Uniform cooling crystallizer

A uniform cooling and crystallizer technology, applied in the field of steelmaking continuous casting, can solve the problems of large water gap width, high cost, uneven cooling, etc., and achieve the effect of improving cooling strength and reducing corner cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

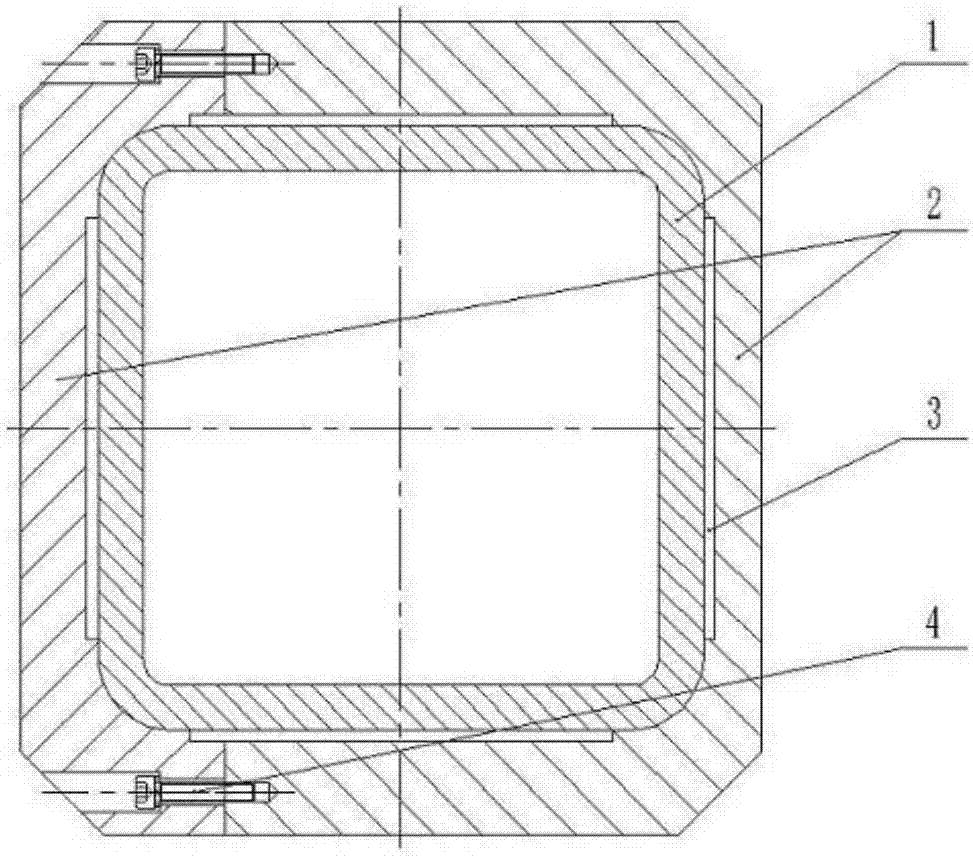

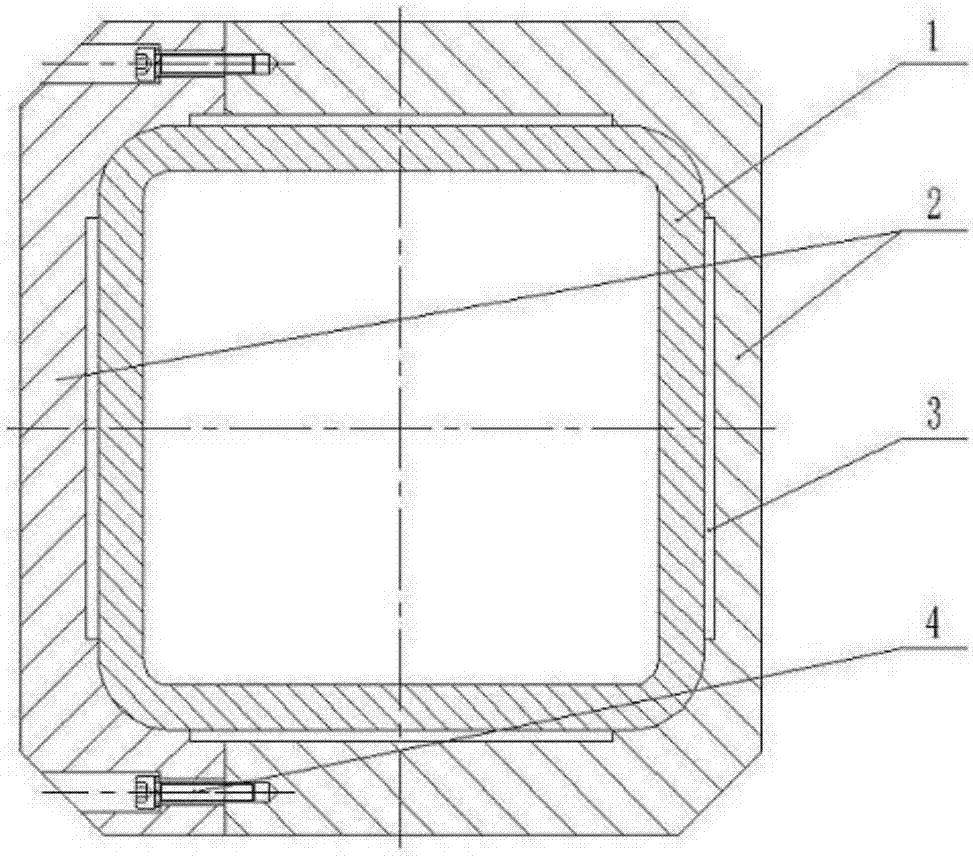

[0035] according to figure 1 As shown, use the bolt 4 to assemble the split diversion water jacket 2 outside the crystallizer copper tube 1, the diversion water jacket 2 contacts and supports the four corners of the crystallizer copper tube 1, and the diversion water jacket 2 and the crystallizer The contact range of the four corners of the copper tube 1 is: along the length direction of the copper tube 1 of the crystallizer, from the upper mouth of the copper tube to the lower mouth, and the width is an area of 30 mm on both sides of the corner of the copper tube 1 of the crystallizer.

[0036] While weakening the cooling strength of the corners of the mold copper tube 1, horizontal or oblique corrugations are arranged on the outer surface of the mold copper tube 1 to strengthen the cooling of the mold copper tube 1 face, so that the crystallizer copper tube 1 corners and The face is cooled evenly.

[0037] On the outer surface of the crystallizer copper tube 1, except for...

Embodiment 2

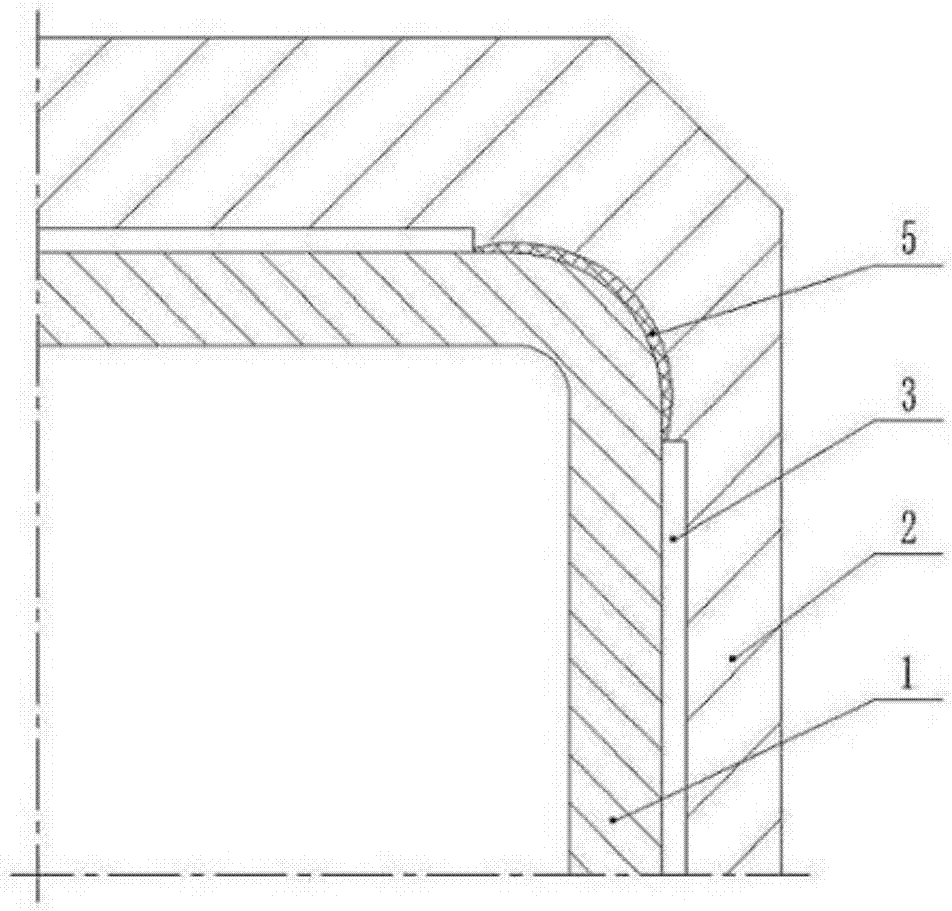

[0040] according to figure 2 As shown, the difference from Example 1 is that a low thermal conductivity material 5 is provided on the surface where the diversion water jacket 2 is in contact with the corner of the crystallizer copper tube 1. The thermal conductivity of the low thermal conductivity material 5, the material The thickness of the mold can be determined according to the needs, so as to accurately adjust the cooling intensity of the corner of the mold copper tube 1, and achieve the purpose of uniform cooling intensity of the mold copper tube 1 corner and the face.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com