Nitrogen-containing germanium carbon alloy membrane material and preparation method thereof

An alloy film and germanium carbon technology, which is applied in the field of film materials and their preparation for improving the hardness and optical band gap of germanium carbon alloy films, can solve the problems of narrow optical band gap, influence on thermal imaging effect, low light absorption, etc. And the effects of good and stable mechanical properties, good application prospects and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adjust the distance between the target and the substrate to be 8±0.5cm; pump the vacuum chamber of the deposition system to 2×10 with mechanical pump and molecular pump respectively -3 Below Pa, discharge gas N 2 、CH 4 , Ar is sent from the bottom of the vacuum chamber, and the three gases are mixed into the vacuum reaction chamber by a gas regulating valve and each mass flow meter at a certain ratio. A vacuum pump is connected below the reaction chamber system to control the pressure of the reaction chamber at 0.7 ~1.0Pa.

[0025] Before formal deposition, pre-sputter the Ge target with pure Ar for 5 to 15 minutes to remove residual pollutants on the target. When formally deposited, N 2 、CH 4 , Ar three-way gases are introduced into the reaction vacuum chamber at the same time, and the positive ions generated by their ionization bombard the Ge target upward under the action of the electric field, and the sputtered Ge particles are combined with N 2 、CH 4 The plas...

Embodiment 2

[0038] The preparation process is the same as in Example 1.

[0039] The preparation conditions are as follows.

[0040] Target material: single crystal Ge(111);

[0041] Discharge gas: Ar (99.99%), CH 4 (99.99%) and N 2 (99.99%);

[0042] Single crystal Si substrate temperature: 200°C, or hot-pressed ZnS substrate;

[0043] RF power: 150W;

[0044] Substrate bias: floating potential (Floating);

[0045] Ar and CH 4 The flows are 38.3SCCM and 4.8SCCM respectively, and the flow ratio is 8;

[0046] N 2 Flow: 18SCCM;

[0047] The sputtering time was 20 minutes.

[0048] Test Results:

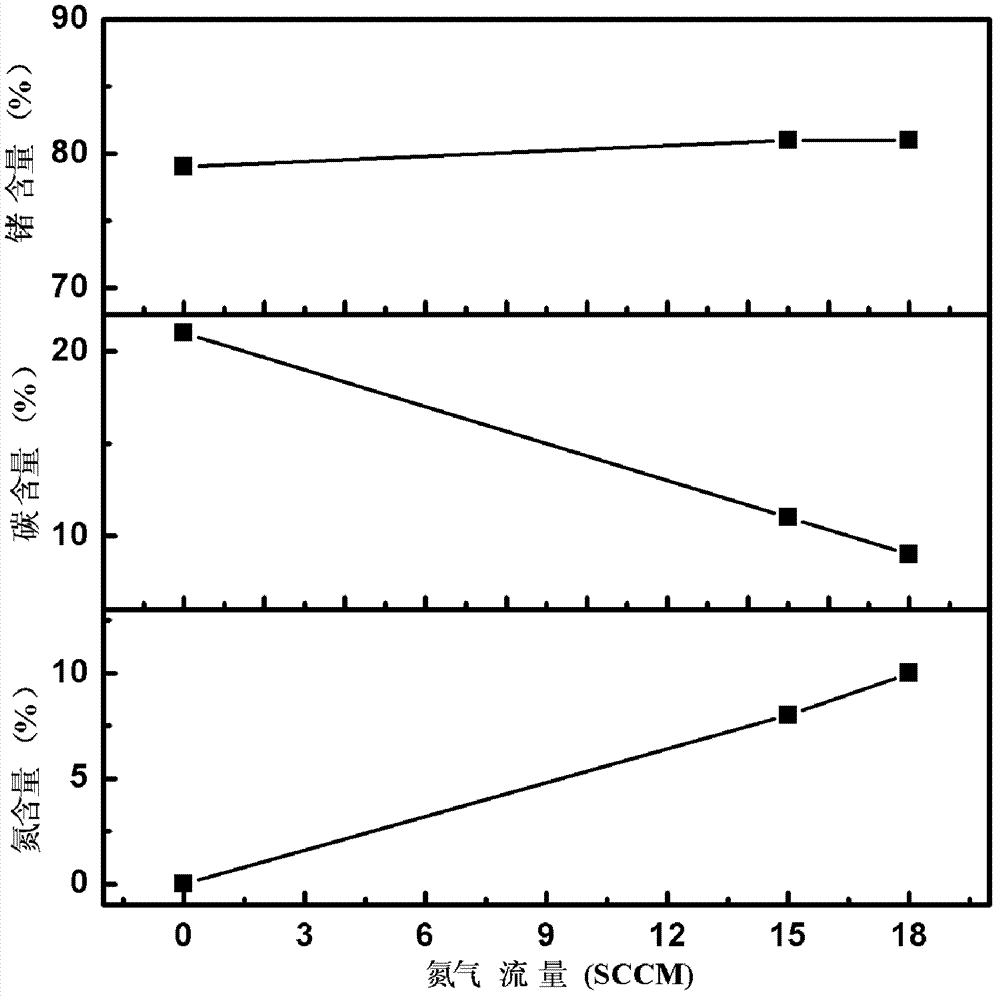

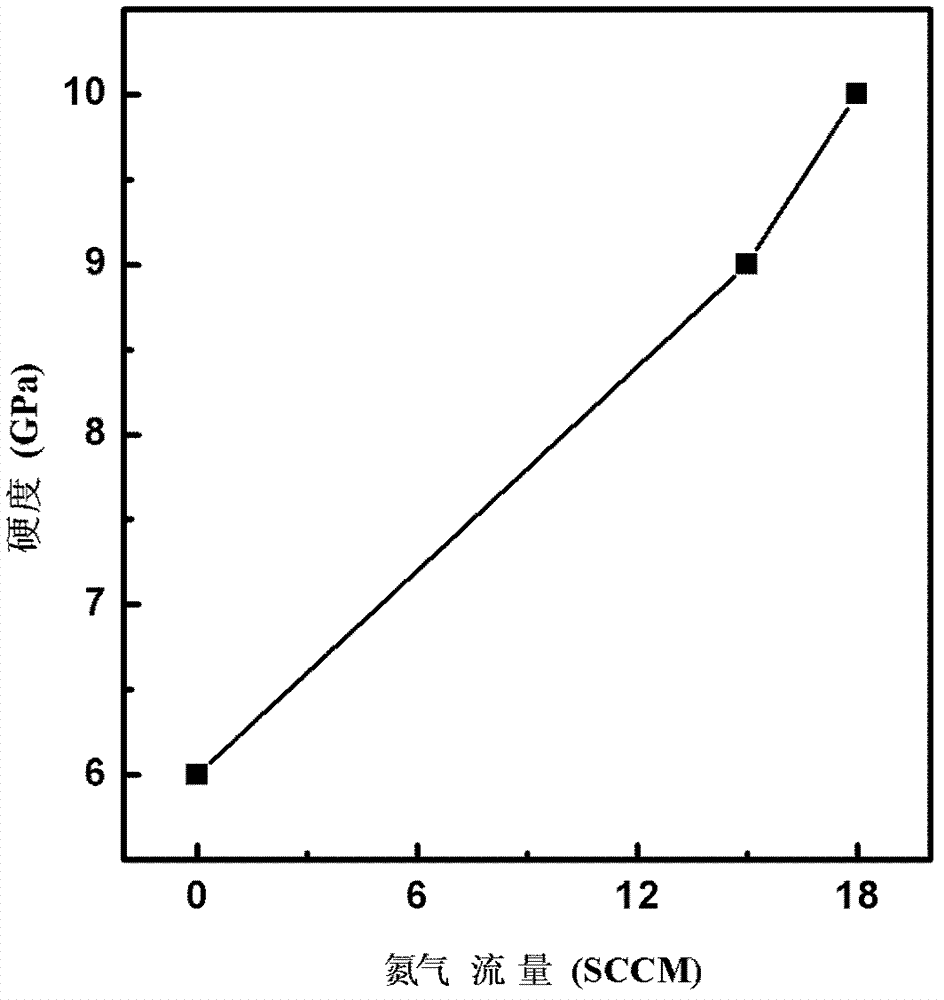

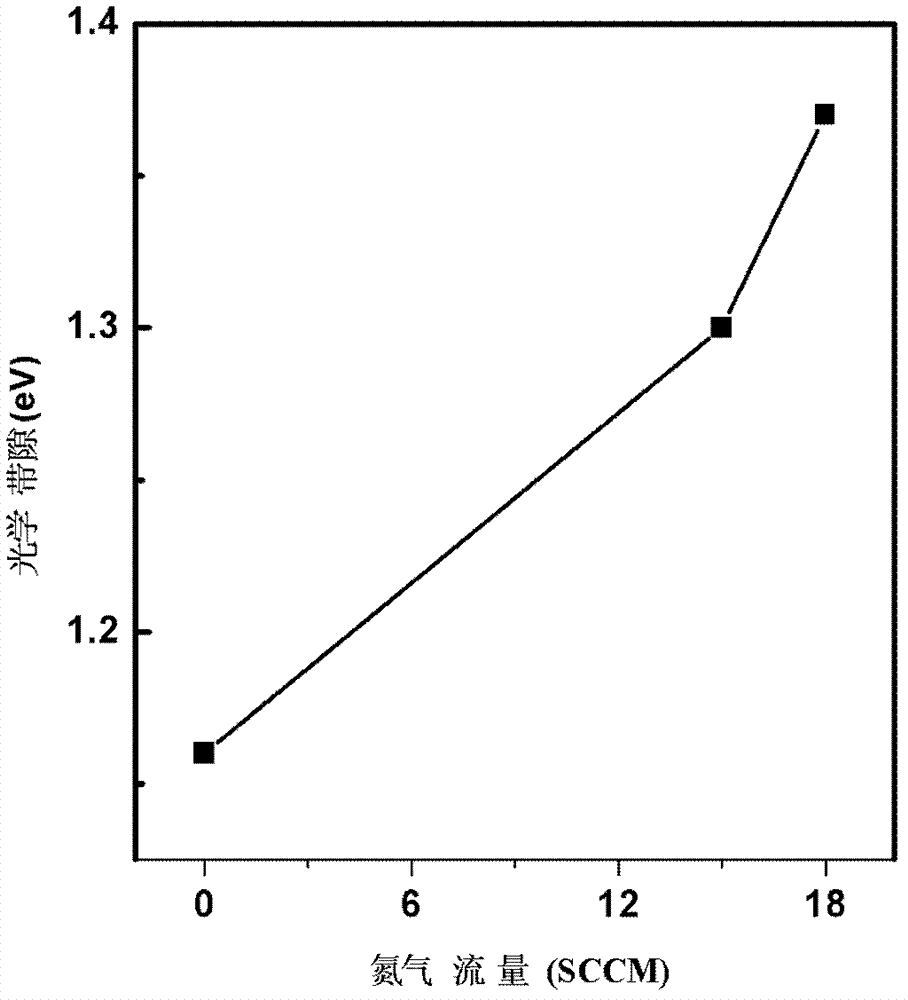

[0049] A nitrogen-containing germanium-carbon alloy film (such as figure 1), the film thickness is 824nm, and the stress is 0.667GPa, which is lower than the stress (1.106GPa) of the nitrogen-free germanium-carbon alloy film, indicating that the nitrogen-containing germanium-carbon alloy film is more stable. The hardness and the optical bandgap of nitrogen-containing germanium-carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com