Profile punching table with electromagnet spring damping and protecting structures

A protection structure and electromagnet technology, applied in the field of profile stamping, can solve the problems of poor fixation and vibration reduction effect of the stamping table, the stamping table does not have the function of lifting and lowering, and the fixing effect of the stamping table plate is not good, so as to improve the anti-seismic ability, The effect of enhancing the firmness of the fixation and improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

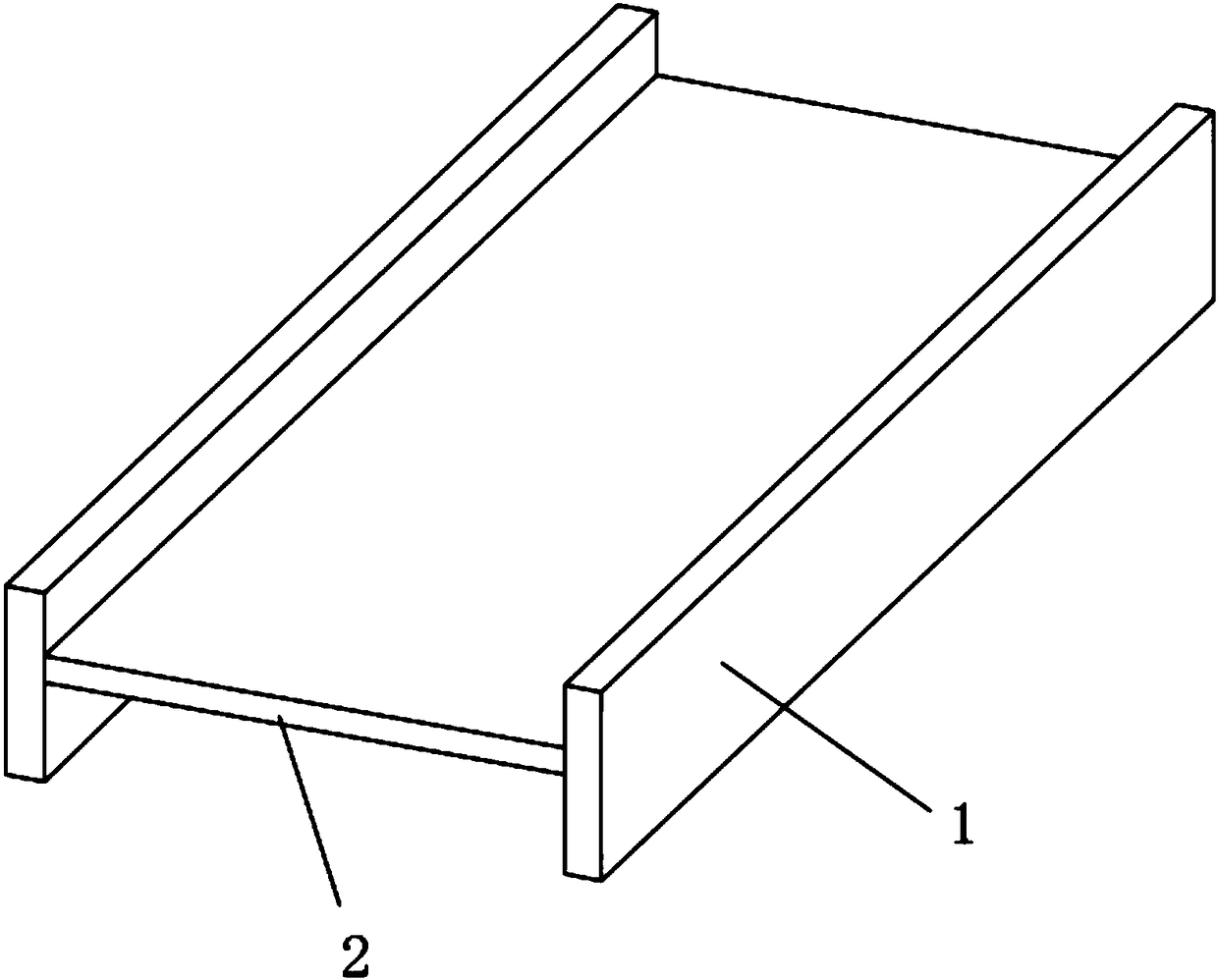

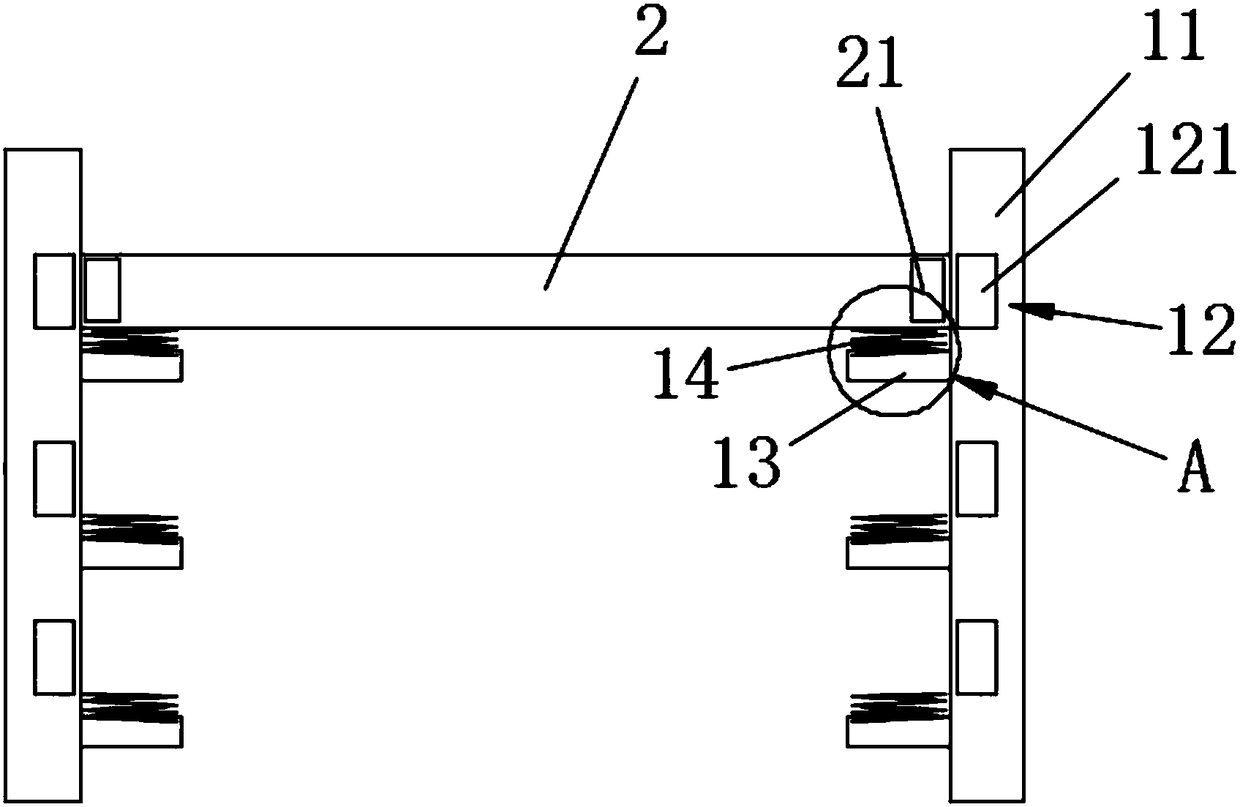

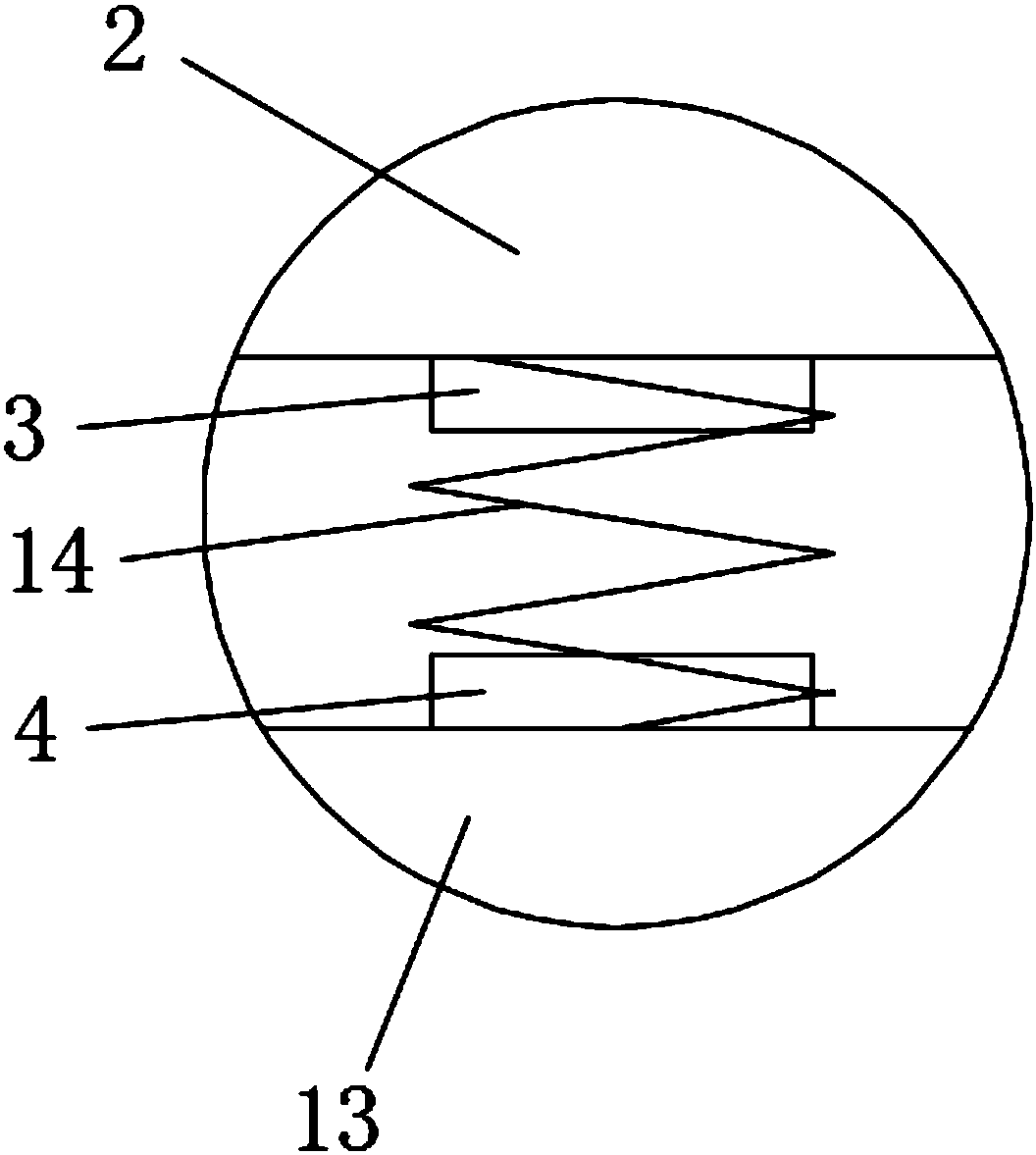

[0014] Please refer to Figure 1-3 , the embodiment of the present invention includes:

[0015] A profile punching table with an electromagnet spring vibration damping and protection structure, comprising a bracket 1, a punching platen 2 located above the bracket 1; the bracket 1 includes vertical plates 11 arranged on both sides, and the vertical plates 11 are fixedly connected with Three sets of electromagnet groups 12 arranged side by side, the electromagnet group 12 includes 8 electromagnets 121 in the same horizontal line on the vertical plate, the electromagnet 121 is connected with the battery and the switch, and the vertical plate 11 is provided with a battery compartment for placing the battery And the switch compartment for accommodating the switch, each electromagnet 121 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com