Electro-slag-welding welding construction method for partition plate of special-shaped box-type structure

A box-shaped structure and electroslag welding technology, which is applied in the field of building steel structure construction, can solve the problems of molten pool overflow, lack of fusion, and low qualification rate, and achieve the effect of ensuring welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

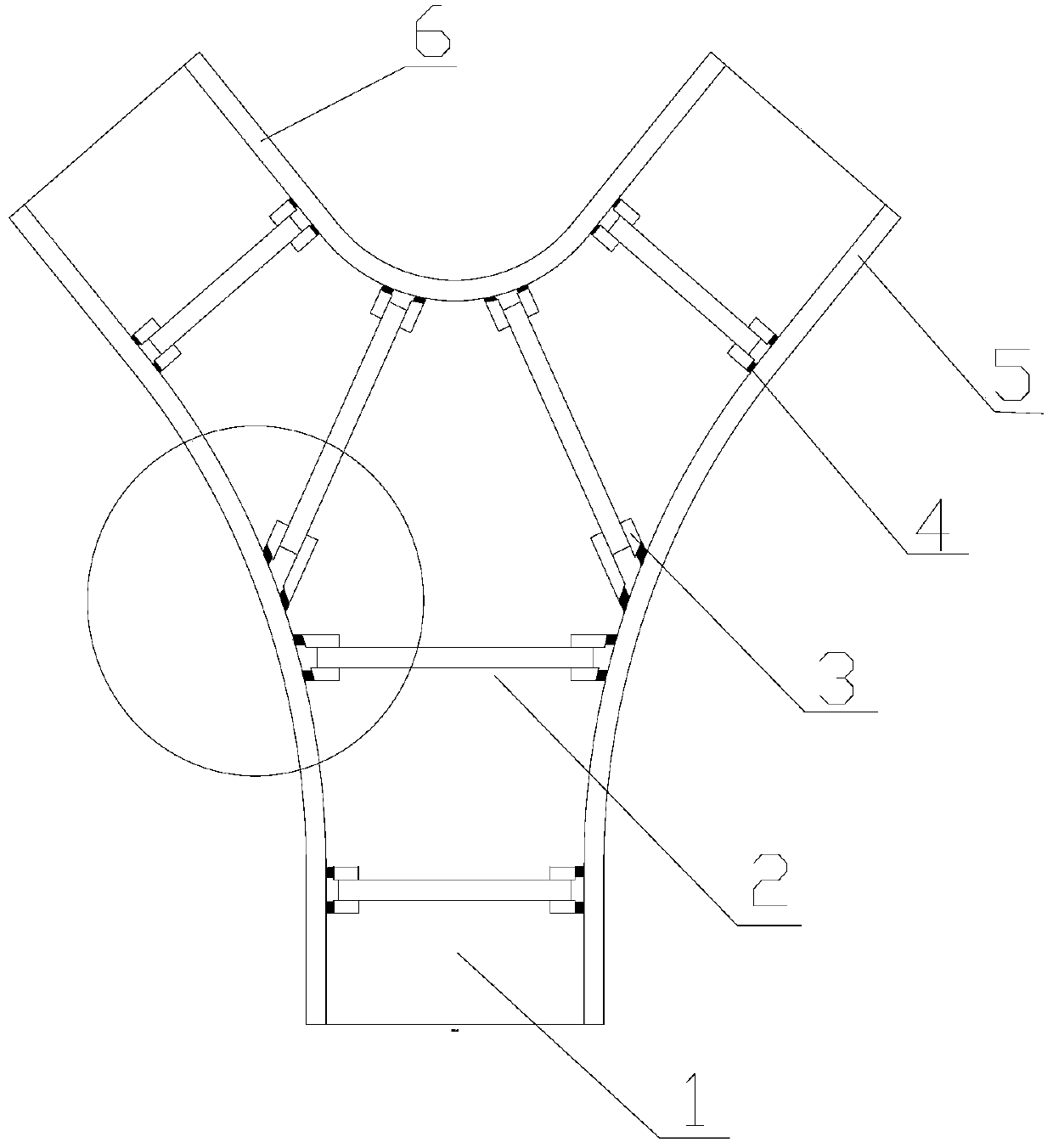

[0023] The specific embodiment of the present invention adopts following steps construction:

[0024] 1. The Y-shaped wing plate 1 is drawn by CAD software at 1:1, and then cut and blanked by a CNC flame cutting machine. The accuracy error is controlled within 1mm.

[0025] 2. The first web 5 and the second web 6 are manually set out at a ratio of 1:1, cut by a semi-automatic cutting machine, and then arcs are made by rolling plate mechanism, and the precision error is controlled within 2mm.

[0026] 3. Partition 2 adopts manual 1:1 lofting and semi-automatic cutting machine blanking, and the accuracy error is controlled within 1mm.

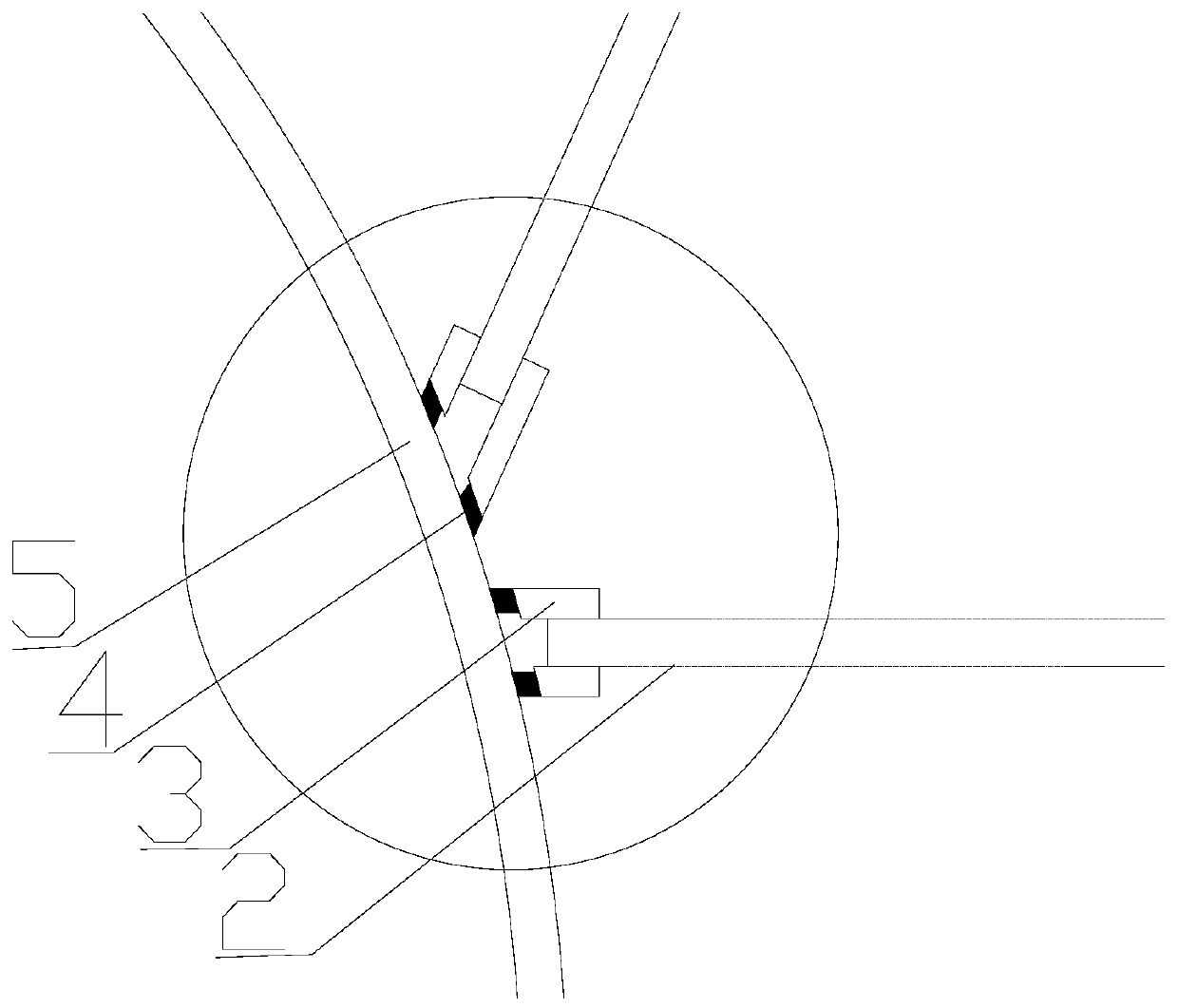

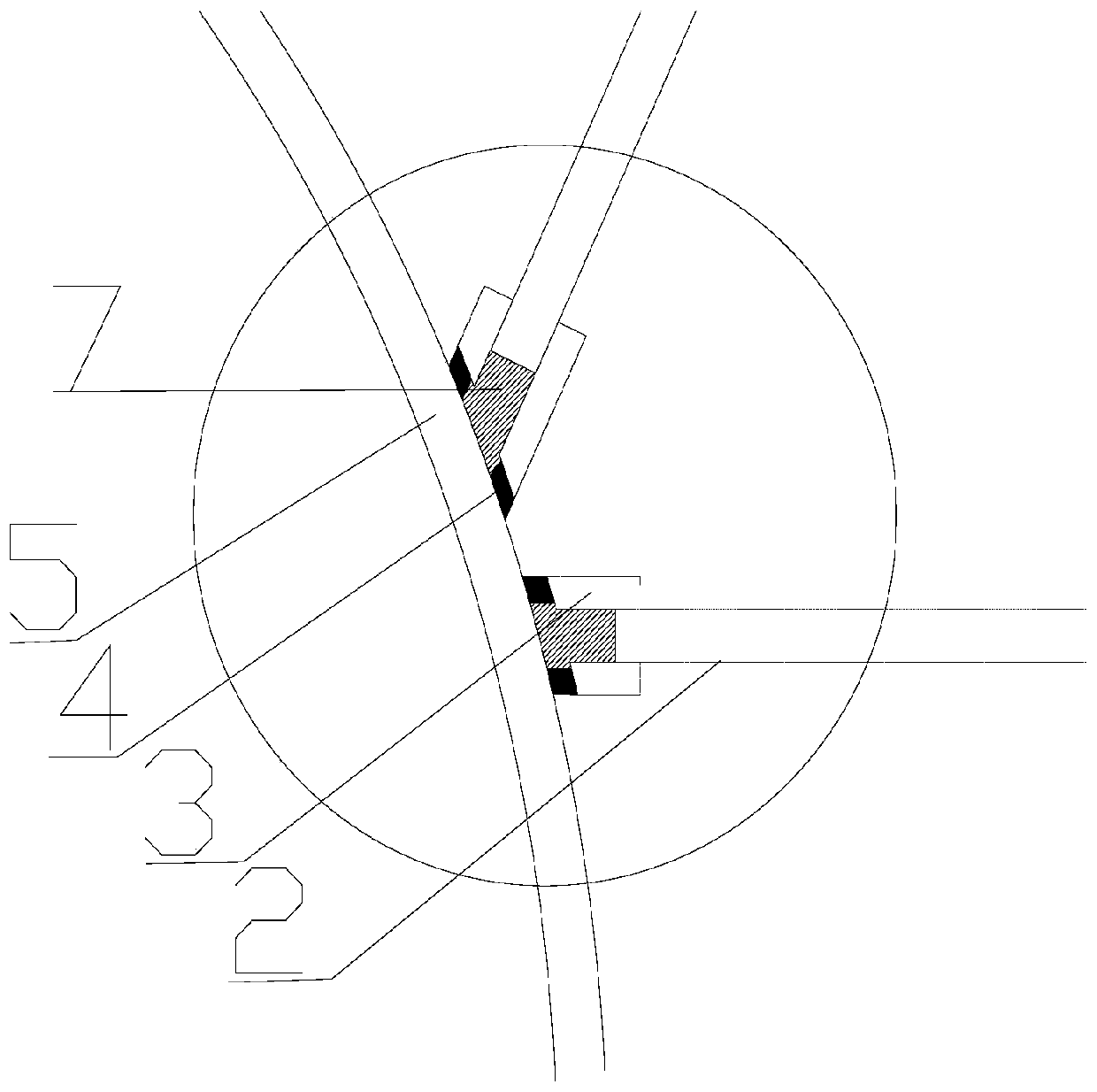

[0027] 4. Electroslag welding lining strip 3 adopts manual 1:1 lofting, semi-automatic cutting machine blanking, and bevel cutting, and the error is controlled within 1mm.

[0028] 5. Assemble the partition plate 2 and the electroslag welding lining strip 3, and weld with carbon dioxide gas shielded welding, and the error is controlled within 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com