Dynamic damper and diesel engine where dynamic damper is mounted

A technology for dampers and diesel engines, applied in engine components, machines/engines, noise reduction devices, etc., can solve problems such as liquid leakage, unclear structure, unoptimized, etc., reduce vibration, improve safety and reliability, and handle easily Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0099] Next, a second embodiment will be described. However, the same reference numerals are assigned to the same components as those constituting the horizontal dynamic damper 1 described in the first embodiment, and detailed description thereof will be omitted.

[0100] The 2nd dynamic damper 1 as Figure 12 As shown, the guide rod support body 3 b is screwed onto the end of the housing 2 . That is, the female thread portion 42 provided inside the hem portion 28 of the guide rod support body 3 b is screwed to the male thread portion 41 provided on the outer peripheral surface of the housing 2 .

[0101] In addition, the threaded part 6a is provided only in the front end part of the guide rod outside the guide rod support body 3b, and the fastener 27 with the leg part or the hem part 26 is screwed to this threaded part 6a. And, the nut 7 as a fastener is screwed on the outside of the fastener 27 .

[0102] Furthermore, the protective cover 40 is screwed on the guide rod su...

no. 3 Embodiment approach

[0105] Next, a third embodiment will be described.

[0106] exist Figure 14 Among them, the reference numeral 30a is a large and low-speed two-cycle diesel engine for power generation equipment (for example, the rated speed is 100 to 200 rpm, and the output is about several thousand kW to 50,000 kW). A platform 210 for inspection of a grid (not shown). These inspection platforms 210 are vertically provided with longitudinal dynamic dampers (hereinafter simply referred to as dampers) 100 at positions where the vertical vibration is large, for example, at the ends of the inspection platforms 210 .

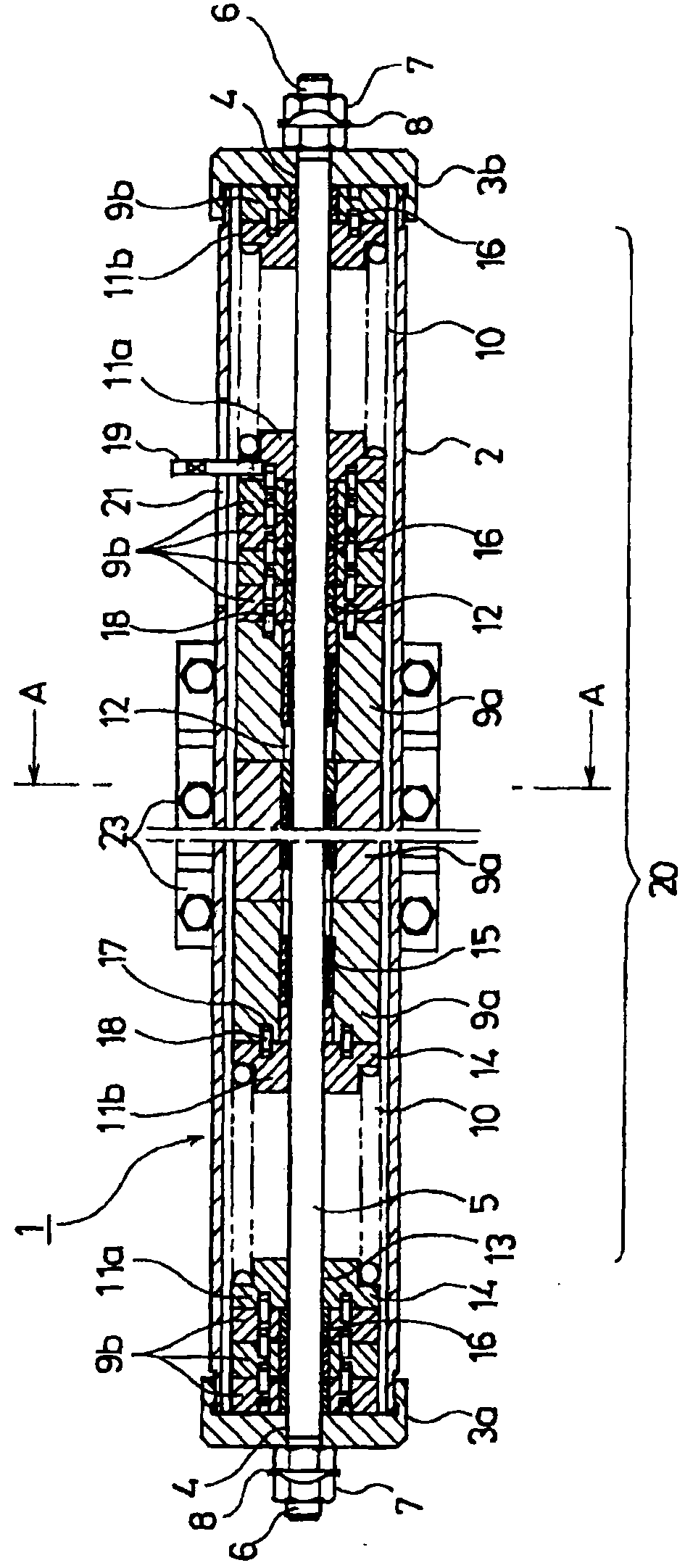

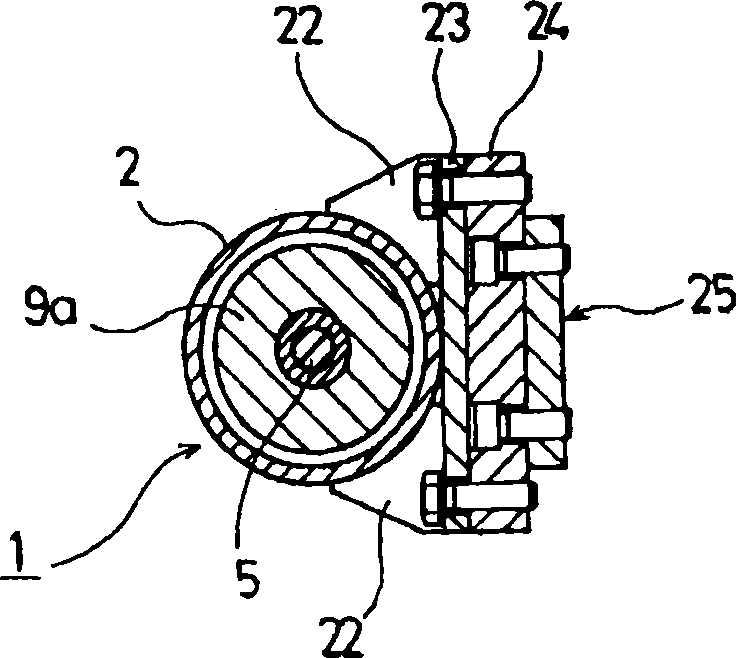

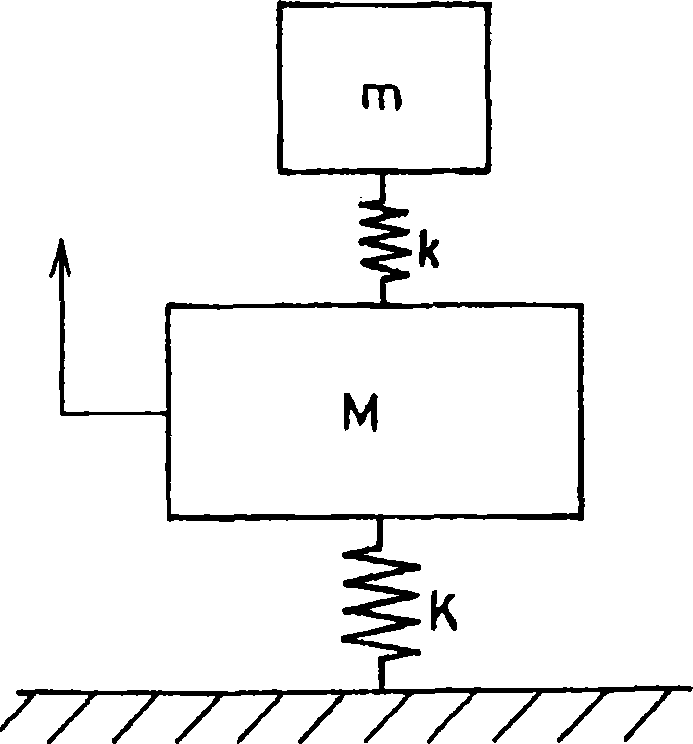

[0107] Damper 100 as Figure 15 As shown, it is a lengthwise structure. And, the damper main body 110 is composed of a cylindrical housing 112, a guide rod 113 provided in the housing 112, a vibration suppression weight 114 slidably provided on the guide rod 113, and a vibration suppression weight disposed on the vibration suppression weight. Coil-shaped springs 115, 116 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com