Fuel pipeline structure of vehicle

A technology for fuel pipelines and vehicles, which is applied to liquid fuel feeders, charging systems, combustion engines, etc. It can solve the problems of large size, increased weight, difficulty in ensuring space, and increased weight, etc., to achieve lightweight , shorten the wheel space, reduce the effect of vibration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

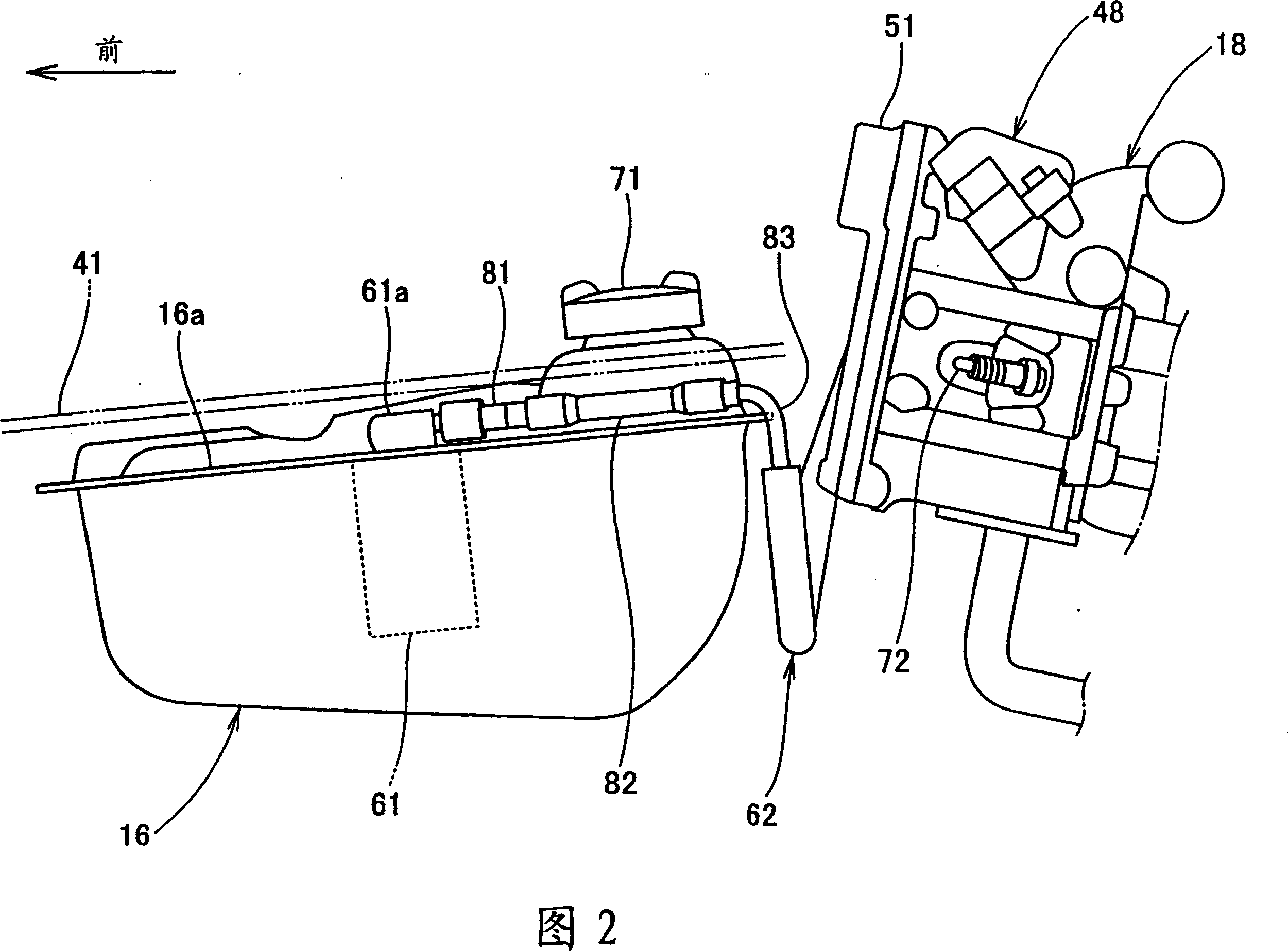

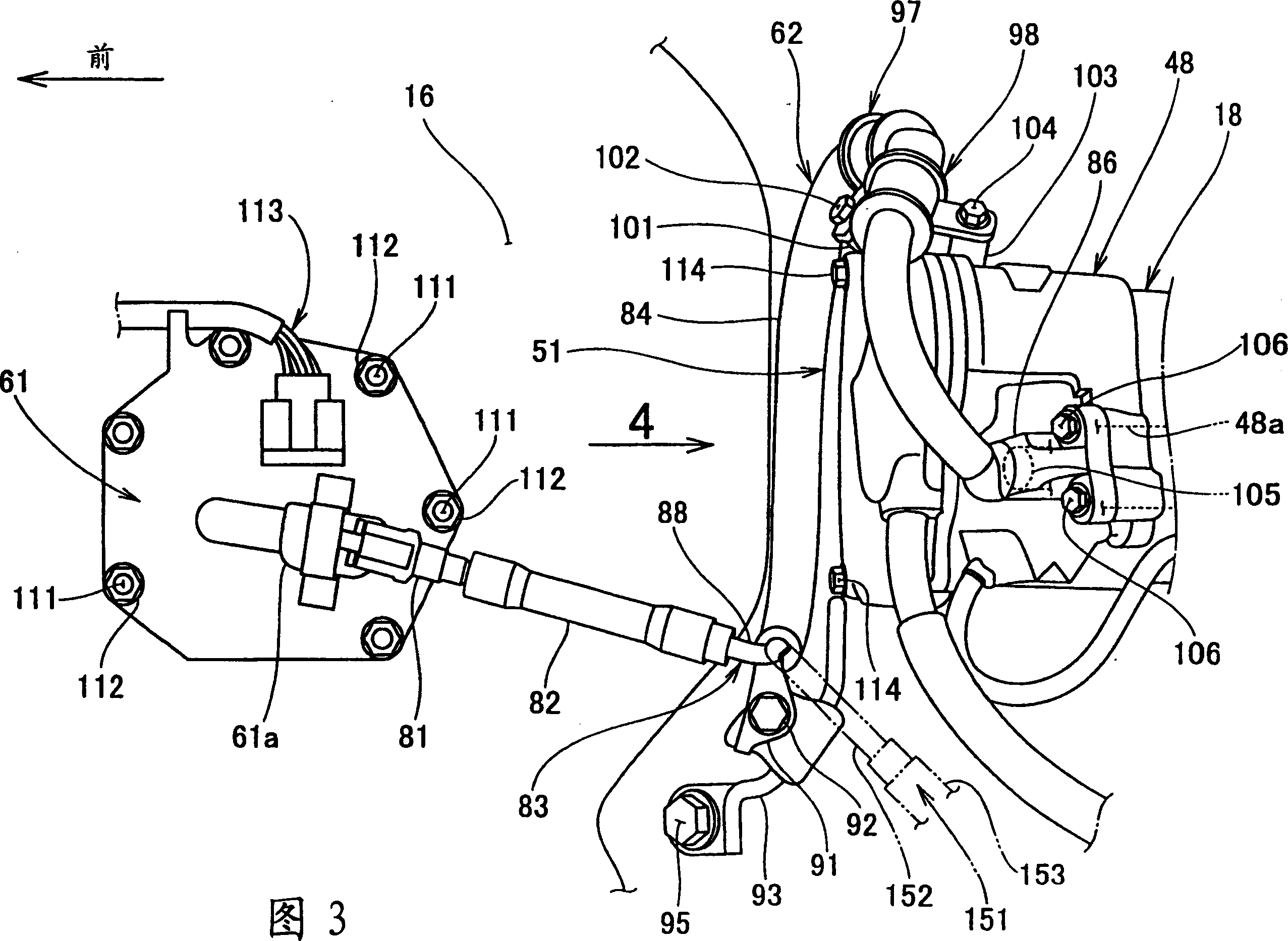

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In addition, the drawings are viewed towards the symbol.

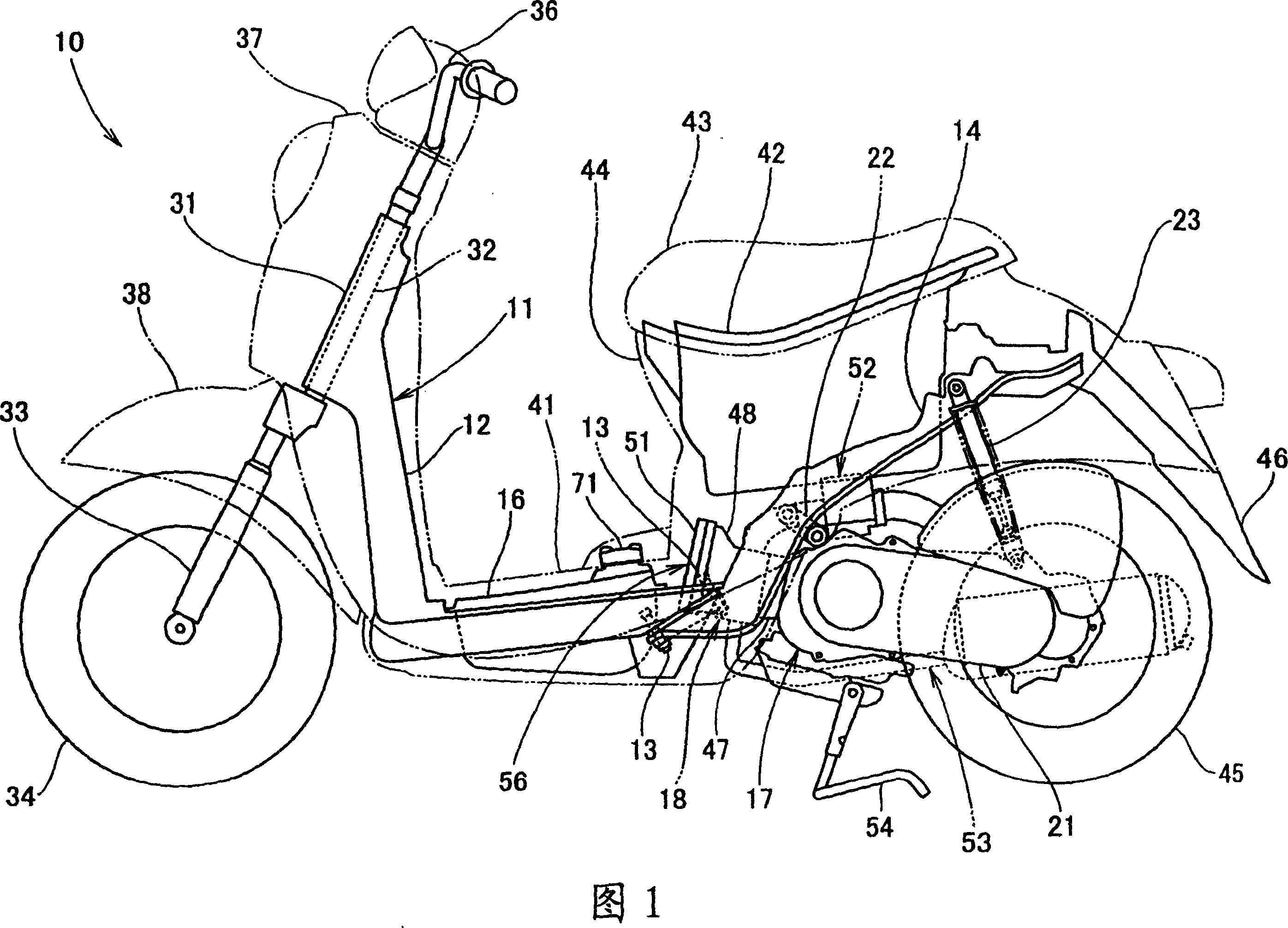

[0037] Fig. 1 is the side view of vehicle of the present invention, and the vehicle frame 11 of vehicle 10 is installed on the rear frame of the rear portion of this front frame 12 by front frame 12 and with bolt 13... (... represents a plurality of, hereinafter the same) 14, a fuel tank 16 is mounted on the lower part of the front frame 12, and a power assembly 17 that is substantially horizontal in the front and rear direction of the vehicle (by the engine 18 and connected to the rear frame 14) The power transmission mechanism 21 on the engine 18 constitutes), the rear portion of the power assembly 17 is installed on the rear portion of the rear frame 14 by the rear shock absorber assembly 23, is such a two-wheeled motorcycle.

[0038] Here, 31 is a head pipe mounted on the front frame 12, 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com