Die seat for punching machine

A die base and punching machine technology, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem that the cooling strength is difficult to meet the stamping requirements of large-tonnage workpieces, and achieve the effect of meeting the stamping requirements and improving the cooling strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

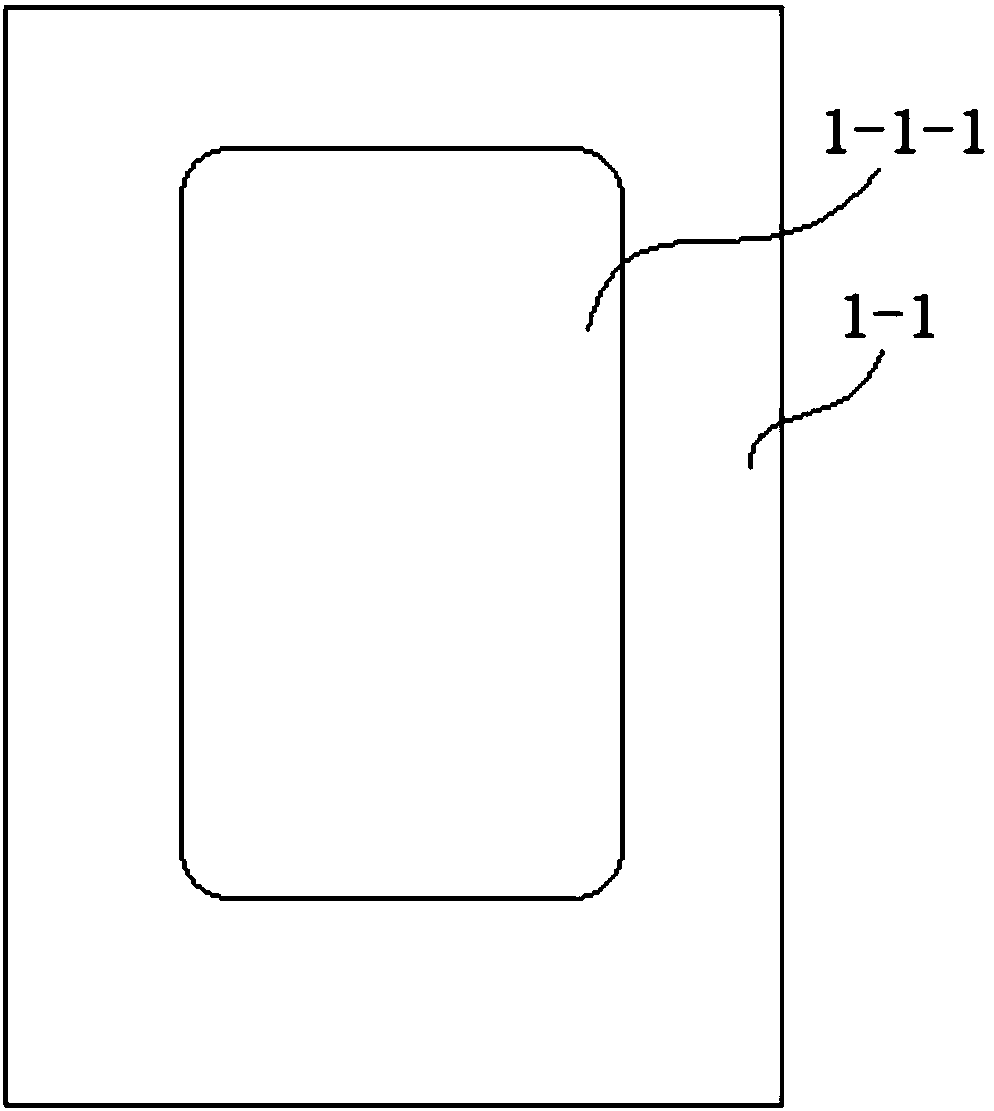

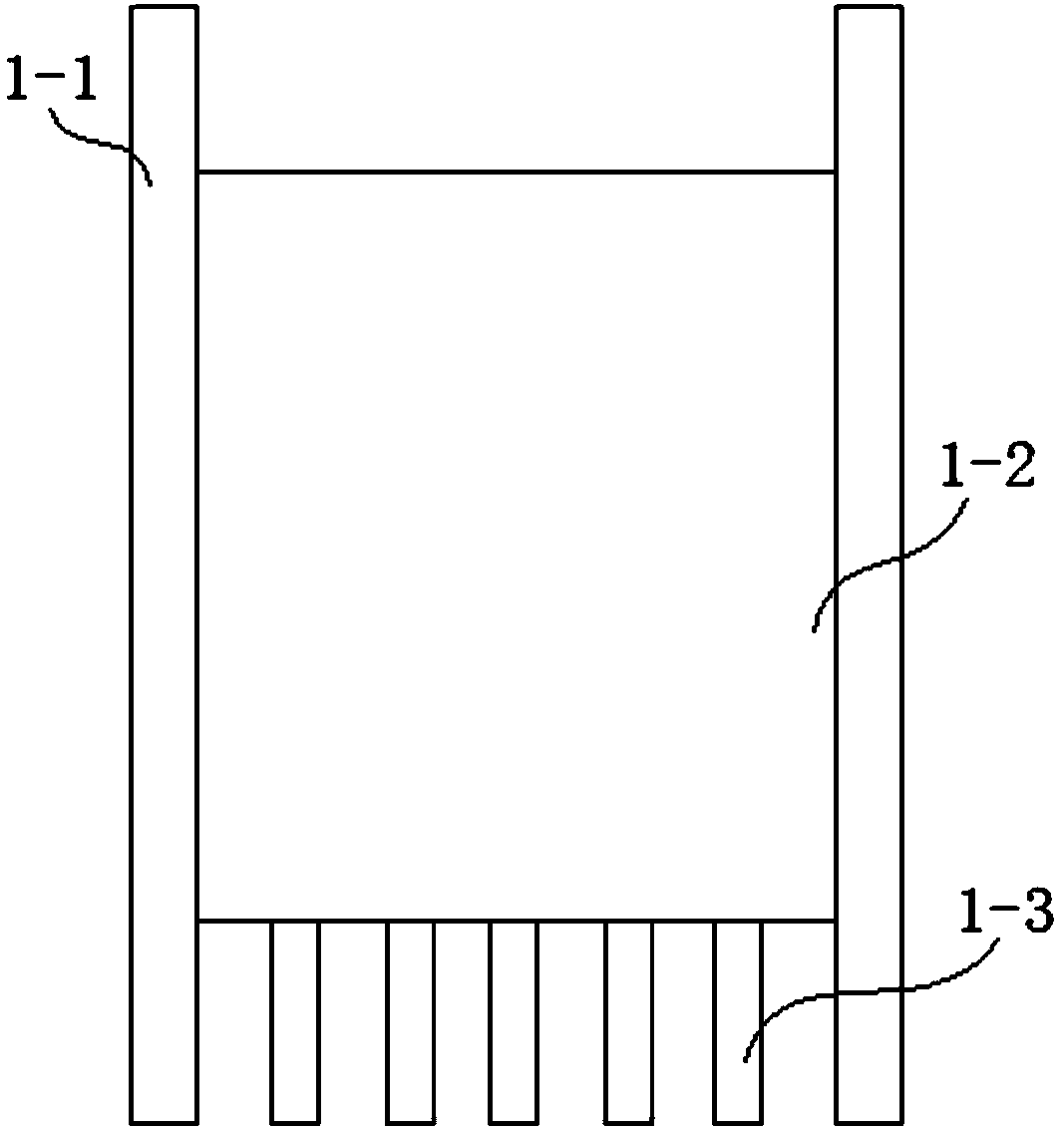

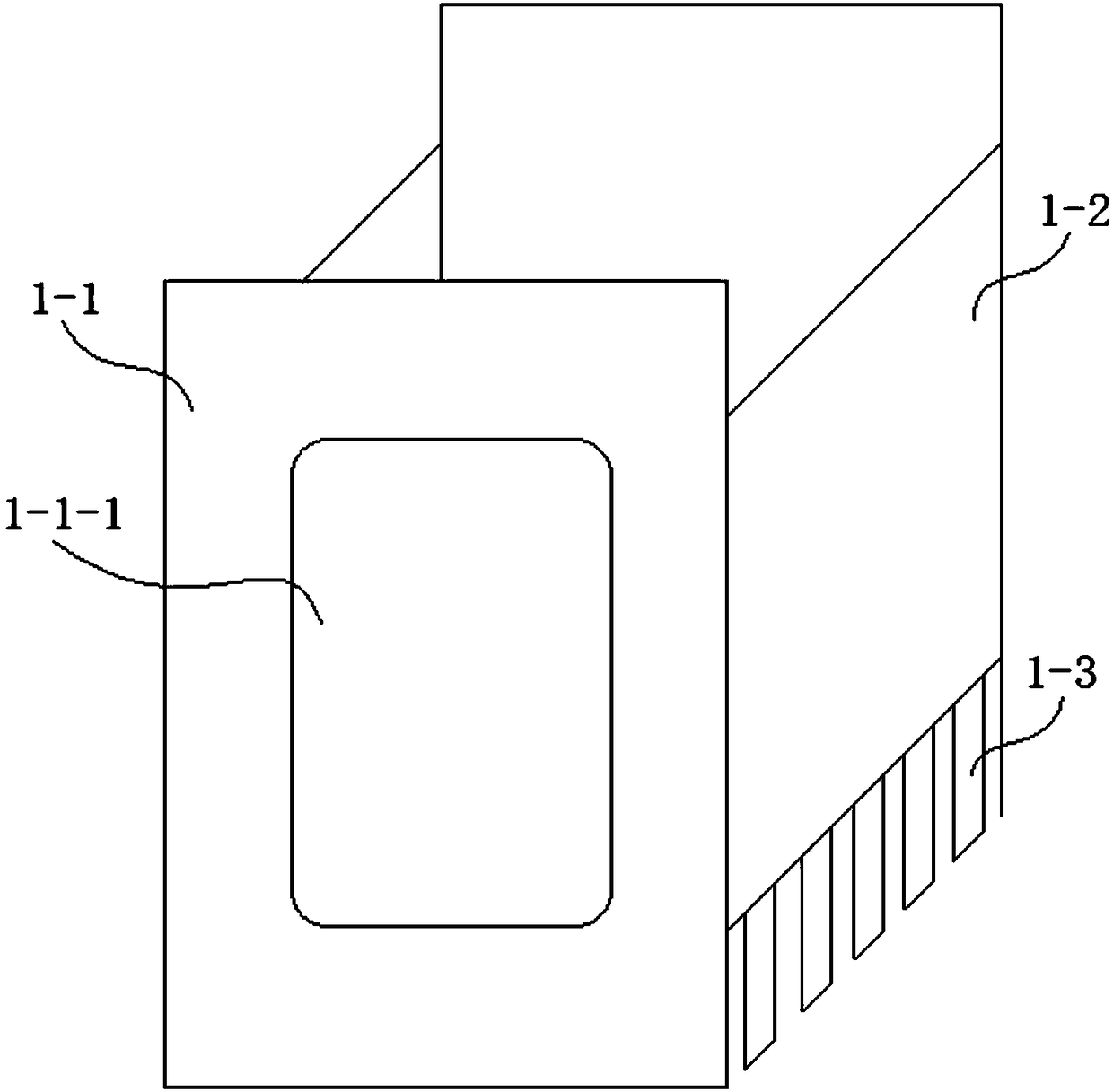

[0041] refer to Figure 1-9 , an integral hydraulic punching machine in this embodiment, comprising a main frame, the main frame includes two vertical plates 1-1 placed longitudinally on the front and rear sides of the two vertical plates 1-1, and the left and right sides of the two vertical plates 1-1 pass through the corresponding The side connection plate 1-2 is connected; the bottom end of the side connection plate 1-2 is connected with several parallel bottom reinforcement plates 1-3; the vertical plate 1-1 is provided with a vertical plate through hole 1-1-1, the The through hole 1-1-1 of the vertical plate is a rectangular through hole, and the four corners of the rectangular through hole are rounded;

[0042]In this embodiment, the main frame with the above-mentioned structure can significantly reduce the consumption of steel on the premise of ensuring the good strength, rigidity and vibration resistance of the fuselage itself, especially for working conditions that re...

Embodiment 2

[0062] refer to Figure 10 , an assembly method of the integral hydraulic stamping machine as described in embodiment 1, comprising the following steps:

[0063] Step 1, set up hoisting holes on the four corners of the vertical plate 1-1 respectively, so as to facilitate the hoisting of the vertical plate 1-1;

[0064] Step 2. First, place the two vertical boards 1-1 horizontally, and then adjust the distance between the two vertical boards 1-1 to the specified value. Because the vertical boards 1-1 are high and difficult to locate , in this embodiment, the two vertical plates 1-1 are laid down horizontally, which reduces the difficulty of processing;

[0065] Step 3: Correspondingly connect the four corners of the two vertical plates 1-1 through the four positioning connecting columns. In this embodiment, first determine the distance between the two vertical plates 1-1 through the four positioning connecting columns, and then Subsequent processing is carried out to avoid th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com