Nano inorganic composite pigment and preparation method thereof

A nano-inorganic and composite pigment technology, applied in the field of materials, can solve the problems of poor dispersion, poor acid resistance of ordinary iron oxide brown, and limit the development of iron oxide brown, so as to achieve improved protection performance, reduced porosity, and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to nano-inorganic composite pigment and its preparation method.

Embodiment 11

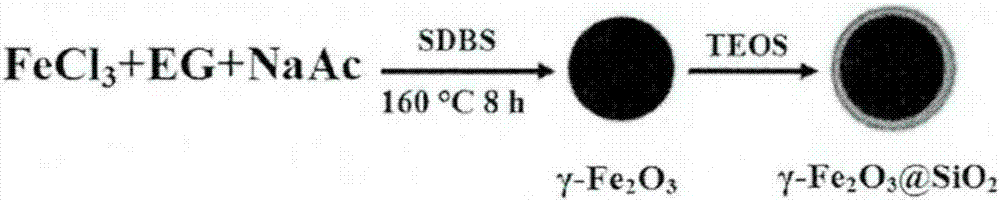

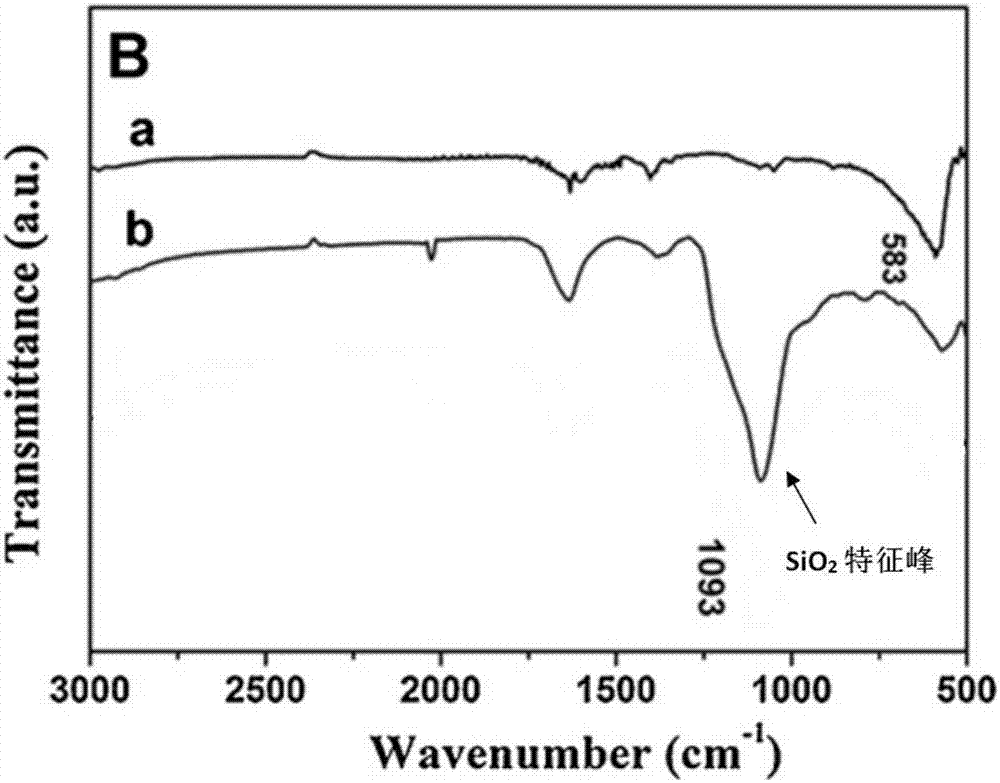

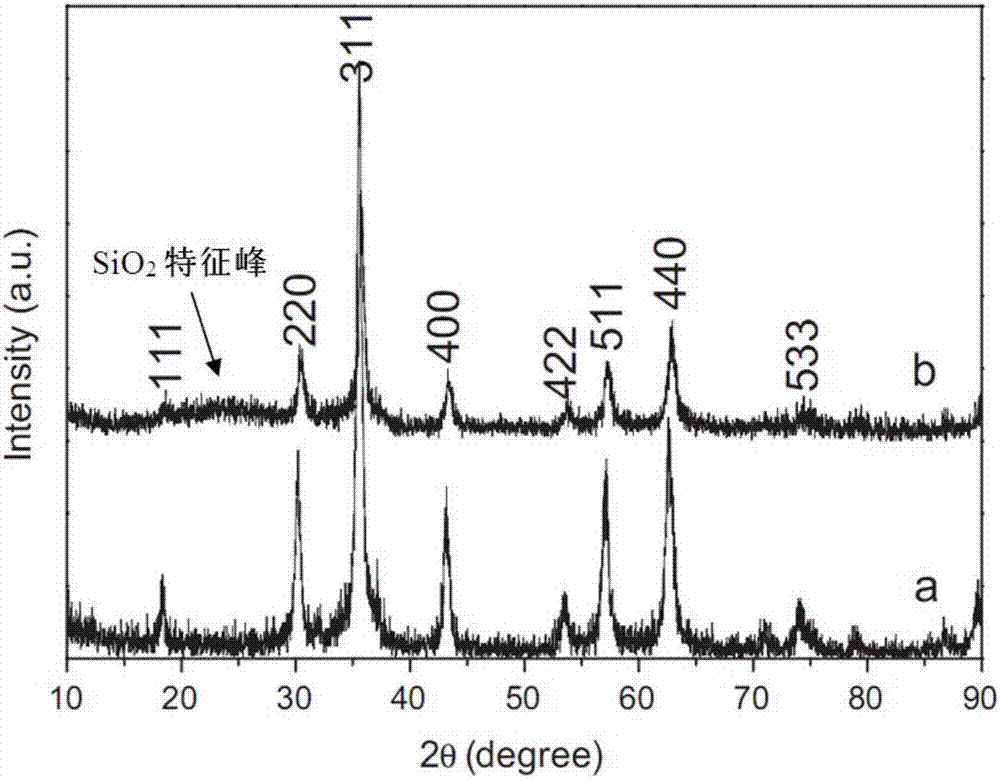

[0034] The present embodiment relates to nano-iron oxide brown (γ-Fe 2 o 3 ) as the core, and the nano-inorganic composite pigment whose outer layer is wrapped with silica, the preparation process is as follows figure 1 Specifically, follow the steps below:

[0035] a. Obtaining nano-iron oxide brown (γ-Fe 2 o 3 ) particles: 2.1mmol of FeCl 3 ·6H 2 O was dissolved in 35 mL of ethylene glycol solution, magnetically stirred until dissolved, and then 7.2 mmol of NaAc·3H was added to it 2 O, and then placed in a high-pressure reactor with a volume of 50 mL, reacted at 160 °C for 8 h, and cooled to room temperature naturally. The obtained product was washed several times with deionized water and dried at 60 °C to obtain γ-Fe 2 o 3 particles;

[0036] b. Add 0.10g of γ-Fe 2 o 3 The particles were dispersed in 70mL of ethanol solution with a concentration of 90%, ultrasonically treated at a frequency of 40kHz and a power of 90W for 30min, and the mass of γ-Fe 2 o 3 0.4 ti...

Embodiment 12

[0039] This embodiment relates to a nano-inorganic composite pigment with nano-iron oxide yellow as the core and an outer layer of silicon dioxide, and the specific steps are as follows:

[0040] a. Obtain nano-iron oxide yellow particles with a particle size of 80-120nm:

[0041] Step 1. Add 300mL of FeSO with a concentration of 1moL / L in the three-neck flask 4 Solution, add 16mL of 10moL / L sulfuric acid dropwise under stirring conditions, oxidize with 50mL sodium chlorate solution with a concentration of 1moL / L at about 50°C, and then raise the temperature to 85°C at a constant temperature to completely decompose excess sodium chlorate;

[0042]Step 2: Take 100mL of the solution prepared in Step 1, dilute it with an equal volume of water, add sodium hexametaphosphate and OP-10, and adjust the pH of the solution to 6.8-7.2 with 1moL / L NaOH solution;

[0043] Step 3. Heat up the iron glue prepared in step 2, add 150mL of the solution prepared in step 1 and 3g of iron powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com