Flux-cored wire for electrogas welding

A gas-electric vertical welding and welding wire technology, applied in arc welding equipment, welding medium, welding equipment, etc., can solve problems affecting mechanical properties, unable to meet the needs of production or life, large welding heat input, etc., to achieve weld seam Beautiful appearance, excellent and stable mechanical properties, stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is made up of steel strip and welding flux, and welding flux is wrapped in the steel strip, and steel strip adopts the carbon steel steel strip of low P, S, and its composition is as follows (% by weight):

[0037] C

Si

mn

Al

0.010-0.055

0.01-0.03

0.1-0.3

0.005~0.060

P

S

Fe

0.007-0.012

0.007-0.012

margin

[0038] The flux accounts for 20% to 30% of the total weight of the welding wire, and its flux composition is as follows (percentage by weight):

[0039] Fluoride

mn

Si

Ni

0.2~2.0

0.2~1.0

1.0~3.0

0.2~1.0

0.4~1.2

Mg

Ti

B

Fe

0.1~1.0

0.002~0.16

0.002~0.010

margin

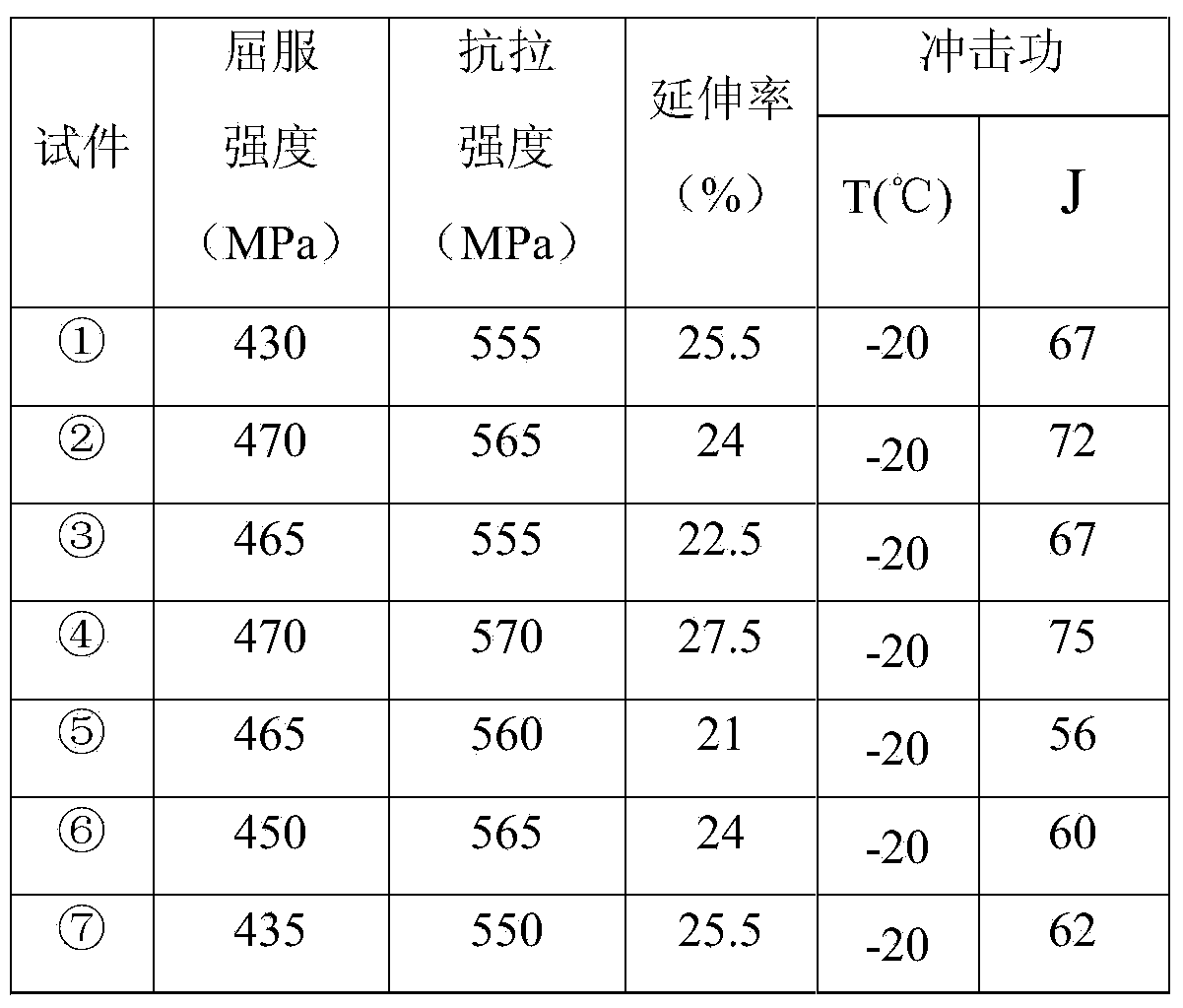

[0040] In order to understand the present invention better, below through embodiment ①~⑦ will further illustrate, but the present invention is not limited to following embodiment:

[0041] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com