Europium hafnate neutron absorbing material and application thereof

A technology of absorbing material, europium hafnium acid, applied in reactors, nuclear reaction control, nuclear power generation and other directions, can solve the problems of shortening the service life of materials, sample degradation and performance degradation, and achieve long-term stability, stable comprehensive properties, melting point and other problems. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

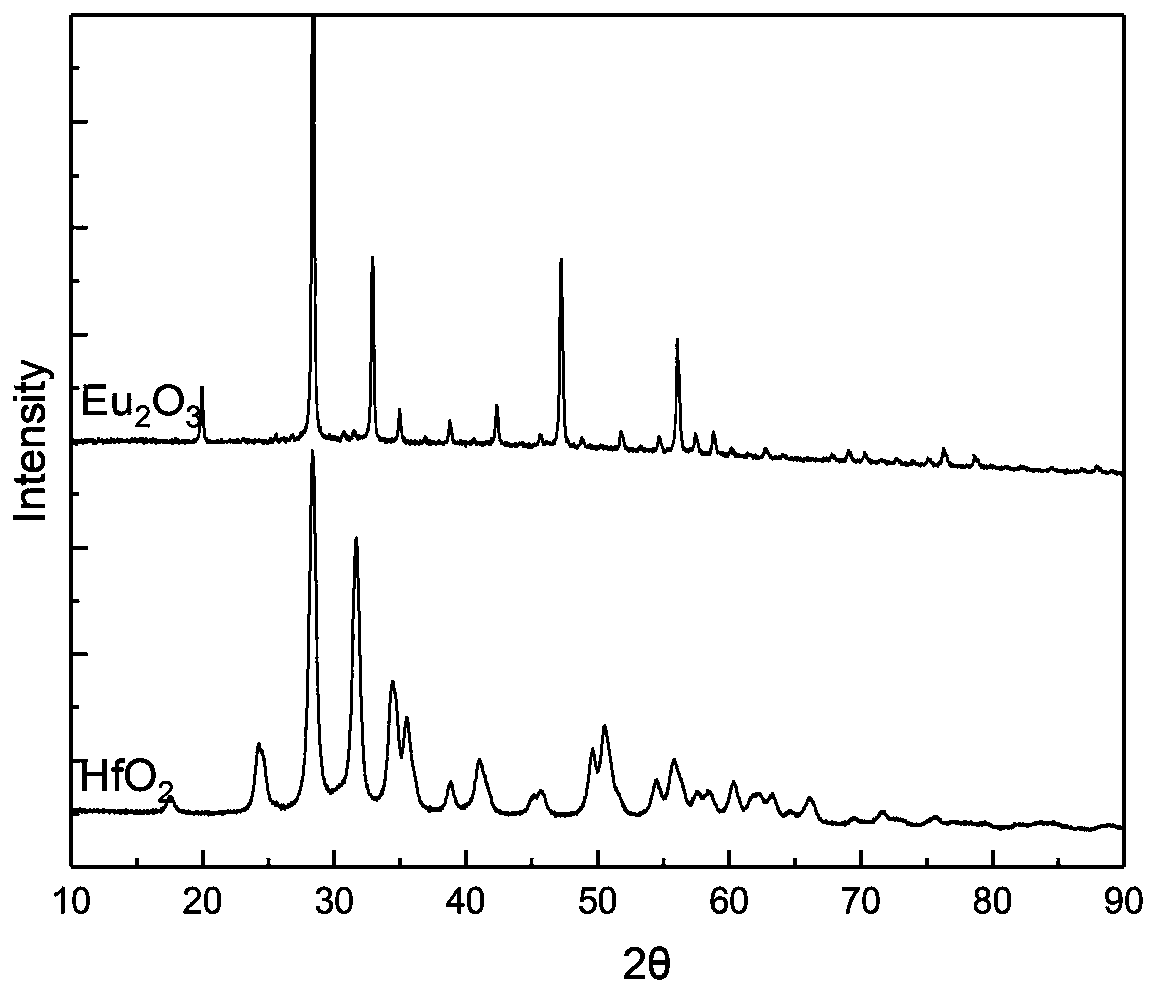

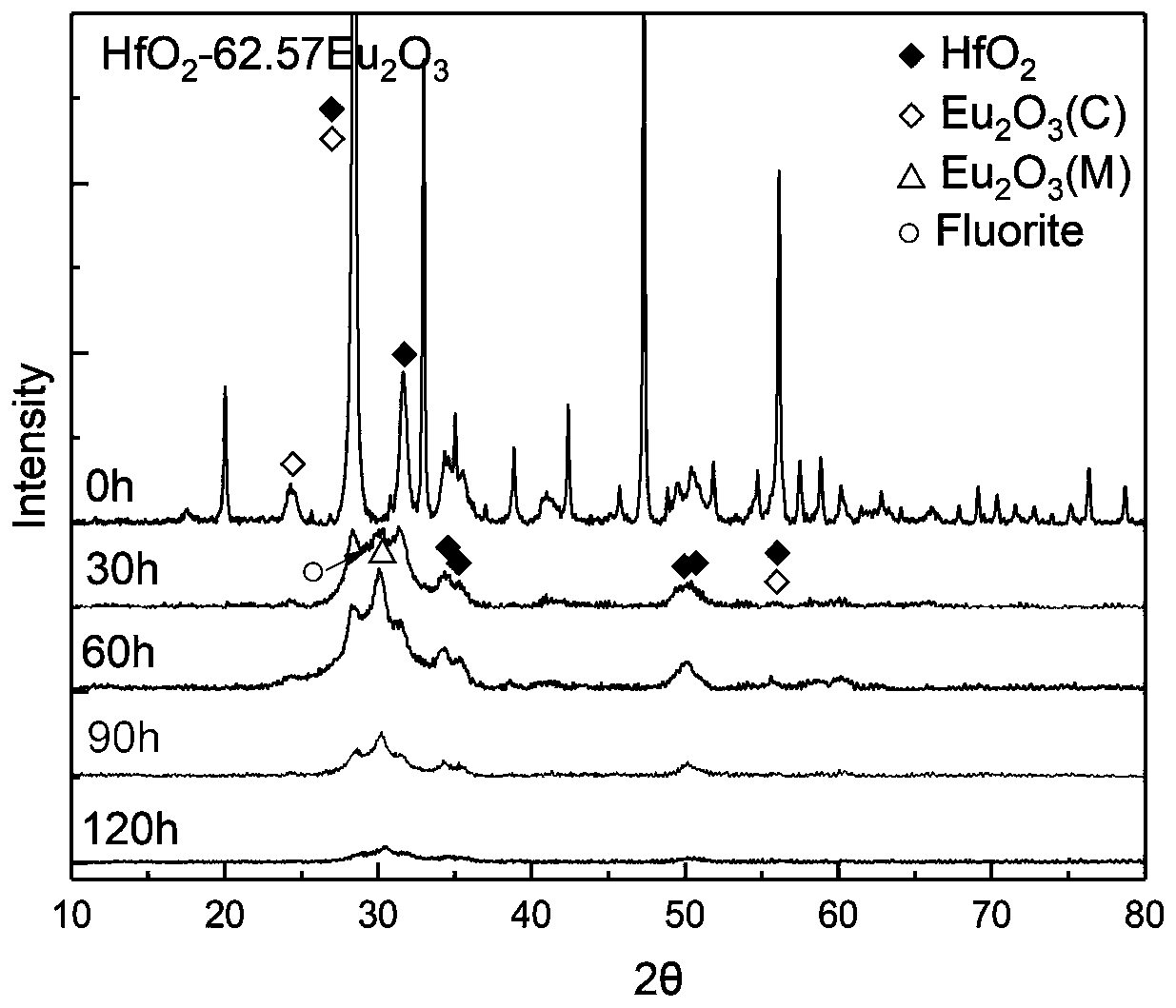

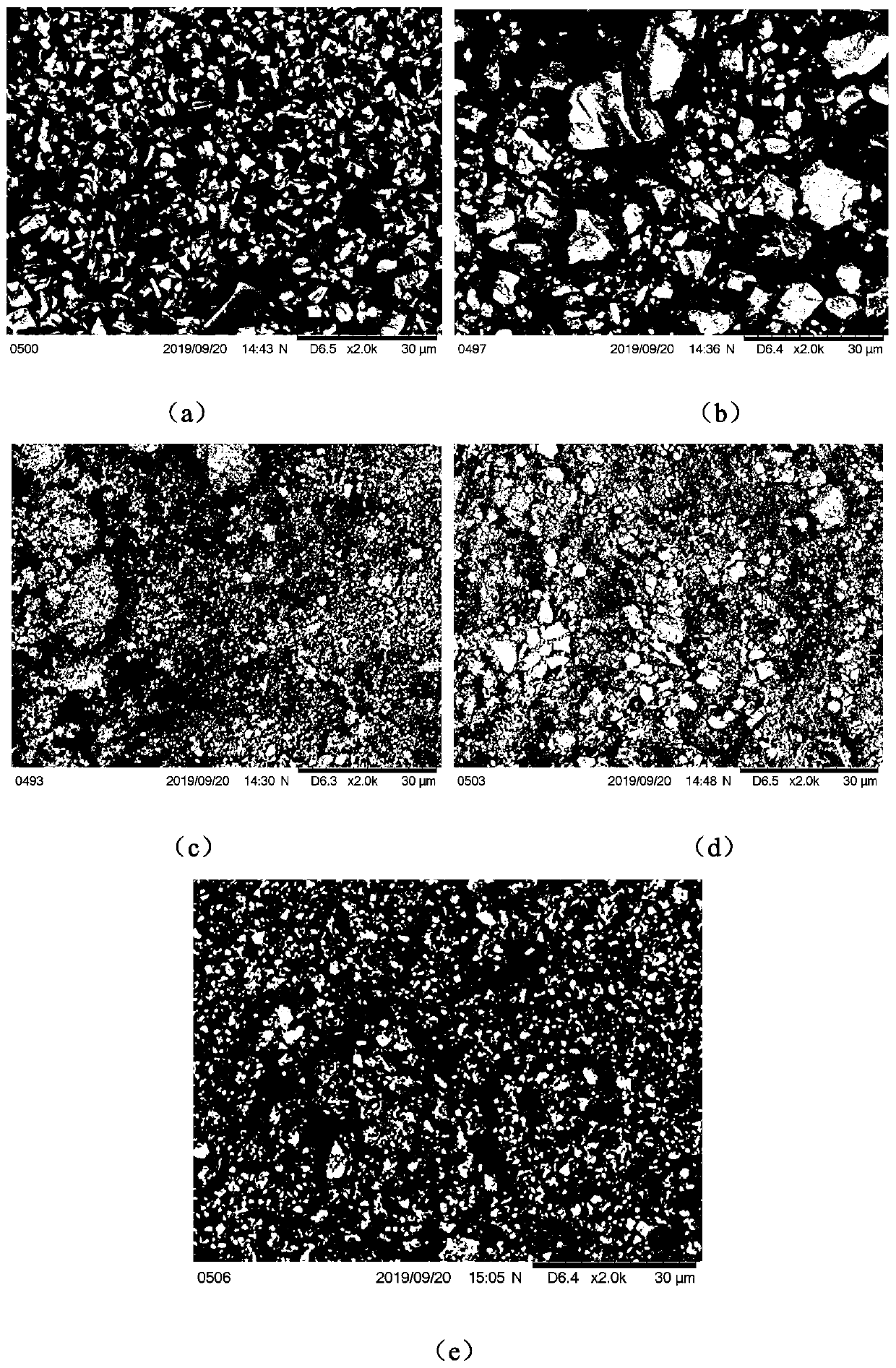

[0039] Take the dried hafnium oxide powder with a purity of 99.9% and the dried europium oxide powder with a purity of 99.9%, under the protection of an inert gas, according to the molar percentage of Hf 2 o 3 -50% Eu 2 o 3 (i.e. mass percentage Hf 2 o 3 -62.57wt.%Eu 2 o 3 ) mixed after weighing, then add the process control agent stearic acid and make its final mass concentration no more than 1.5wt.%, to obtain the initial mixed powder, put into the ball mill jar and tighten the ball mill jar lid. The above initial mixed powder was ball-milled for 120 hours under the conditions of ball-to-material ratio of 10:1, filling coefficient of 0.5, and ball milling speed of 500 rpm to obtain ball-milled powder. In a glove box protected by inert gas argon, put the mixed powder of the ball mill for 30 hours into a rubber sheath and tighten the seal, then place the tight rubber sheath in the hydraulic cylinder of the cold isostatic pressing instrument, Cold isostatic pressing for ...

Embodiment 2

[0044] Take the dried hafnium oxide powder with a purity of 99.9% and the dried europium oxide powder with a purity of 99.9%, under the protection of an inert gas, according to the molar percentage of Hf 2 o 3 -47.29% Eu 2 o 3 (mass percentage Hf 2 o 3 -60wt.%Eu 2 o 3) mixed after weighing, then add the process control agent stearic acid and make its final mass concentration no more than 1.5wt.%, to obtain the initial mixed powder, put into the ball mill jar and tighten the ball mill jar lid. The above initial mixed powder was ball-milled for 30 hours under the conditions of ball-to-material ratio of 10:1, filling coefficient of 0.5, and ball milling speed of 500 rpm to obtain ball-milled powder. In a glove box protected by inert gas argon, put the mixed powder of the ball mill for 30 hours into a rubber sheath and tighten the seal, then place the tight rubber sheath in the hydraulic cylinder of the cold isostatic pressing instrument, Cold isostatic pressing for 2h unde...

Embodiment 3

[0049] Take the dried hafnium oxide powder with a purity of 99.9% and the dried europium oxide powder with a purity of 99.9%, under the protection of an inert gas, according to the molar percentage of Hf 2 o 3 -47.29% Eu 2 o 3 (mass percentage Hf 2 o 3 -60wt.%Eu 2 o 3 ) mixed after weighing, then add the process control agent stearic acid and make its final mass concentration no more than 1.5wt.%, to obtain the initial mixed powder, put into the ball mill jar and tighten the ball mill jar lid. The above initial mixed powder was ball milled for 8 hours under the conditions of a ball-to-material ratio of 10:1, a filling coefficient of 0.5, and a ball milling speed of 500 rpm to obtain a ball milled powder. Put the above-mentioned ball milling powder in the mould, place the mold in the furnace cavity of the vacuum hot pressing sintering furnace, and vacuum the furnace cavity to 10 -3 Below Pa; apply a pressure of 100MPa, then heat up to 1200°C at a rate of 15°C / min for hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com