Metal ion-doped graphene oxide composite film, and preparation method and application thereof

A graphene composite and metal ion technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as difficult to effectively separate alkenes and alkanes, and achieve efficient and economical separation and purification, low energy consumption, and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

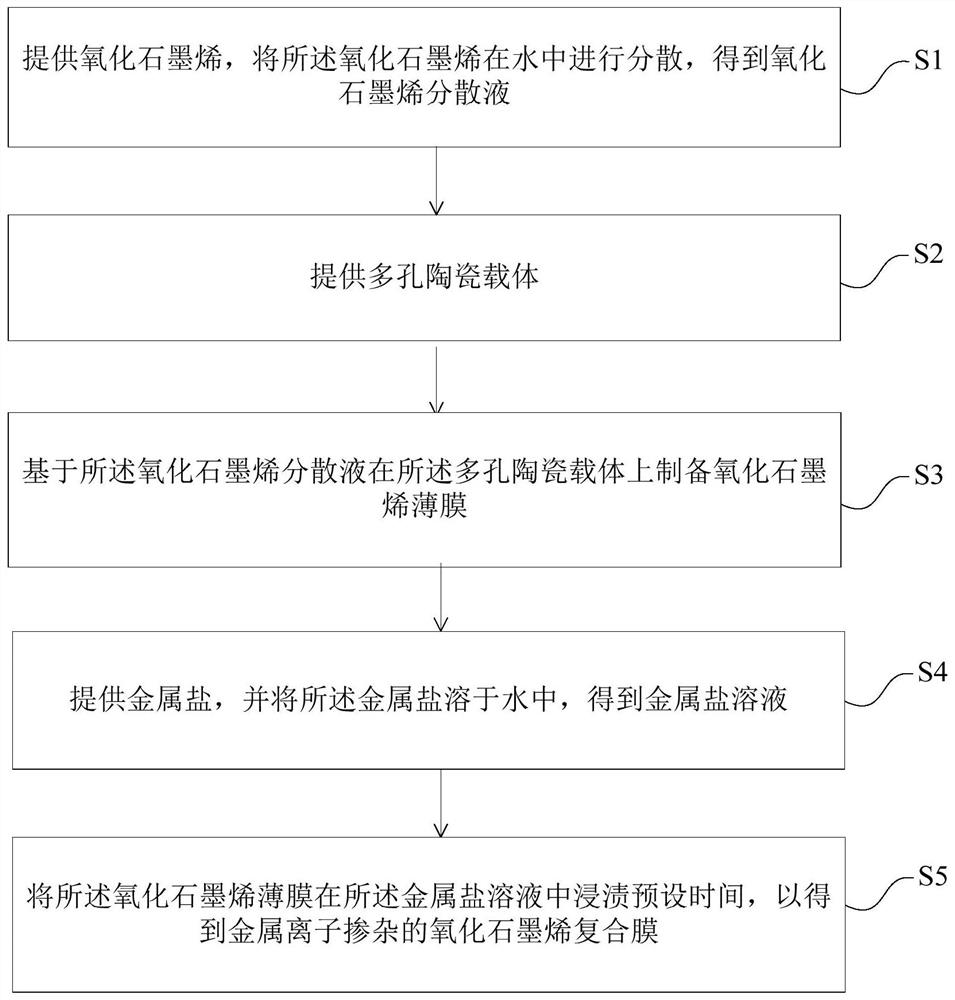

[0036] like figure 1 Shown, the present invention provides a kind of preparation method of the graphene oxide composite film of metal ion doping, and described preparation method comprises:

[0037] S1, providing graphene oxide, dispersing the graphene oxide in water to obtain a graphene oxide dispersion;

[0038] S2, providing a porous ceramic carrier;

[0039] S3, preparing a graphene oxide film on the porous ceramic carrier based on the graphene oxide dispersion;

[0040] S4, providing a metal salt, and dissolving the metal salt in water to obtain a metal salt solution;

[0041] S5, immersing the graphene oxide film in the metal salt solution for a preset time to obtain a metal ion-doped graphene oxide composite film.

[0042] The preparation method of the metal ion-doped graphene oxide composite film of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein, it should be noted that the above sequence does not stric...

Embodiment 1

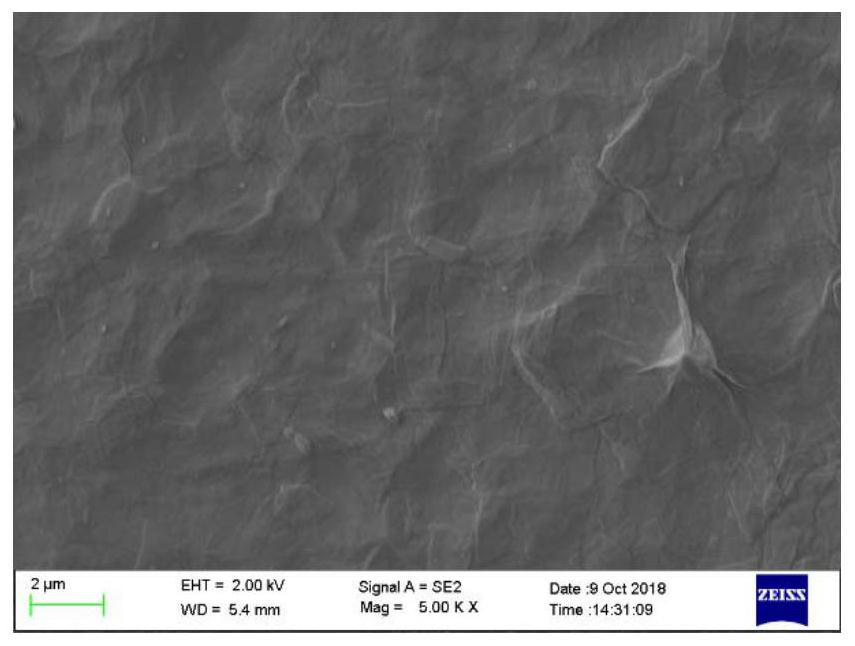

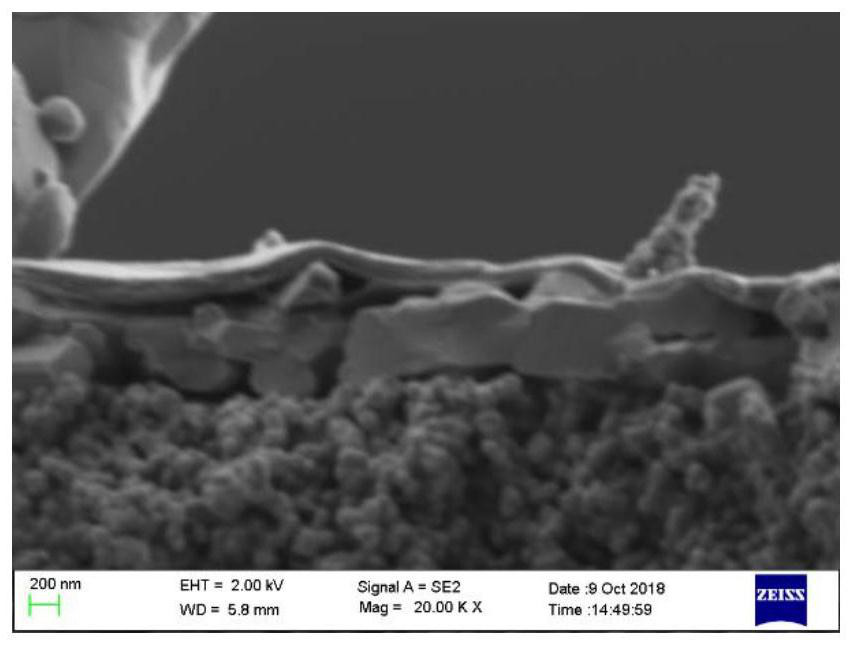

[0069] Step 1: Add 25 mg of graphene oxide into 100 mL of ultrapure water, and ultrasonically crush it for 1 hour at room temperature to form a 0.4 mg / mL GO dispersion;

[0070] Step 2: Select a porous titanium oxide ceramic tube as the carrier. The outer and inner diameters of the porous ceramic tube are 10mm and 7mm respectively, and the average pore diameter of the inner surface is 5nm. Both ends of the carrier are sealed with glaze, and the effective film length is 25mm. Roasting 0.5h;

[0071] Step 3: Using the filter press deposition method, put the ceramic tube into the membrane module, pass the graphene oxide hydrosol from the inside of the membrane tube, use a certain pressure of nitrogen as the driving force, the pressure range is 1-15bar, and place the membrane tube at room temperature for 2 hours;

[0072] Step 4: Immerse the membrane tube in step 3 in 0.25mol / L Cu(BF4) 2 1h in aqueous solution, vacuum drying at 45°C for 12h;

[0073] Step 5: Use a gas permeation...

Embodiment 2

[0076] The difference from Example 1 is that in step 4, the membrane tube is immersed in 0.25mol / L CuCl 2 1h in aqueous solution. All the other steps are the same as in Example 1. The separation test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com