Preparation method of electromagnetic shielding layer

An electromagnetic shielding layer and equipment technology, applied in the direction of copying/marking methods, coatings, circuits, etc., can solve the problems of high cost of PVD coating, unfavorable for PCBA miniaturization, etc., so as to achieve no need for long cycle time and high cost, and reduce materials Waste, simple effect of inkjet process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The application provides a preparation method of an electromagnetic shielding layer, the preparation method comprising:

[0031] S1. Plasma treatment is performed on the surface of the workpiece;

[0032] S2, prepare an insulating layer on the surface of the workpiece;

[0033] S3, using inkjet equipment, according to the inkjet graphic data, inkjet printing to form a spray coating on the surface of the workpiece;

[0034] S4, preparing a protective layer on the spray coating.

[0035] Specifically, the workpiece is a device such as a PCBA board or an FPC board welded with a high-frequency and high-speed semiconductor processor. It should be noted that the surface of the workpiece includes the surface of the PCBA board and the surface of the semiconductor processor located on the PCBA board.

[0036] Plasma treatment is to bombard the surface of the workpiece with a plasma gun, and the surface of the workpiece will form a concave-convex structure, which reduces the sm...

Embodiment 1

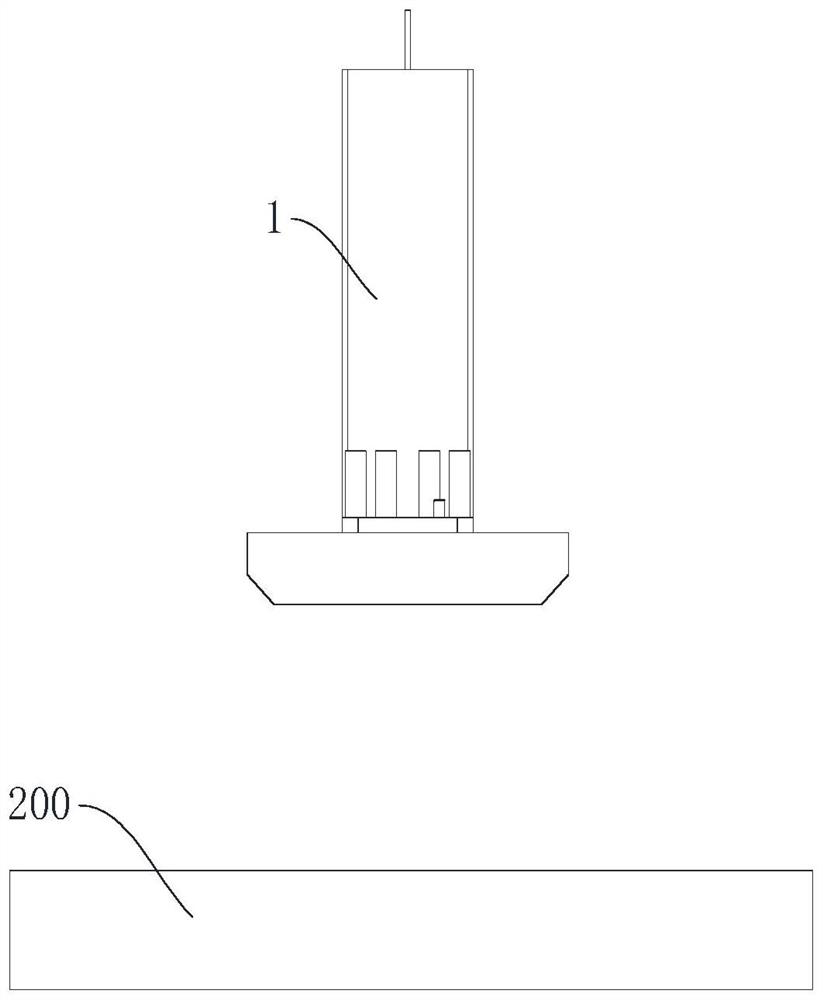

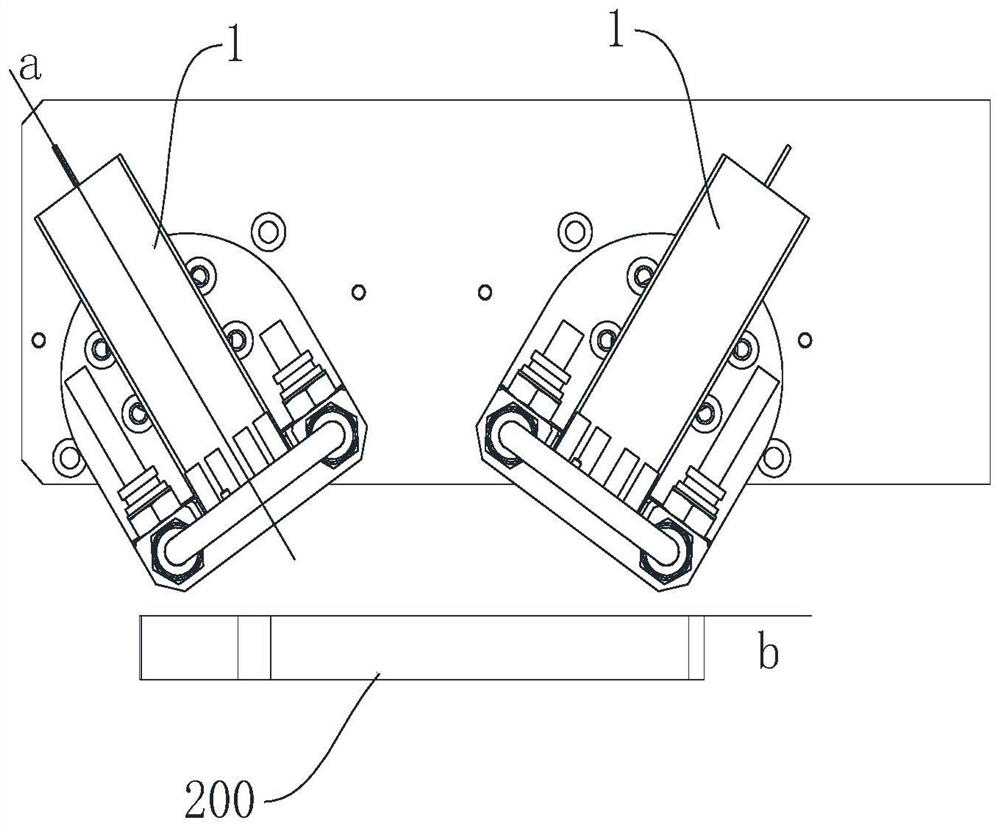

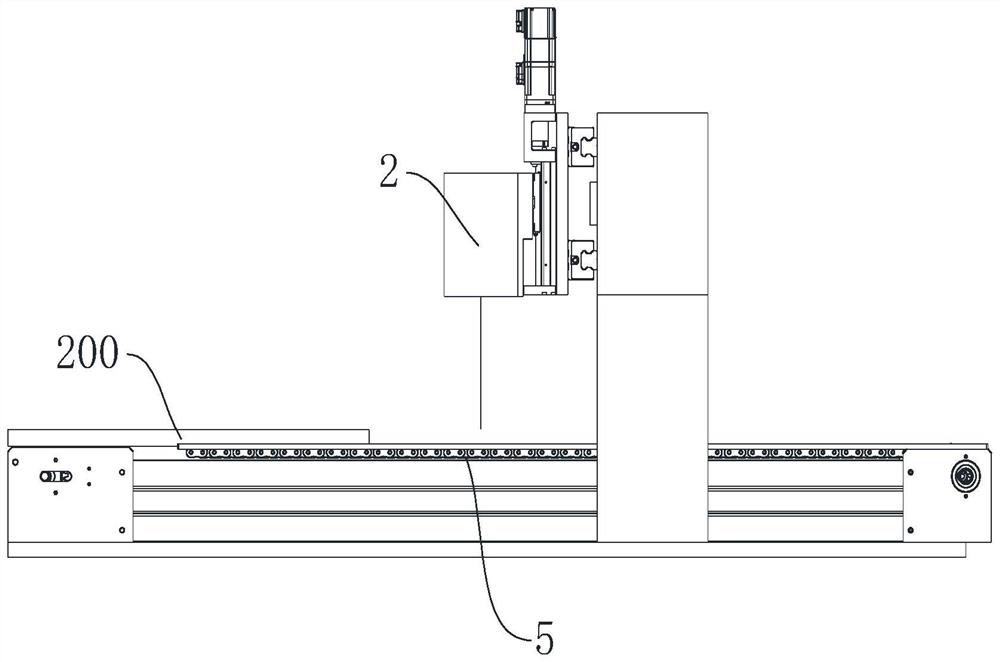

[0073] Step 1, see image 3 , install the workpiece 200 on the working platform 2 with the plasma spray gun 3, after completing the positioning, drive the plasma spray gun 3 to perform surface treatment on the workpiece 200, which is the prior art, and the specific parameters are set according to actual needs.

[0074] Step 2, see Figure 4 , move the workpiece 200 to the working platform 2 on which the glue dispenser 4 is installed, and after the positioning is completed, drive the glue dispenser 4 to perform insulation coating on the pair. The specific operation is in the prior art, and will not be repeated here.

[0075] Step 3, see Figure 5 , the workpiece 200 moves on the working platform 2 of the inkjet printing device 100, starts the inkjet printing device 100, and prints the spray coating on the surface and side of the workpiece 200 according to the inkjet graphic data and solidifies, and the method for printing and curing the spray coating is as described above. ,N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com