An all-position welding method for metal pipelines in a slope state

A technology of metal pipes and welding methods, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve the problems of increasing processing difficulty and the number of machines and tools, serious surface inclination tendency, unstable state of molten pool, etc., and achieve the elimination of welding Trend of molten pool dripping, improvement of welding efficiency and quality, effect of solving unfused defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

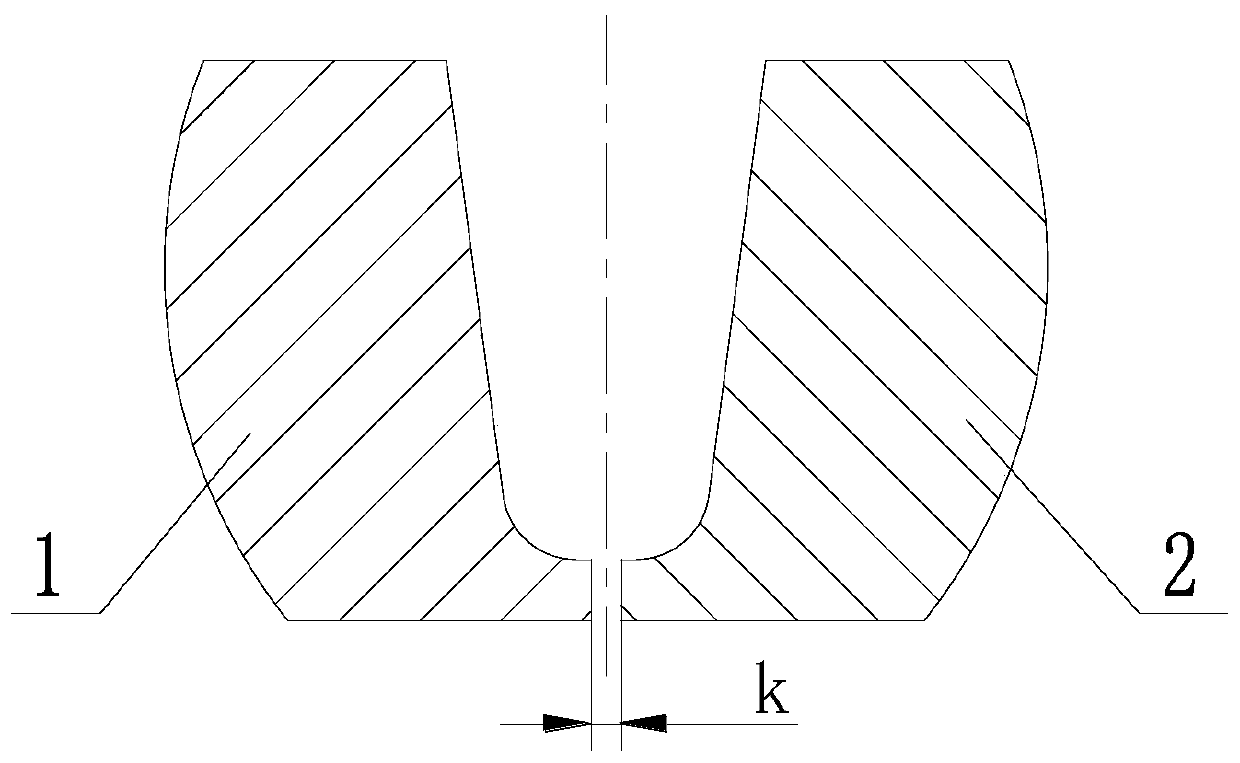

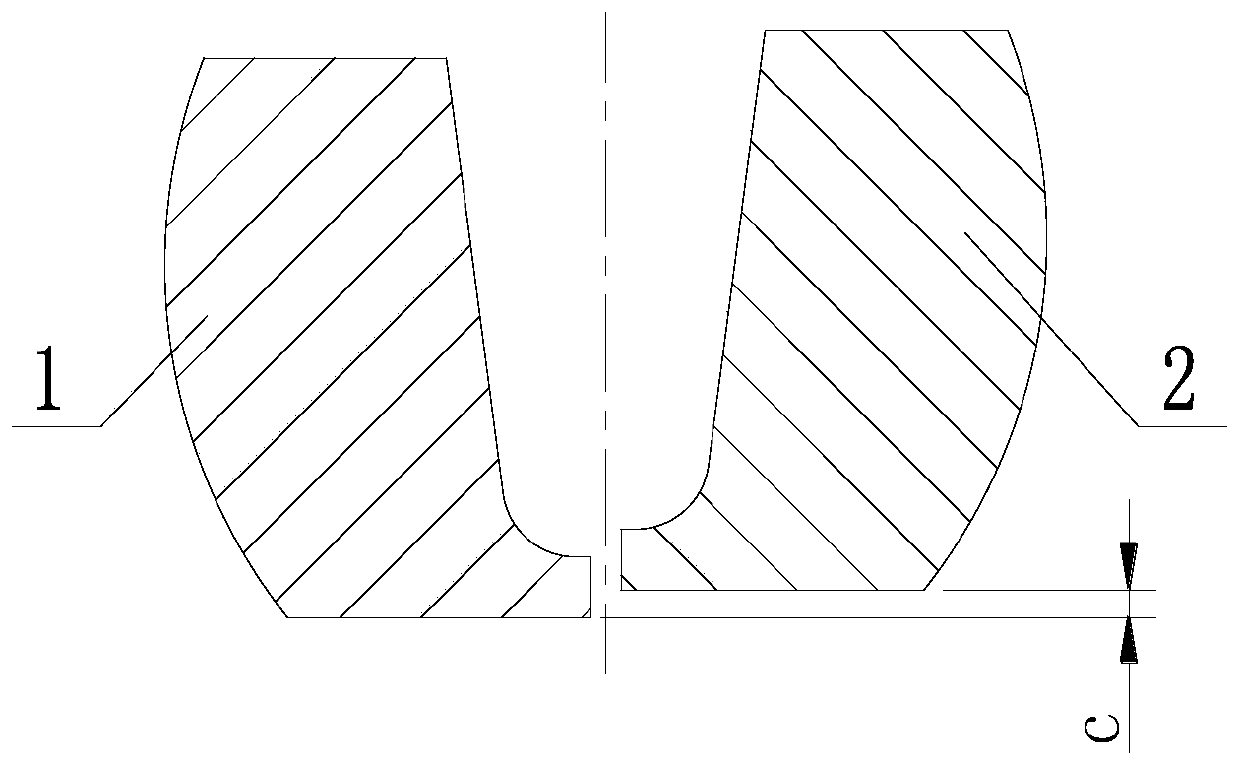

[0034] The invention provides an all-position welding method for metal pipelines in a slope state, the process flow of which can be found in Figure 8 , the method includes: using a beveling machine to perform bevel processing on the upper nozzle 1 and the lower nozzle 2 of the pipeline to be welded, and then preheating the pipe end grooves of the upper nozzle 1 and the lower nozzle 2; Welding counterpart machine for CMT outer root welding; use single torch solid wire gas shielded welding to complete automatic welding of filling welding and cover welding.

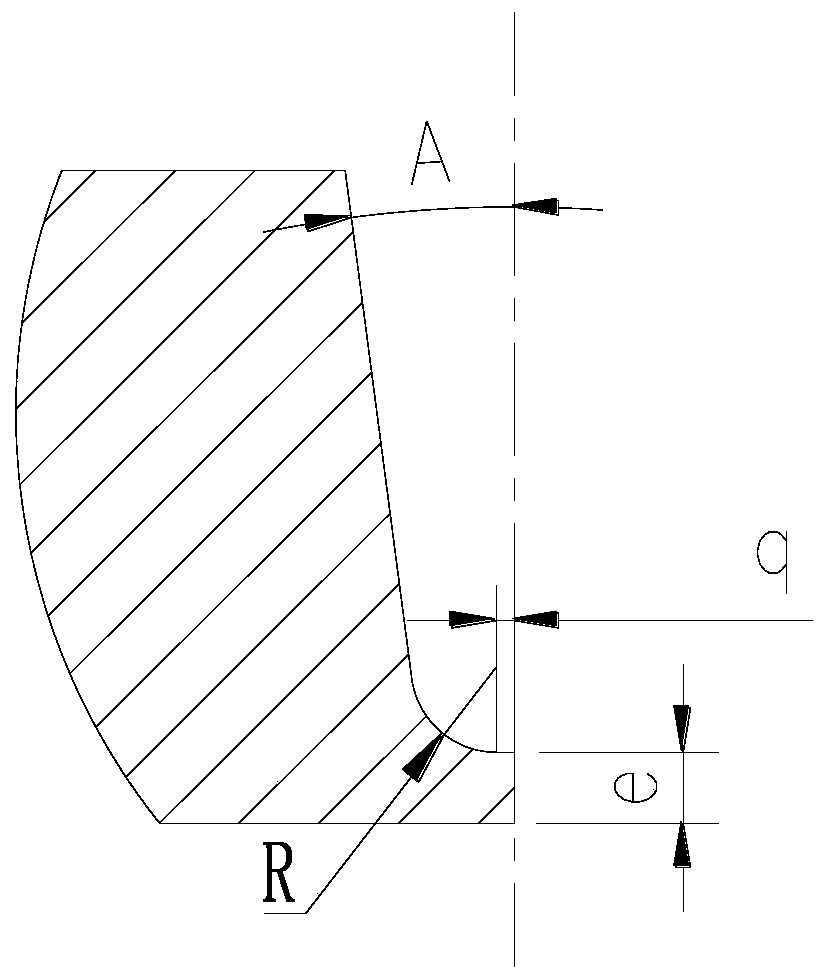

[0035] In this embodiment of the welding method, under the condition that the longitudinal gradient of the pipeline is 30 degrees, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com