Automatic disk welding machine

An automatic welding machine, disc technology, applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

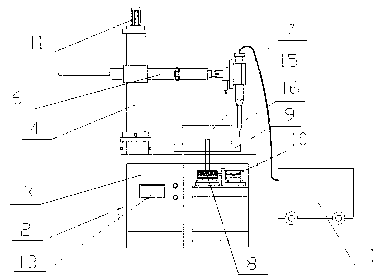

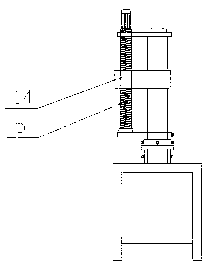

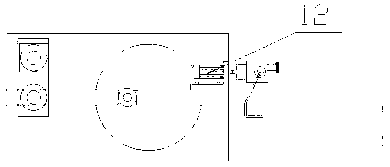

[0017] Such as figure 1 , figure 2 , image 3 The disc automatic welding machine shown is characterized in that it includes a welding machine 1, a frame 2, an electric control part 3, a column 4, an adjustment screw 5, a swing arm 6, a welding nozzle device 7, a power motor, a reducer 8, a circular Disc support 9; the right side of the disc automatic welding machine is externally connected to the welding machine 1, the lower part is the frame 2, the left side of the frame 2 is equipped with an electric control part 3, and the right side of the frame 2 is equipped with a reducer 8 , the power motor (1) 10 is installed on the right side of the reducer 8, and the disc support 9 is installed above the reducer 8 and the frame 2; Adjust the screw mandrel 5, the power motor (two) 11 is installed directly above the adjustment screw mandrel, the swing arm 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com