Brazing flux-free brazed aluminum alloy composite strip and manufacturing method thereof

A technology for composite strips and manufacturing methods, applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., to achieve the effects of high brazing strength, cost reduction, and uniform and fine brazing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

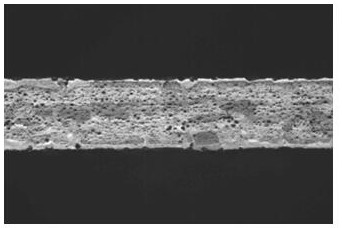

Image

Examples

Embodiment 1

[0028] The invention discloses a flux-free brazing aluminum alloy composite strip, which comprises a core layer and a brazing layer, the brazing layer is arranged on both sides of the core layer, and the thickness of the brazing layer on each side is 10% of the total thickness of the composite strip.

[0029] Wherein, the core layer includes the following components in weight percentage: 0.35% Fe, 0.75% Si, 0.50% Mn, 0.30% Mg, 0.10% Zn, 0.25% Cu, 0.12% Ti, and the single content of other elements ≤ 0.05%, the total amount of other elements ≤ 0.15%, and the rest is Al.

[0030] The brazing layer does not contain flux and is an aluminum-silicon alloy. The aluminum-silicon alloy includes the following components in weight percentage: 0.15% Fe, 7.8% Si, 0.01% Cu, 0.01% Mn, 0.01% Mg, Sr 0.001%, Ti 0.05%, individual content of other elements ≤0.05%, and the balance is Al.

[0031] The method for manufacturing the above-mentioned flux-free brazing aluminum alloy composite strip com...

Embodiment 2

[0046] The invention discloses a flux-free brazing aluminum alloy composite strip, which comprises a core layer and a brazing layer, the brazing layer is arranged on both sides of the core layer, and the thickness of the brazing layer on each side is 5% of the total thickness of the composite strip.

[0047] Wherein, the core layer includes the following components in weight percentage: 0.45% Fe, 0.85% Si, 0.60% Mn, 0.40% Mg, 0.05% Zn, 0.35% Cu, 0.24% Ti, and the single content of other elements ≤ 0.05%, the total amount of other elements ≤ 0.15%, and the rest is Al.

[0048] The brazing layer is an aluminum-silicon alloy, and the aluminum-silicon alloy includes the following components in weight percentage: Fe 0.1%, Si 8.2%, Cu 0.05%, Mn 0.05%, Mg 0.005%, Sr 0.001%, Ti 0.01%, the individual content of other elements is ≤0.05%, and the balance is Al.

[0049] The preparation method and processing conditions are the same as in Example 1.

[0050] The flux-free brazing alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com