speaker module

A loudspeaker module and loudspeaker technology, applied in the direction of frequency/directional characteristic device, etc., can solve the problems such as the inability to meet the development direction of the miniaturization of the loudspeaker module, the noise of the loudspeaker module, the waste of vibration space, etc., to meet the requirements of the miniaturization development, vibration The effect of displacement equalization and high acoustic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

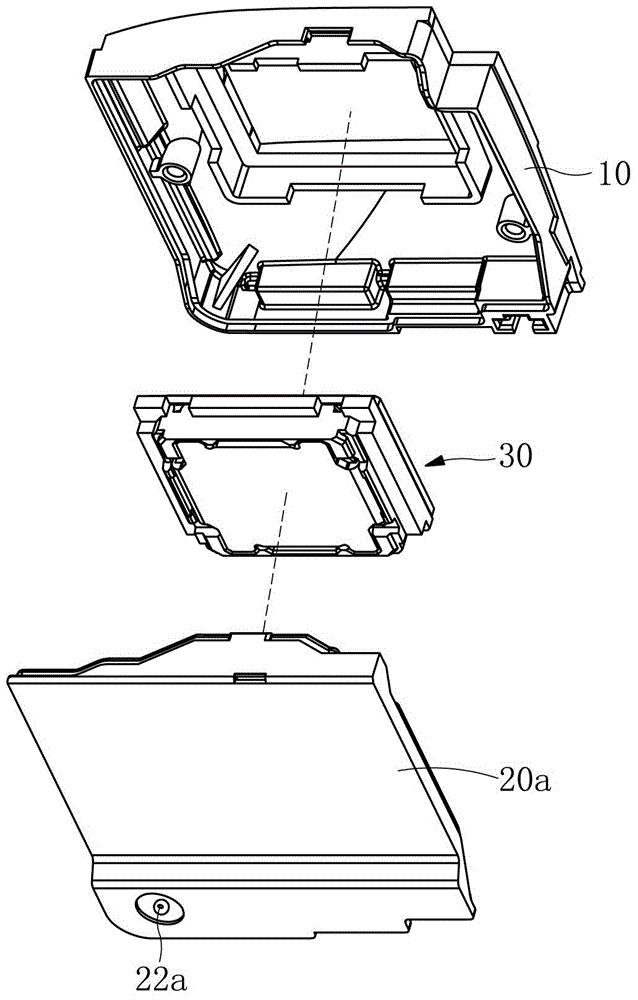

[0023] Such as figure 1 As shown, a loudspeaker module includes a combined module upper case 10 and a module lower case 20a, the space enclosed by the module upper case 10 and the module lower case 20a accommodates a speaker unit 30, and the speaker A rear acoustic cavity is formed between the unit 30 and the module lower shell 20a. A sound leakage hole 22a for adjusting the air pressure in the inner cavity of the module is provided at the position corresponding to the rear acoustic cavity on the lower module shell 20a.

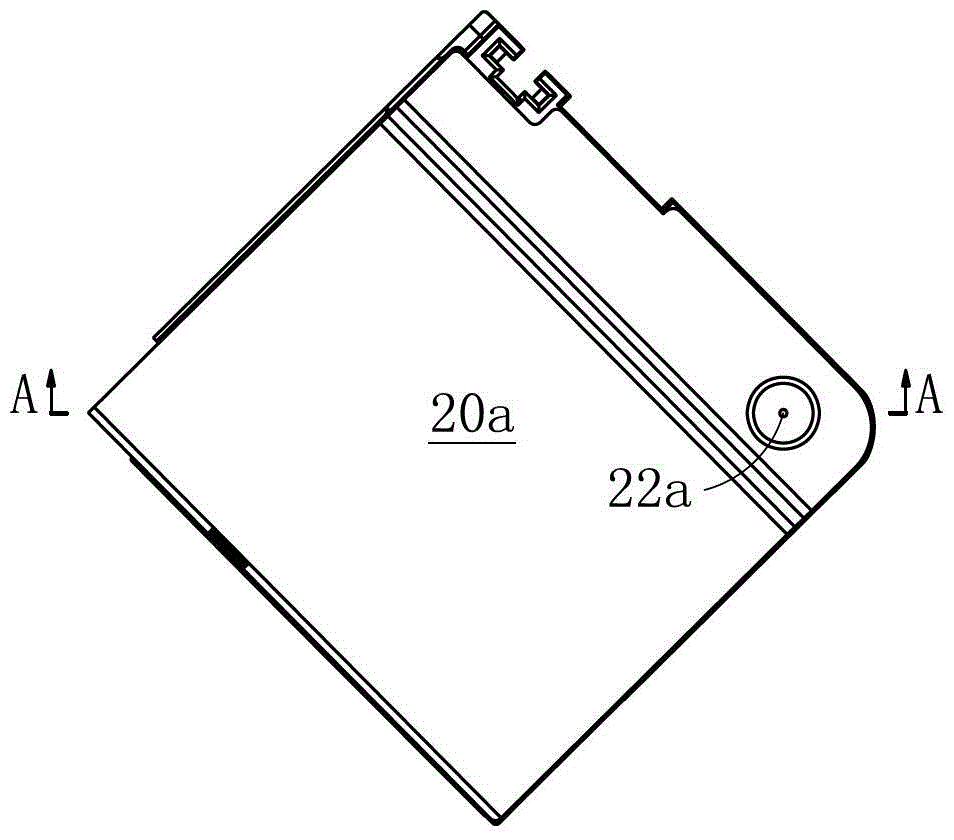

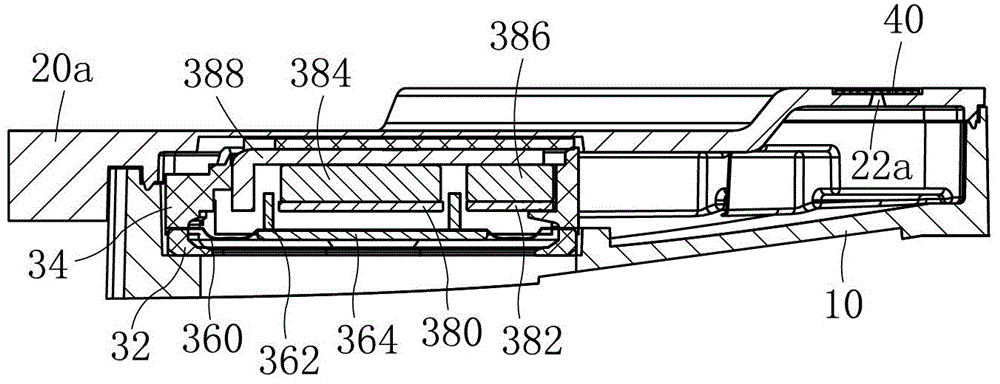

[0024] Such as figure 2 with image 3 Commonly shown, the side of the module lower case 20a close to the speaker unit 30 is defined as the inner side, the other side is the outer side, the sound leakage hole 22a is a conical structure, and the sound leakage hole 22a is located at one end of the outer side of the module lower case 20a The caliber is smaller, and one port located on the inner side of the module lower case 20a has a larger caliber. A dampin...

Embodiment 2

[0031] Such as Figure 5 As shown, the present embodiment is basically the same as Embodiment 1, the difference is:

[0032] The diameter of the sound leakage hole 22b located on the inner side of the module lower case 20b is smaller, and the diameter of the sound leakage hole 22b located on the outer side of the module lower case 20b is larger.

[0033] In this embodiment, the resistance of the air flow from the inner cavity of the module to the outside is large, and the resistance of the air flow from the outside to the inner cavity of the module is small, so that the air pressure inside the module is greater than the outside air pressure, and the downward vibration displacement of the diaphragm can be reduced , suitable for loudspeaker modules with large downward vibration displacement of the diaphragm.

[0034] The definition of the module upper shell and the module lower shell in the present invention is a common term in the field, and the side where the sound of the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com