Coaxial cable type graphene oxide-zeolite molecular sieve hollow fiber composite membrane and preparation method thereof

A zeolite molecular sieve and fiber composite technology, applied in the field of membrane separation, can solve problems such as weak interaction and affecting separation efficiency, and achieve the effects of high packing density, large gas flux and excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of graphene oxide dispersion: Dissolve 100mg of graphene oxide powder in 50mL of deionized water and sonicate for 2 hours to prepare a dispersion with a concentration of 2mg / mL, take 2.5mL and dilute to 1L, and then sonicate for 1 hour to obtain the concentration It is a 0.005mg / mL graphene oxide dispersion.

[0034] Preparation of zeolite dispersion: disperse 50 mg of sodalite powder with an average particle size of 40 nm in 1000 mL of deionized water, and ultrasonicate for 1 hour to obtain a 0.05 mg / mL sodalite dispersion.

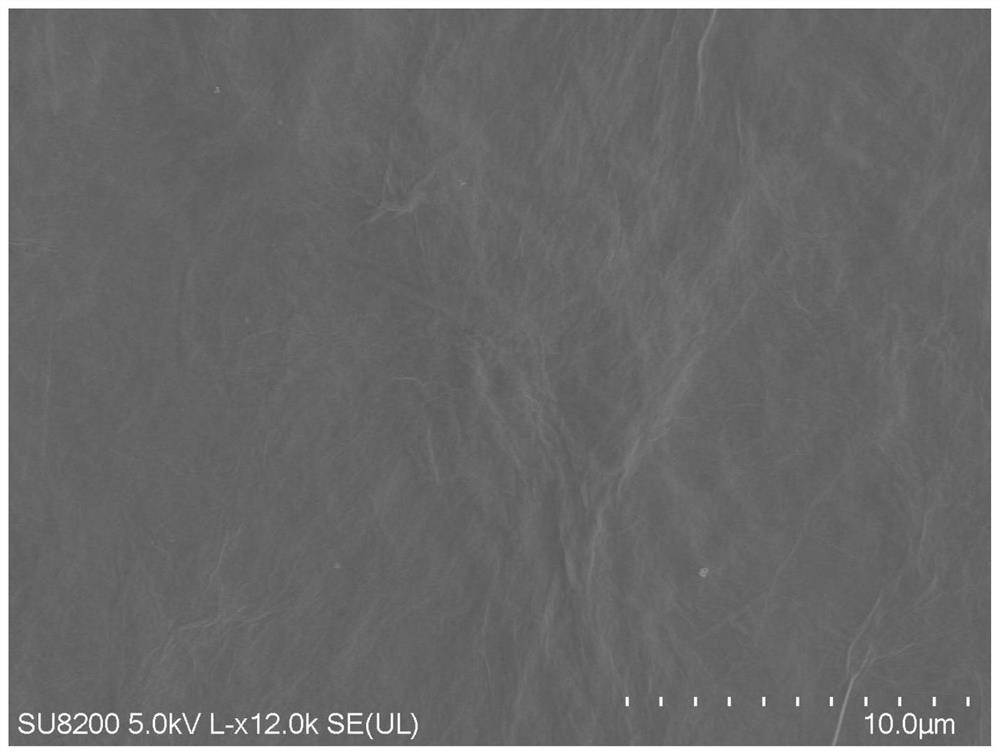

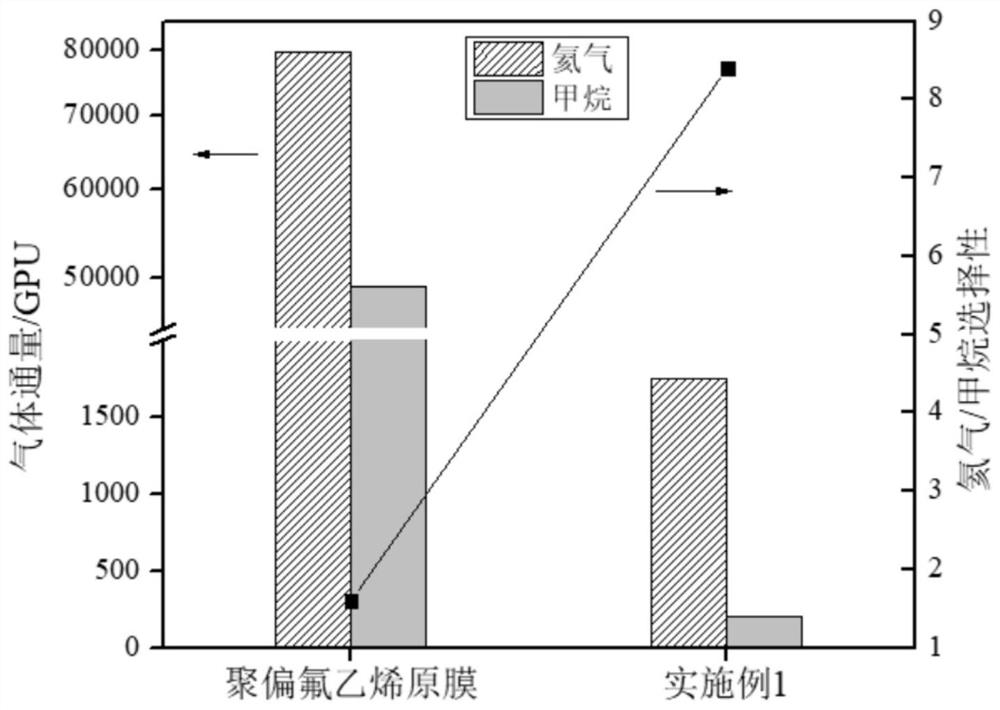

[0035]Take a polyvinylidene fluoride hollow fiber membrane with a length of 80 mm and a diameter of 2 mm, after ultrasonic cleaning, seal one end with epoxy resin glue, connect the other end to the steel pipe, and seal the joint with epoxy resin glue. Immerse in the above-mentioned graphene oxide dispersion, soak for 0.5 hours, take out after suction filtration for 5 minutes under the condition of vacuum degree of 0.05Mpa, then immerse...

Embodiment 2

[0037] Preparation of titanium dioxide nanofiber dispersion: take 100 mg of titanium dioxide nanofiber powder and disperse it in 50 mL of deionized water, after shearing for 1 hour, then sonicate for 0.5 hour to obtain a titanium dioxide nanofiber dispersion with a concentration of 2 mg / mL, take 2.5 mL Dilute to 500 mL, and then sonicate for 1 hour to obtain a titanium dioxide nanofiber dispersion with a concentration of 0.01 mg / mL.

[0038] Preparation of zeolite dispersion: disperse 50 mg of SAPO-34 powder with an average particle size of 400 nm in 1000 mL of deionized water, and ultrasonicate for 1 hour to obtain a 0.05 mg / mL SAPO-34 dispersion.

[0039] Preparation of graphene oxide dispersion: Dissolve 100mg of graphene oxide powder in 50mL of deionized water and sonicate for 2 hours to prepare a dispersion with a concentration of 2mg / mL, take 2.5mL and dilute to 500mL, and then sonicate for 1 hour to obtain the concentration 0.01mg / mL graphene oxide dispersion.

[0040]...

Embodiment 3

[0042] Preparation of polyaniline nanofiber dispersion: Dissolve 100mg of polyaniline nanofibers in 50mL of deionized water to form a dispersion with a concentration of 2mg / mL. After ultrasonic treatment for 1 hour, take 5mL and dilute to 1000mL, and then sonicate for 1 hour to obtain Polyaniline nanofiber dispersion with a concentration of 0.01 mg / mL.

[0043] Preparation of zeolite dispersion: disperse 30 mg of sodalite powder with an average particle size of 40 nm in 1000 mL of deionized water, and sonicate for 0.5 hour to obtain a 0.03 mg / mL sodalite dispersion.

[0044] Preparation of graphene oxide dispersion: Dissolve 100mg of graphene oxide powder in 50mL of deionized water and sonicate for 2 hours to prepare a dispersion with a concentration of 2mg / mL, take 2.5mL and dilute to 1000mL, and then sonicate for 1 hour to obtain the concentration It is a 0.005mg / mL graphene oxide dispersion.

[0045] Take a polyethersulfone hollow fiber membrane with a length of 80 mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com