Automatic argon arc seal welding method for narrow gap between deep grooves of tube plate and heat exchange tube

A welding method and technology for heat exchange tubes, applied in welding equipment, arc welding equipment, heat exchange equipment, etc., can solve the problems of welding defects, structures with deep grooves and narrow gaps that cannot be effectively welded, and achieve beautiful appearance and improved performance. Welding work efficiency and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

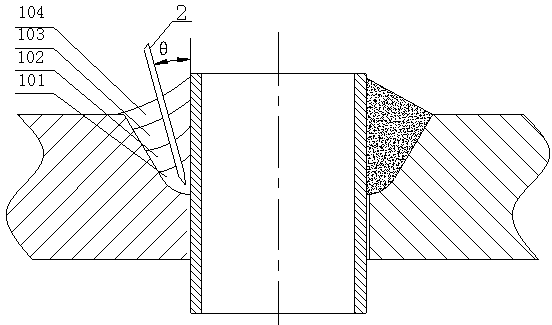

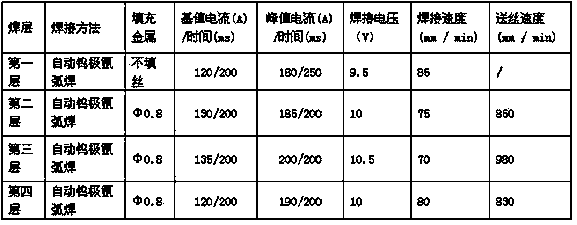

[0042] Taking a groove with a depth of 4-5mm and a width of 4mm formed by a shell-and-tube heat exchanger tube sheet and heat exchange tubes as an example, the following description is given:

[0043] 1. Material preparation: The material of the tube sheet of the shell-and-tube heat exchanger is Q245R, and the thickness of the tube sheet is 34mm; the material of the heat exchange tube is 20G, and the specification is φ38×3mm. The groove depth and width of the two are 4mm and 4mm.

[0044] 2. Preparation before welding

[0045] 1) Type of welding machine: automatic argon arc sealing welding machine is selected, using PS406 power supply (PS406 is a type of power supply with integrated control function) and welding head of model TS-2000.

[0046] 2) Welding tungsten electrode: choose WCe-20 cerium tungsten electrode with a diameter of Φ2.5mm, its welding end is ground into a cone shape, and its front end is ground to a Φ0.5mm end face.

[0047] 3) Welding shielding gas: choose b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com