High-entropy alloy particle refined and reinforced aluminum-based composite material and preparation method thereof

A high-entropy alloy and composite material technology, which is applied in the field of high-entropy alloy particle-reinforced aluminum-based composite materials and their stirring casting preparation technology, can solve the problems of inability to wet and disperse the aluminum alloy matrix, poor dispersion of microscopic parts, high-entropy alloy Poor dispersion and other problems, to achieve the effect of smooth and clean interface, good high temperature stability and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of high-entropy alloy particle refinement reinforced aluminum matrix composite material:

[0033] Step 1. Preparation of high-entropy alloy powder:

[0034] First of all, AlCoCrFeNi high-entropy alloy particles are selected as the reinforcing phase, and the ratio of each component is 1:1:1:1:1. According to the molar atomic ratio and mass fraction of each element, the mass of each component is calculated, weighed and packed Into a stainless steel ball mill tank, the process control agent is absolute ethanol, vacuumized, filled with argon, and then mechanically alloyed on a planetary ball mill tank for 60 hours, the ball-to-material ratio is 8:1, and the rotation speed is 250r / min. The high-entropy alloy powder is produced, and the particle size after sieving is 1-20 μm.

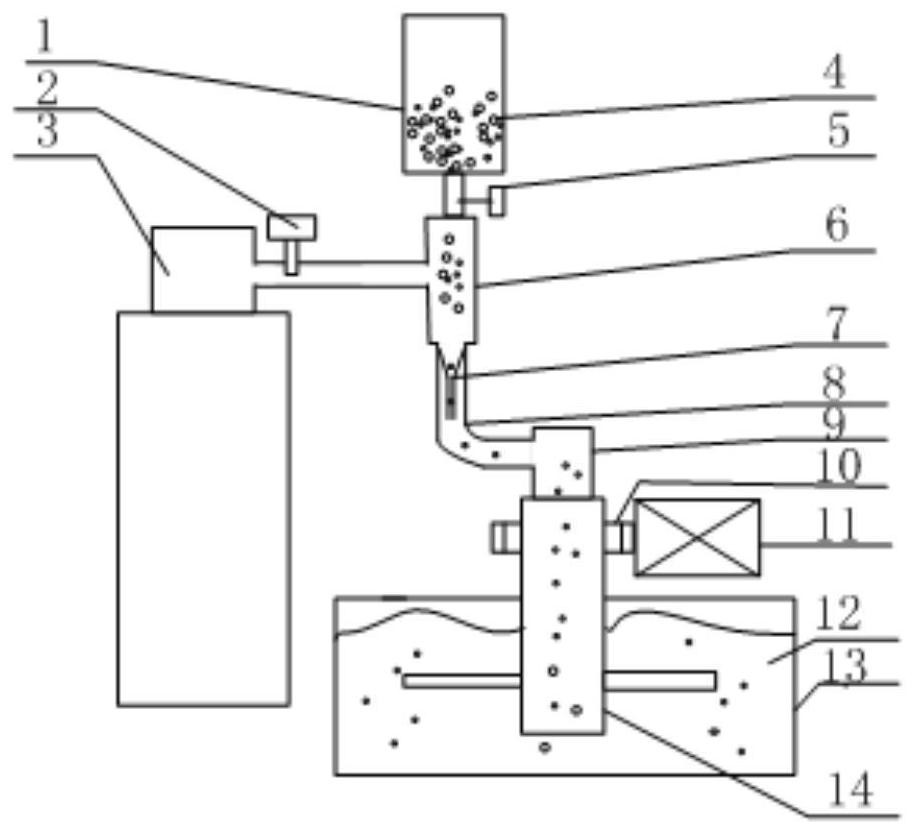

[0035] Step 2. Introduce the high-entropy alloy powder into the aluminum alloy matrix using a gas stirring and dispersing device, and perform vibration treatment:

[0036] Weigh ...

Embodiment 2

[0040] A preparation method of high-entropy alloy particle refinement reinforced aluminum matrix composite material:

[0041] Step 1. Preparation of high-entropy alloy powder:

[0042] First of all, AlCoCrFeCu series high-entropy alloy particles are selected as the reinforcing phase, and the ratio of each component is 1:1:1:1:1. According to the molar atomic ratio and mass fraction of each element, the mass of each component is calculated, weighed and packed Into a stainless steel ball mill tank, the process control agent is absolute ethanol, vacuumized, filled with argon, and then mechanically alloyed on a planetary ball mill tank for 50 hours, the ball-to-material ratio is 8:1, and the rotation speed is 280r / min. The high-entropy alloy powder is produced, and the particle size after sieving is 2-10 μm.

[0043] Step 2. Introduce the high-entropy alloy powder into the aluminum alloy matrix using a gas stirring and dispersing device, and perform vibration treatment:

[0044]...

Embodiment 3

[0048] A preparation method of high-entropy alloy particle refinement reinforced aluminum matrix composite material:

[0049] Step 1. Preparation of high-entropy alloy powder:

[0050] First, the reinforcing phase is made of CoCrFeNiCu high-entropy alloy particles, and the specific composition is CoCrFeNiCu0.25Ti0.25Mn0.25. According to the molar atomic ratio and mass fraction of each element, the mass of each component is calculated, weighed and put into a stainless steel ball mill tank In the process, the process control agent is anhydrous ethanol, vacuumized, filled with argon, and then mechanically alloyed on a planetary ball mill for 65 hours, with a ball-to-material ratio of 8:1 and a rotational speed of 300r / min, to prepare a high-entropy alloy Powder, particle size after sieving is 1-15μm.

[0051] Step 2. Introduce the high-entropy alloy powder into the aluminum alloy matrix using a gas stirring and dispersing device, and perform vibration treatment:

[0052] Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com