Production process and application of moderately strong 7-series aluminum alloy profile

A technology of aluminum alloy profile and production process, which is applied in the field of aluminum alloy production and manufacturing, can solve the problems of short parking time, inability to take into account industrial production efficiency, weakening strengthening effect, etc., achieve good mechanical properties, shorten natural parking time, and mechanical performance area stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention is further described in detail through examples.

[0026] Medium-strength 7-series aluminum alloys were smelted using conventional raw materials such as industrial pure aluminum, pure zinc, pure magnesium, and various intermediate alloys. The measured composition of the alloys is shown in Table 1.

[0027] The measured composition wt.% of the strong 7-series aluminum alloy in Table 1

[0028]

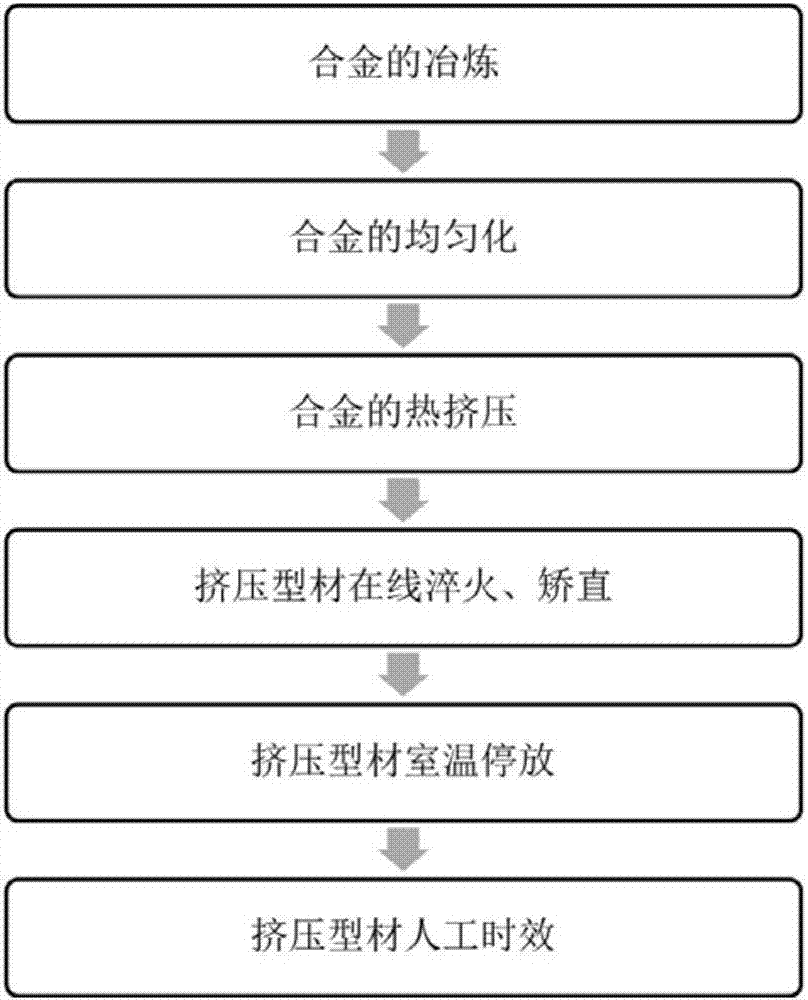

[0029] Such as figure 1 As shown, the actual operation steps of the production process of Zhongqiang 7 series aluminum alloy profiles are as follows:

[0030] 1) Alloy smelting (smelting at 820°C, casting at 690°C) to obtain medium-strength 7-series aluminum alloy ingots;

[0031] 2) Homogenization treatment of ingots (470 ° C for 24 hours, air cooling to room temperature);

[0032] 3) Hot extrusion of ingot (extrusion temperature 450°C, holding time 1h, extrusion speed 14mm / s, extrusion ratio 35), online quenching, straightening;

[0033] 4) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com