Production method for Al-Zn-Mg-Cu series aluminum alloy panel for safety shoe box toes

A technology of aluminum alloy plate and production method, which is applied in the field of aluminum alloy, can solve problems such as unstable electrical conductivity, low electrical conductivity, and poor surface quality of the plate, and achieve the effects of excellent mechanical properties, stable mechanical properties, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

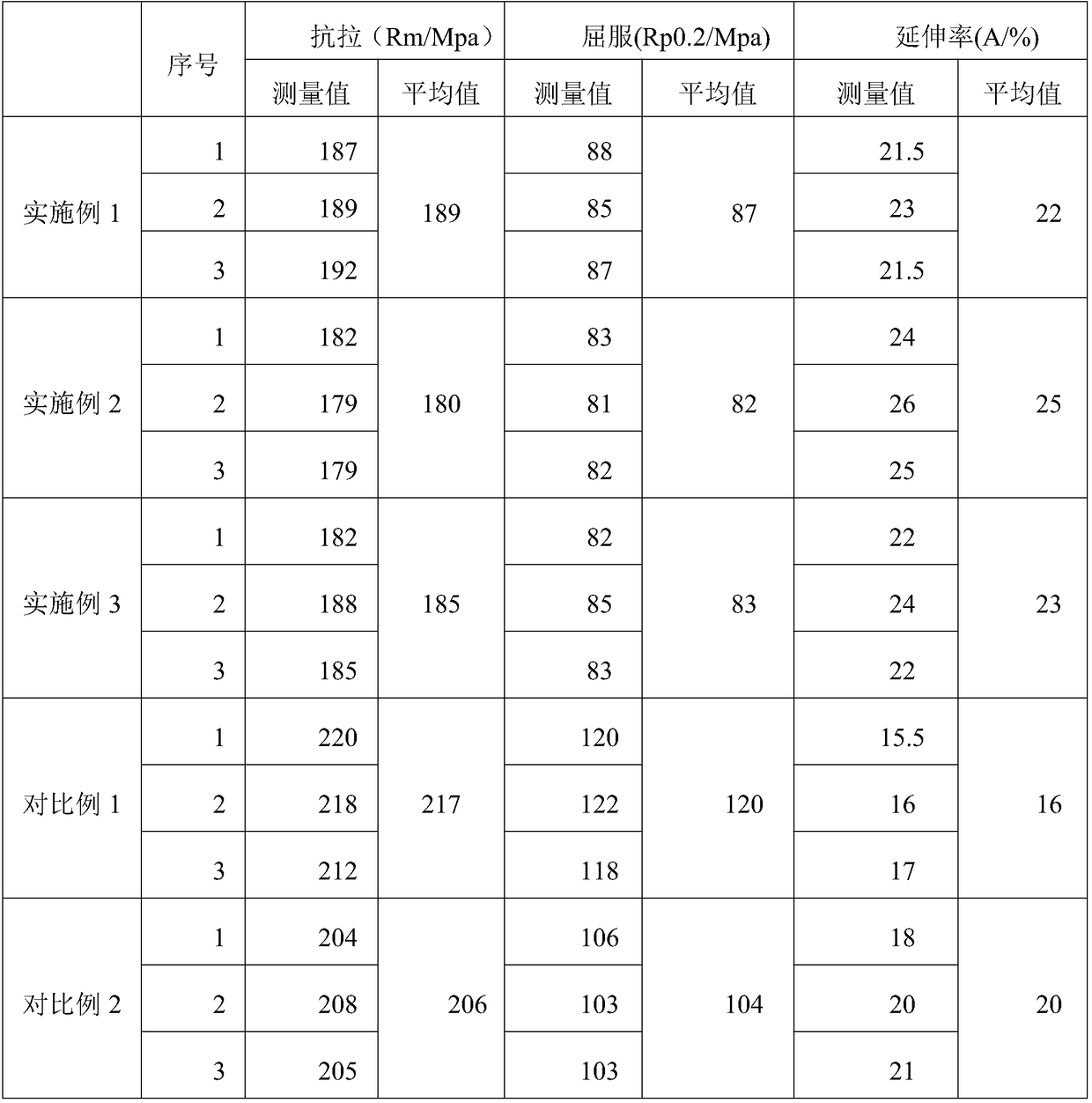

Embodiment 1

[0029] Melting and casting aluminum alloy slabs with the following components, the chemical components in the aluminum alloy slabs are: Si0.07, Fe 0.13, Cu 1.2, Mn 0.05, Mg 2.3, Cr 0.18, Zn 5.4, Ti 0.02, Yu The amount is composed of Al and unavoidable impurities; after the aluminum alloy melt is degassed and refined, it is cast into a 490×1600mm aluminum alloy flat ingot by the hot top semi-continuous casting method;

[0030] Preheating: Place the cast ingot in a pit furnace, heat it to 380°C, keep it warm for 1 hour, and then release it from the furnace.

[0031] Hot rolling: hot rough rolling of the preheated ingot to a 15mm thickness plate, transfer to hot finish rolling, rolling to a 4mm coil, trimming to 50mm.

[0032] Cold rolling: After 2 passes, the reduction in a single pass is 40-45%, and the coil is rolled to a thickness of 1.4mm.

[0033] Heavy coil cleaning: Use 50°C high-pressure water to clean the residual rolling oil in the cold-rolled coil, and use a high-pre...

Embodiment 2

[0040] Melting and casting aluminum alloy slabs with the following components, the chemical components in the aluminum alloy slabs are: Si0.05, Fe 0.11, Cu 1.5, Mn 0.03, Mg 2.5, Cr 0.25, Zn 5.8, Ti 0.1, Yu The amount is composed of Al and unavoidable impurities; after the aluminum alloy melt is degassed and refined, it is cast into a 490×1600mm aluminum alloy flat ingot by the hot top semi-continuous casting method;

[0041] Preheating: Place the cast ingot in a pit furnace, heat it to 450°C, keep it warm for 8 hours, and then release it from the furnace.

[0042] Hot rolling: Hot rough rolling of the preheated ingot to 20mm thick plate, transfer to hot finish rolling, rolling to 7mm coil, trimming to 90mm.

[0043] Cold rolling: After 2 passes, the reduction in a single pass is 40-45%, and the coil is rolled to a thickness of 2.5mm.

[0044] Heavy coil cleaning: Use 60°C high-pressure water to clean the residual rolling oil in the cold-rolled coil, and use a high-pressure pu...

Embodiment 3

[0051] Melting and casting aluminum alloy slabs with the following components, the chemical components in the aluminum alloy slabs are: Si0.03, Fe 0.09, Cu 2.0, Mn 0.02, Mg 2.8, Cr 0.28, Zn 6.1, Ti 0.2 balance It is composed of Al and unavoidable impurities; after the aluminum alloy melt is degassed and refined, it is cast into a 490×1600mm aluminum alloy flat ingot by a hot-top semi-continuous casting method;

[0052]Preheating: Place the cast ingot in a pit furnace, heat it to 480°C, keep it warm for 12 hours, and then release it from the furnace.

[0053] Hot rolling: hot rough rolling of the preheated ingot to 25mm thick plate, transfer to hot finish rolling, rolling to 9mm coil, trimming to 120mm.

[0054] Cold rolling: after 1 pass, the single-pass reduction is 45%, and the coil is rolled to a thickness of 5.0mm.

[0055] Heavy coil cleaning: Use 80°C high-pressure water to clean the residual rolling oil in the cold-rolled coil, and use a high-pressure purge device to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com