Water pump impeller welding working station

A technology for welding workstations and water pump impellers, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of reasonable design mechanism, high degree of automation, and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

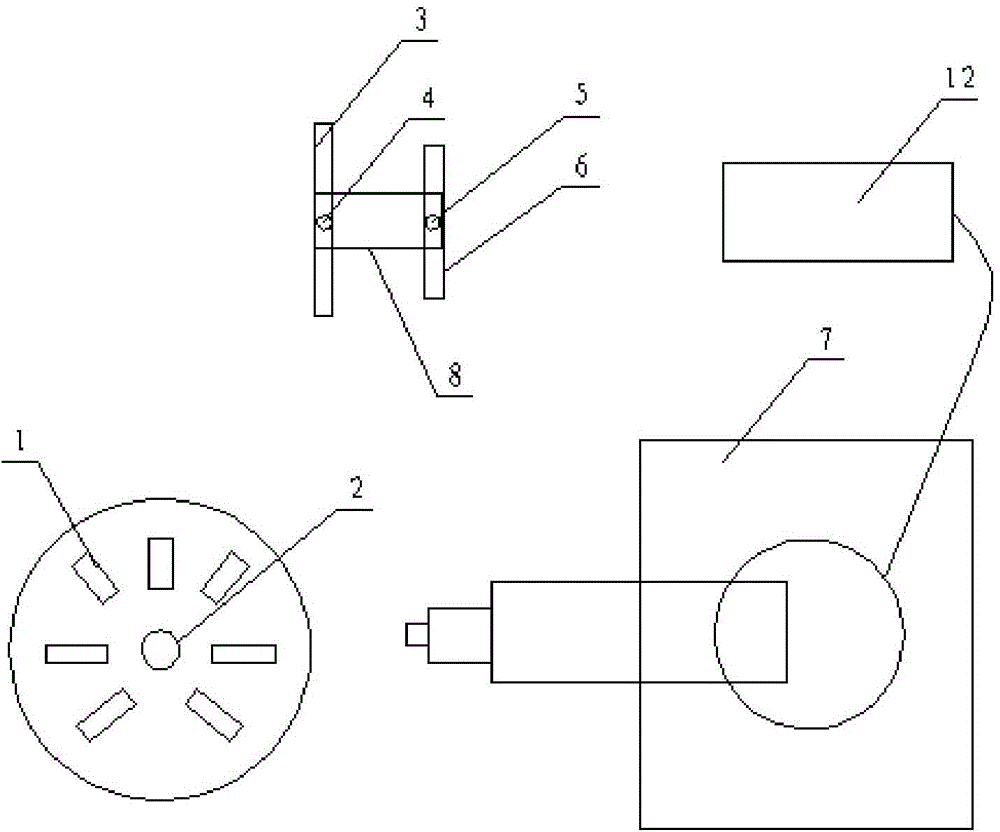

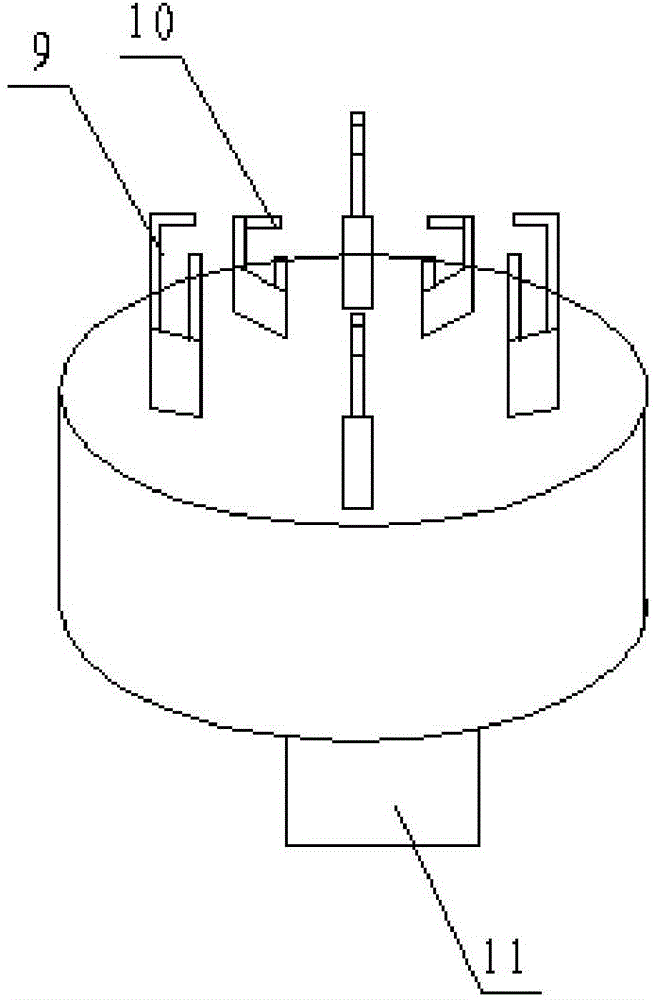

[0015] Referring to the accompanying drawings, a water pump impeller welding workstation includes a rotary turntable 1, a welding robot 7, a welding gun rack 8 and a welding control cabinet 12. The rotary turntable 1 is composed of a servo motor 11 and a turntable fixture 9 and 10, which can be controlled by the servo motor 11 controls forward and reverse precise rotation, the welding robot 7 adopts a spot welding robot equipped with two standard welding torches 3 and 6, and the welding torch rack 8 is located on the right side of the welding robot 7 to place the welding robot welding torches 3 and 6 , the welding control cabinet 12 has a protection device and a welding current setting device inside. The servo motor 11 of the rotary turntable 1 is an SEW high-performance rotary servo motor with a resolution of 10,000. The turntable fixture of the rotary turntable 1 is divided into upper and lower layers, which are clamped twice. After the lower jaws 10 clamp the impeller in pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com