A Ni-based welding rod for 9% Ni steel for overhead welding

A nickel-based electrode, 9% Ni technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of excellent low-temperature impact toughness, excellent mechanical properties, and excellent joint bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited to these examples.

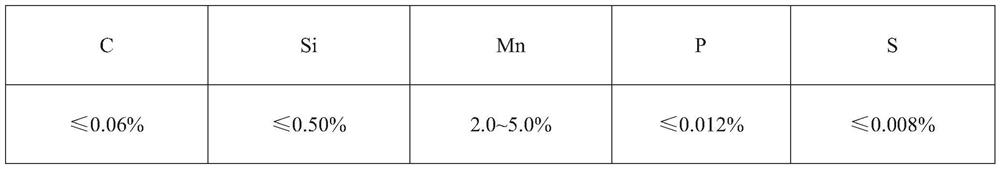

[0054] A nickel-based electrode for bonding is made of a nickel-based electrode, which is composed of a dielectric core and a pharmaceutical, and the drug intake is applied to the outer wall of the die. Iron welding core; its welding core component (weight percentage%) is shown in Table 1:

[0055] Table 1: Welding core components

[0056]

[0057]

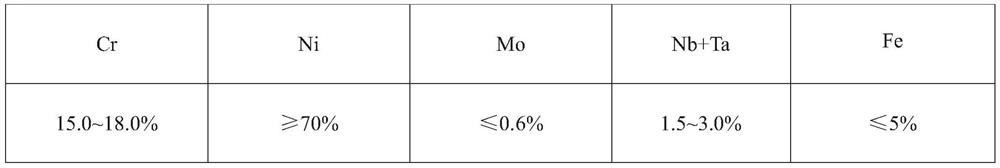

[0058] Table 2: Welding core components (weight percent) in Examples 1 to 5

[0059]

[0060] Hydrographic Caco 3 -MGCO 3 -CAF 2 The low hydrogen residue is 0.3 to 0.5, the core is 2.6 mm, 3.2 mm, and the pharmaceutical group of 3.2 mm, and the pharmaceutical group of each embodiment.

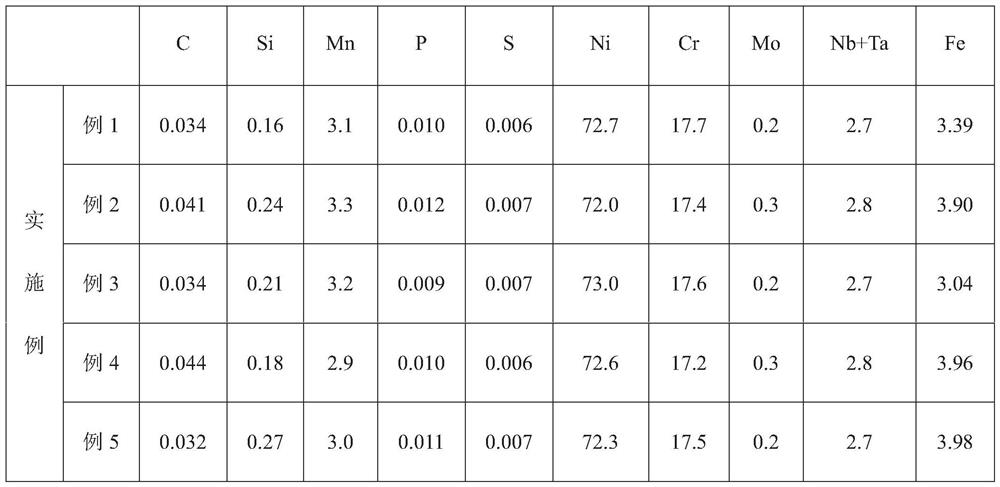

[0061] Table 3: Embodiment of the pharmaceutical epidermal (weight percent)

[0062]

[0063]

[0064] The results of each embodiment correspond to its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com