Patents

Literature

33results about How to "Increased gas flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

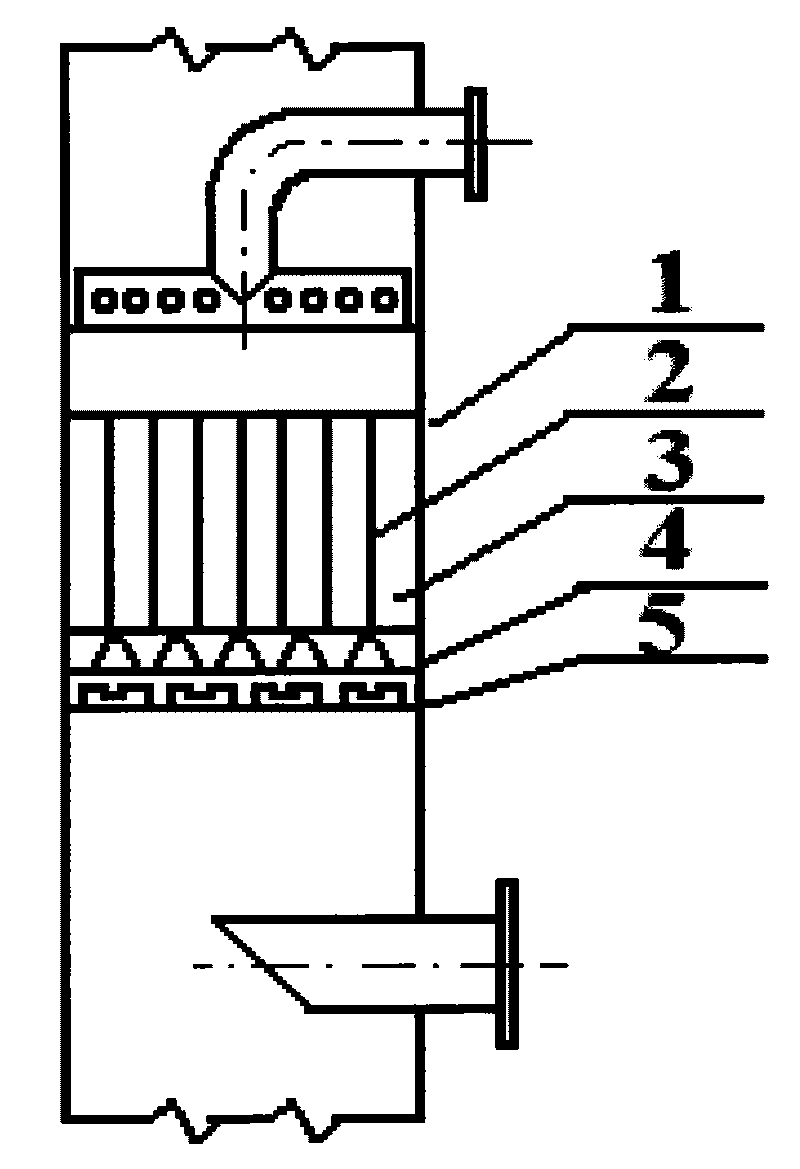

Device for treating organic smelly waste gas by utilizing coupled dielectric barrier discharge plasma

ActiveCN102553409AAvoid depositionLow investment costDispersed particle separationAlcoholTreatment effect

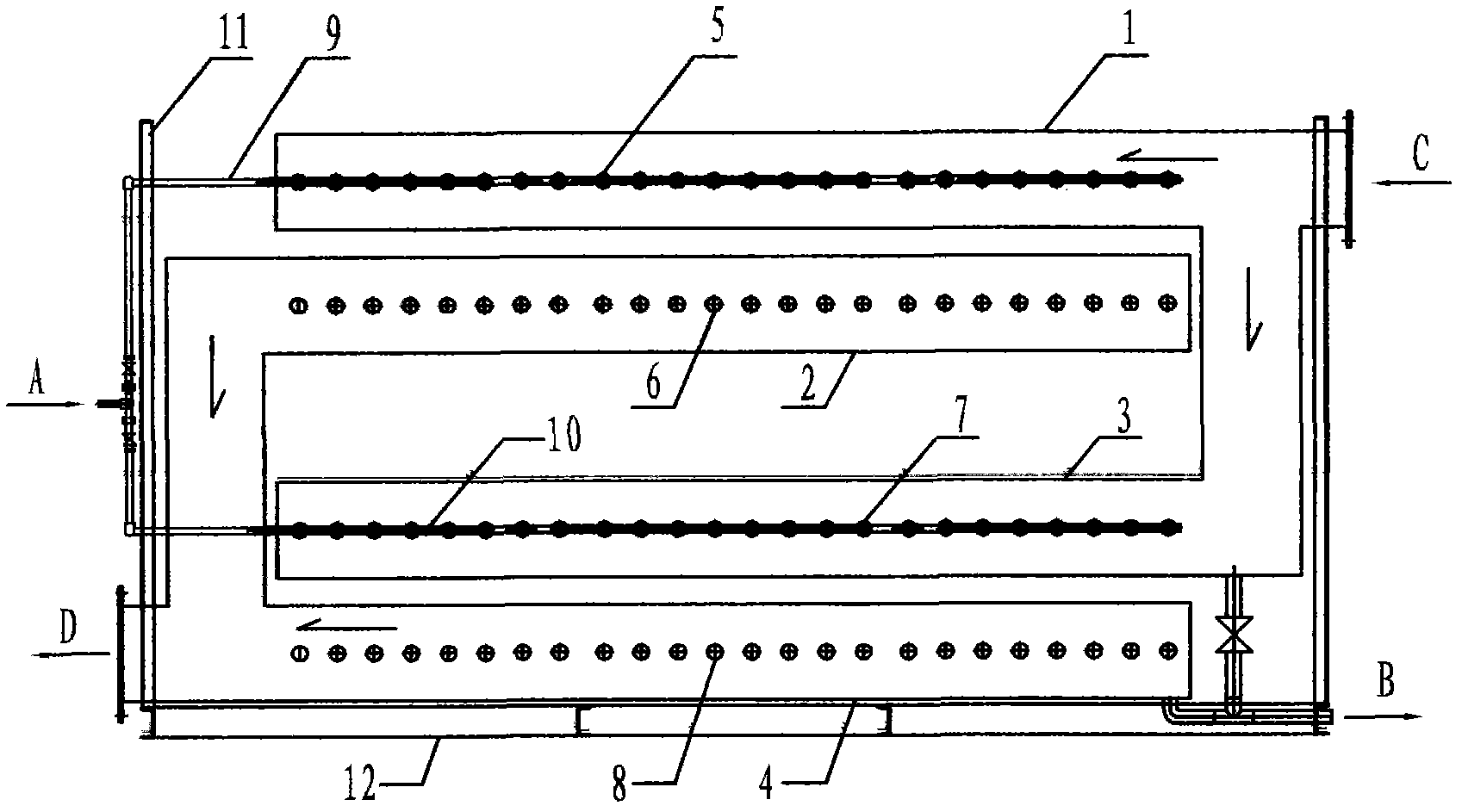

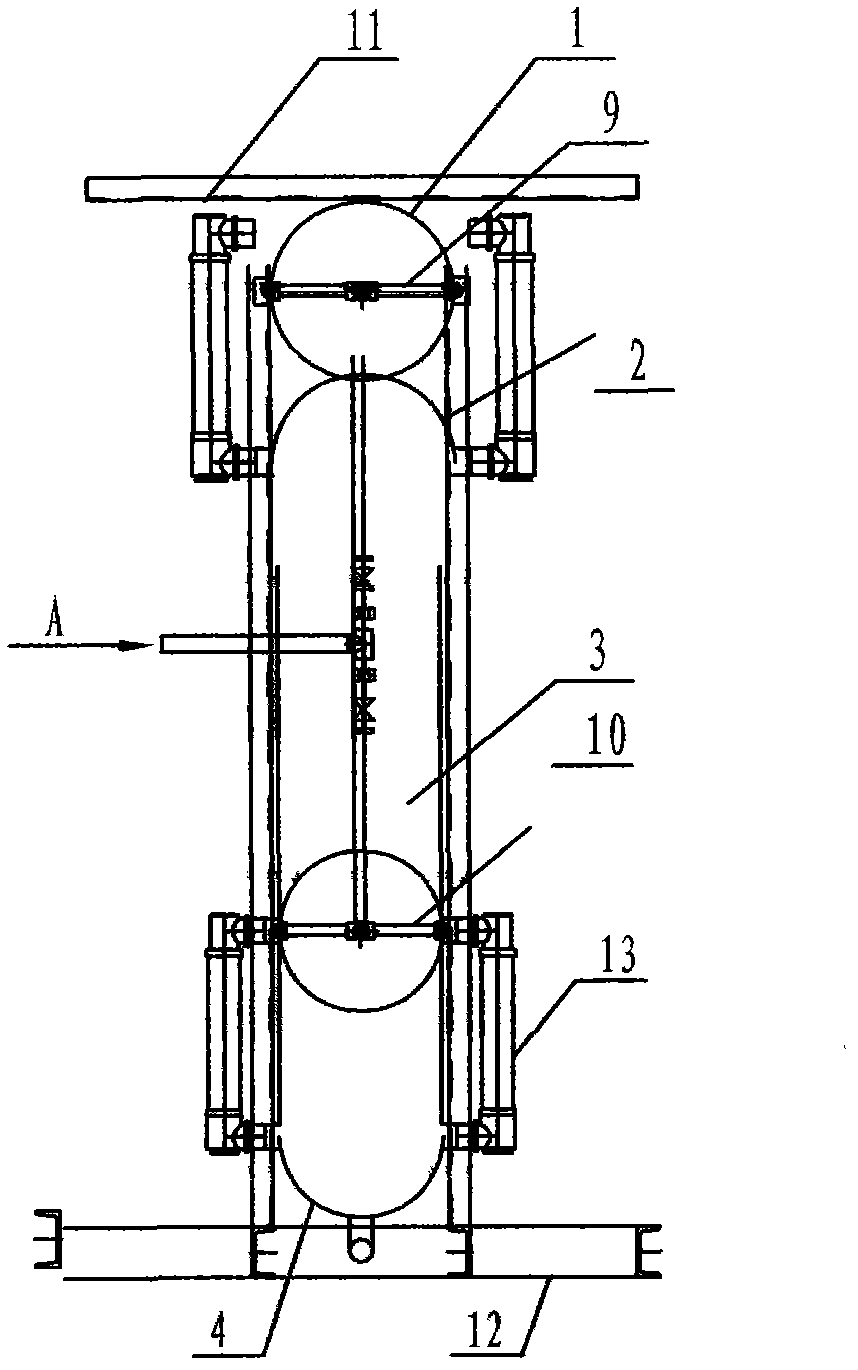

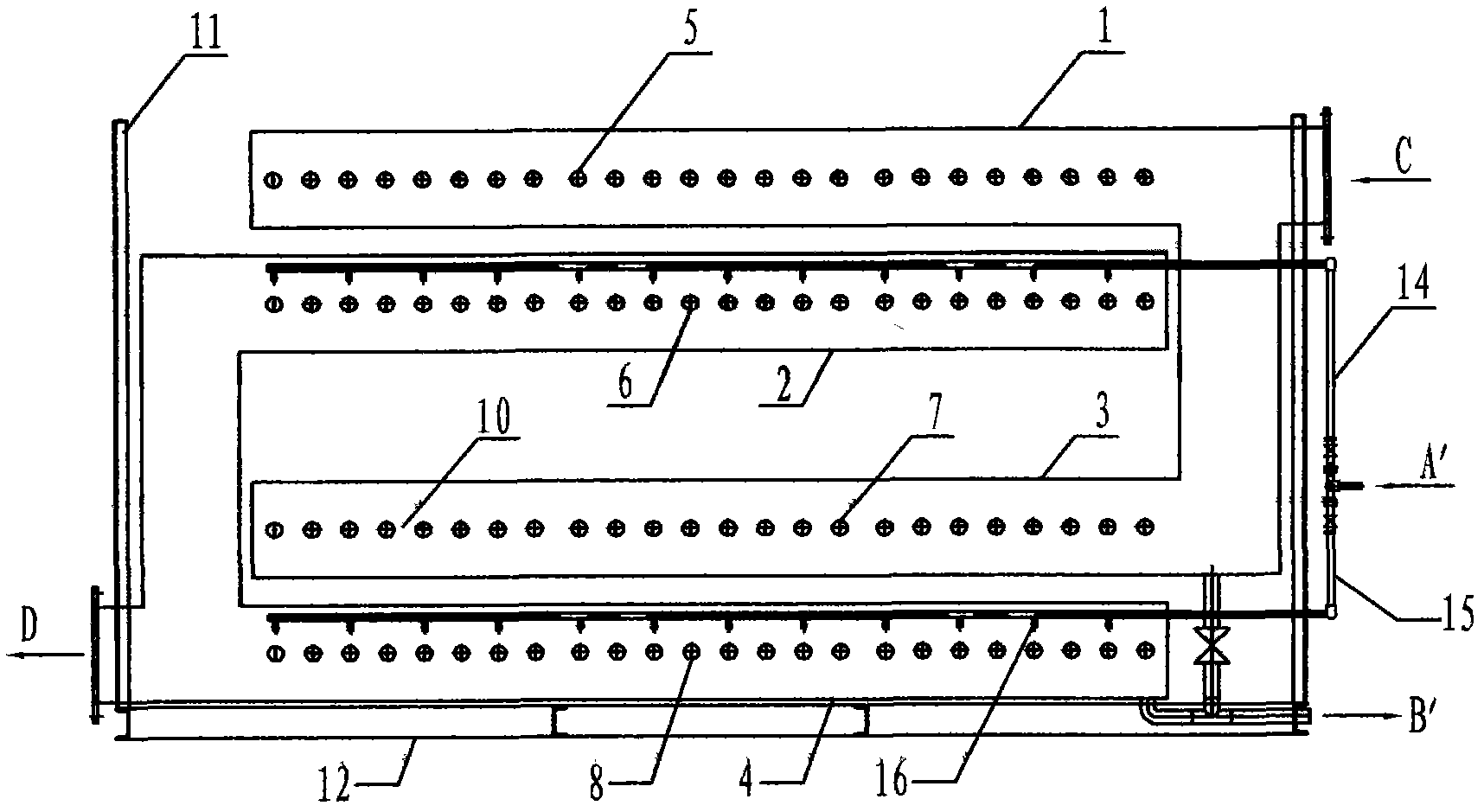

The invention relates to a device for treating organic smelly waste gas by utilizing coupled dielectric barrier discharge plasma and belongs to the technical field of organic smelly waste gas treatment process. The device comprises an upper air inlet distribution pipe, an upper air outlet collecting pipe, a lower air inlet distribution pipe, a lower air outlet collecting pipe, an upper discharging pipe air inlet, an upper discharging pipe air outlet, a lower discharging pipe air inlet, a lower discharging pipe air outlet, a bracket, a pedestal, a discharging pipe, a discharging pipe flushing system and a spraying system which is coupled in the upper air outlet collecting pipe and the lower air outlet collecting pipe. The coupled dielectric barrier discharge plasma has a compact structure, a good smelly pollution treatment effect and high energy efficiency, and can be widely applied to treatment on waste gas containing smelly substances such as benzene series, aldehyde, alcohol, carbon disulfide, organic amine and the like.

Owner:水木清研生态环保(山东)有限公司

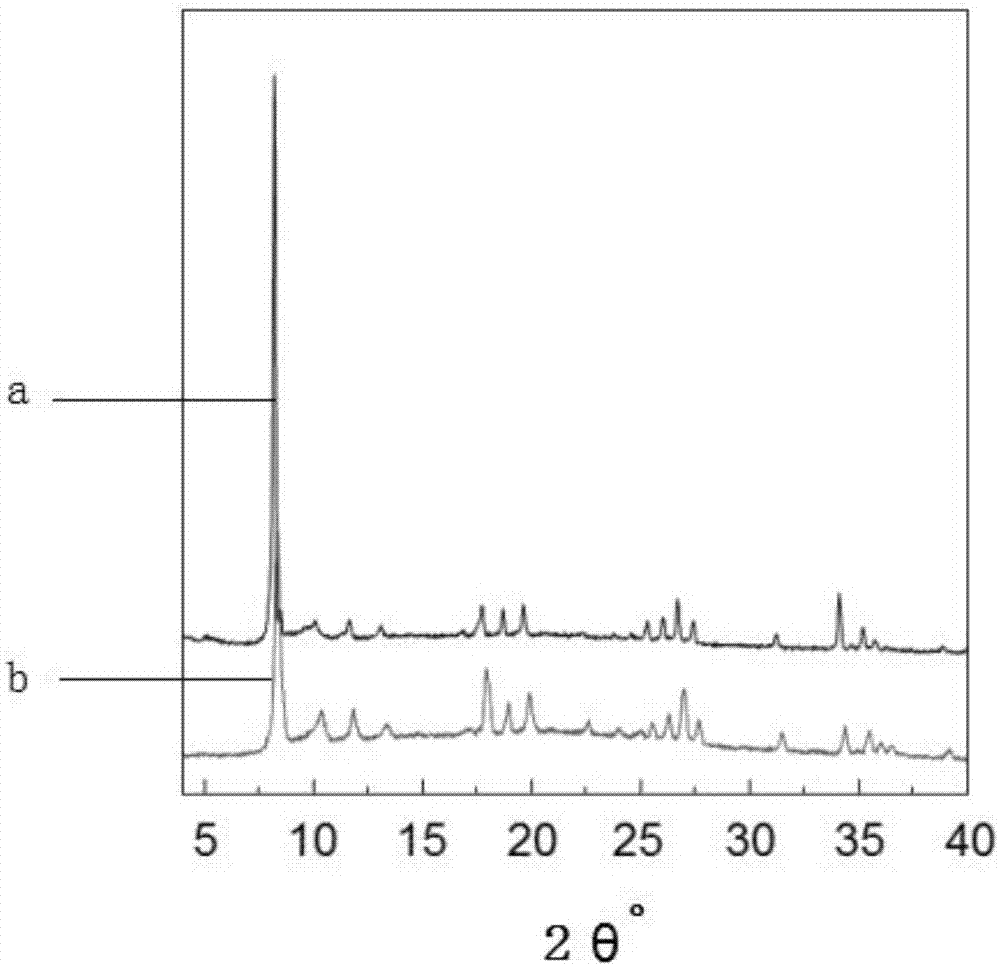

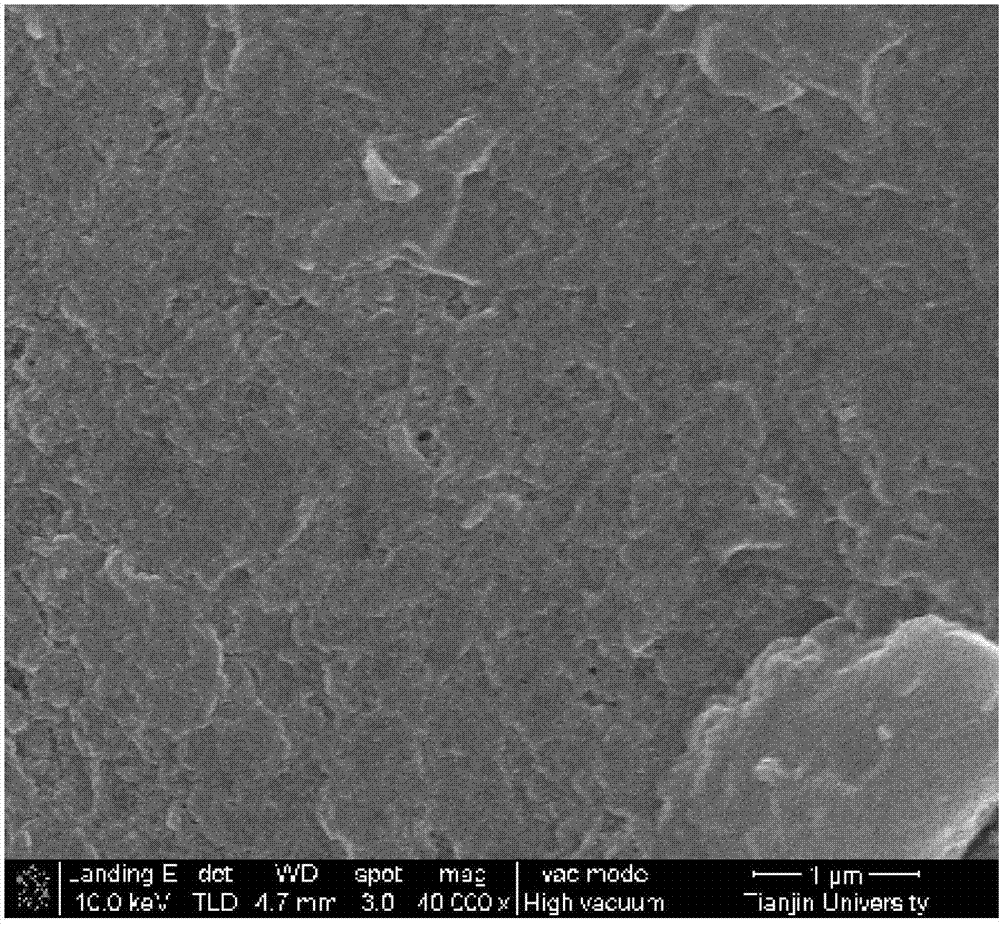

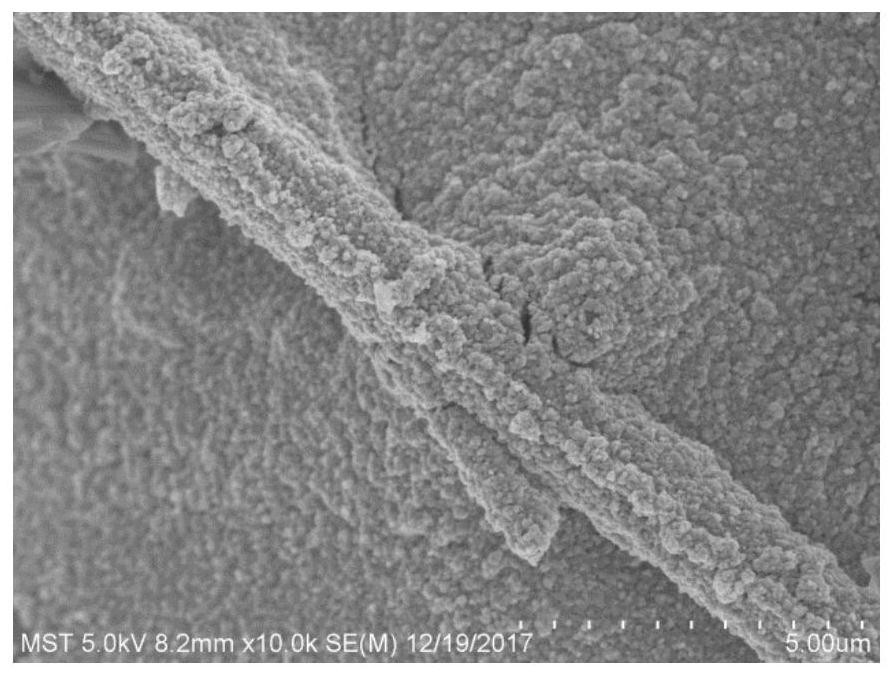

Composite film for MABR and preparation method

ActiveCN103182254AHigh oxygen permeabilityImprove surface hydrophilicitySemi-permeable membranesSustainable biological treatmentComposite filmBiocompatibility Testing

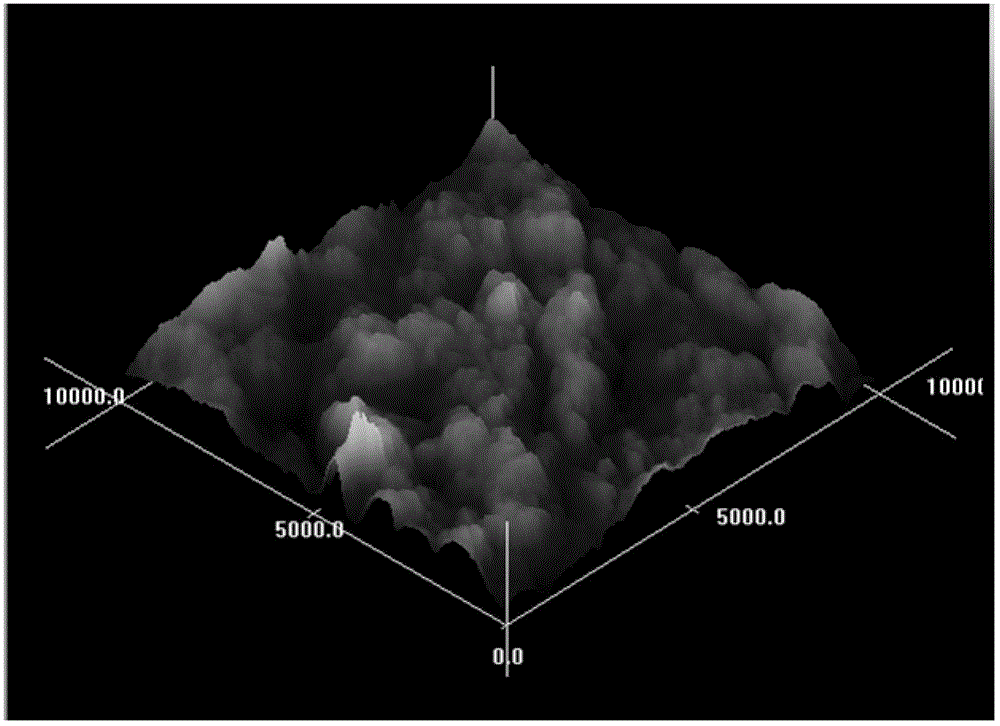

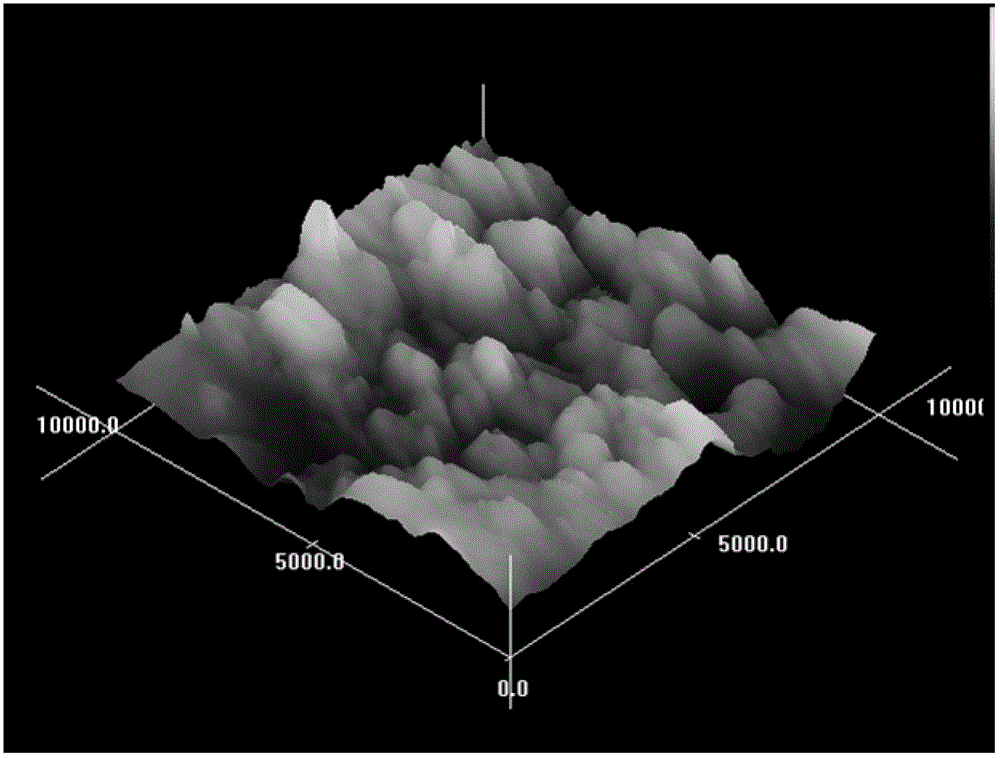

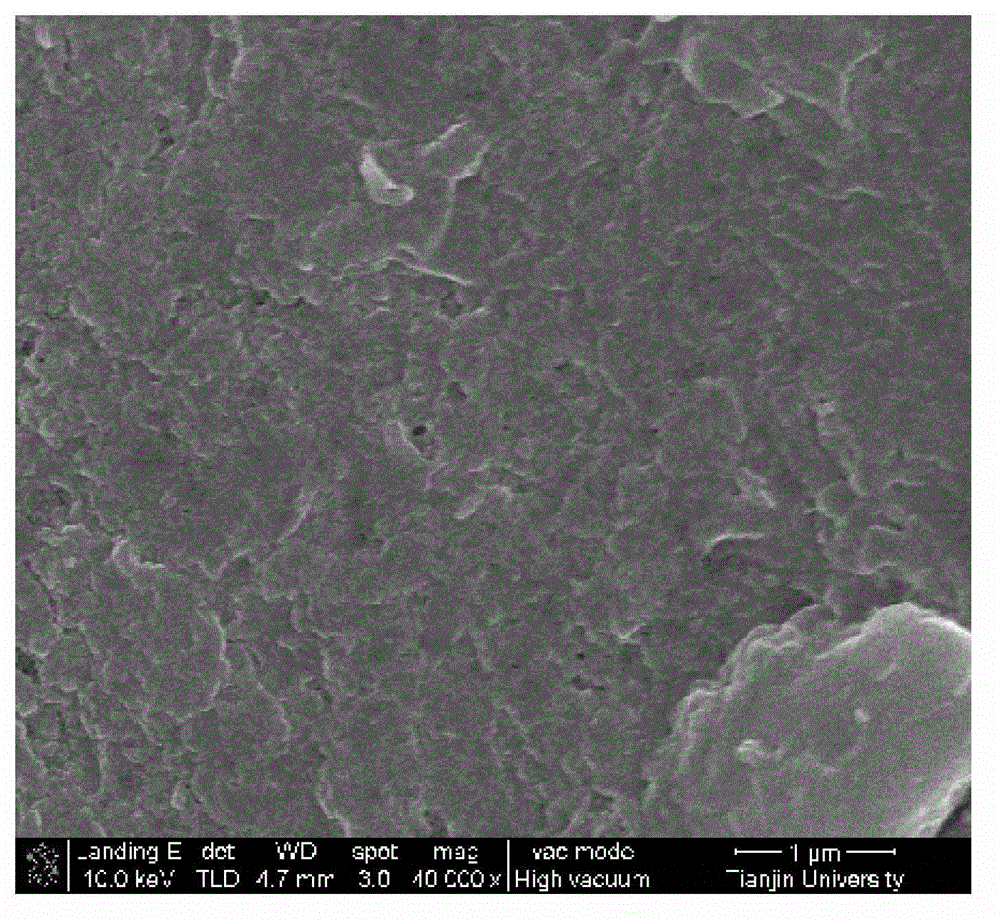

The invention relates to a composite film for an MABR (Membrane Aeration Biofilm Reactor) and a preparation method. The composite film is formed by a porous film and a levodopa composite layer compound on the surface of the porous film. The preparation method comprises the following steps: (1) preparing levodopa solution, i.e. preparing levodopa into the levodopa solution with concentration of 0.05 to 3g / L; (2) coating, i.e. uniformly coating the levodopa solution on the outer surface of the film; and (3) carrying out heat treatment, i.e. carrying out heat treatment on the composite film. The MABR composite film prepared by the preparation method disclosed by the invention has the advantages that the prepared film has high oxygen transmission performance, good surface hydrophilicity and biocompatibility and high roughness of the film surface.

Owner:TIANJIN HYDROKING SCI & TECH

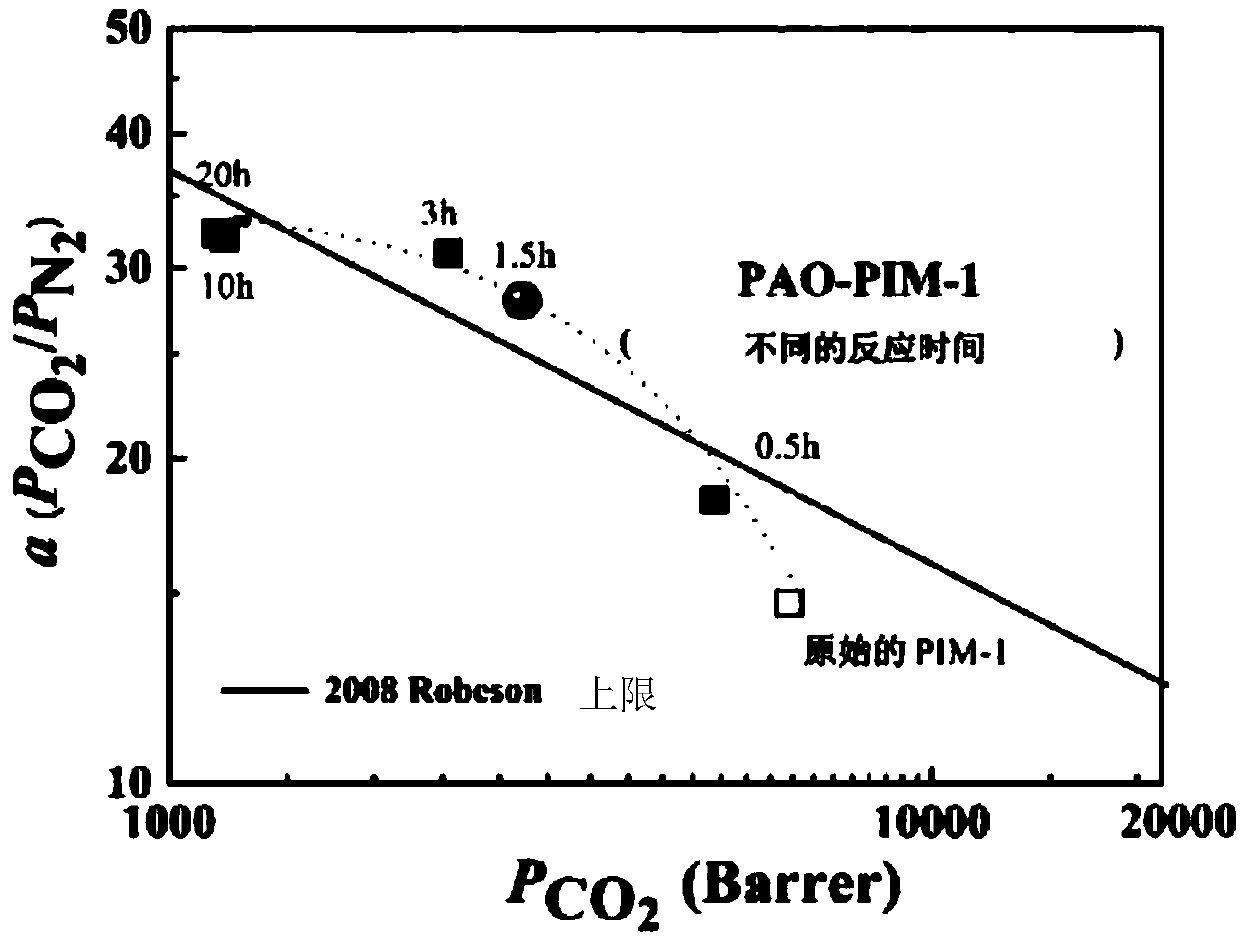

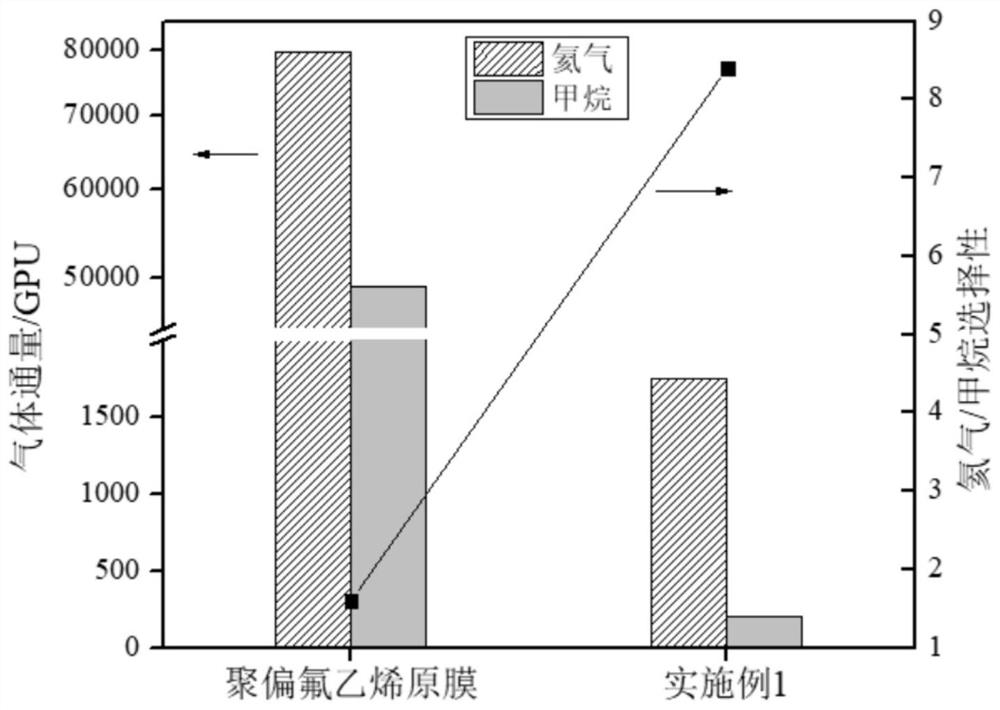

Macromolecular separation film as well as preparation method and application thereof

InactiveCN108854604AHigh selectivityImprove gas selectivitySemi-permeable membranesDispersed particle separationPolymer scienceSolvent

The invention discloses a macromolecular separation film as well as a preparation method and application thereof. The macromolecular separation film comprises a continuous phase of a polymer with a micropore structure, wherein the polymer comprises a microporous polymer and a dispersion phase containing inorganic materials; the microporous polymer comprises PIM-1 and / or PIM-1 derivatives. The preparation method comprises the following steps of uniformly mixing the microporous polymer and the inorganic materials into a solvent to obtain a blended solution; coating the blended solution onto a polymer support layer to obtain a macromolecular separation film. The composite gas separation film maintains good mechanical performance, thermal stability and processing performance of the polymer materials and good gas selection performance of inorganic materials, and has the advantages of high seepage performance and high selectivity during mixed gas separation, particularly oxygen gas and nitrogen gas separation; the preparation method is simple; the method is suitable for scaled industrial production; the potential application prospects are realized in the aspects of rich-oxygen, namely oxygen gas enriching application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

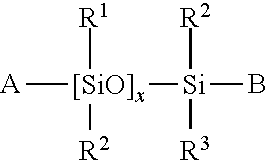

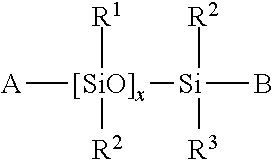

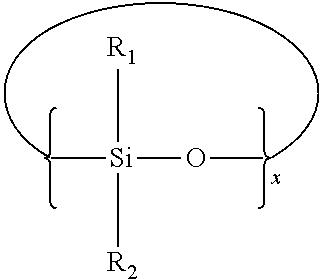

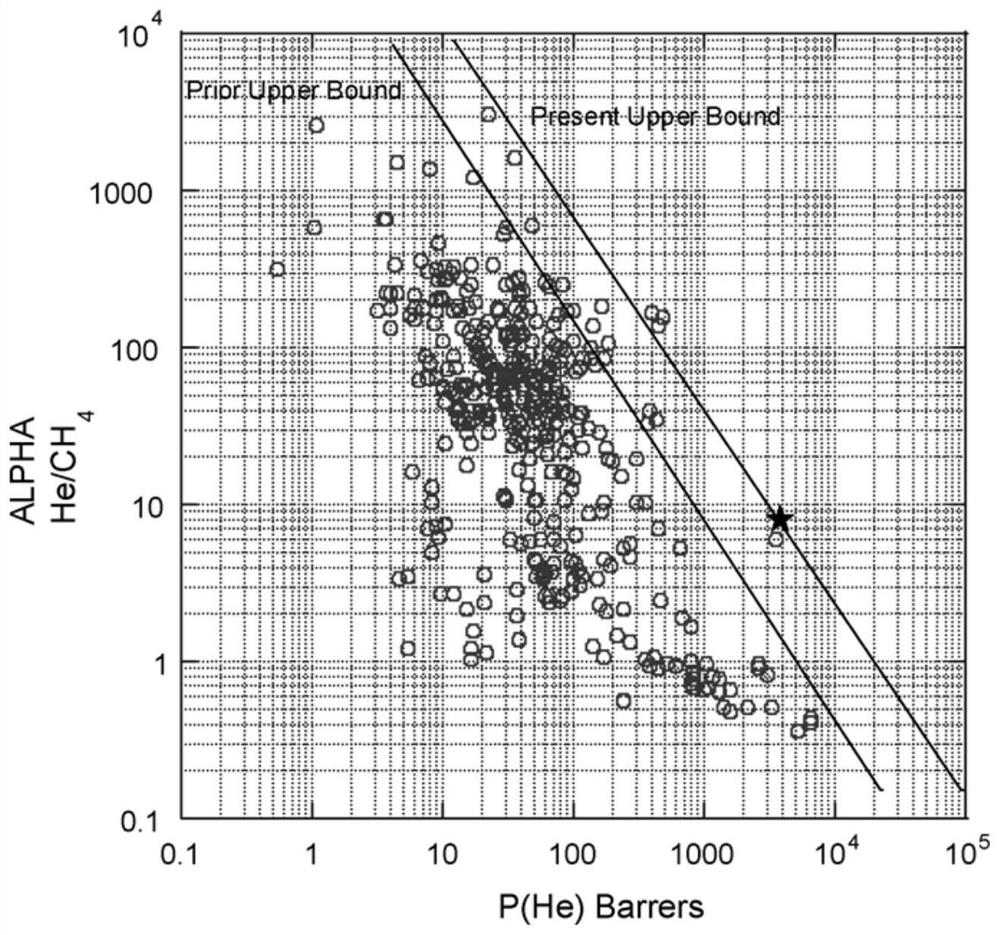

Organosiloxane Films for Gas Separations

ActiveUS20150306549A1Rapid fragmentationReduce volatilityNitrogen purification/separationMembranesPorous substrateHydrogen atom

A semipermeable gas separation membrane is plasma deposited from liquid organosiloxane monomer having at least three silicon atoms and an alpha hydrogen atom. The semipermeable membrane may be employed as a gas-selective membrane in combination with a porous substrate.

Owner:APPLIED MEMBRANE TECH

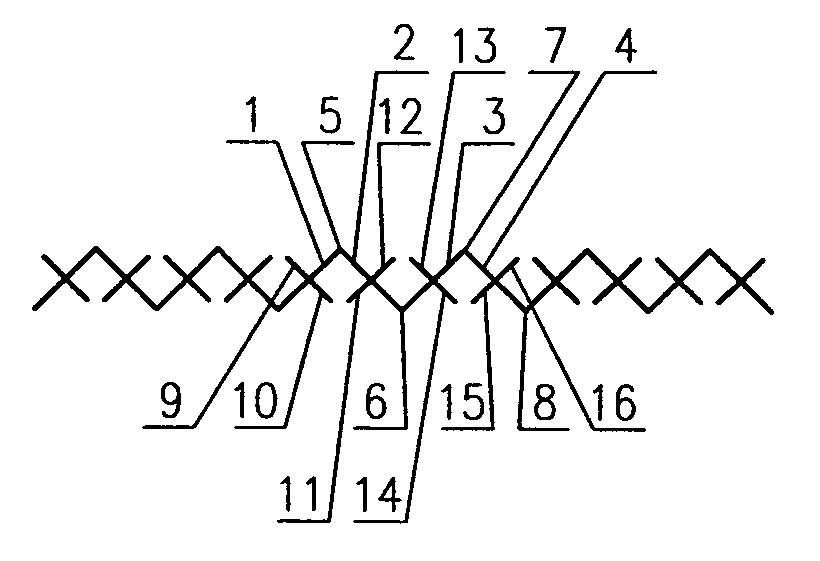

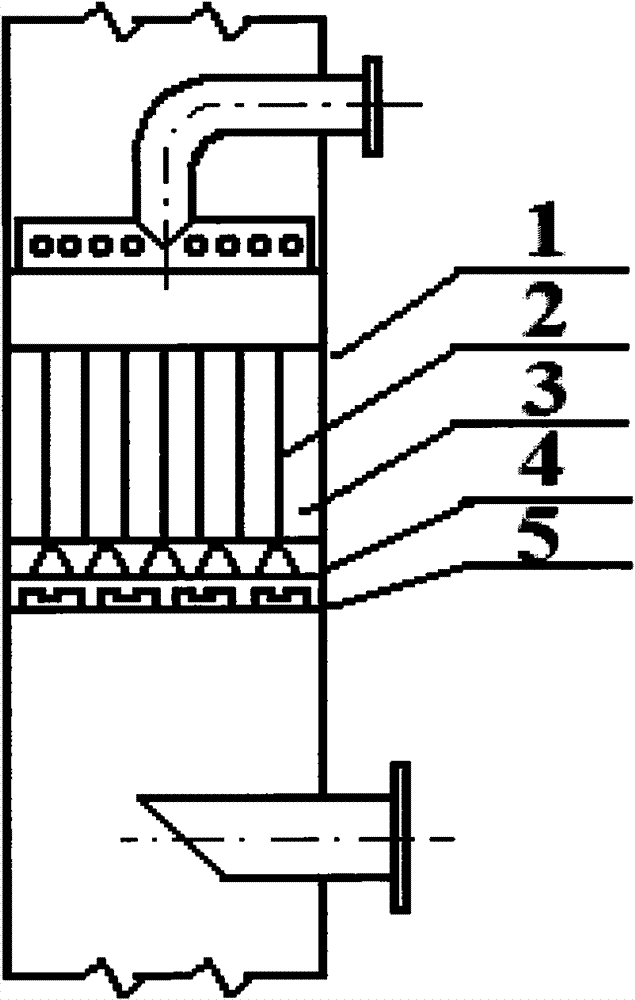

Filler assembly capable of eliminating amplification effect

ActiveCN101708452AEvenly distributedEfficient and stable mass transfer effectChemical/physical/physico-chemical processesFractional distillationEngineeringTower

The invention discloses a filler assembly capable of eliminating amplification effect, which comprises a filler section, a filler clapboard, filler units, a filler support plate and a liquid redistribution board, wherein the filler clapboard partitions the filler section into a plurality of filler units, the liquid redistribution board is provided with open pores matched with the filler units, a weir is arranged around the open pores, the weir is provided with tooth gaps, and the open pores have the shapes similar to those of the filler units, and have small area. The assembly changes a filler tower into the plurality of filler units connected in parallel, and the vapor and liquid of the filler section are uniformly distributed and the wall flow effect is eliminated by matching the corresponding liquid redistribution board so as to ensure efficient and stable mass transfer effect and eliminate the amplification effect; the adverse initial distribution of a liquid distributor is corrected; by adopting a plug-in structure, the treatment capacity of the tower is only related to the number of the filler units, so the design of the tower is not limited by the scale; and the liquid distributor is replaced by a distribution board so as to reduce the requirements on tower height and mounting level and reduce the investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

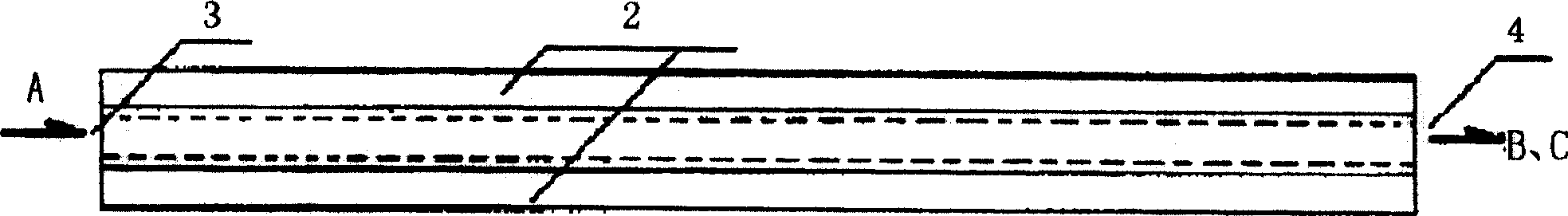

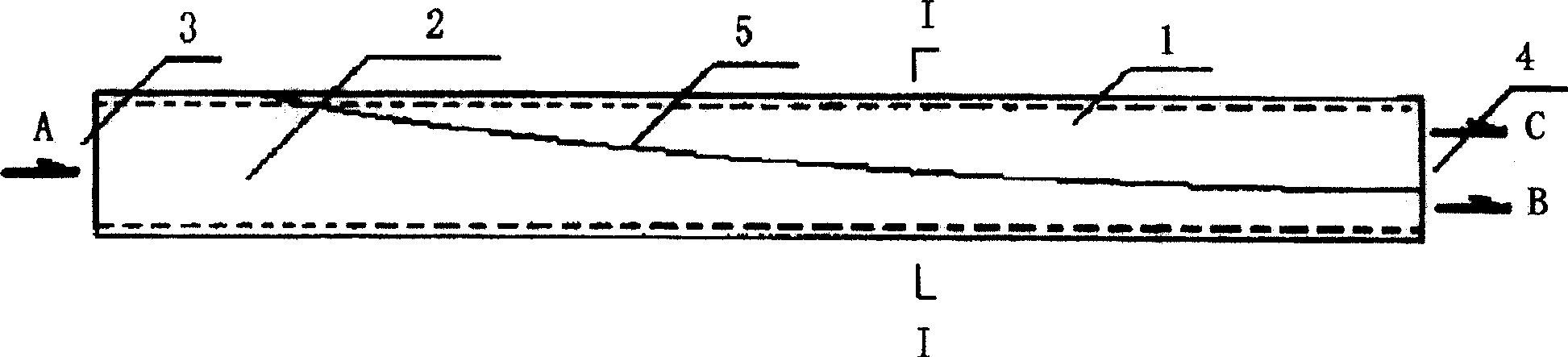

Preparation method of hollow fiber oxygen permeable membrane

The invention relates to a preparation method of a hollow fiber oxygen-enriched membrane, which can effectively solve the problems of small specific surface area, small processing capacity, low efficiency, complicated preparation process, difficult operation, and difficulty in industrialized production of the membrane. The method is that the lining support pipe The outer surface of the hollow fiber oxygen-enriched membrane is prepared by needle electrospinning equipment, and then cleaned with deionized water and left to dry; it is prepared by mixing a hydroxyl-terminated polymer, a catalyst, a cross-linking agent and a first solvent Molding solution: Coat the casting solution on the porous substrate, firstly cure it at room temperature for 1-20 minutes, and then cure it at 50-80°C for 20-45 minutes, so that the silicone rubber can be completely cross-linked and form a hollow fiber oxygen-enriched membrane ; The present invention has higher gas flux, and the flux can reach 1.3m 3 / (m 2 h), the process is simple, easy to operate, and suitable for industrial applications.

Owner:ANYANG HUASEN PAPER

Organosiloxane Films for Gas Separations

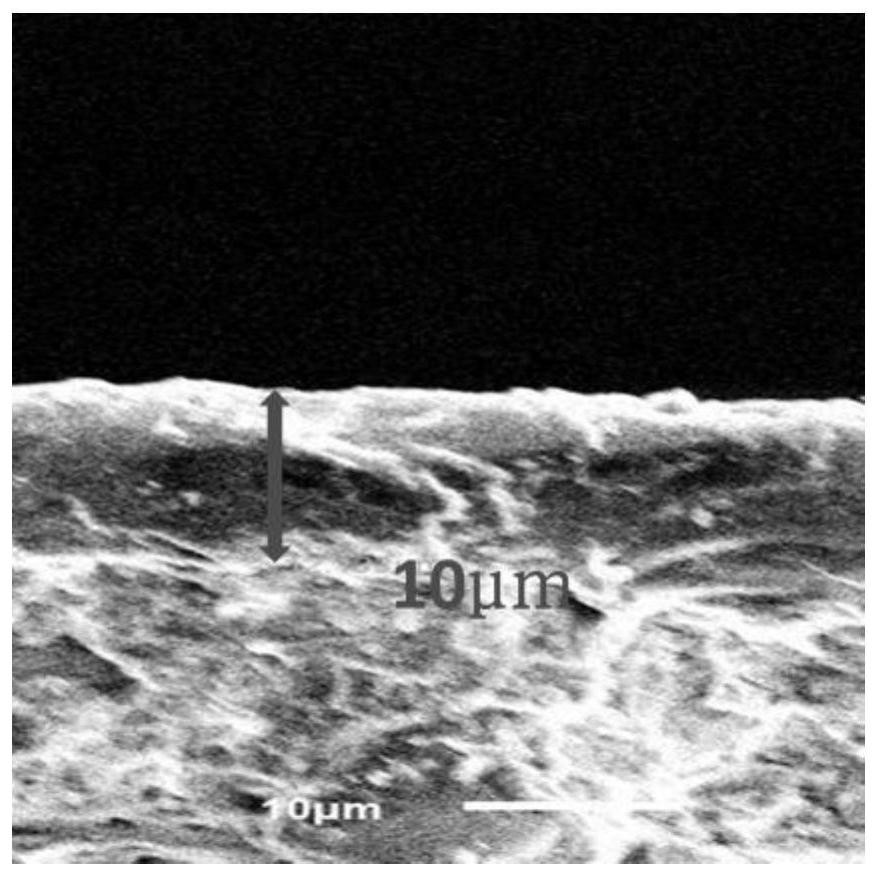

InactiveUS20150135957A1Increased gas fluxReduce the effects of agingSemi-permeable membranesGas treatmentPorous substrateHydrogen atom

A semipermeable gas separation membrane is plasma deposited from liquid organosiloxane monomer having at least three silicon atoms and an alpha hydrogen atom. The semipermeable membrane may be employed as a gas-selective membrane in combination with a porous substrate.

Owner:APPLIED MEMBRANE TECH

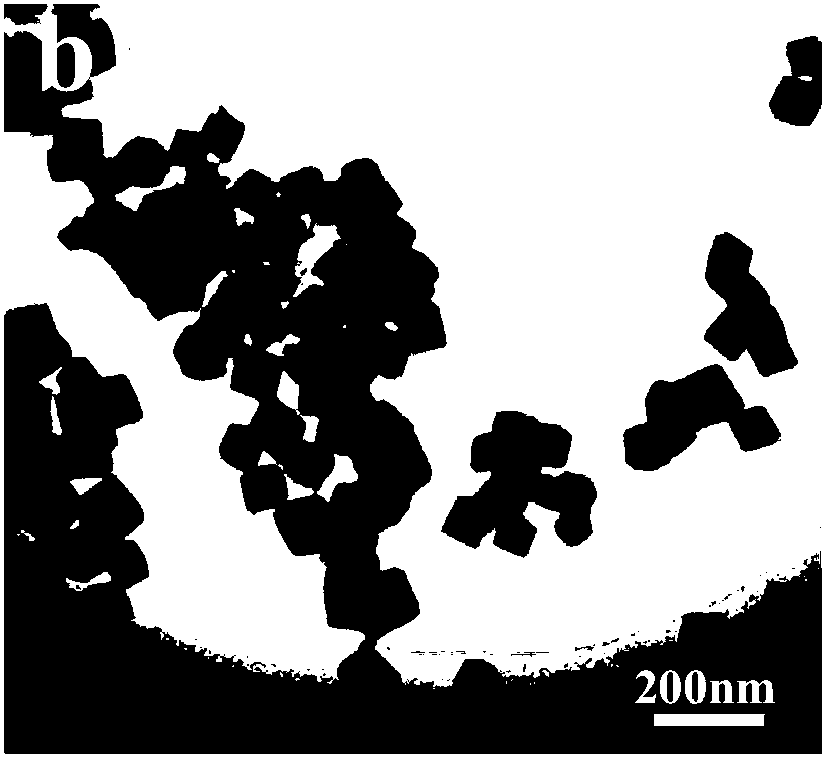

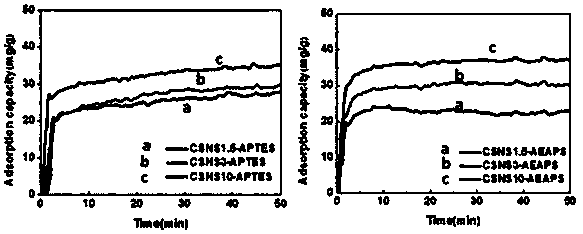

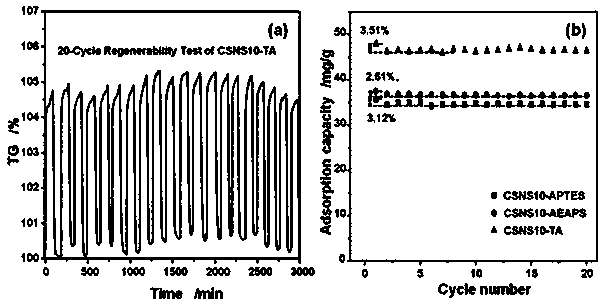

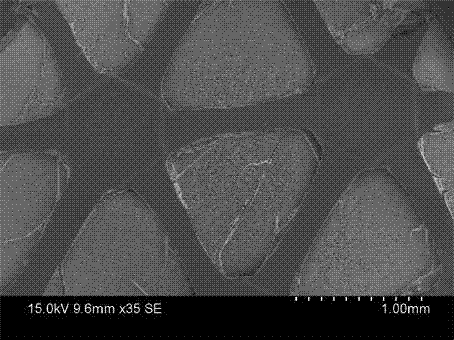

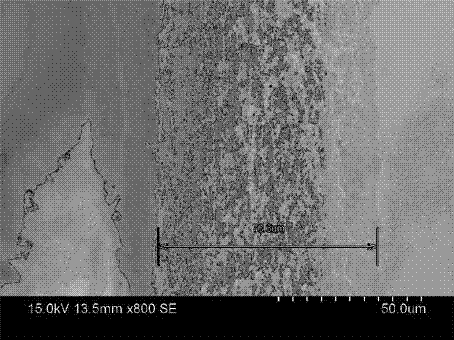

Preparation method of spherical CSNS-Amine nanostructure CO2 adsorbent

The invention discloses a CO2 solid amine adsorbent and a preparation method thereof. The adsorbent comprises a mesoporous copper silicate nano-microsphere carrier (core-shell microspheres and hollowspheres); 3-aminopropyltriethoxysilane (APTES), N-(beta-aminoethyl)-gama-aminopropyltrimethoxysilane (AEAPS) and diethylenetriamine trimethoxysilane (TA) are bonded to the surfaces of copper silicatenanospheres by a grafting method to obtain the solid amine adsorbent which is applied to CO2 adsorption. The preparation method comprises the following specific steps: (1), synthesizing SiO2 nanospheres (200 nanometers) by an improved Stober method; (2), with the SiO2 microspheres as moulds, synthesizing copper silicate nanospheres by a hydrothermal method, and preparing CuSiO3@SiO2 core-shell nanosphere materials and CuSiO3 hollow nanosphere materials through different hydrothermal reaction times; (3), aminating the surface of copper silicate nanosphere carrier by using the APTES, the AEAPS and the TA. The adsorbent has the significant advantages of good heat stability, relatively low adsorption and desorption temperature, good adsorption and desorption cycle stability, relatively large adsorption capacity and the like, and can capture CO2 relatively efficiently.

Owner:SICHUAN UNIV

Micro-filtration membrane for filtering PM2.5 particulate matters and preparation method of membrane

InactiveCN103785249AAvoid uneven pore size distributionUniform thicknessSemi-permeable membranesDispersed particle filtrationFiberParticulates

The invention discloses a micro-filtration membrane for filtering PM2.5 particulate matters. The micro-filtration membrane comprises a composite layer formed by performing high-temperature hot-pressing on a separation layer and a supporting layer, wherein the separation layer is a PTFE (polytetrafluoroethylene) porous film formed by heating and stretching a PTFE base band and is in a three-dimensional stereoscopic crossed structure; the PTFE base band is formed by mixing fine PTFE powder and a lubricating agent such as petroleum ether into paste and performing extrusion by a die; the supporting layer is made of a polyethylene material and is in a meshed structure. The micro-filtration membrane has the largest pore diameter of 0.3 micron, is uniform in fiber fineness and uniform in thickness and has the porosity within 80-90 percent. According to the measurement, the gas flux can be 18000L / m<2>.min under the differential pressure of 0.1 bar, and the filtering effect is relatively obvious.

Owner:ANHUI NAWE ENVIRONMENTAL PROTECTION TECH

Hybrid mechanism film and preparation method thereof

InactiveCN107970786AIncreased gas fluxGood chemical stabilityMembranesSemi-permeable membranesSilicon dioxideChemical stability

The invention relates to a hybrid mechanism film and a preparation method thereof and belongs to the technical field of a gas separation film. The invention aims to provide the hybrid mechanism film and the preparation method thereof. The hybrid mechanism film is uniform, continuous and long-acting, and has high gas flux, high selectivity, high gas separation property and excellent chemical stability. According to the hybrid mechanism film, a porous silicon dioxide film serves as a substrate, and a mixture of a soluble inherent microporous polymer and a metal organic frame material with the mass ratio of (90-70):(10-30) serves as a surface; and in the preparation process, the soluble inherent microporous polymer and the metal organic frame material are mixed and the surface of the porous silicon dioxide film is coated with the mixture uniformly. The hybrid mechanism film is uniform, continuous and long-acting, has high gas flux and high gas selectivity and has high gas separation property and excellent chemical stability; and the preparation method is simple, low in cost and favorable for industrialization.

Owner:JILIN UNIV

Composite membrane for mabr and preparation method thereof

ActiveCN103182254BHigh oxygen permeabilityImprove surface hydrophilicitySemi-permeable membranesSustainable biological treatmentSurface roughnessBiocompatibility Testing

The invention relates to a composite film for an MABR (Membrane Aeration Biofilm Reactor) and a preparation method. The composite film is formed by a porous film and a levodopa composite layer compound on the surface of the porous film. The preparation method comprises the following steps: (1) preparing levodopa solution, i.e. preparing levodopa into the levodopa solution with concentration of 0.05 to 3g / L; (2) coating, i.e. uniformly coating the levodopa solution on the outer surface of the film; and (3) carrying out heat treatment, i.e. carrying out heat treatment on the composite film. The MABR composite film prepared by the preparation method disclosed by the invention has the advantages that the prepared film has high oxygen transmission performance, good surface hydrophilicity and biocompatibility and high roughness of the film surface.

Owner:TIANJIN HYDROKING SCI & TECH

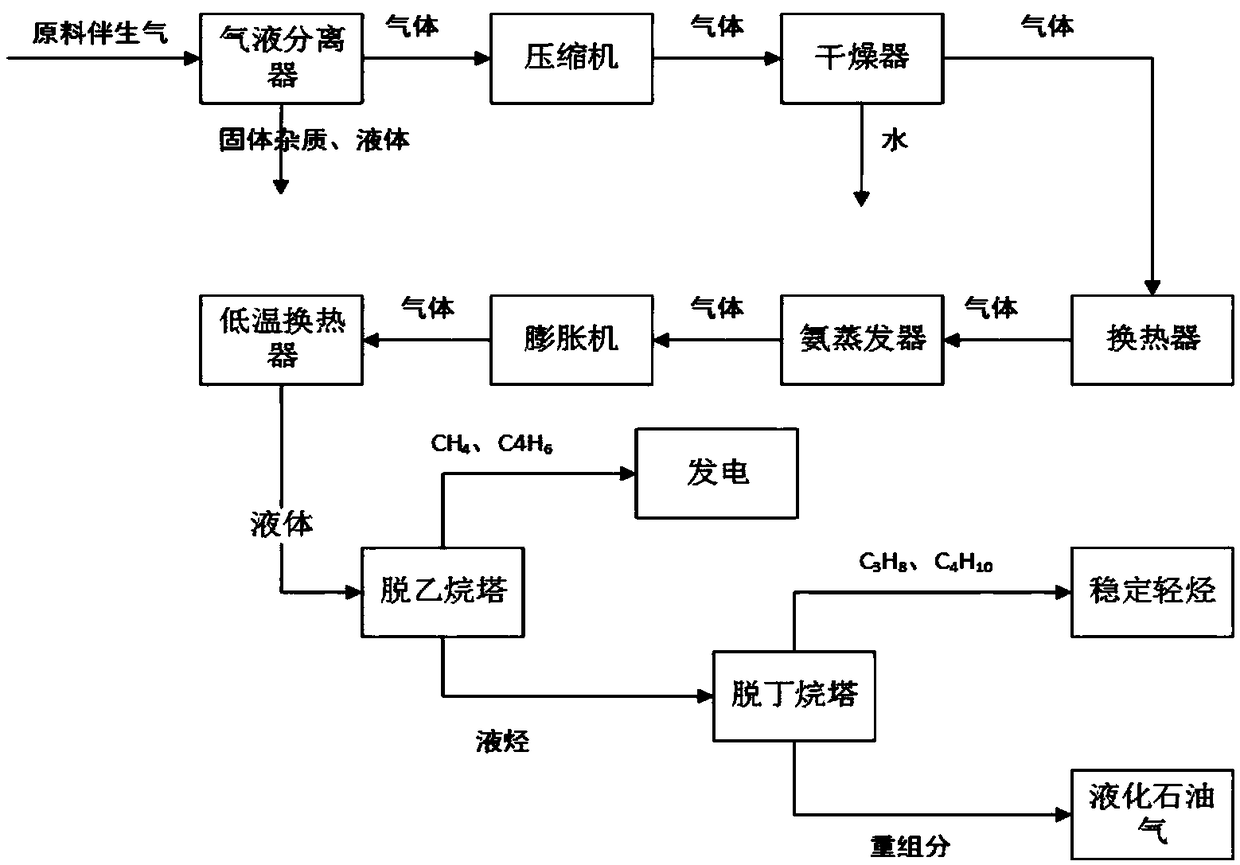

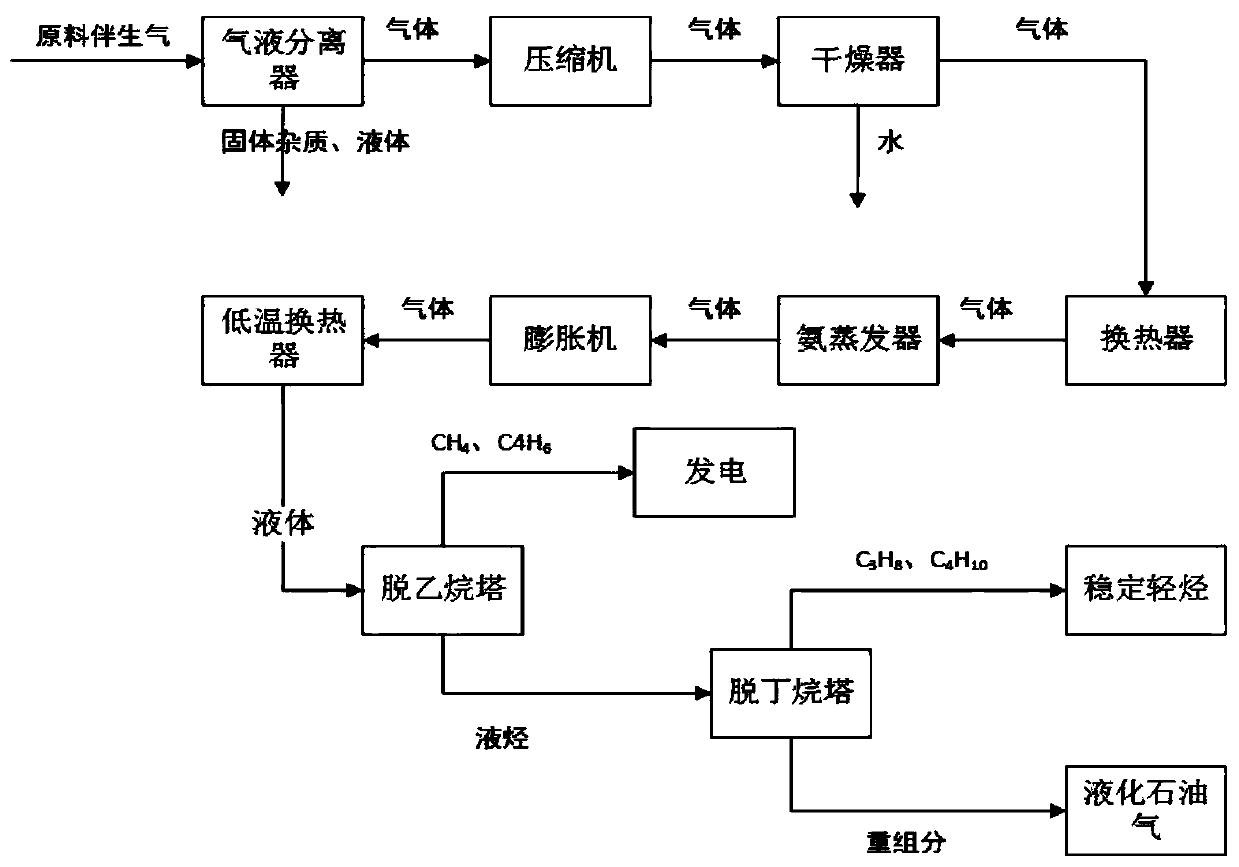

Treatment technology for petroleum associated gas

ActiveCN109321297APrevent liquefactionConducive to liquefactionGaseous fuelsComposite filmDistillation

The invention discloses a treatment technology for petroleum associated gas, and belongs to the technical field of treatment of petroleum associated gas. The treatment technology comprises the following steps of compression of the associated gas, drying, pre-cooling by ammonia, refrigerating by an expansion machine, distillation of product, and dry gas power generation; in the drying process, a composite film is used for drying and dewatering; the composite film is a double-layer composite film which is prepared by mixing and weaving stainless steel fibers and glass fibers into a net-shaped bottom film, pressing a thin film into a blank, firing and forming. The treatment technology for the petroleum associated gas has the advantages that the petroleum associated gas is treated and is usedfor dry gas power generation; the operation is simple, and the treatment steps are concise; a film drying technique is used for dewatering, the dewatering speed is high, the permeation amount of gas is high, and the secondary pollution due to production of dust is avoided.

Owner:杭州勃扬能源设备有限公司

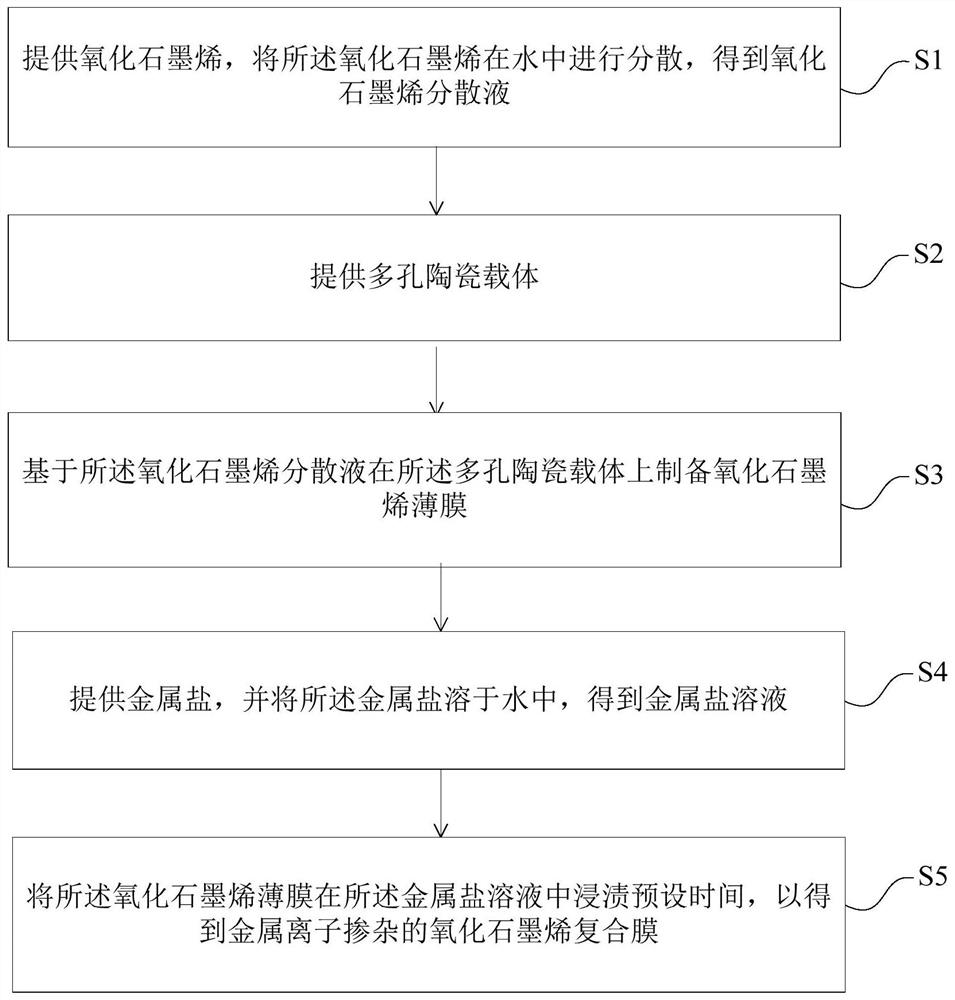

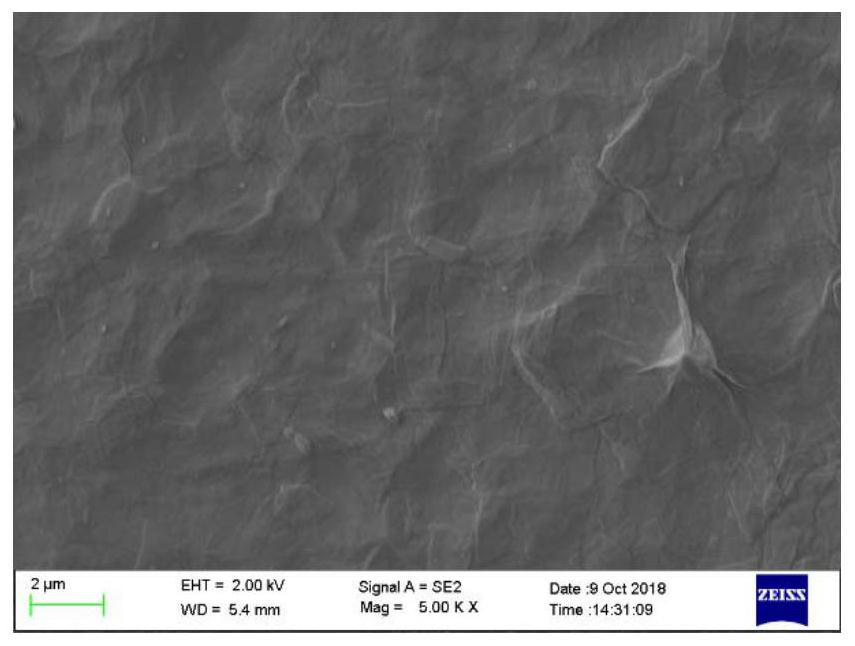

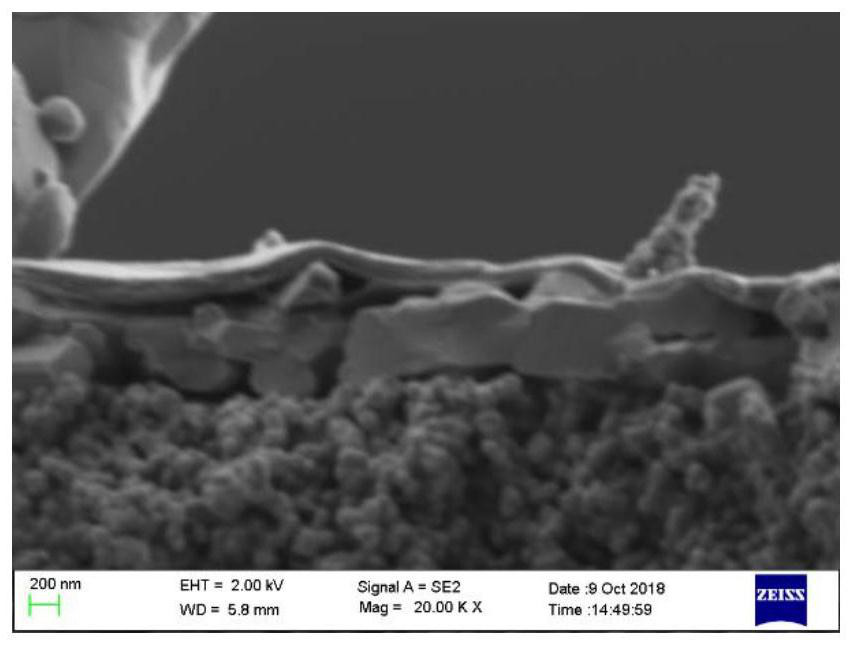

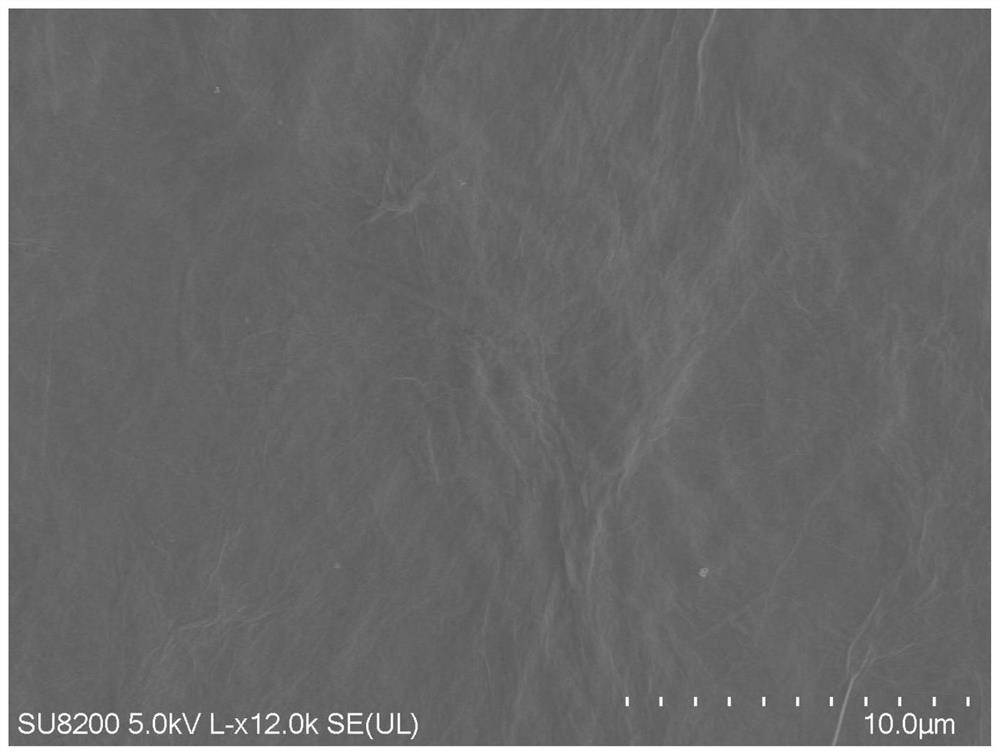

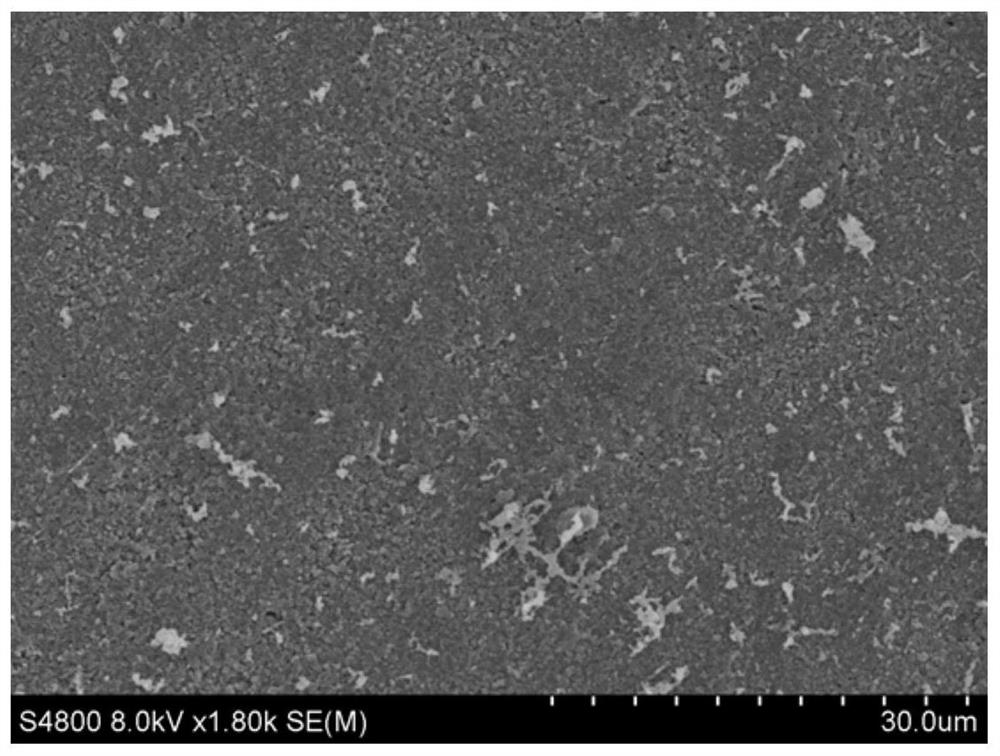

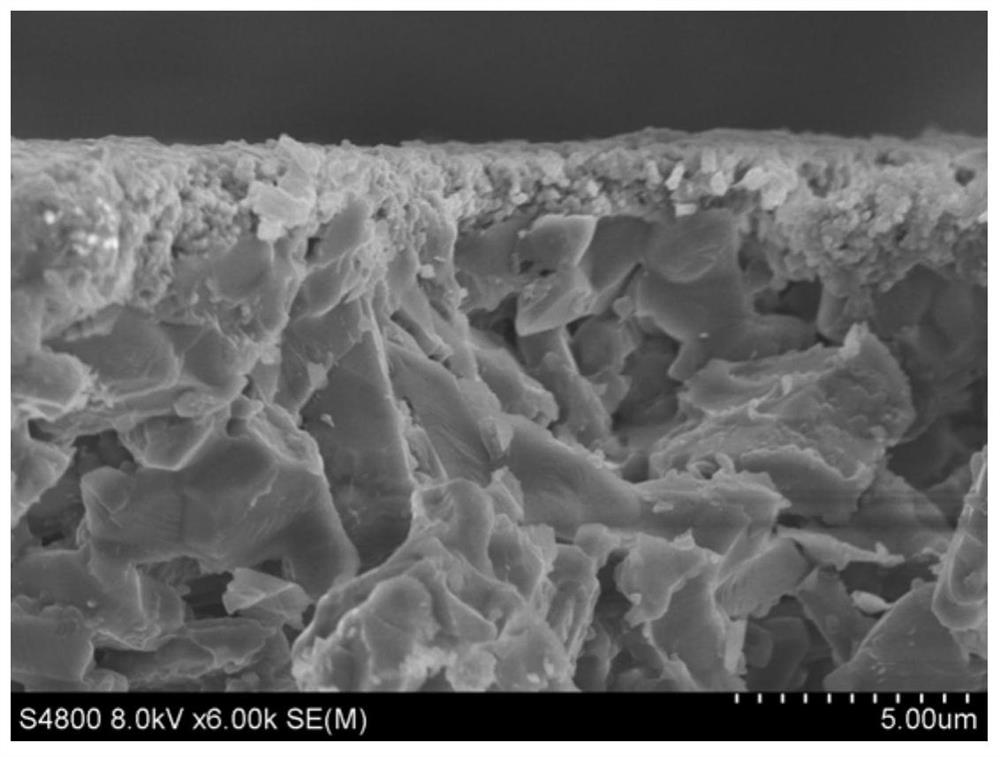

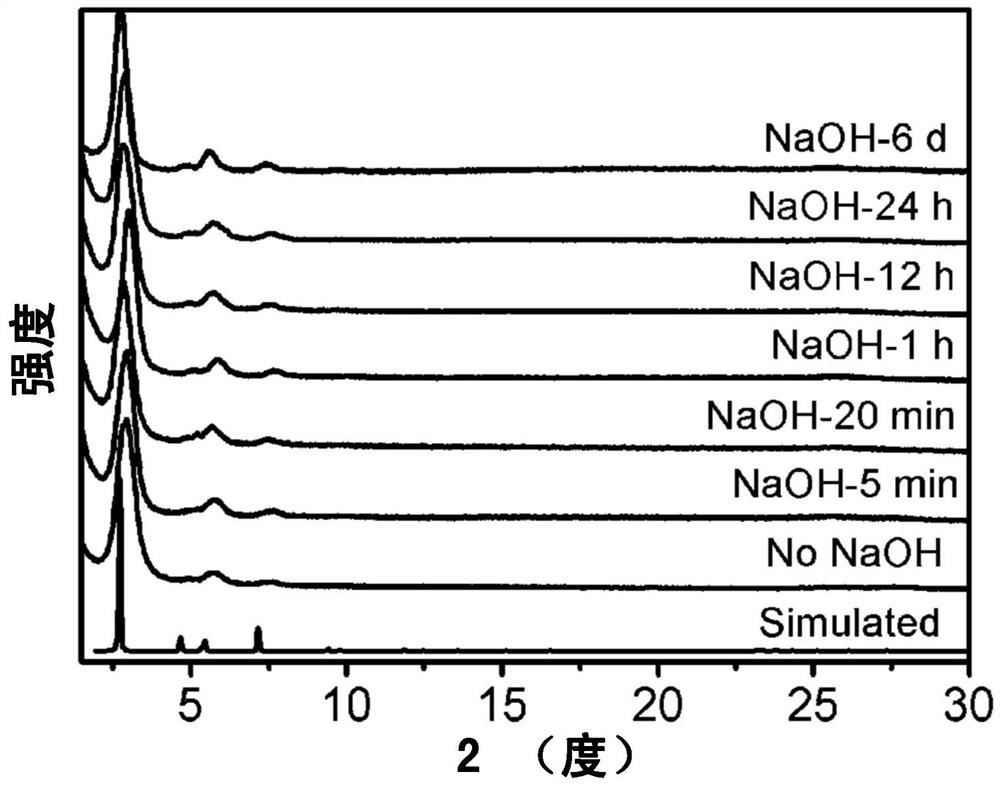

Metal ion-doped graphene oxide composite film, and preparation method and application thereof

PendingCN112957930AIncreased gas fluxEfficient separationSemi-permeable membranesDispersed particle separationThin membraneAlkene

The invention provides a metal ion-doped graphene oxide composite film, and a preparation method and application thereof. The preparation method comprises the following steps: preparing a graphene oxide dispersion liquid, preparing a graphene oxide film on a porous ceramic carrier based on the graphene oxide dispersion liquid, and dipping the graphene oxide film structure in a metal salt solution so as to obtain the metal ion-doped graphene oxide composite film. According to the method, the graphene oxide film is formed through control, metal ion doping is conducted on the graphene oxide film in the corresponding metal salt solution through an impregnation method, effective ion-pi effect can be formed through the above technical scheme, and the metal ions are introduced into the graphene oxide film through the ion-pi effect, so the purpose of separating olefin from alkane is achieved; and the graphene oxide composite film has high gas flux and can effectively separate olefin and alkane, and the preparation method has characteristics of simple operation, low energy consumption and low investment.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

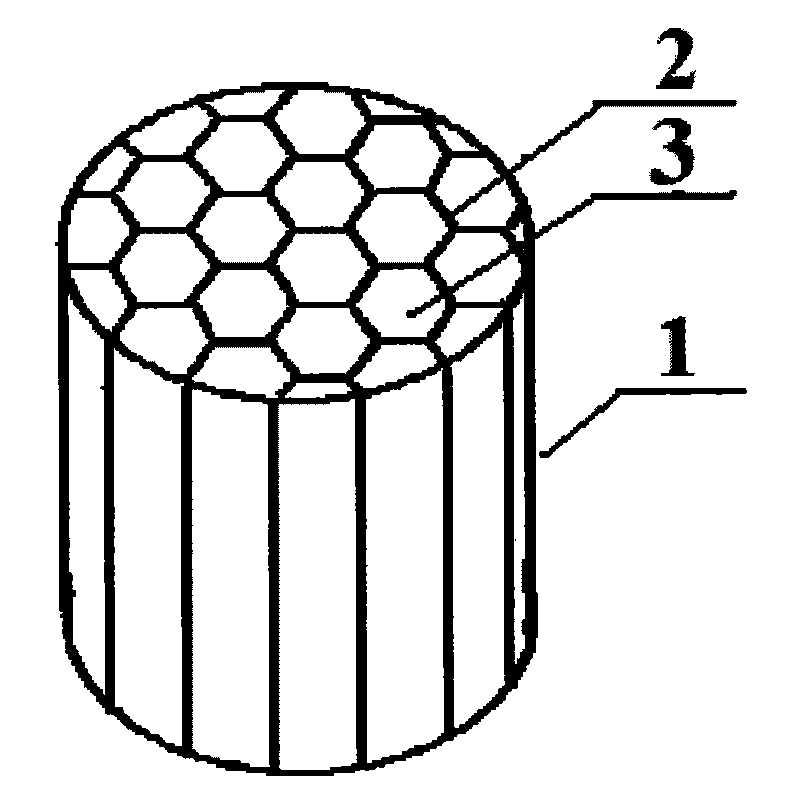

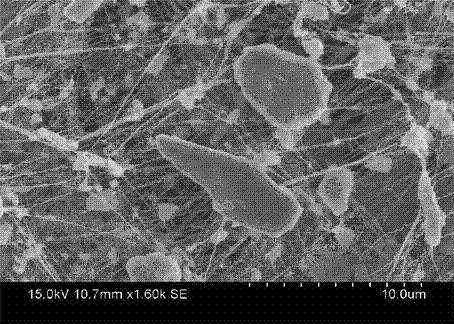

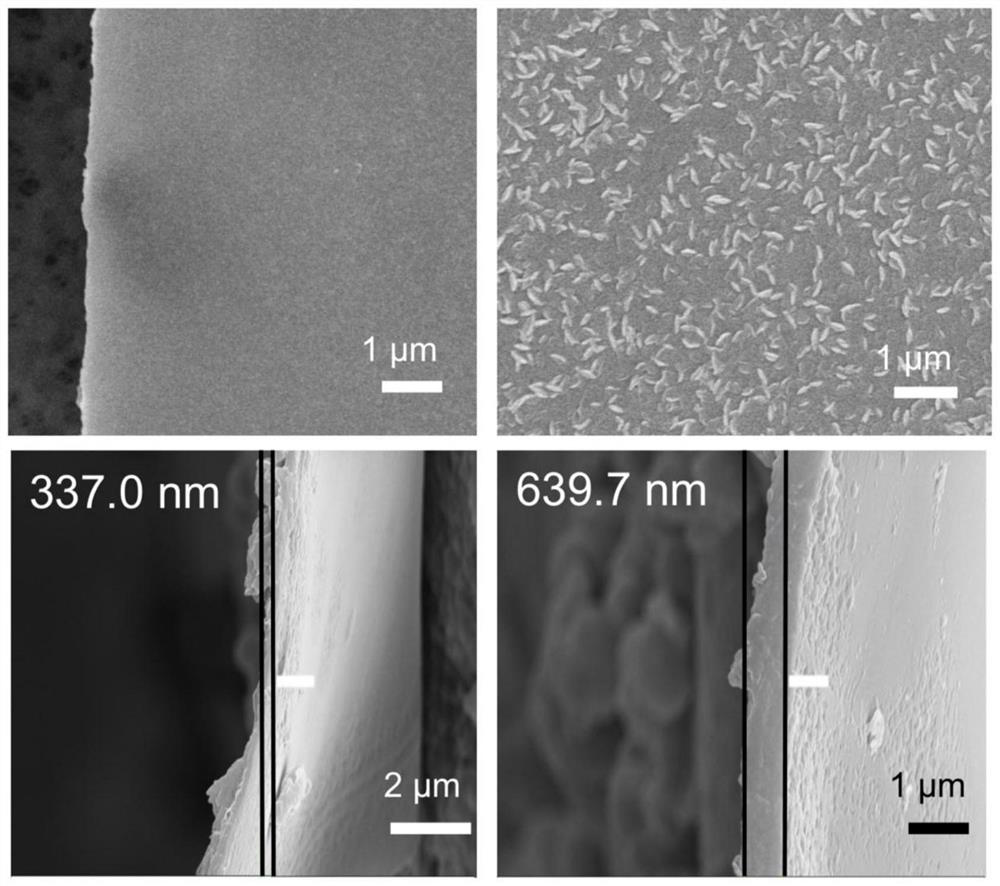

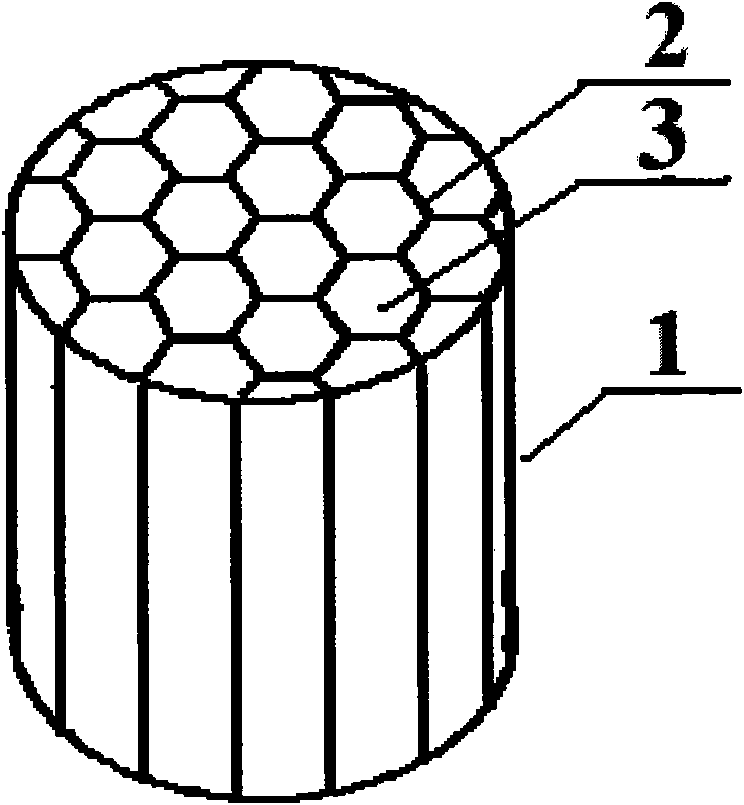

Coaxial cable type graphene oxide-zeolite molecular sieve hollow fiber composite membrane and preparation method thereof

ActiveCN113144922AUniform and complete surfaceInhibit sheddingSemi-permeable membranesHollow fibreFiber

The invention discloses a coaxial cable type graphene oxide-zeolite molecular sieve hollow fiber composite membrane and a preparation method thereof, and belongs to the technical field of membrane separation. The composite membrane is composed of a graphene oxide coating layer, a zeolite molecular sieve separation layer, a modification layer and a hollow fiber base membrane which are coaxial and are sequentially arranged from outside to inside, and a powdery zeolite molecular sieve is limited between the graphene oxide coating layer and a modified support membrane, so that layered falling of the powdery zeolite molecular sieve in a membrane configuration is effectively avoided; the technical prejudice that a powder zeolite molecular sieve is difficult to form a membrane is broken through, the preparation method is simple in process and low in cost, the prepared composite membrane is uniform and complete in surface, and the composite membrane has the advantages of being large in filling density of a membrane separator in unit volume, suitable for high-pressure operation, large in gas flux, excellent in separation performance and the like.

Owner:DALIAN UNIV OF TECH

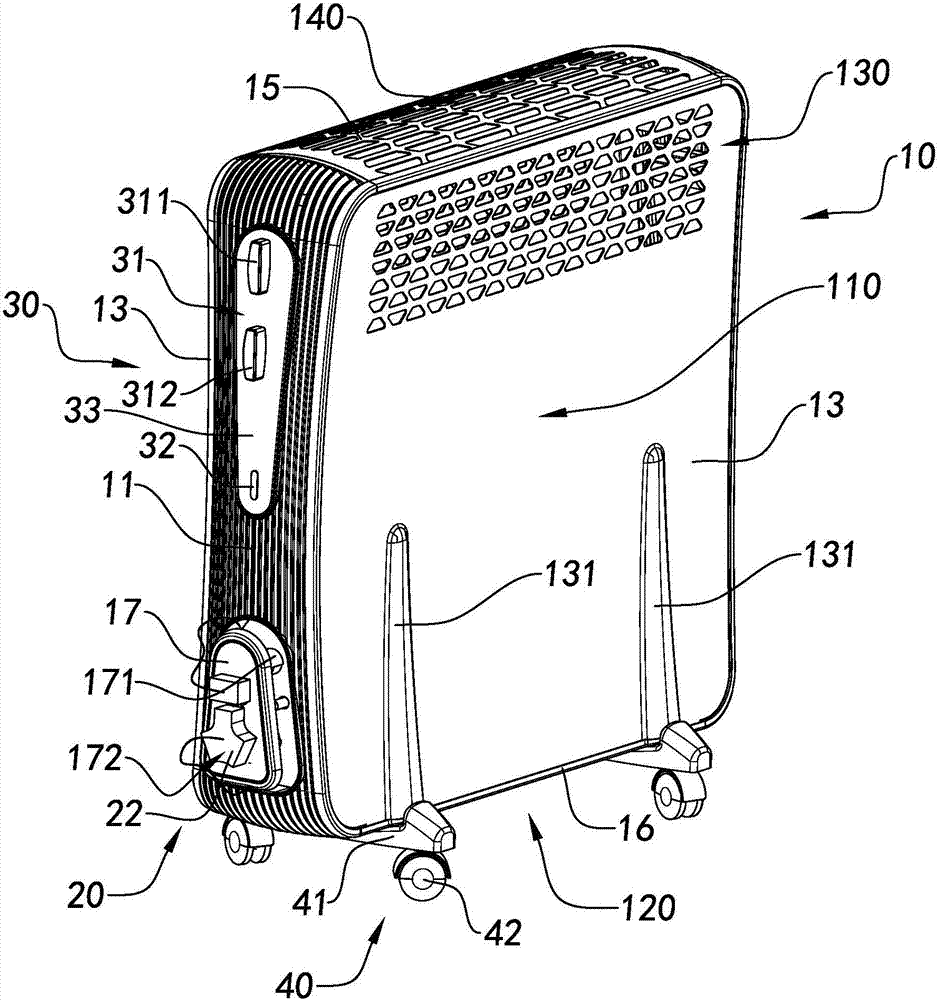

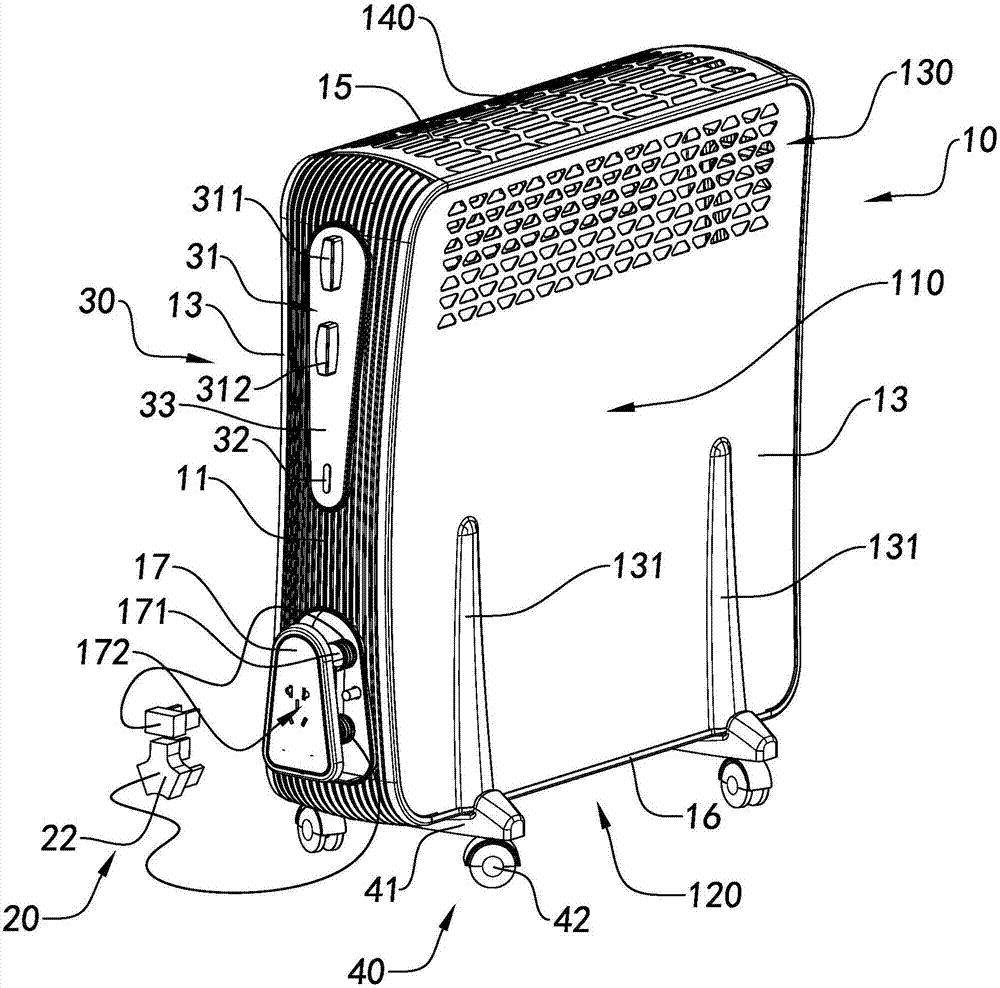

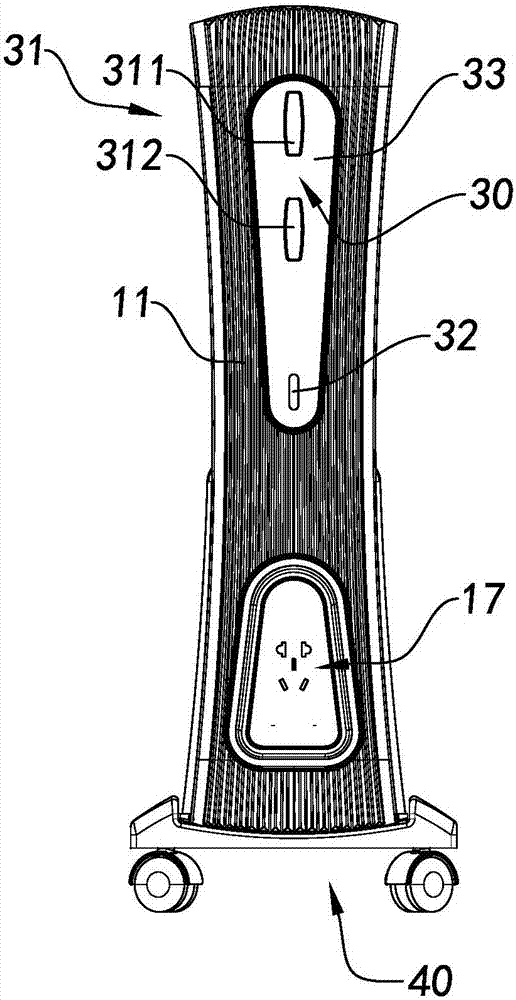

Convector and application thereof

InactiveCN107300204ARaise the gas temperatureIncreased gas fluxHeating fuelLighting and heating apparatusEngineeringConvection

The invention provides a convector and application thereof. The convector comprises a housing and a heat dissipation part. The housing is provided with a convection chamber communicated with the outside, the heat dissipation part comprises at least one heat dissipation piece, and the heat dissipation pieces are arranged in the housing so as to improve the temperature of gas in the convection chamber. The convection chamber is of a waisted type structure, so that the flux of the gas flowing into or out of the convection chamber is expanded.

Owner:浙江佳星电器有限公司

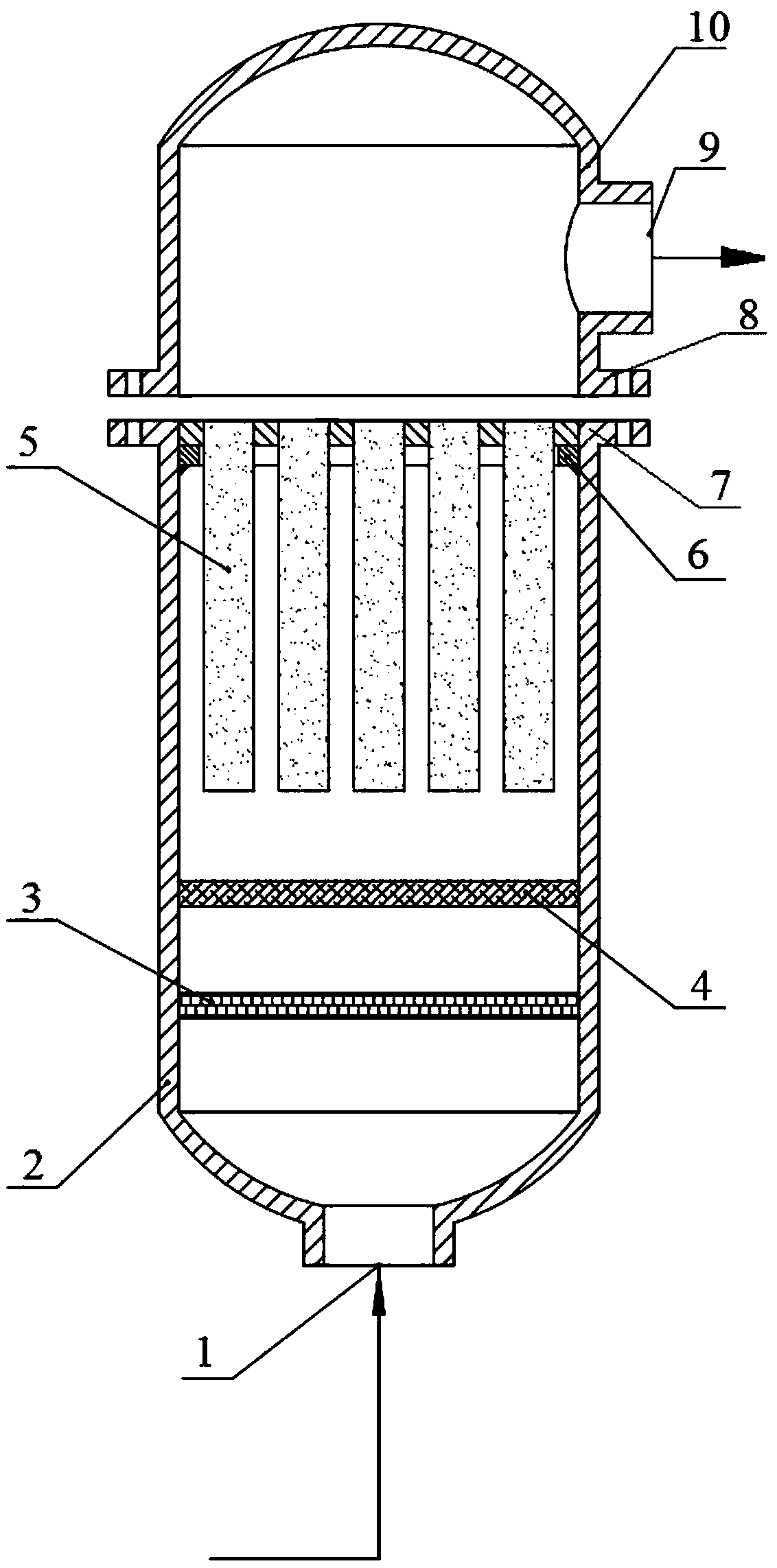

Hydrogen isotope purification filter

InactiveCN109381941AImprove separation efficiencyAvoid cloggingDispersed particle filtrationTransportation and packagingEngineeringImpurity

The invention discloses a hydrogen isotope purification filter which comprises an upper shell and a lower shell, wherein a gas inlet is formed in the lower end of the lower shell; a rough filter element and a primary filter element are sequentially arranged in parallel along the gas inlet of the lower shell; a lower flange is arranged at an upper end ring of the lower shell; an annular boss matched with the lower flange is arranged on the upper wall of the lower shell; a secondary filter element is mounted on the annular boss; the secondary filter element is perpendicular to the primary filterelement; an upper flange parallel to the lower flange is arranged at the upper end ring of the upper shell; the lower flange is fixedly connected with the upper flange through a bolt; and a gas exhaust hole is formed in a side of the upper shell. The rough filter element, the primary filter element and the secondary filter element are sequentially arranged in the filter disclosed by the invention, particles and impurity gases are removed through the rough filter element and the primary filter element firstly, and deuterium tritium is separated and recycled through the secondary filter elementsecondly, so that the consequence that the particles and the impurity gases in gases after reactions of deuterium tritium fuel are adsorbed and filter element membrane holes are blocked can be avoided, the separation efficiency can be improved, and the service life of the filter elements can be prolonged.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

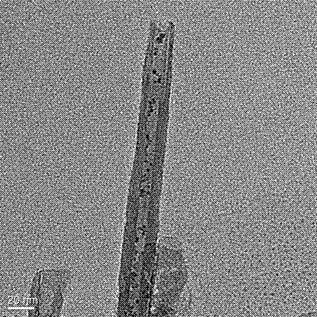

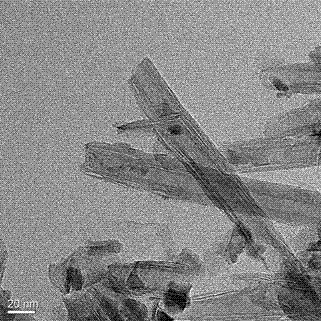

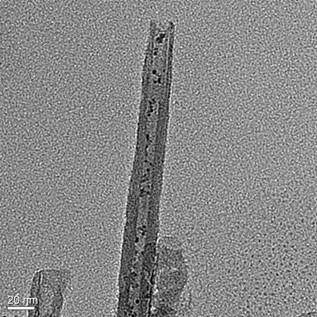

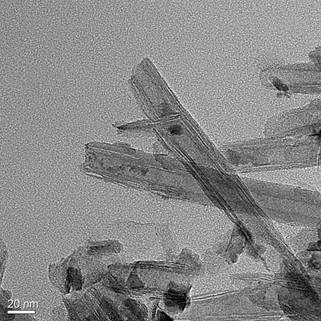

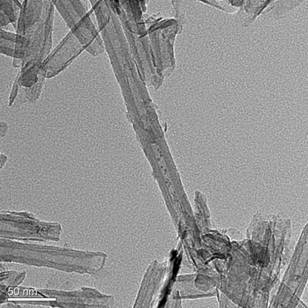

Preparation method of Rh@CuSiO3 core-sheath structured catalyst

InactiveCN107961798ASolve the problem of prone to grain migrationSolve sinteringCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityNano structuring

The invention discloses an Rh@CuSiO3 nano-structure hydrogenation catalyst and a preparation method of same. The preparation method includes the steps of: 1) synthesizing silicate nanotubes in an ethanol-water system through a hydrothermal method, and controllably synthesizing cupric silicate nanotubes by adjusting experimental conditions; 2) supporting metal rhodium in the cupric silicate nanotubes through an impregnation method. In the Rh@CuSiO3 hydrogenation catalyst, the structural confinement effect of the core-sheath material and synergistic effect among the components are coupled, so that dispersity of active components is increased and interaction between the active components and the supporter is improved, thereby improving the catalytic performance in the hydrogenation. The catalyst has extensive application prospect.

Owner:SICHUAN UNIV

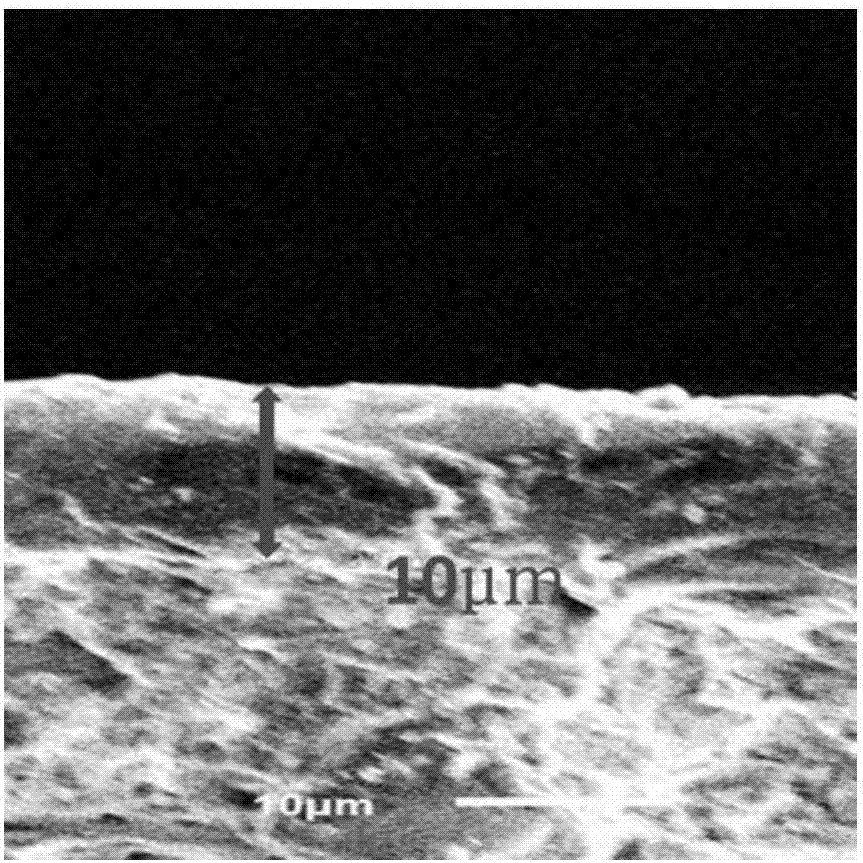

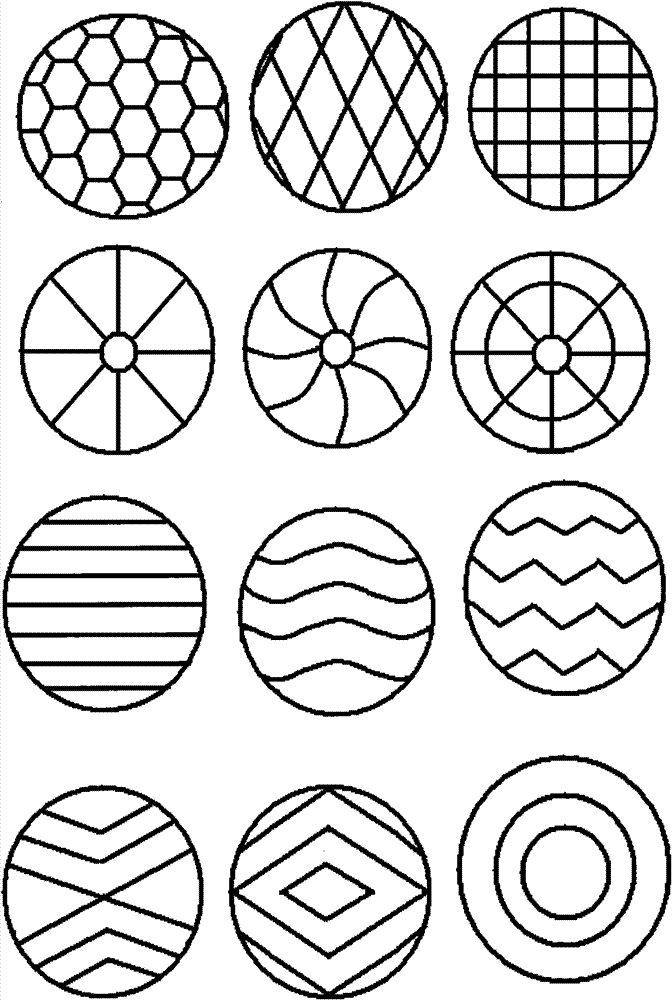

Rotary film-coating preparation process of coal-based flat plate composite carbon film

InactiveCN102755843AHigh mechanical strengthIncreased gas fluxSemi-permeable membranesPretreated surfacesComposite effectCarbon film

The invention relates to the technical field of film materials, in particular to a rotary film-coating preparation process of a coal-based flat plate composite carbon film. The invention aims at selecting a cheap coal-based flat plate carbon film supporting body to prepare the composite carbon film by using a rotary film-coating technology. The rotary film coating preparation process provided by the invention has the advantages of simple production method and low cost; and the flat plate composite carbon film prepared by the rotary film-coating preparation process provided by the invention has the advantages of large mechanical strength and high gas flux. Therefore, a cheap carbon film supporting body is prepared; and the preparation of the composite carbon film on the basis and the exploration of a method for improving a composite effect of the supporting body and a precursor have been key points of accelerating the industrialization process of the carbon films.

Owner:KUNSHAN ZHIJI MATERIAL TECH

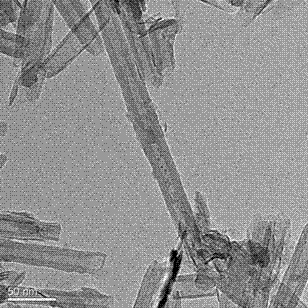

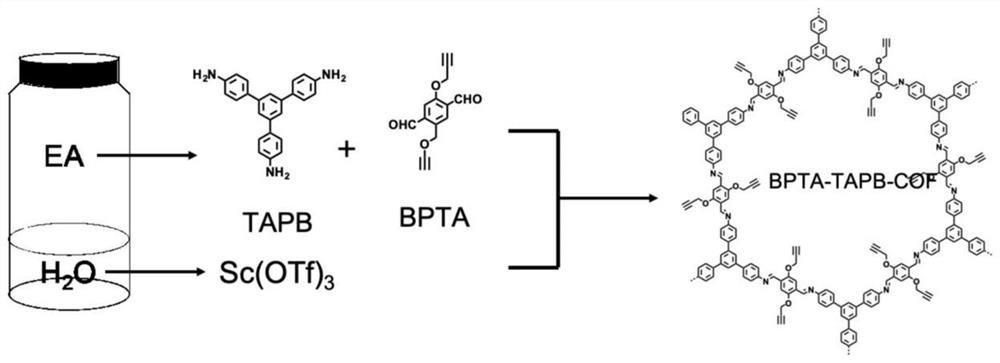

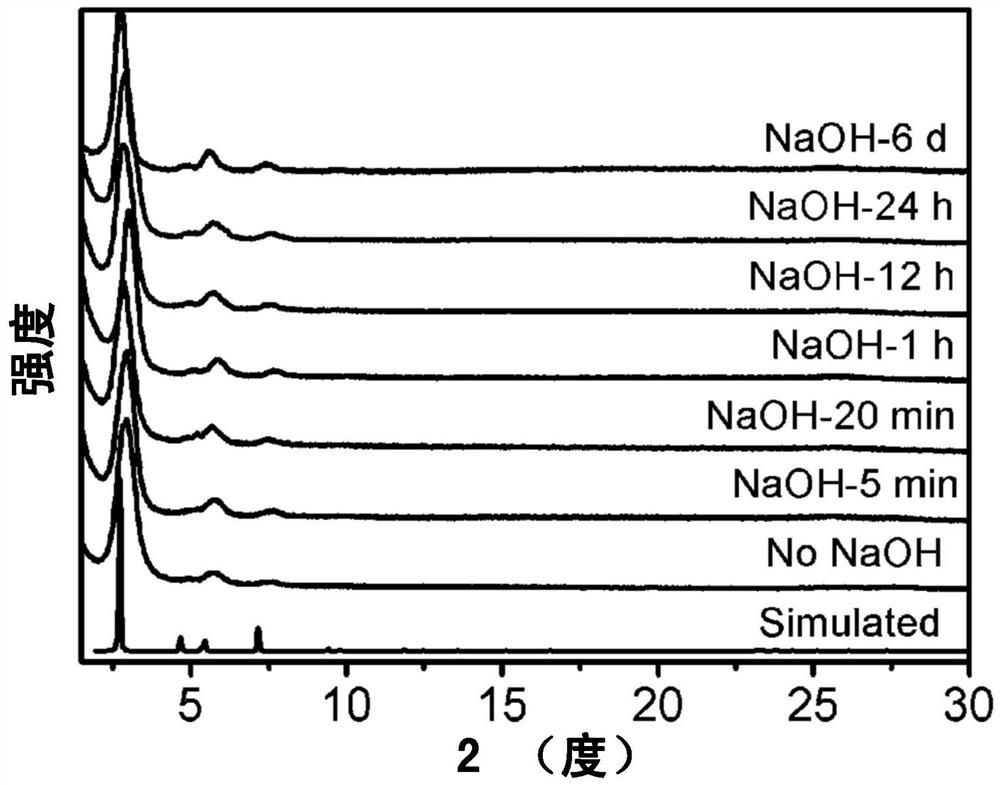

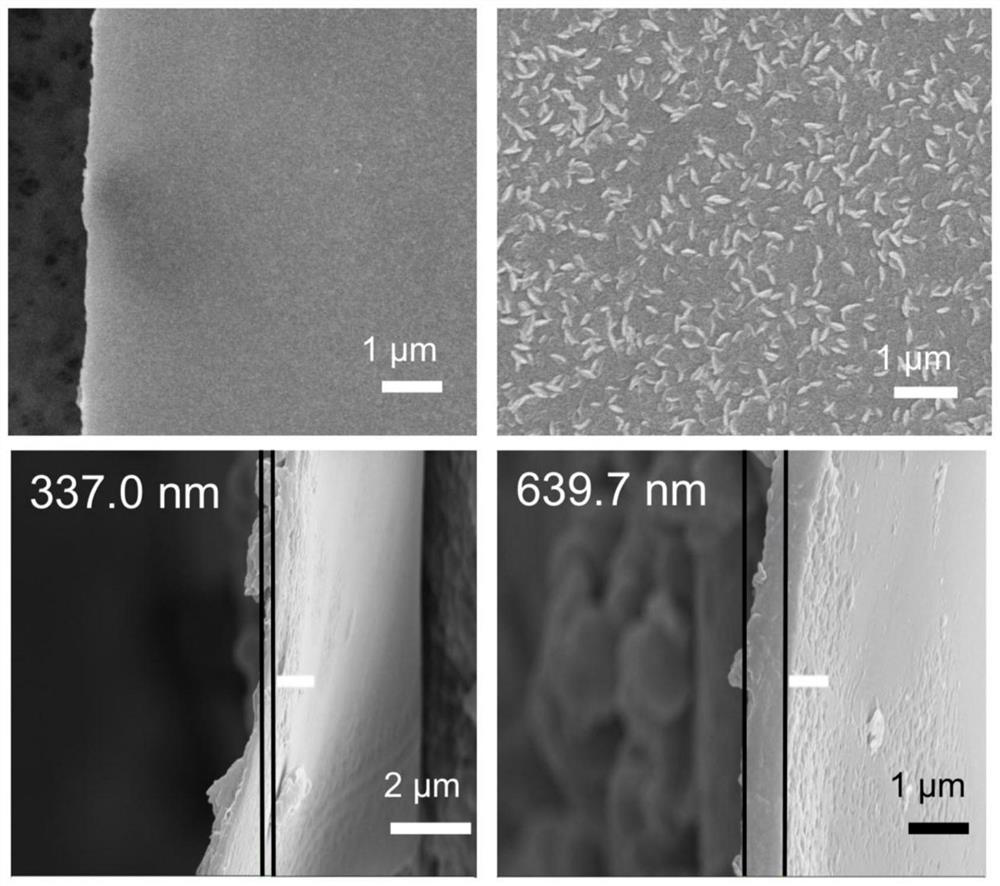

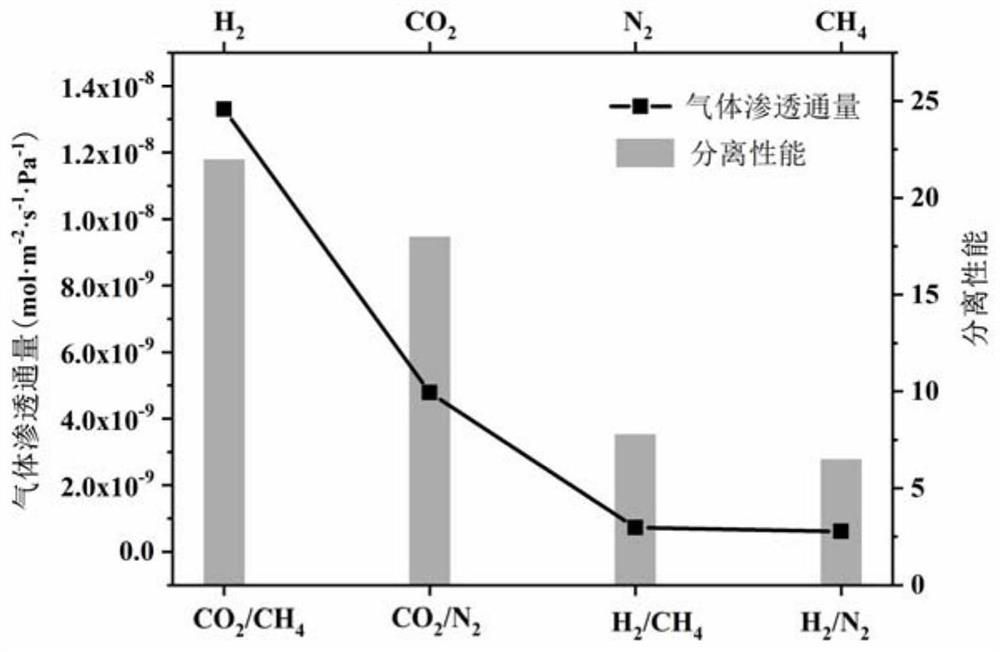

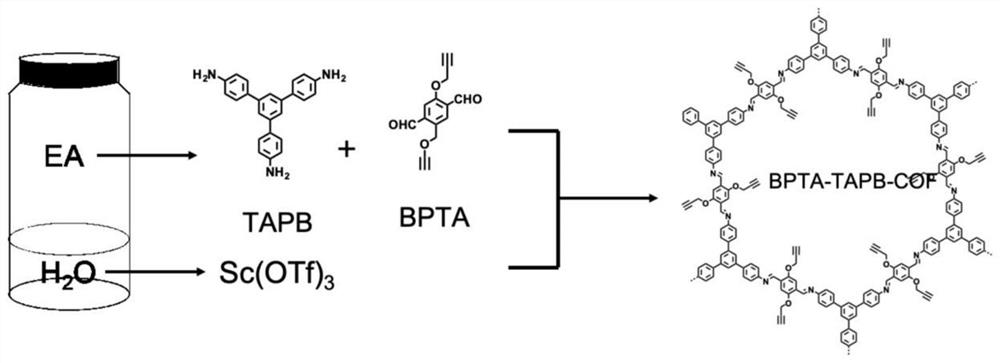

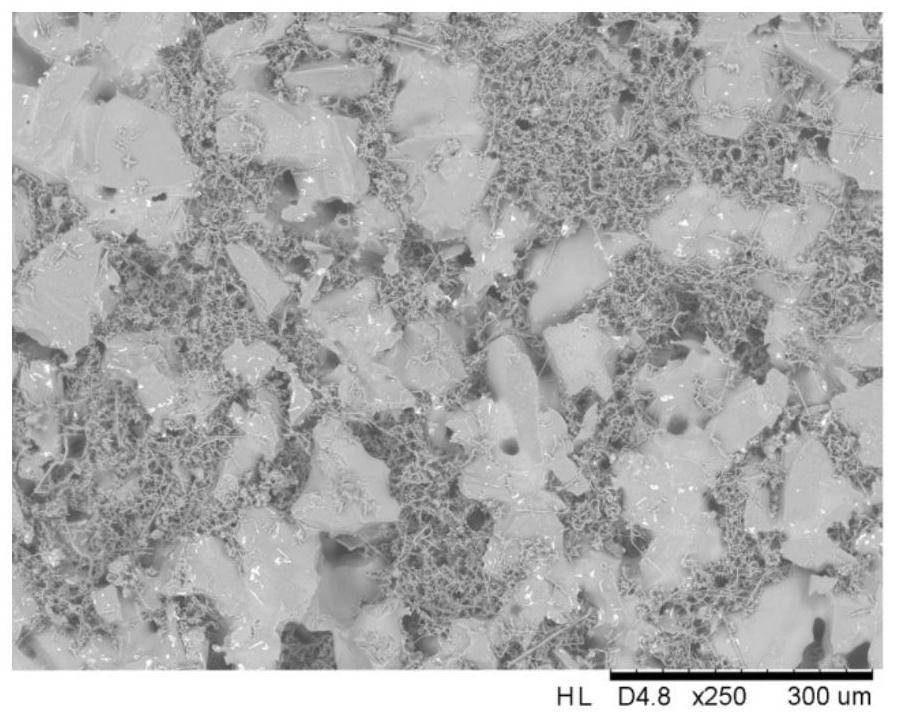

Method for realizing efficient gas separation of COFs film through modification after synthesis

ActiveCN112679781ALow costUniversalProductsSemi-permeable membranesInterfacial reactionPtru catalyst

The invention discloses a method for realizing efficient gas separation of a COFs film. A COFs film material is formed by an interface reaction between an organic solution and the wall of a glass bottle; after a film on the bottle wall is peeled off, post-synthetic modification is carried out on the film through a click reaction, metal ions are introduced to be chelated and coordinated with grafted molecules, and therefore, the pore channels of the COFs film material is effectively segmented; the COFs film material is synthesized through a liquid-solid interface method, and the method has the advantages of universality, easiness in operation, low raw material cost and large-scale processability; the thickness, the pore channel environment and the gas separation performance of the film material can be effectively regulated and controlled by controlling the concentrations of reactants, catalysts and introduced grafted molecules; and the prepared COFs film material shows large gas flux in a test of separating H2 / CO2 mixed gas under the conditions of normal temperature and normal pressure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Preparation method and application of polymer-based composite membrane

PendingCN114602331AImprove gas separation performanceImprove gas permeabilitySemi-permeable membranesDispersed particle separationMolecular sievePolymer science

The invention discloses a preparation method and application of a polymer-based composite tube membrane, compared with a traditional method, the composite membrane prepared by the method has the advantages that the thickness of a polymer matrix membrane is greatly reduced, and meanwhile, a metal framework material grows in a limited range in a polymer; the size of the metal organic framework material is controlled, the defect that the metal organic framework material is easy to fall off on the carrier is overcome, and a continuous and compact metal organic framework-high-molecular polymer selective separation layer is formed on the surface of the tubular carrier. According to the composite separation membrane, by reducing the thickness of the membrane and introducing the metal organic framework material, the gas flux of the high-molecular polymer membrane is improved, the molecular screening capacity is high, the gas permeation flux is high, and the composite separation membrane has a good application prospect in the chemical field needing gas separation and purification.

Owner:NINGBO ELECTRIC POWER DESIGN INST +1

A method for COFs thin films to achieve high-efficiency gas separation through post-synthetic modification

ActiveCN112679781BLow costUniversalSemi-permeable membranesProductsInterfacial reactionPtru catalyst

The present invention provides a method for realizing high-efficiency gas separation by the COFs film. The COFs film material is formed by the interface reaction between the organic solution and the glass bottle wall; Post-synthesis modification is carried out, and metal ions and grafted molecules are introduced for chelation coordination, so as to effectively divide the pores of COFs thin films. Such COFs thin film materials are synthesized by the liquid-solid interface method, which is universal. The operation is simple, the cost of raw materials is low, and it has large-scale processability, and its thickness, pore environment and gas separation performance can be effectively regulated by controlling the concentration of reactants, catalysts and introduced graft molecules. The prepared COFs thin film material Separation of H at normal temperature and pressure 2 / CO 2 Larger gas fluxes were shown in the mixed gas test.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

A kind of preparation method of silicon carbide nanofiber film

ActiveCN108176249BStrong membrane bindingHigh separation precisionPhysical/chemical process catalystsDispersed particle separationFiberCarbide silicon

Owner:NANJING TECH UNIV +1

Paramagnetic laminar-flow self-aggregation type oxygen enrichment device

InactiveCN100469687CSmall circulation resistance.High oxygen enrichment efficiencyOxygen preparationChemistryMagnetic field

A Cis-magnetic lamellar flow self-convergent oxygen enricher, belonging to gas separate technique realm. The invention utilize the distinguish of oxygenic paramgnetism and other gaseous antimagnetism, providing a gas which can wash speccally distribute in the condition of the forming sready lamellar flow postural diversified press and diversified temperature, utilizing the speccal distributed strong magnetic field which the oxygen molecular paramgnetism washed in lamellar flow, realizing selfgather thereby separating from other antimagnetic gas to reach the purpose of oxygen's enrichment, the lamellar flow state can eliminate the remix phenomenon of detached cis-magnetism oxygen with other antimagnetic gas.

Owner:CHINA THREE GORGES UNIV +2

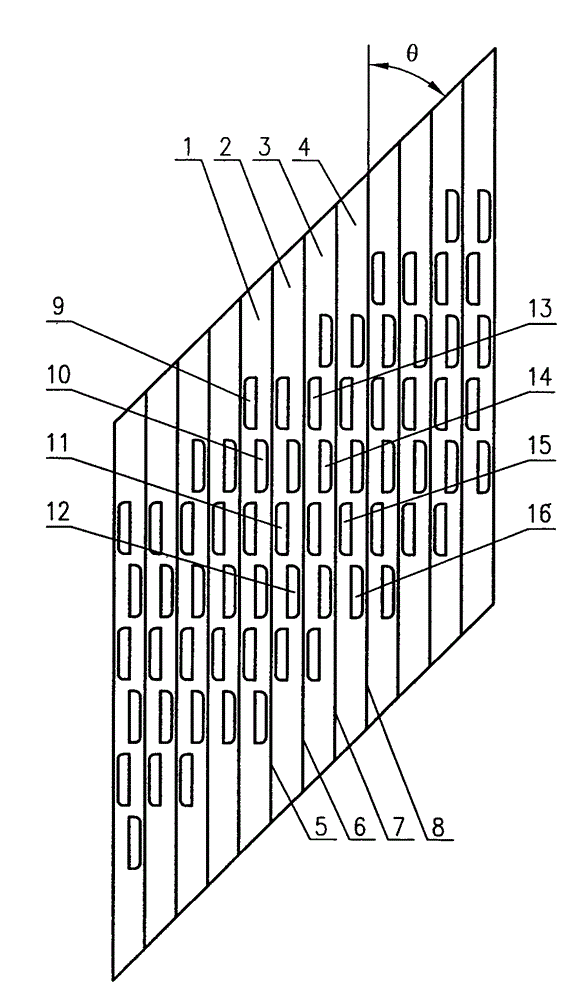

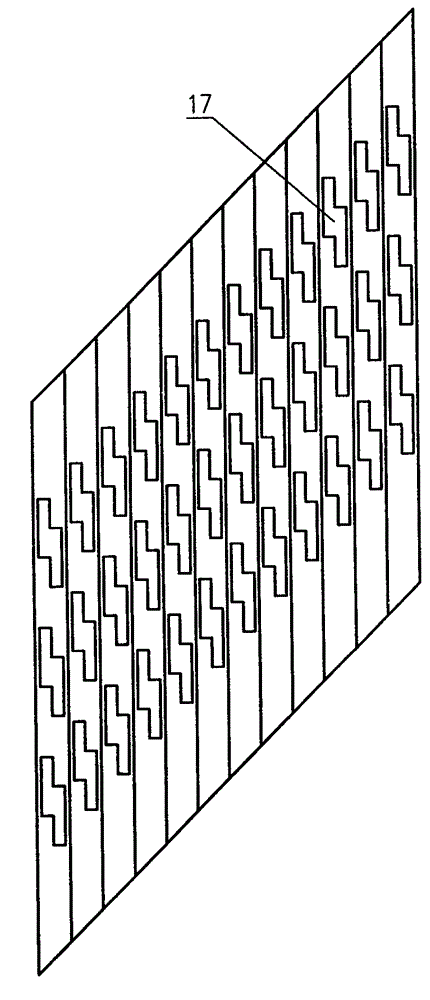

Windowing type corrugated packing sheet

InactiveCN106140071AGood gas-liquid distributionImprove heat transfer performanceChemical/physical/physico-chemical processesCrest lineChemical industry

The window-type corrugated packing sheet is mainly composed of a plurality of window-type corrugated packing units that circulate continuously. The left and right packing corrugations of each window-type corrugated packing unit are composed of four strip-shaped packing surfaces, and the four strip-shaped Every two adjacent strip-shaped packing surfaces in the packing surface intersect to form four ridgelines, and the down-turned upper window and the up-turned lower window are punched out on the four strip-shaped packing surfaces, and the bottom-turned upper window and the up-turned window are punched out. The lower window creates corresponding windows on the four strip packing faces. The window-opening corrugated packing sheet has good gas-liquid distribution effect, high heat transfer and mass transfer efficiency, and the pressure drop is significantly reduced; the window-opening corrugated packing sheet is easy to process and manufacture, and the phenomenon of interspersed and biting between the packing corrugated sheets is completely eliminated, and the production The speed is fast and the cost is significantly reduced. The window-type corrugated packing sheet can be widely used in packed tower equipment in the fields of chemical industry, chemical fertilizer, oil refining and petrochemical industry.

Owner:梁泰安 +1

Organosiloxane films for gas separations

ActiveUS9339770B2Rapid fragmentationReduce volatilityNitrogen purification/separationSemi-permeable membranesPorous substrateHydrogen atom

Owner:APPLIED MEMBRANE TECH

A process for treating petroleum associated gas

ActiveCN109321297BPrevent liquefactionConducive to liquefactionGaseous fuelsGlass fiberThermodynamics

The invention discloses a treatment technology for petroleum associated gas, and belongs to the technical field of treatment of petroleum associated gas. The treatment technology comprises the following steps of compression of the associated gas, drying, pre-cooling by ammonia, refrigerating by an expansion machine, distillation of product, and dry gas power generation; in the drying process, a composite film is used for drying and dewatering; the composite film is a double-layer composite film which is prepared by mixing and weaving stainless steel fibers and glass fibers into a net-shaped bottom film, pressing a thin film into a blank, firing and forming. The treatment technology for the petroleum associated gas has the advantages that the petroleum associated gas is treated and is usedfor dry gas power generation; the operation is simple, and the treatment steps are concise; a film drying technique is used for dewatering, the dewatering speed is high, the permeation amount of gas is high, and the secondary pollution due to production of dust is avoided.

Owner:杭州勃扬能源设备有限公司

Preparation process of coal-based flat-sheet composite carbon membrane

InactiveCN102247766AHigh mechanical strengthIncreased gas fluxSemi-permeable membranesUltimate tensile strengthCoal

The invention provides to a spin-coating preparation process of a coal-based flat-sheet composite carbon membrane, relating to the technical field of membrane materials and aiming at preparing a composite carbon membrane by selecting a low-cost coal-based flat-sheet carbon membrane support body and adopting a spin-coating technology. The invention has the advantages of simple production method and low cost; the coal-based flat-sheet composite carbon membrane has the characteristics of high mechanical strength and high gas flux; in addition, a method for preparing the composite carbon membrane on the basis of preparing the low-cost coal-based flat-sheet carbon membrane support body and exploring to improve the compound effect of the low-cost coal-based flat-sheet carbon membrane support body and a precursor becomes a key of accelerating the industrialization process of carbon membranes.

Owner:张永昶

Filler assembly capable of eliminating amplification effect

ActiveCN101708452BEvenly distributedEfficient and stable mass transfer effectChemical/physical/physico-chemical processesFractional distillationEngineeringTower

The invention discloses a filler assembly capable of eliminating amplification effect, which comprises a filler section, a filler clapboard, filler units, a filler support plate and a liquid redistribution board, wherein the filler clapboard partitions the filler section into a plurality of filler units, the liquid redistribution board is provided with open pores matched with the filler units, a weir is arranged around the open pores, the weir is provided with tooth gaps, and the open pores have the shapes similar to those of the filler units, and have small area. The assembly changes a filler tower into the plurality of filler units connected in parallel, and the vapor and liquid of the filler section are uniformly distributed and the wall flow effect is eliminated by matching the corresponding liquid redistribution board so as to ensure efficient and stable mass transfer effect and eliminate the amplification effect; the adverse initial distribution of a liquid distributor is corrected; by adopting a plug-in structure, the treatment capacity of the tower is only related to the number of the filler units, so the design of the tower is not limited by the scale; and the liquid distributor is replaced by a distribution board so as to reduce the requirements on tower height and mounting level and reduce the investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

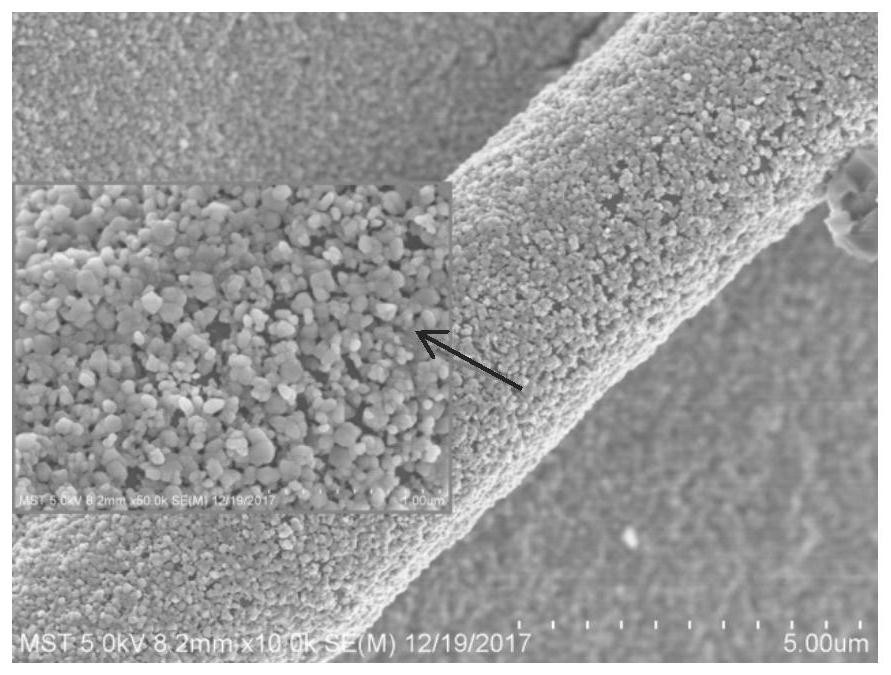

a rh @cusio 3 Preparation method of core-sheath structure catalyst

InactiveCN107961798BHigh pore volumeIncreased gas fluxCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicic acid

The invention discloses a Rh@CuSiO 3 Nanostructured hydrogenation catalyst and preparation method thereof. This Rh@CuSiO 3 The preparation process of the hydrogenation catalyst is: first, use a hydrothermal method to synthesize silicate nanotubes in an ethanol-water system, and control the synthesis of copper silicate nanotubes by adjusting experimental conditions; then, use an impregnation method to synthesize copper silicate nanotubes. The nanotube is loaded with metal rhodium. Rh@CuSiO prepared by this method 3 By coupling the structural confinement effect of the core-sheath material and the synergistic effect between components, the hydrogenation catalyst can improve the dispersion of active components and their interaction with the carrier, thereby improving the catalytic hydrogenation reaction performance and has a wide range of applications. prospect.

Owner:SICHUAN UNIV

A kind of mixed matrix film and preparation method thereof

InactiveCN107970786BIncreased gas fluxGood gas separation propertiesMembranesSemi-permeable membranesPolymer scienceMembrane technology

The invention relates to a mixed mechanism membrane and a preparation method thereof, belonging to the technical field of gas separation membranes. The technical problem to be solved by the present invention is how to provide a uniform, continuous, long-term, high gas flux, high selectivity, good gas separation and excellent chemical stability of the mixed mechanism membrane and its preparation method. The mixed mechanism membrane of the present invention is based on a porous silica film, and a mixture of soluble inherent microporous polymers and metal-organic framework materials with a mass ratio of (90-70):(10-30) is the surface; its preparation process is The soluble intrinsic microporous polymer is mixed with the metal-organic framework material, and evenly coated on the surface of the porous silica film. The mixed mechanism membrane is uniform and continuous, has long-term effect, high gas flux, high gas selectivity, good gas separation properties, excellent chemical stability, simple preparation method, low cost, and is beneficial to industrialization.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com