Method and die for preparing long and thin ceramic pipe blank through alternated die pressing

A technology for ceramic tubes and blanks, which is applied in the field of material preparation, can solve the problems of difficulty in preparing slender ceramic tubes, complicated processes and high cost, and achieves the effects of short cycle, simple process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

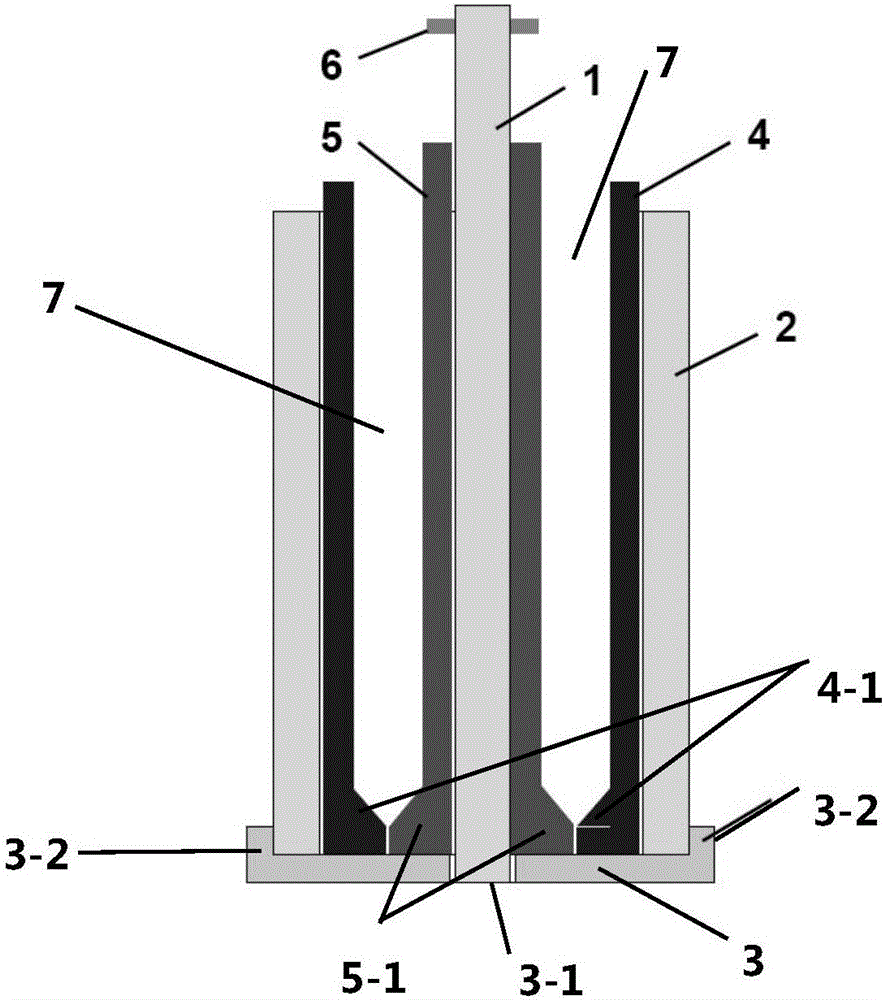

[0046] Embodiment 1 A kind of mold and the method for using it to prepare elongated ceramic tube body

[0047] A mold for preparing an elongated ceramic tube blank by alternate molding, comprising an inner core 1, a sleeve 2, a base 3, an outer mold 4, an inner mold 5, positioning pins 6, and a feeding cavity 7,

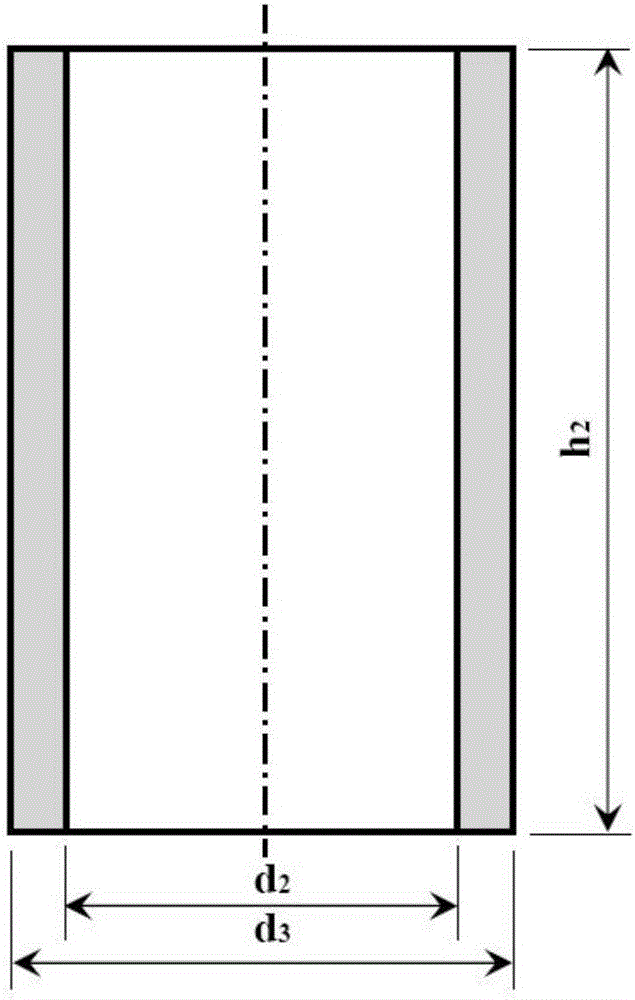

[0048] Wherein, the base 3 is a circular disk-shaped structure, the bottom is a plane, and the limiting protrusion 3-2 is restricted along the circular edge of the base 3, and the inner diameter of the annular limiting protrusion 3-2 is in line with the outer diameter of the sleeve 2. The diameter is the same or slightly larger, which is used to insert the sleeve 2 into it and limit the position; the center of the base 3 is provided with a through hole 3-1, and the inner diameter of the through hole 3-1 is the same as or slightly larger than the diameter of the inner core 1. To insert and limit the inner core 1;

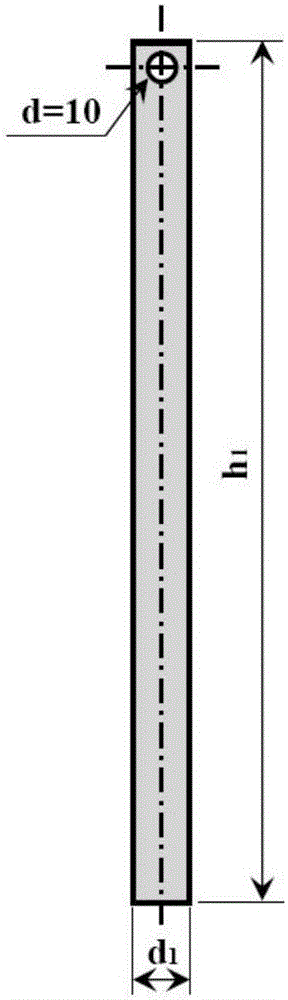

[0049] The inner core 1 is a cylinder, fixed vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com