Pipeline welding process for sloping field

A welding process and pipeline technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of difficult control of weld quality, molten pool deviation to one side, large longitudinal slope of pipeline, etc. Difficult forming, reduced welding cost, small groove size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

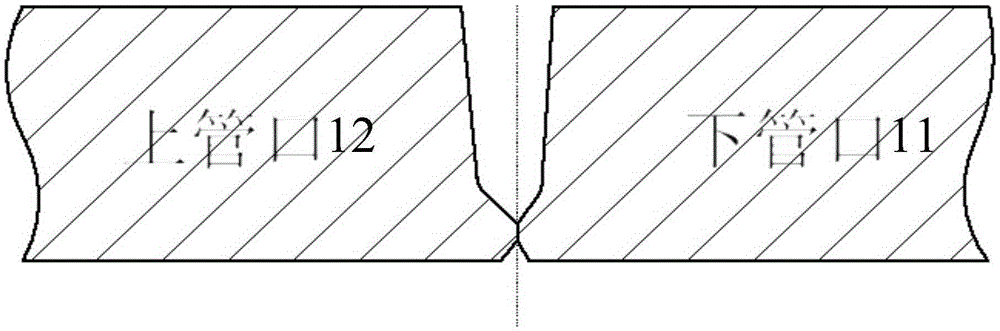

[0038] The invention provides a welding process for pipelines on slopes, please refer to Figure 8 , the method includes: using a beveling machine to bevel the mouth of the pipe to be welded; using an internal welding machine to perform root welding and using a single torch solid welding wire gas shielded welding to complete automatic welding of heat welding, filling and capping.

[0039] The specific operation steps of this welding method are:

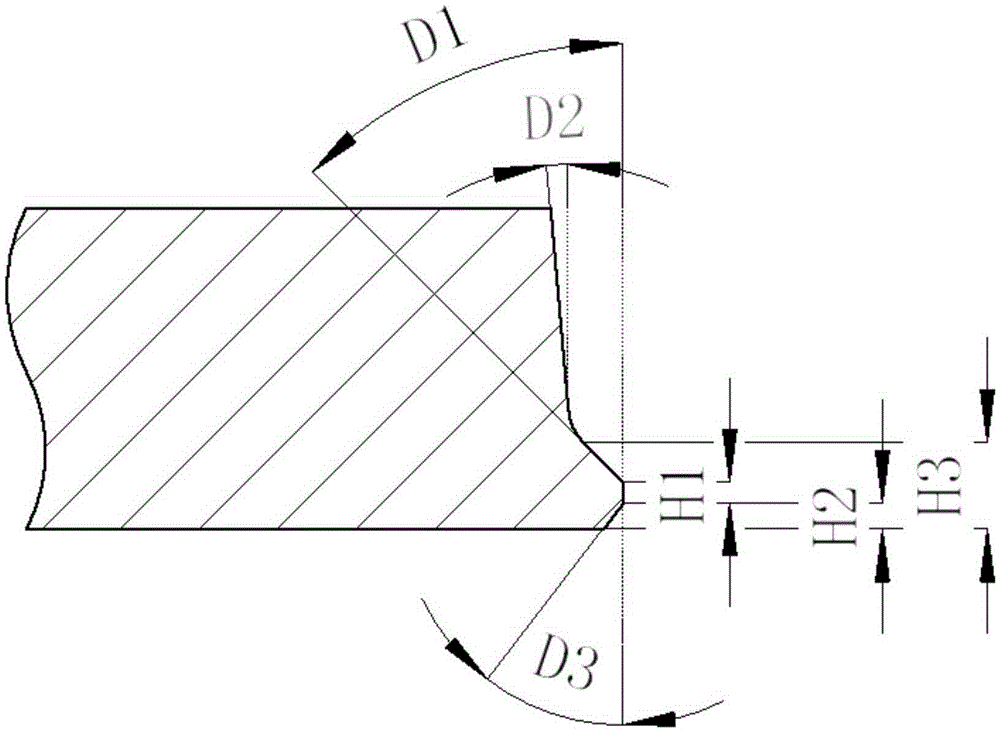

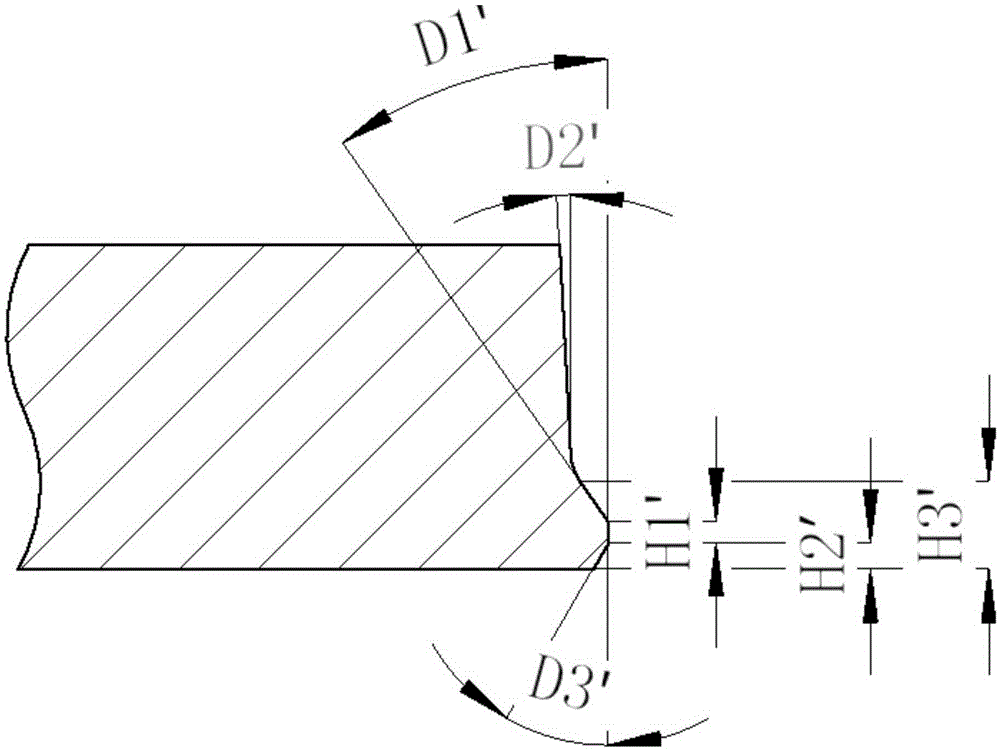

[0040] S1, the nozzles of the two pipes to be welded (that is, the nozzles of the first pipeline and the nozzles of the second pipeline) are respectively subjected to groove processing to form an asymmetrical double-V composite groove.

[0041]The groove respectively includes an upper groove, a lower groove, a blunt edge and an inner groove from the outer wall of the nozzle to the inner wall of the nozzle. For a butt weld bead, the nozzle located on the upper side of the slope (hereinafter referred to as "upper nozzle"): the angle D1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com