Surface sensor chip packaging structure and manufacturing method

A sensor chip and package structure technology, which is applied in the field of surface sensor chip package structure and production, can solve the problems of large surface sensor chip package thickness, lower product reliability, and non-replacement, etc., to meet the needs of miniaturization development, The effect of reducing the package size and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

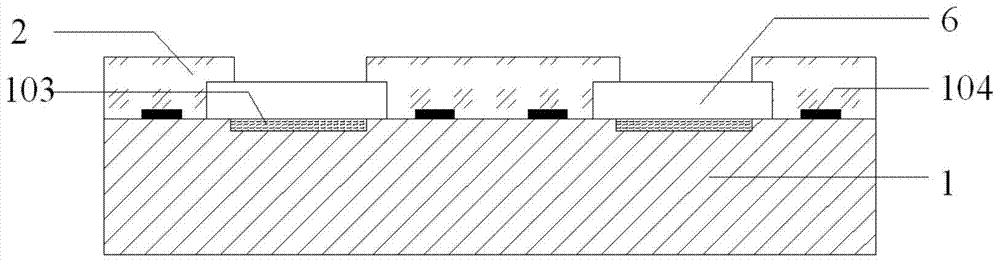

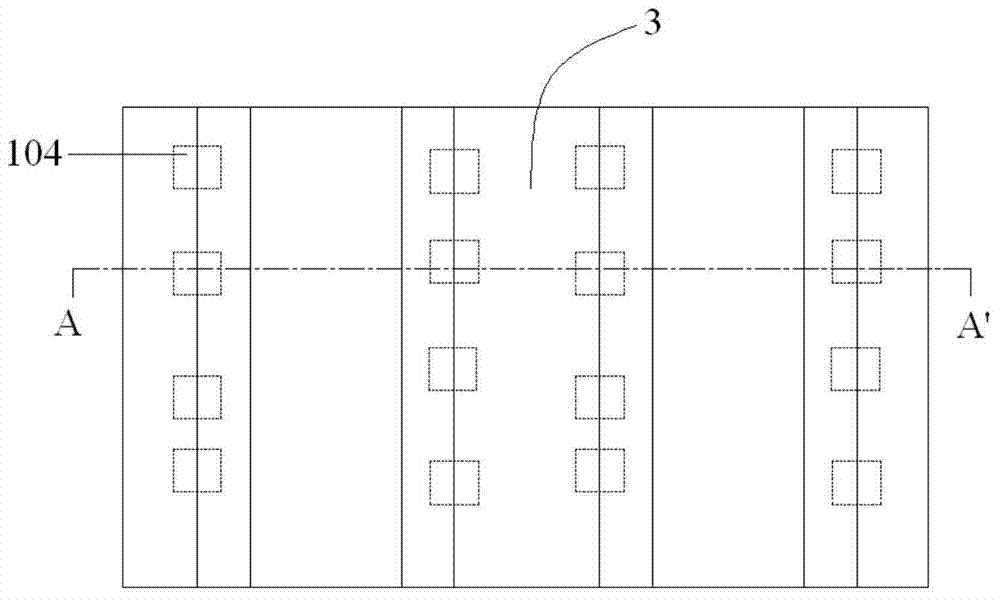

[0053] Such as Figure 11As shown, a surface sensing chip packaging structure includes a surface sensing chip having a first surface 101 and a second surface 102 opposite to each other, the first surface 101 has a sensing area 103 and a sensor located around the sensing area 103 Several welding pads 104 are electrically connected to the sensing area 103; the first plastic sealing layer 2 exposing the sensing area 103 is formed on the first surface 101, and the exposed sensing area 103 is formed on the first surface 101; A protective cover 6 is provided on the area 103; a first opening 3 is formed on the second surface 102 at a position opposite to each of the welding pads 104, and on the inner wall of the second surface 102 and the first opening 3 An insulating layer 4 exposing the welding pad 104 is formed, and a metal wiring layer 5 electrically connected to the exposed part of the welding pad 104 is formed on the insulating layer 4; a protective layer is formed outside the ...

Embodiment 2

[0068] This embodiment 2 includes all the technical features in embodiment 1, such as Figure 12 As shown, the difference is that there is another functional chip 9, the functional chip 9 is electrically connected to the metal wiring layer 5 on the second surface 102, and the functional chip 9 is fixed on the insulating layer on the second surface 102. layer 4 and the second plastic encapsulation layer 7 , and the functional chip 9 is electrically connected to the metal wiring layer 5 on the second surface 102 by wire bonding.

[0069] The manufacturing method of the package structure of the surface sensing chip of the present embodiment 2 comprises the following steps:

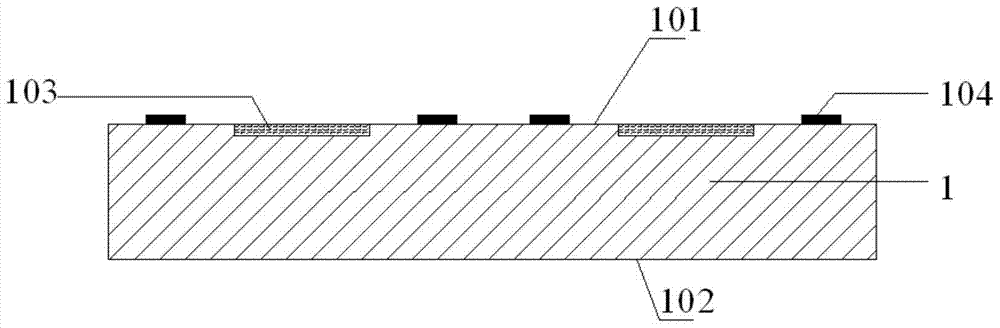

[0070] a. see figure 1 , prepare a wafer with several surface sensing chip units, each of the surface sensing chip units has a first surface 101 and a second surface 102 opposite to the first surface 101; the surface sensing chip unit The first surface 101 has a sensing area 103 and several welding pads 104...

Embodiment 3

[0081] This embodiment 3 includes all the technical features in embodiment 1, such as Figure 13 As shown, the difference is that 1. There is another functional chip 9, the functional chip 9 is electrically connected to the metal wiring layer 5 on the second surface 102, and the functional chip 9 is connected to the The metal wiring layer 5 on the second surface 102 is electrically connected. 2. The protective cover 6 covering the sensing area 103 formed on the first surface 101 is replaced by a layer of first plastic sealing layer 2, the first plastic sealing layer 2 covers the sensing area 103, and the first plastic sealing layer covering the sensing area 103 Layer 2 has a predetermined thickness, and the material of the first plastic encapsulation layer may have a relatively large Mohs hardness.

[0082] The manufacturing method of the package structure of the surface sensing chip of the present embodiment 3 comprises the following steps:

[0083] a. see figure 1 , prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com