Ultra-low hydrogen type acid flux-cored wire and production method thereof

A technology of flux-cored welding wire and production method, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor low-temperature impact toughness of weld metal

Inactive Publication Date: 2020-09-25

KUSN GINTUNE WELDING

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, one of the biggest problems with acidic flux cored wire is th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

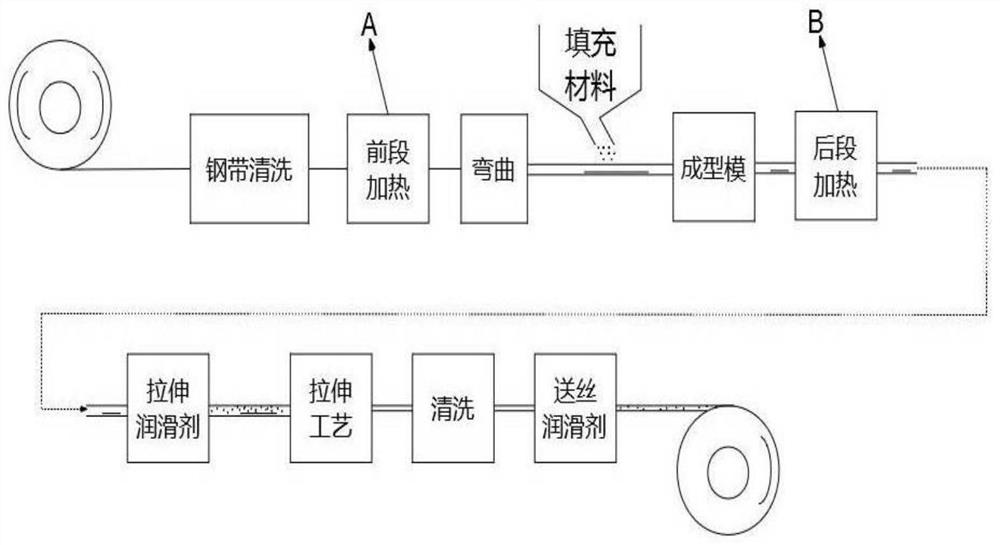

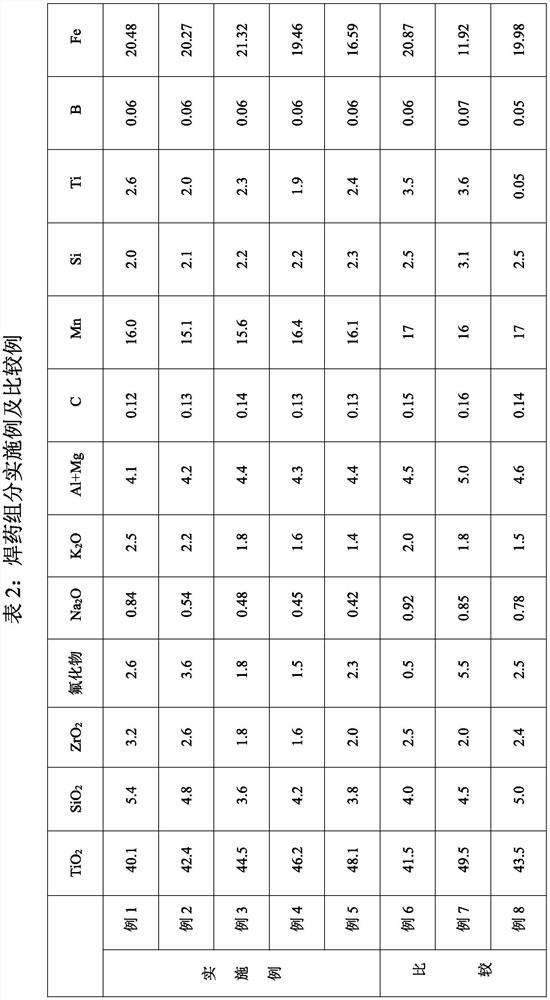

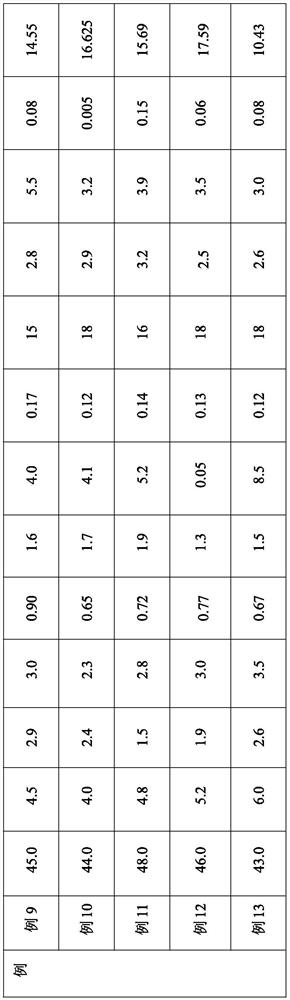

The invention discloses an ultra-low hydrogen type acid flux-cored wire and a production method thereof. The flux-cored wire is composed of a low-P and low-S steel strip and a flux core wrapped with the steel strip, wherein a welding flux accounts for 10%-20% of the total weight of a welding wire. The production method comprises the steps that after a heating process is carried out before and after a forming process to remove residual oil, the flux core is wrapped with the low-P and low-S steel strip through a precision forming process, and then the welding wire is obtained through diameter reduction, wire drawing and wire take-up. The flux-cored wire has excellent welding process performance, deposited metal of the flux-cored wire is excellent and stable in mechanical performance, the diffusible hydrogen content of the deposited metal of the flux-cored wire is reduced to an ultra-low hydrogen level (smaller than 3 ml/100 g, and a mercury method), and therefore a weld joint has good cold crack resistance.

Description

technical field [0001] The invention belongs to the field of welding materials, in particular to an ultra-low hydrogen type acidic flux-cored welding wire and a production method thereof. Background technique [0002] In recent years, flux cored wire has been widely used in shipbuilding, steel structure, petrochemical and other fields by virtue of a series of advantages such as high efficiency and energy saving. However, the existence of hydrogen in the weld will cause process defects such as pores, cracks, white spots and brittle fracture, so it is necessary to reduce the hydrogen content in the weld as much as possible. And such welding mainly adopts ultra-low hydrogen type flux-cored welding wire of alkaline slag system, but this welding wire is used in CO 2 When used as shielding gas, the fluidity of slag is too large, the form of droplet transfer is coarse particle transfer, the operation feel and welding process performance are extremely poor, and it is difficult to c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30B23K35/368B23K35/40

CPCB23K35/0266B23K35/3073B23K35/3608B23K35/368B23K35/406

Inventor 周峙宏林耿宏

Owner KUSN GINTUNE WELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com