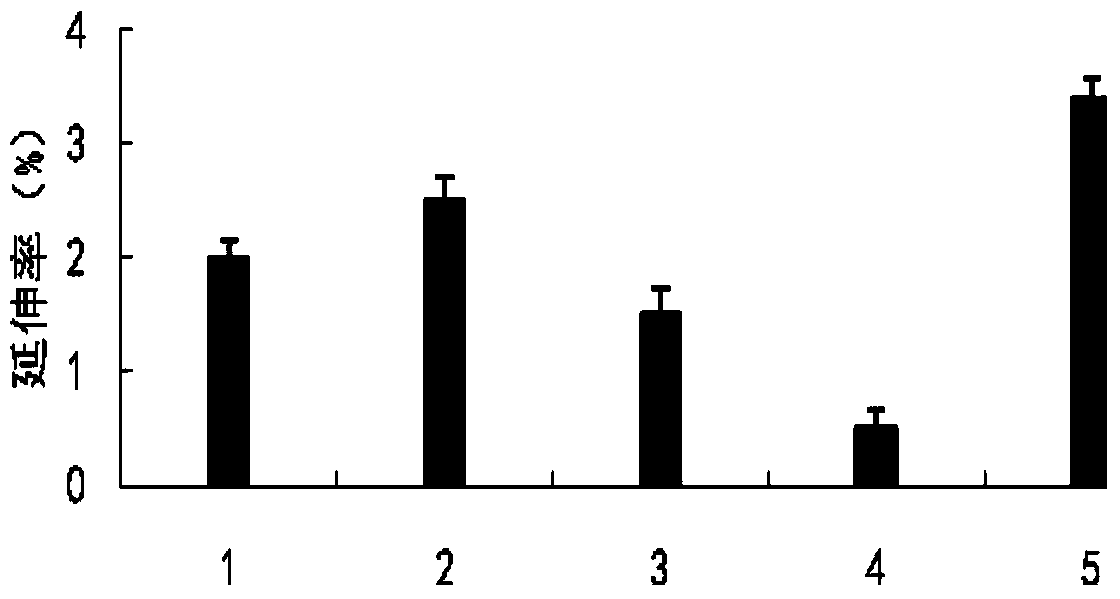

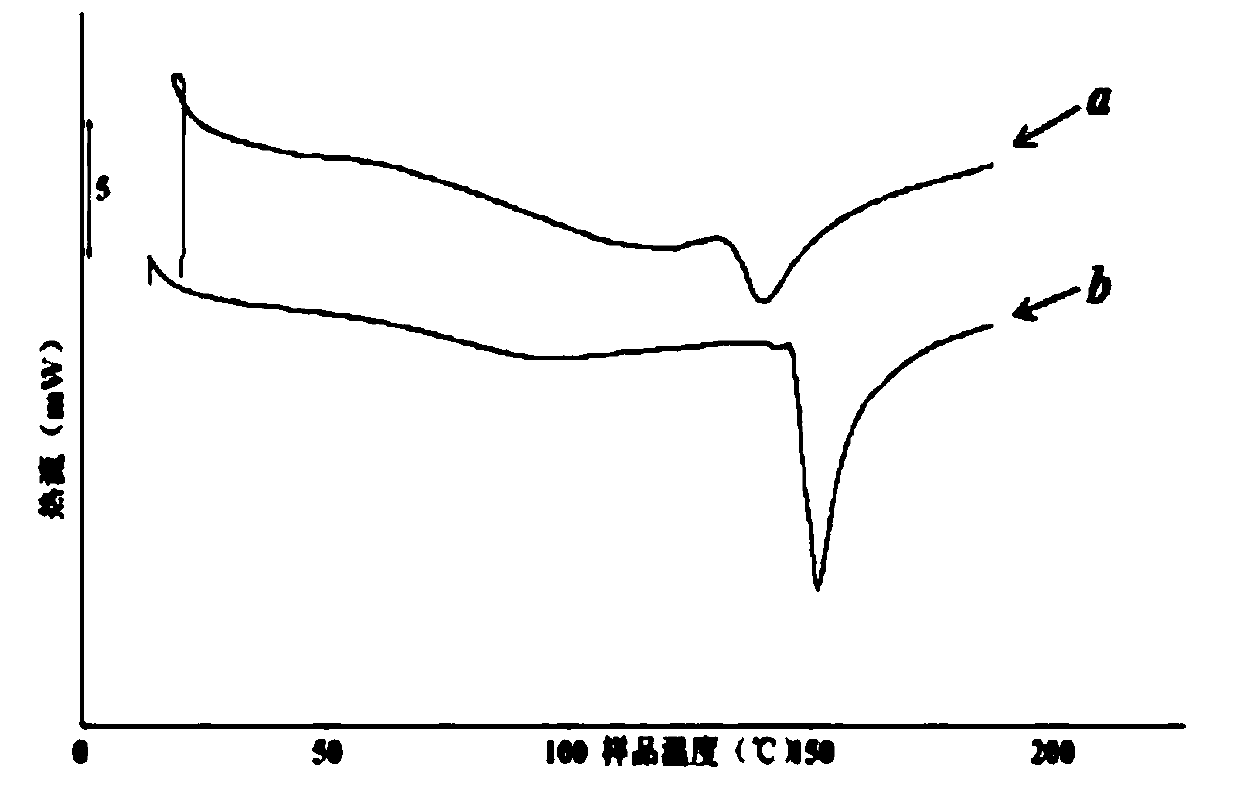

Embodiment 1

[0027] The one-time molding preparation method of the sodium alginate / starch-based enteric-coated hollow capsule of embodiment 1 comprises the following steps:

[0028] 1) Ingredients, sol: According to 63.8% of starch, 3.8% of high viscosity sodium alginate with a viscosity of 450mPa·s, 15.9% of low viscosity sodium alginate with a viscosity of 5mPa·s, 3.8% of low acyl gellan gum, glycerin (ie Glycerol) 12.7% weight percentage carries out the batching of each raw material, and all raw materials are mixed with 100g deionized water, and sol in the constant temperature water bath of 80 ℃, proper stirring makes raw material absorb water and swell and dissolve in the sol process 1.5 hours;

[0029] 2) Degassing of gelatinization: After the sol is completed, put the gelatinization in a constant temperature water bath at 55°C for 3 hours for degassing, and set aside;

[0030] 3) Embryo dipping in glue: Select a suitable type of capsule mold, first apply an appropriate amount of sal...

Embodiment 2

[0032] The one-time molding preparation method of the sodium alginate / starch-based enteric-coated hollow capsule of embodiment 2 comprises the following steps:

[0033] 1) Ingredients and sol: 65% starch, 3.5% high-viscosity sodium alginate with a viscosity of 450mPa·s, 16% low-viscosity sodium alginate with a viscosity of 5mPa·s, 3.8% low-acyl gellan gum, and 11.7% glycerin The weight percentage of each raw material was mixed, and all raw materials were mixed with 100g deionized water, and sol was carried out in a constant temperature water bath at 85°C. During the sol process, the raw materials were properly stirred to absorb water and swell and dissolve for 2 hours;

[0034] 2) Degassing of gelatinization: After the sol is completed, put the gelatinization in a constant temperature water bath at 60°C to degas for 2.5 hours, and set aside;

[0035] 3) Embryo dipping in glue: Select a suitable type of capsule mold, first smear an appropriate amount of corn oil on the surface of...

Embodiment 3

[0037] The one-time molding preparation method of the sodium alginate / starch-based enteric-coated hollow capsule of embodiment three comprises the following steps:

[0038] 1) Ingredients and sol: 70% starch, 2.2% high-viscosity sodium alginate with a viscosity of 450mPa·s, 14.5% low-viscosity sodium alginate with a viscosity of 5mPa·s, 5% gellan gum, and 11.7% glycerol The weight percentage of each raw material was mixed, and all raw materials were mixed with 100g deionized water, and sol was carried out in a constant temperature water bath at 75°C. During the sol process, the raw materials were properly stirred to absorb water and swell and dissolve for 2 hours;

[0039] 2) Degassing of gelatinization: After the sol is completed, put the gelatinization in a constant temperature water bath at 58°C to degas for 2.5 hours, and set aside;

[0040] 3) Embryo dipping in glue: select a suitable type of capsule mold, first apply an appropriate amount of corn oil on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com