Low-carbon low-alloy chromium-molybdenum steel plate for pressure vessel and heat treatment method for steel plate

A heat treatment method and pressure vessel technology, applied in the field of steel plate manufacturing, can solve the problems of complex production process, high production cost, difficulty in taking into account production cost and product qualification rate, etc., and achieve the effects of simple process, low cost and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

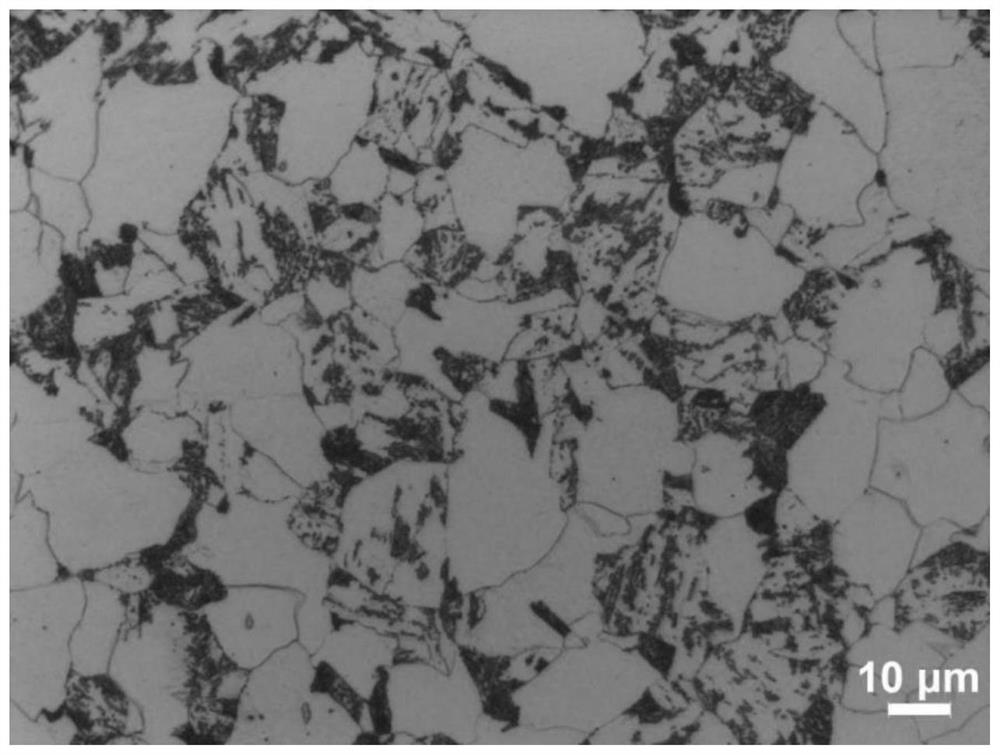

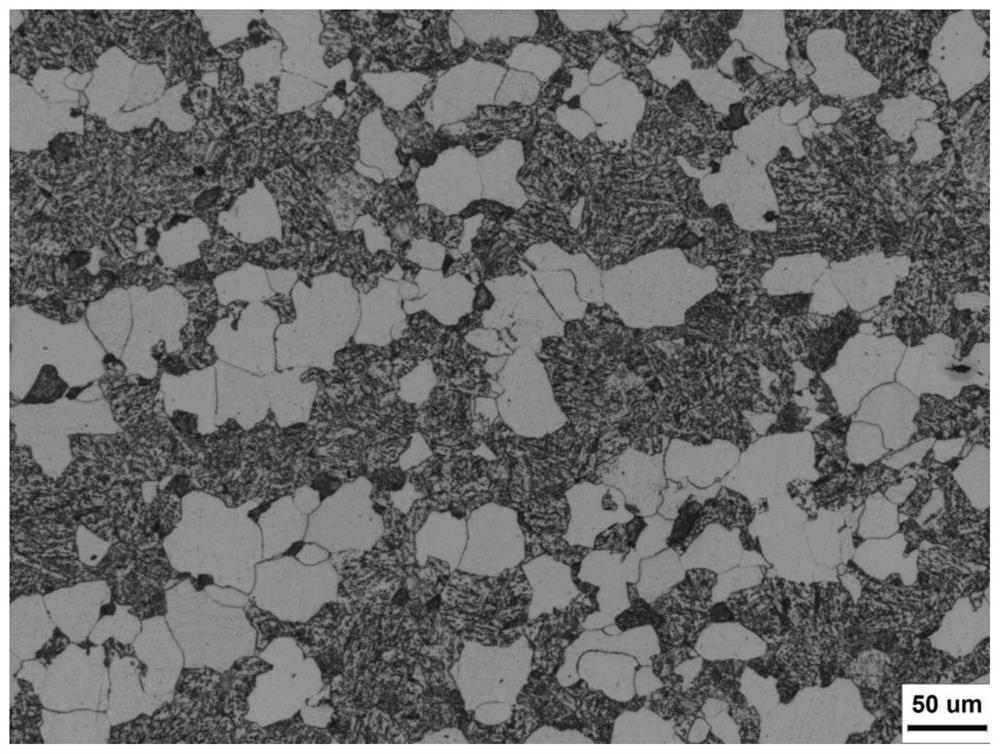

Image

Examples

Embodiment 1

[0027] This example is a 15CrMoR steel plate with a thickness of 25 mm. The chemical composition of the steel plate is: C=0.14, Cr: 0.87, Mo: 0.48, Mn: 0.44, Si: 0.23, P: 0.01, S : 0.0019, Alt: 0.036, Sn: 0.003, As: 0.0066, Sb: 0.0018, the balance is Fe and unavoidable impurity elements, tempering embrittlement coefficient X: 12.8ppm, tempering embrittlement coefficient calculation formula is: X =(10P+5Sb+4Sn+As)×10 -2 .

[0028] The heat treatment method of the steel plate includes normalizing and tempering processes, and the specific process steps are as follows:

[0029] Normalizing: put the steel plate into the furnace at room temperature, and heat it up to 910°C with the furnace temperature rising. After the furnace temperature rises to 910°C, heat preservation starts. The heat preservation time coefficient is 2.2min / mm. After heat preservation, it is taken out of the furnace and air-cooled;

[0030] Tempering: The steel plate is put into the furnace at room temperature...

Embodiment 2

[0033] This embodiment is a 15CrMoR steel plate with a thickness of 28.5 mm. The chemical composition of the steel plate is as follows in terms of mass percentage (wt, %): C=0.15, Cr: 0.98, Mo: 0.46, Mn: 0.52, Si: 0.23, P: 0.01, S: 0.0025, Alt: 0.029, Sn: 0.003, As: 0.0067, Sb: 0.0018, the balance is Fe and unavoidable impurity elements, the tempering embrittlement coefficient X: 12.8ppm, the tempering embrittlement coefficient calculation formula is: X=(10P+5Sb+4Sn+As)×10 -2 .

[0034] The heat treatment method of the steel plate includes normalizing and tempering processes, and the specific process steps are as follows:

[0035] Normalizing: put the steel plate into the furnace at room temperature, and heat it up to 920°C with the furnace temperature rising. After the furnace temperature rises to 920°C, heat preservation starts. The heat preservation time coefficient is 2.2min / mm. After the heat preservation is completed, it is out of the furnace and air cooled;

[0036] T...

Embodiment 3

[0039] This example is a 32mm thick 15CrMoR steel plate. The chemical composition of the steel plate is: C=0.14, Cr: 1.03, Mo: 0.47, Mn: 0.53, Si: 0.24, P: 0.006, S : 0.0011, Alt: 0.03, Sn: 0.002, As: 0.006, Sb: 0.0019, the balance is Fe and unavoidable impurity elements, tempering embrittlement coefficient X: 11.4ppm, tempering embrittlement coefficient calculation formula is: X =(10P+5Sb+4Sn+As)×10 -2 .

[0040] The heat treatment method of the steel plate includes normalizing and tempering processes, and the specific process steps are as follows:

[0041] Normalizing: put the steel plate into the furnace at room temperature, and heat it up to 910°C with the furnace temperature rising. After the furnace temperature rises to 910°C, heat preservation starts. The heat preservation time coefficient is 2.2min / mm. After heat preservation, it is taken out of the furnace and air-cooled;

[0042] Tempering: The steel plate is put into the furnace at room temperature, and heated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com