Method for preparing uvioresistant APET composite film

An anti-ultraviolet and film technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of no anti-ultraviolet function, complicated preparation process, poor practicability, etc., and achieve long-lasting anti-ultraviolet function , excellent mechanical properties and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

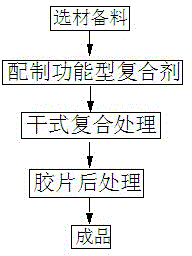

Image

Examples

Embodiment 1

[0015] The specific preparation process of the anti-ultraviolet APET composite film mentioned in the present invention is as follows:

[0016] a) Material selection and preparation, the APET composite film is composed of an inner layer and an outer layer. The inner layer is made of PE film with a thickness of about 0.07mm; the outer layer is made of APET sheet with a thickness of about 0.25mm; the function used when the two layers are combined The main components and percentage ratio of the compound agent are: triazine ultraviolet absorber 30%, acrylate adhesive 40%, and the rest are auxiliary agents; auxiliary agents include ethanol diluent, calcium-zinc composite stabilizer, Glyceryl tristearate dispersant, diphenylamine antioxidant, etc., the percentage of diluent accounts for about 18%-20%;

[0017] b) Prepare functional composite agent, the preparation process is as follows: First, add acrylate adhesive and related additives to the mixing tank, control the temperature of ...

Embodiment 2

[0021] The specific preparation process of the anti-ultraviolet APET composite film mentioned in the present invention is as follows:

[0022] a) Material selection and preparation, the APET composite film is composed of an inner layer and an outer layer. The inner layer is made of PE film with a thickness of about 0.08mm; the outer layer is made of APET sheet with a thickness of about 0.26mm; the function used when the two layers are combined The main components and percentage ratio of the compound agent are: triazine ultraviolet absorber 32%, acrylate adhesive 38%, and the rest are additives; additives include ethanol diluent, calcium-zinc composite stabilizer, Glyceryl tristearate dispersant, p-diphenylamine antioxidant, etc., the percentage of diluent accounts for about 16%-18%;

[0023] b) Prepare functional composite agent, the preparation process is as follows: first, add acrylate adhesive and related additives to the mixing tank, control the temperature of the mixing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com