Preparation method and application of maltodextrin

A maltodextrin and jet liquefaction technology, applied in the field of maltodextrin, can solve the problems of high cost of maltodextrin, low clarity of maltodextrin, shortened shelf life, etc., and achieves good viscosity stability and freeze-thaw stability, The product structure is fine and uniform, and the viscosity and melting rate are reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

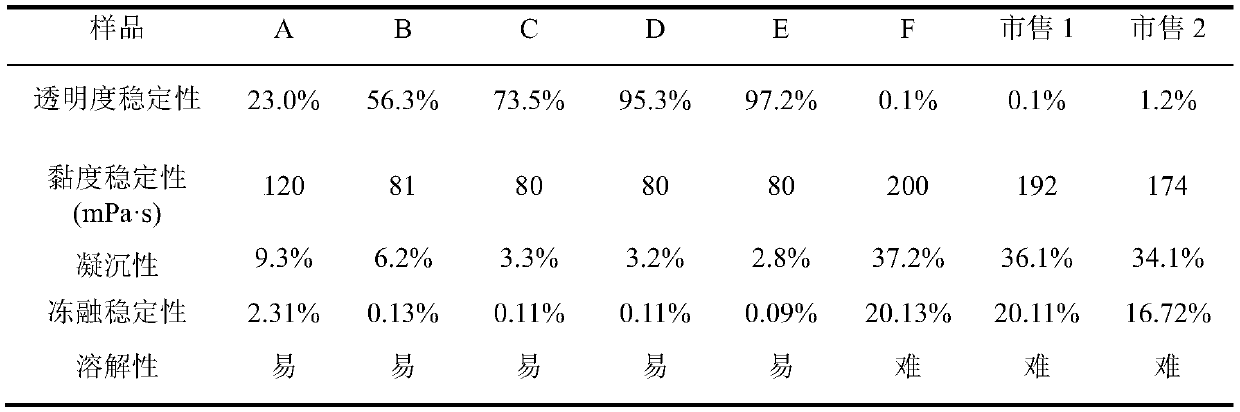

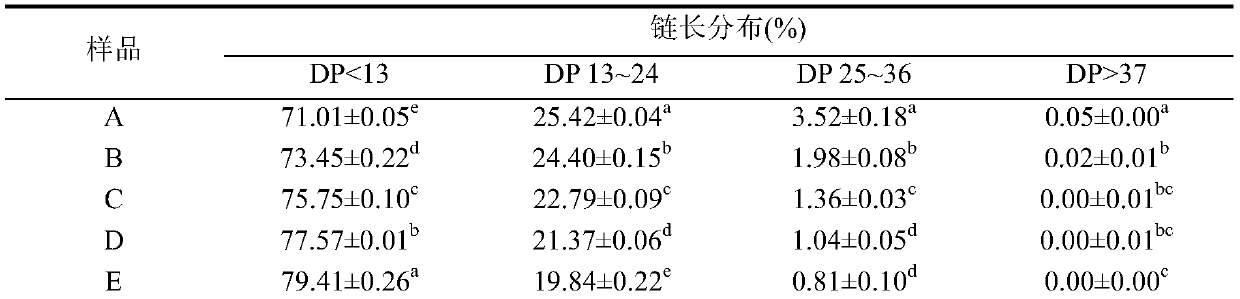

[0052] Example 1: Preparation of maltodextrin by three-step liquefaction

[0053] Add the corn starch raw material into the starch milk adjusted to 30%, and keep it warm at 60°C for 0.5h; add 2U / (g starch) high-temperature-resistant α-amylase, then add calcium chloride to make the final mass concentration reach 0.1%, and adjust the pH to 6.5; liquefy with one spray at 95°C and maintain it in a laminar flow tank for 10 minutes; then add 8U / (g starch) high temperature-resistant α-amylase, liquefy with a second spray at 95°C and maintain it in a laminar flow tank for 20 minutes; Perform three jet liquefaction at 130°C to inactivate the enzyme; enter the flash tank to cool down to 55°C, and reduce the pressure to normal pressure; add 50U / (g starch) starch branching enzyme, adjust the pH to 7.0, and react for 4 hours; heat up to 90°C to inactivate the enzyme 40min; use a plate and frame filter to filter, the pressure is controlled at 0.3MPa; after filtration, add 0.5% activated car...

Embodiment 2

[0054] Embodiment 2: the selection of starch branching enzyme reaction time

[0055] The method of Example 1 was adopted to prepare maltodextrin, and the starch branching enzyme reaction time was adjusted. The starch branching enzyme reaction time was changed to 8 hours to obtain maltodextrin product C; the starch branching enzyme reaction time was changed to 12 hours to obtain maltodextrin product D; the starch branching enzyme reaction time was changed to 16 hours to obtain maltodextrin product E.

Embodiment 3

[0076] Example 3: Preparation of ice cream using maltodextrin

[0077]Adding maltodextrin to ice cream will give the product a uniform tissue state, a smooth and delicate taste, ideal expansion rate and suitable melting resistance. Therefore, the maltodextrin prepared in the examples and comparisons was applied to ice cream to better evaluate the actual application effect of the maltodextrin. The ice cream is made with the following formula: 12% soft white sugar, 8% whole milk powder, 5% maltodextrin, 2% fructose syrup, 1% margarine, 0.4% ice cream emulsification stabilizer, and 71.6% water. Ice cream is prepared according to the following basic process: mixing of raw and auxiliary materials → adding water to dissolve (40-50°C) → mixing and sterilization (85°C, 10min) → high-pressure homogenization (65°C, 10min, pressure 180-200Bar) → ripening and aging (4°C ,3h) → condensing → filling → hardening (-35°C, 30min) → refrigeration (-18°C) → finished product, to obtain ice cream....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com