Method for hot-pressure welding aluminum-steel dissimilar material

A dissimilar material, hot-press welding technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of large differences in thermophysical properties, hinder the combination of dissimilar materials, and high level of internal stress in the weld, and achieve the shape of the weld. Beautiful appearance, easy arc starting, and stable arc combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: adopt commercially available 304L stainless steel as the welding core, the composition and mass percentage of powder are: 42% rutile, 30% feldspar, 10% dolomite, 7% carboxymethyl cellulose, 5% manganese powder, silicon Iron 2% and nickel powder 4%, with potassium silicate as the binder of the drug skin, the addition is 34% of the total mass of the drug powder.

Embodiment 2

[0020] Embodiment two: adopt commercially available 304L stainless steel as the welding core, use potassium silicate as the binding agent of the drug skin, the composition and mass percentage of the drug powder are: 52% rutile, 25% feldspar, 5% dolomite, carboxymethyl Base cellulose 5%, manganese powder 9%, ferrosilicon 4% and nickel powder 0%, with potassium silicate as the binder of the drug skin, the addition is 32% of the total mass of the drug powder.

Embodiment 3

[0021] Embodiment three: adopt commercially available 304L stainless steel as the welding core, use potassium silicate as the binding agent of the coating, the composition and mass percentage of the medicinal powder are: 50% rutile, 20% feldspar, 7% dolomite, carboxymethyl 10% base cellulose, 7% manganese powder, 1% ferrosilicon and 5% nickel powder, with potassium silicate as the binder of the drug skin, the addition is 28% of the total mass of the drug powder.

[0022] The effect of the embodiment:

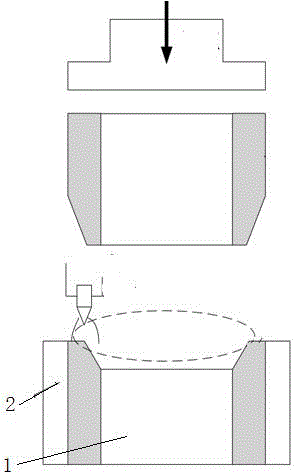

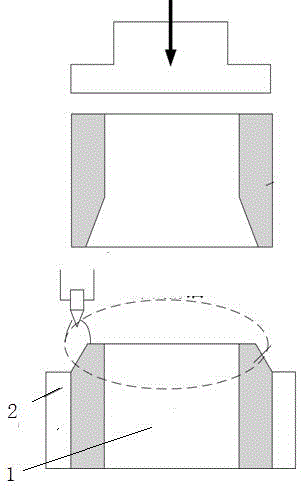

[0023] The object of the present invention is to provide a kind of aluminum-steel dissimilar material hot press that can remove the oxide film on the surface of aluminum alloy under the effect of arc cathode atomization by heating the welded workpiece of welding hot-press welding through the energy of welding arc. Welding method.

[0024] The technical scheme adopted in the present invention is:

[0025] A hot-press welding method containing aluminum-steel dissimilar materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com