HRB400 steel bar and production method of HRB400 steel bar

A production method and technology of steel bars, which are applied in the production field of HRB400 steel bars and HRB400 steel bars, can solve the problems of unstable performance, high cost and poor mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

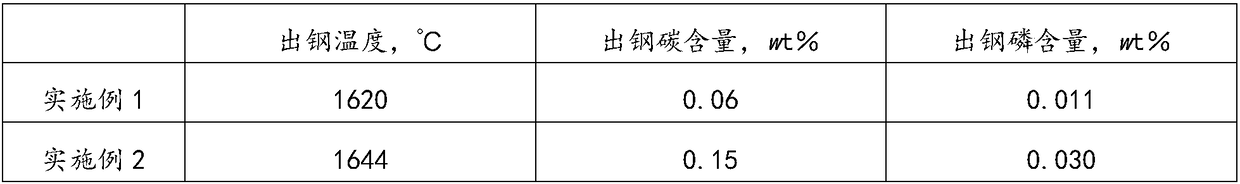

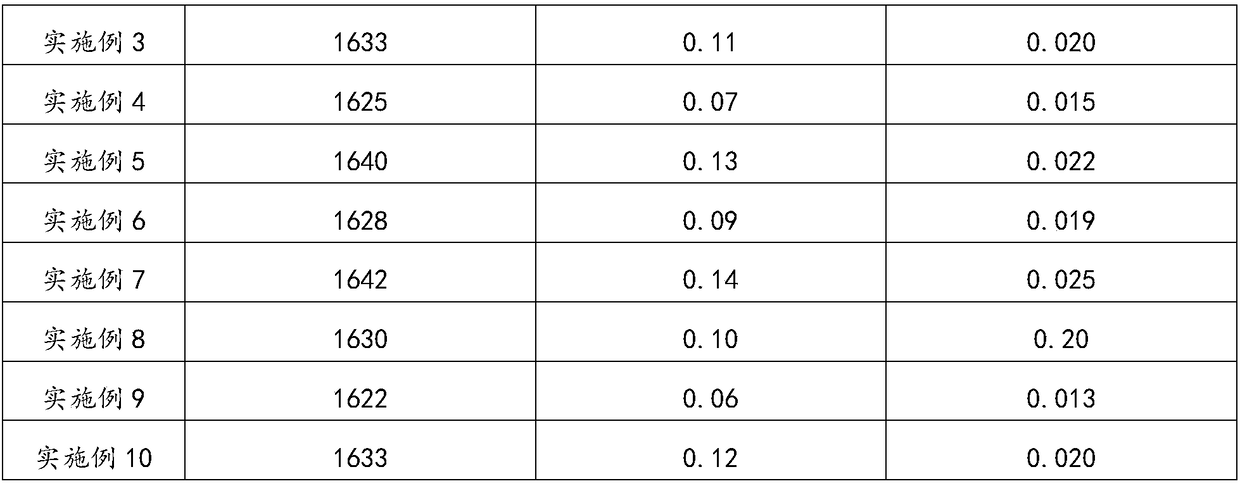

[0030] 10 furnaces of steel have been produced in industrial trials, and the specific process parameters are controlled as follows:

[0031] 1. Converter smelting

[0032] During converter smelting, 5000-6000kg of lime, 3000-4000kg of dolomite, 1000-3000kg of iron balls are added according to the composition requirements, and 500kg of ferrosilicon and 2800kg of silicon-manganese are added during tapping.

[0033] The carbon content, phosphorus content (mass percentage) and tapping temperature of the molten steel at the end of the converter are shown in Table 1.

[0034] Table 1 Composition and temperature of converter tapping

[0035]

[0036]

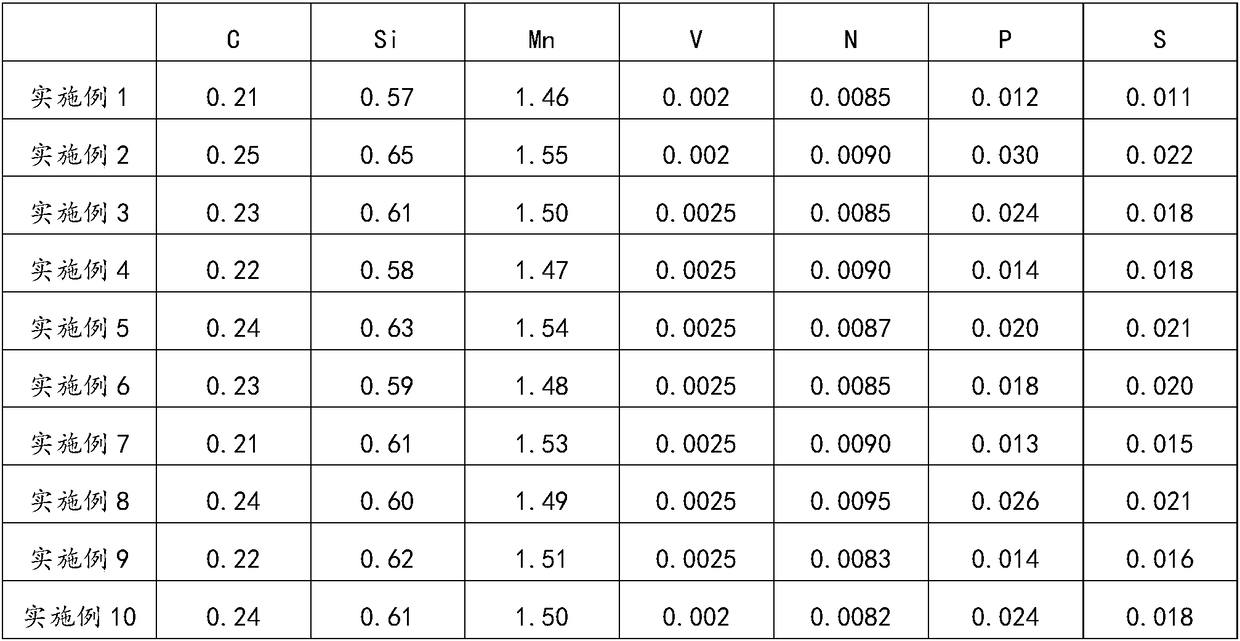

[0037] 2. LF furnace refining

[0038] According to the molten steel composition and temperature changes, add auxiliary materials to make slag, add alloys to perform fine-tuning and temperature-raising operations. Add 500-600kg of lime, 200-300kg of bauxite, and fine-tune the alloy according to the refining composition. Add 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com