Patents

Literature

73results about How to "Improve gas selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

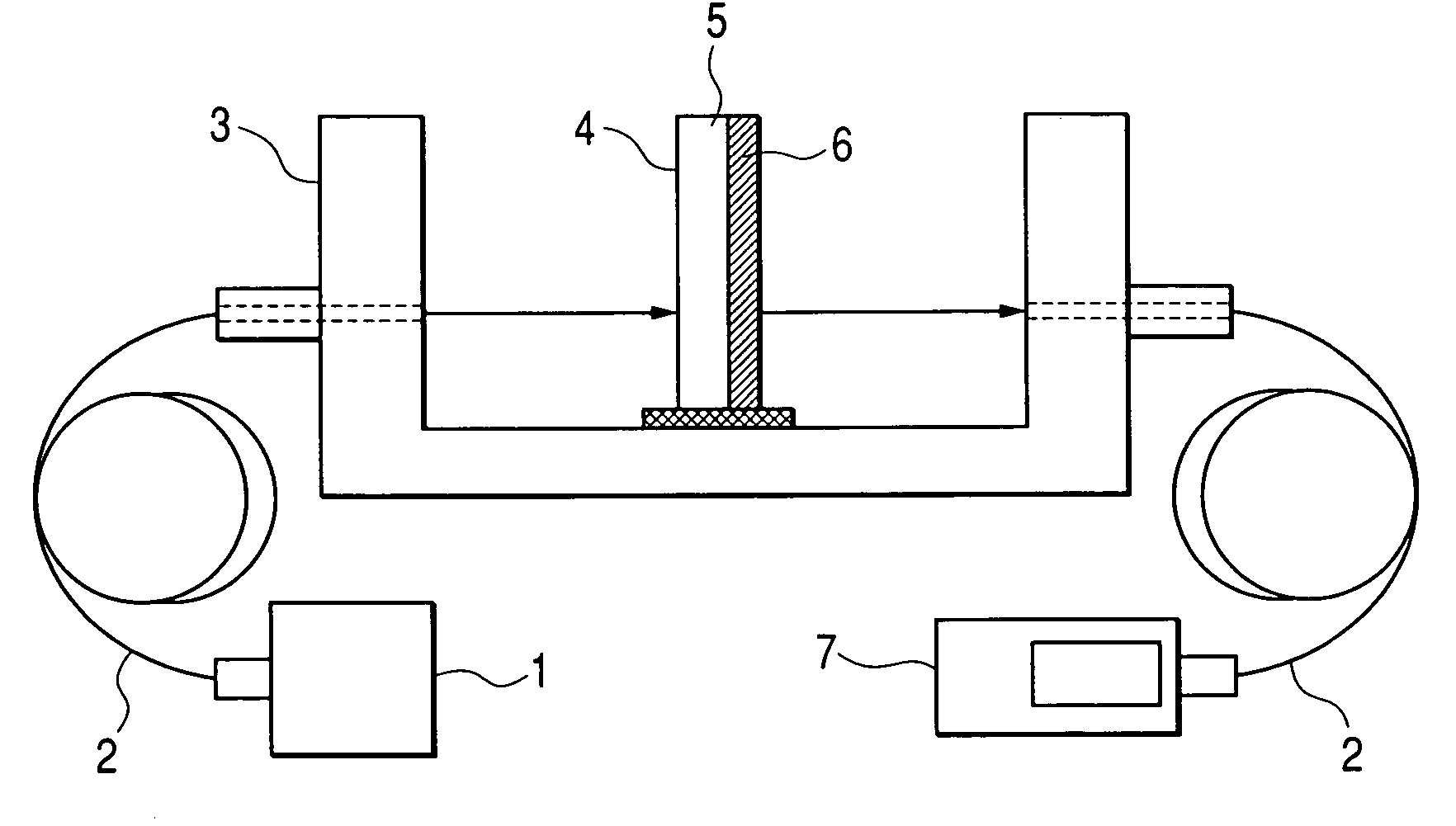

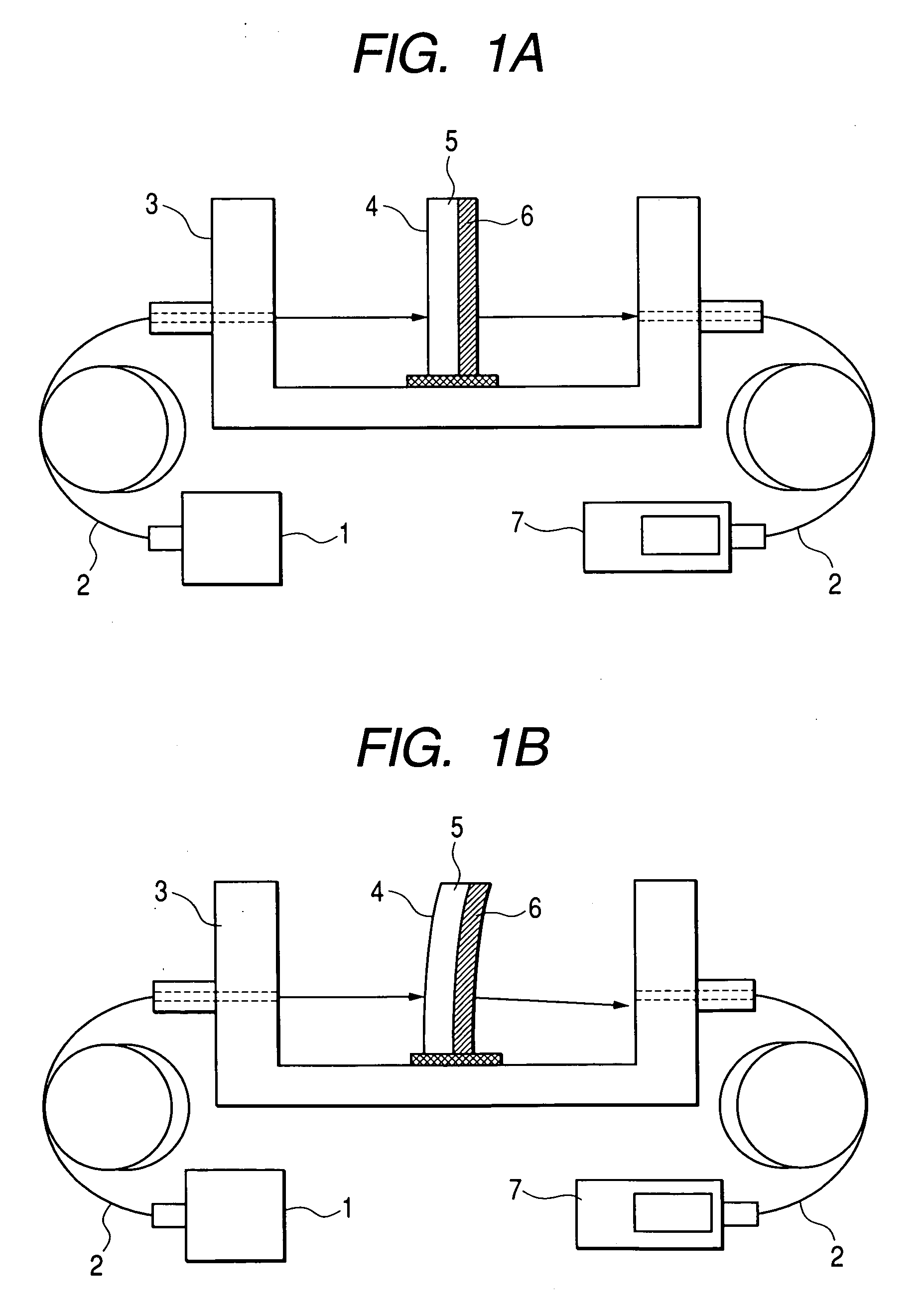

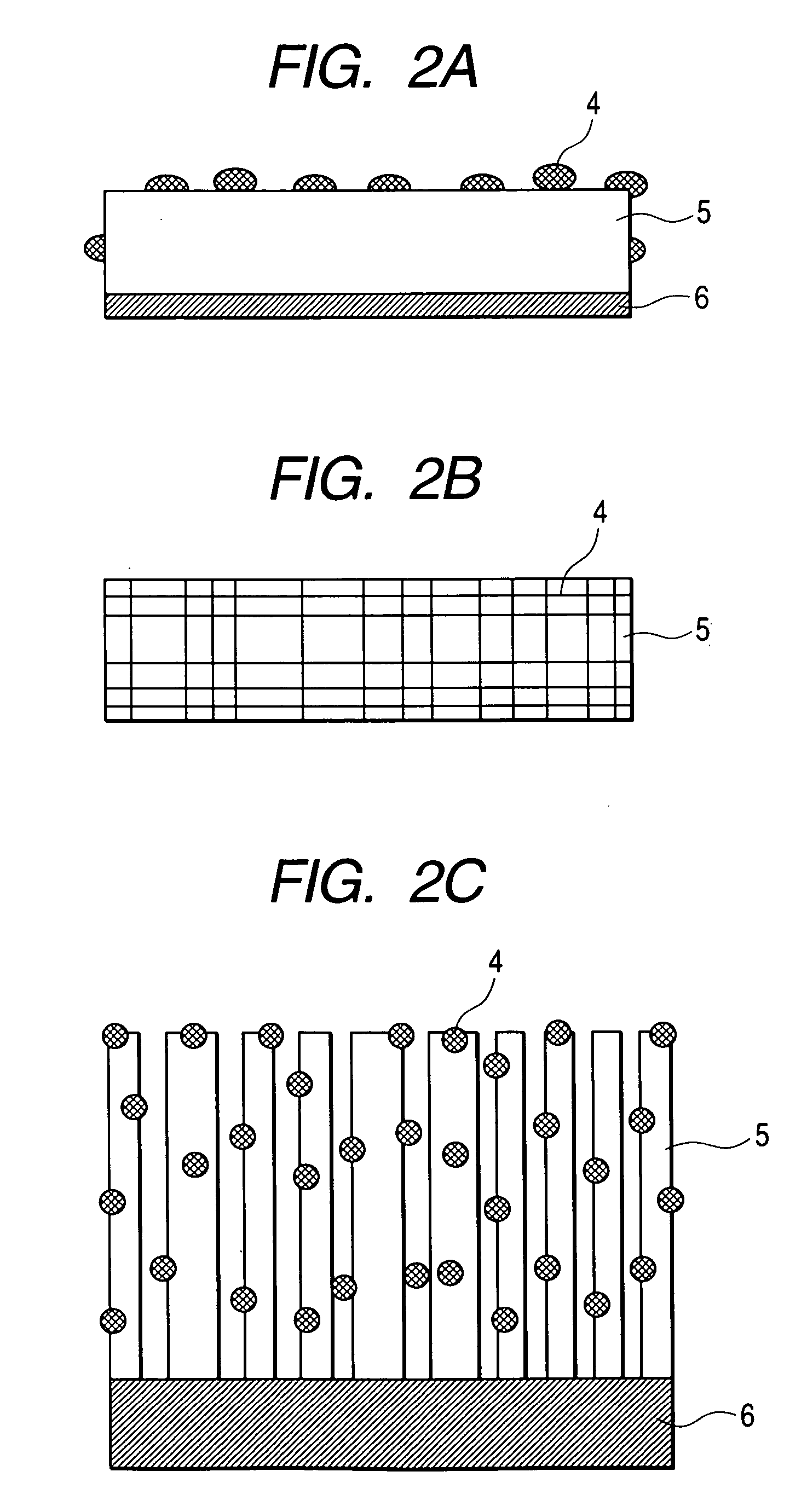

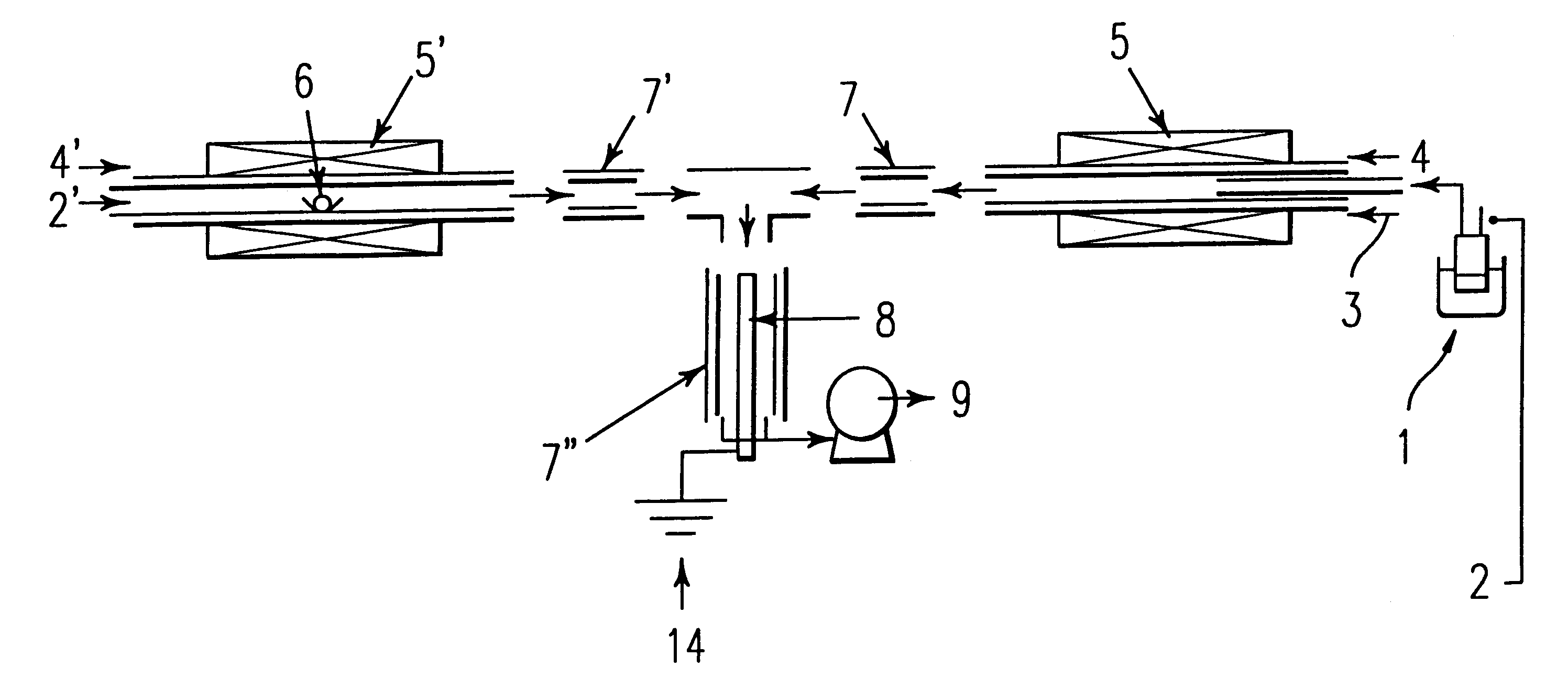

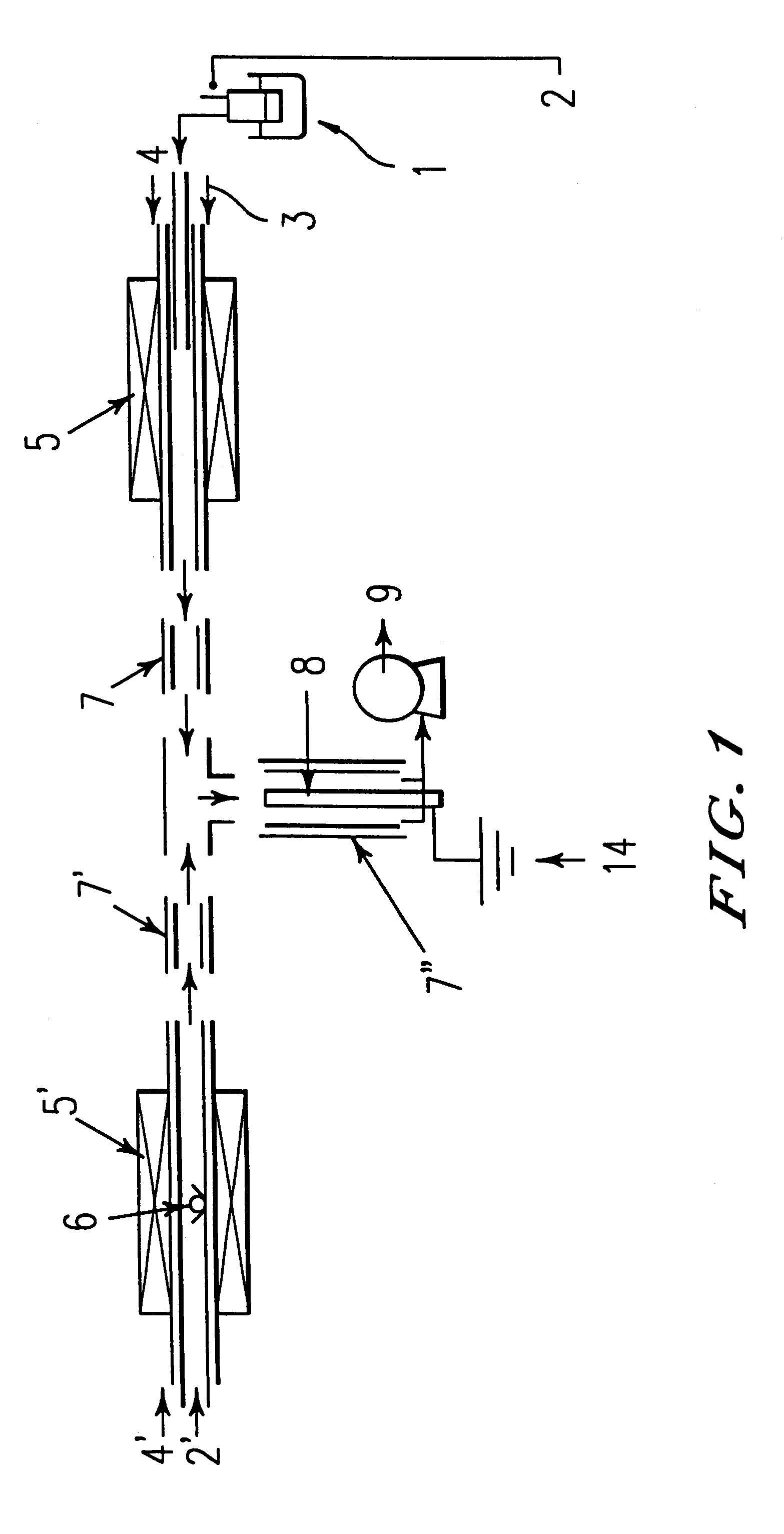

Gas detecting method and gas sensors

InactiveUS20050186117A1Easy to detectImprove gas selectivityWeather/light/corrosion resistanceMaterial analysis by observing effect on chemical indicatorCapacitanceCoupling loss

A gas detection method capable of solving the problem with respect to the operation at normal temperature that was impossible so far in the existent catalyst type sensor and detection with high sensitivity that was impossible by the light absorption type sensor. A multi-layered film formed of a first layer adsorbing a specified gas and a second layer having less adsorption are utilized as a detection film, and the detection film is disposed in the direction perpendicular to the optical channel and optically detects the change of stress caused in the detection film by gas adsorption as coupling loss. Alternatively, the stress generated in the detection film caused by gas adsorption is electrically detected by a piezoelectric element or capacitance element.

Owner:HITACHI CABLE

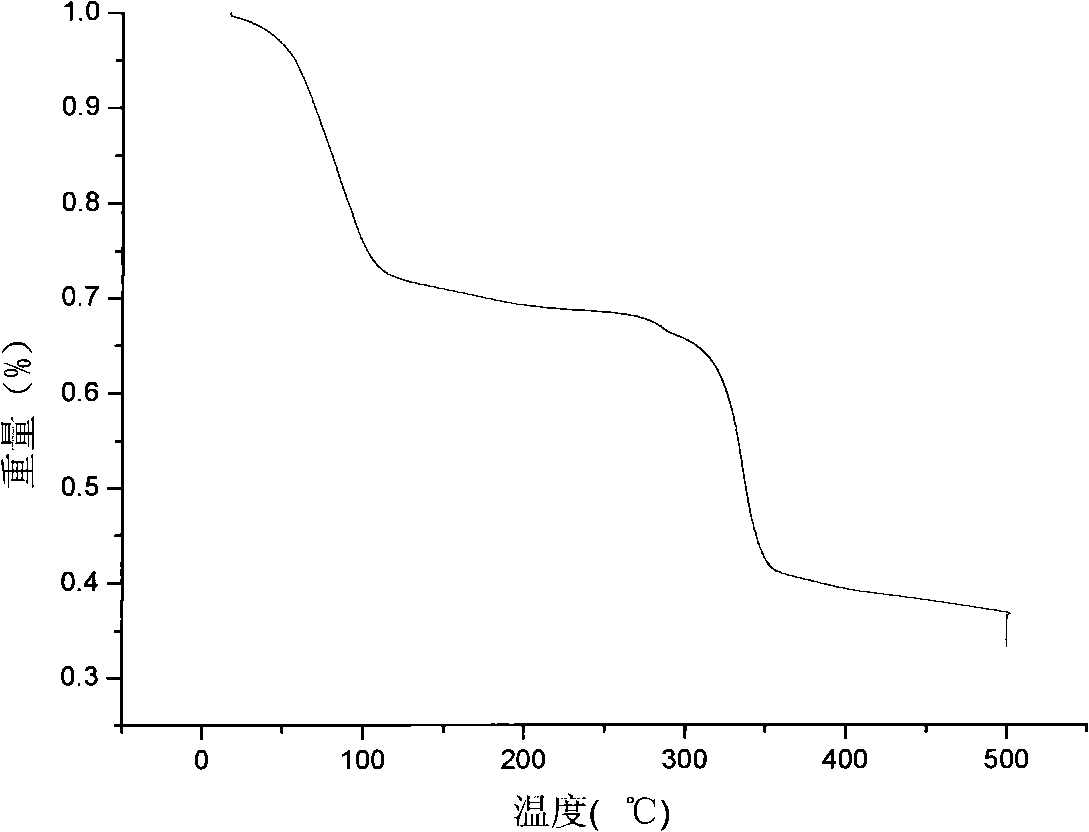

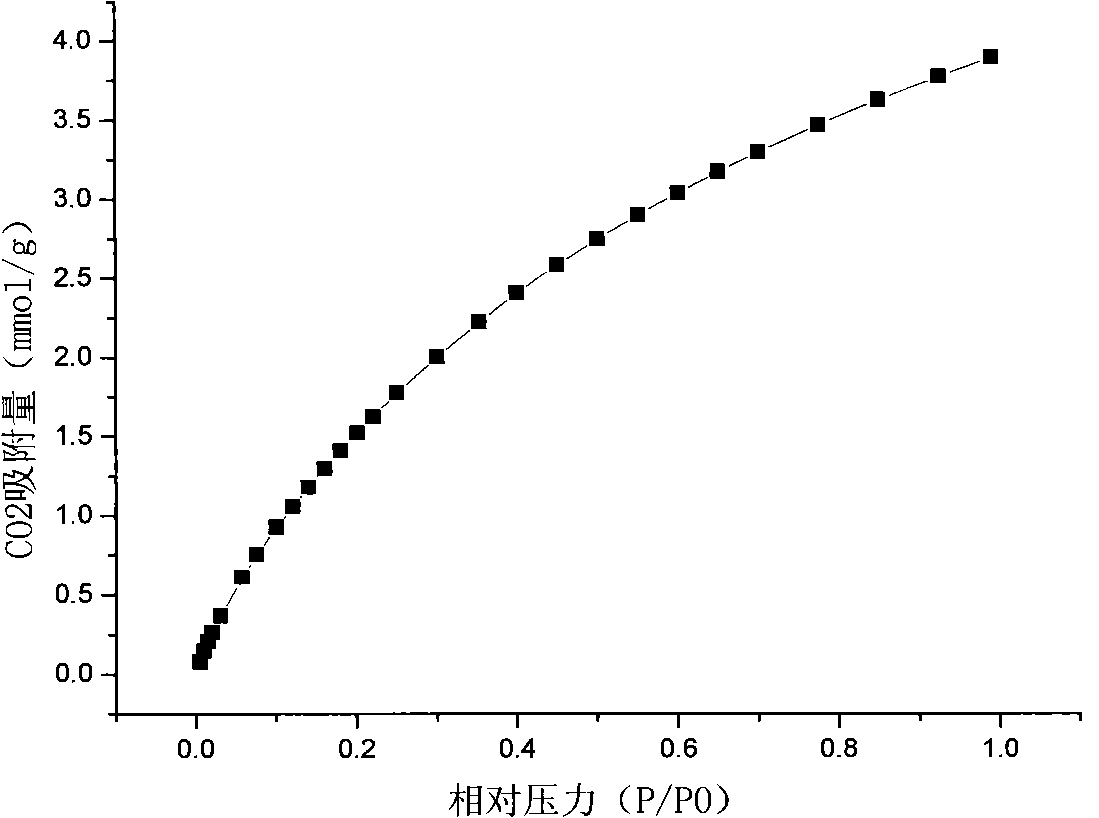

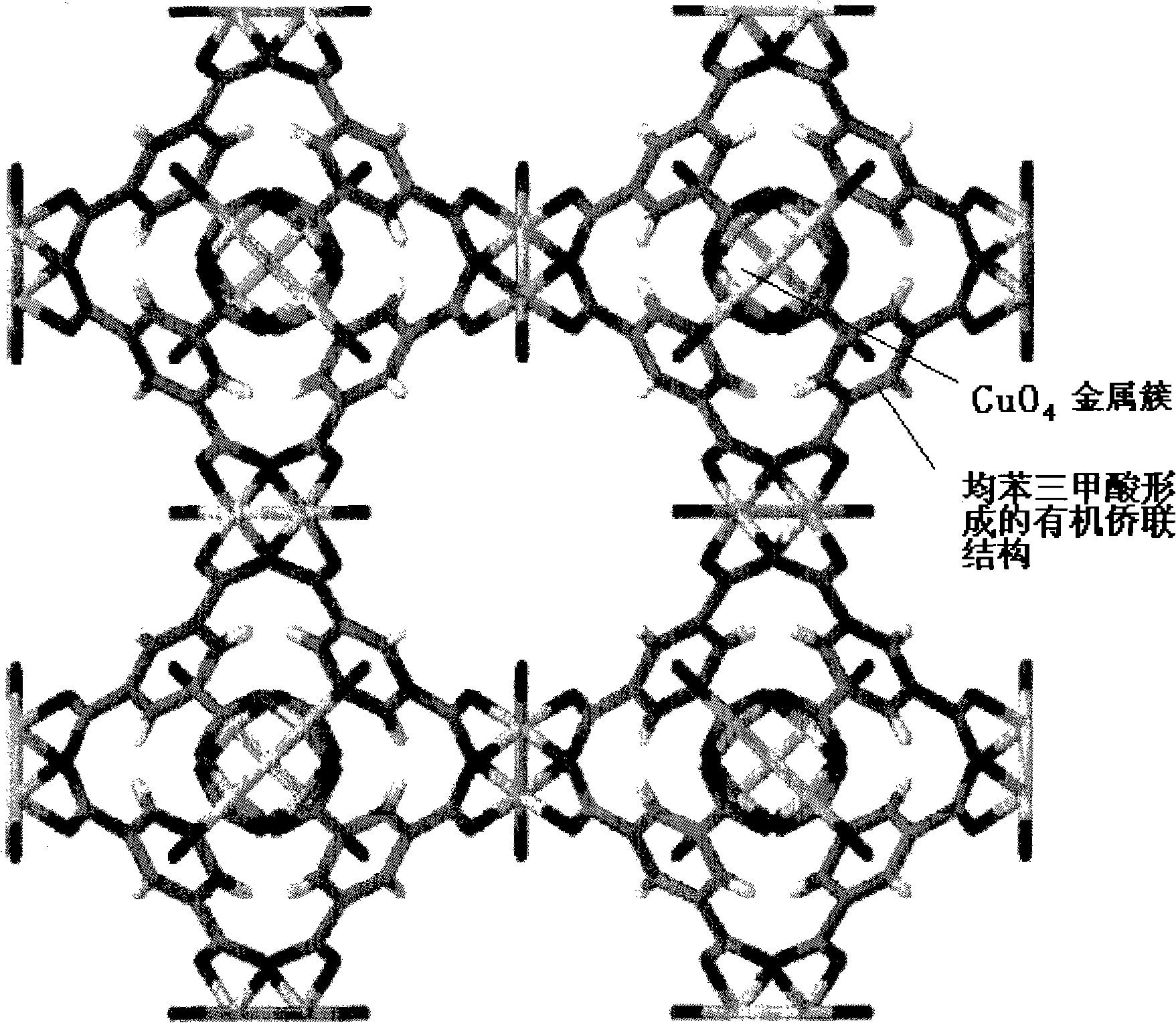

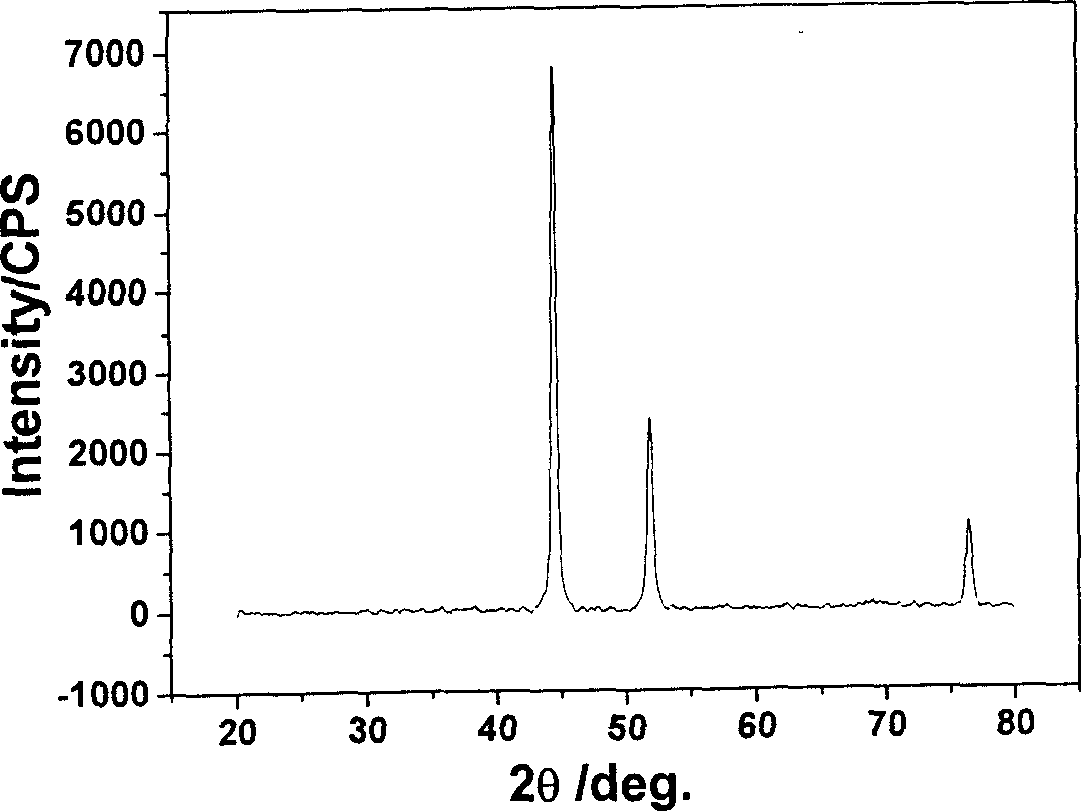

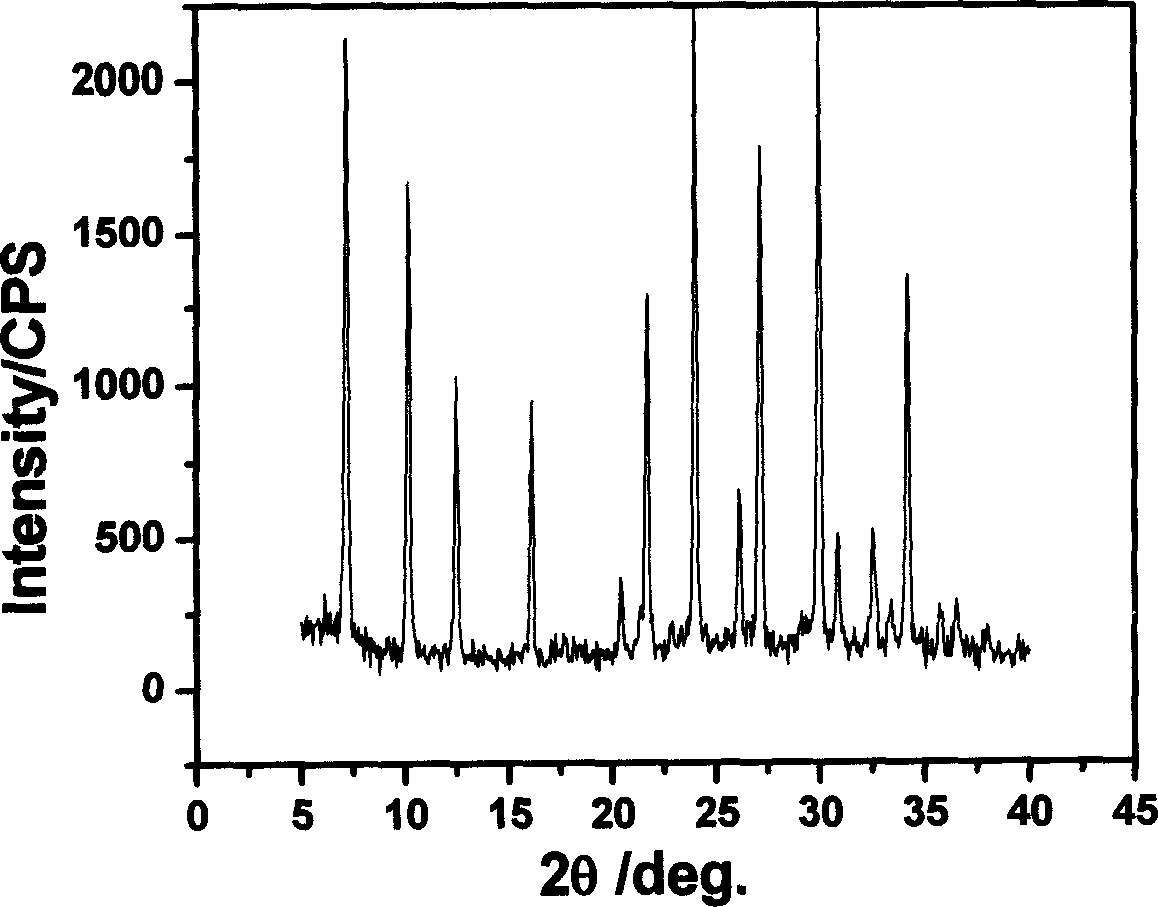

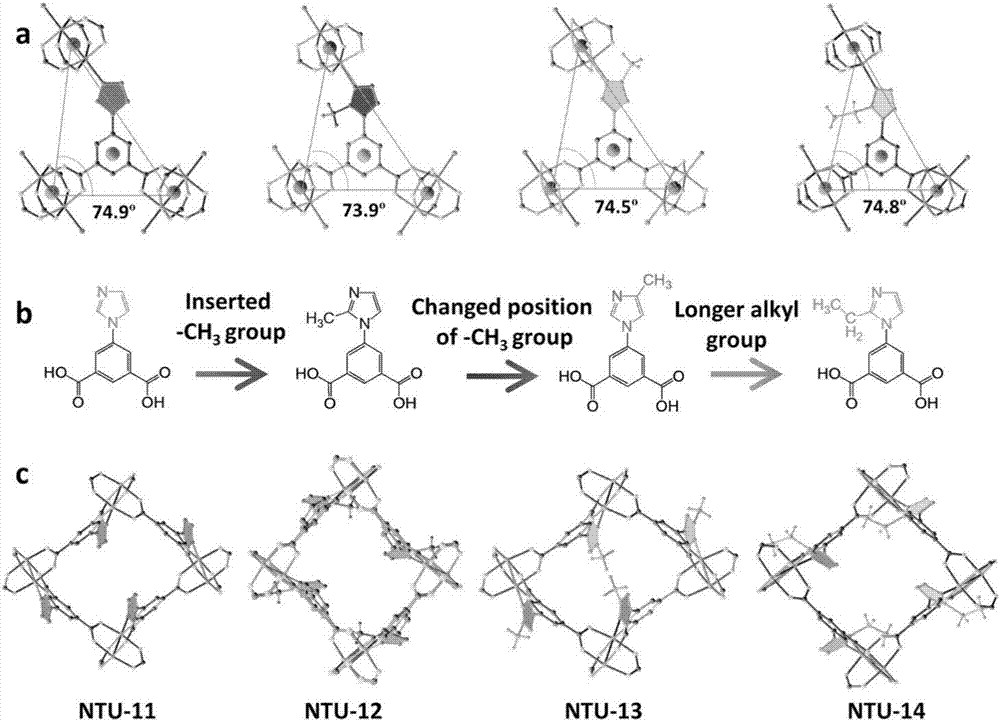

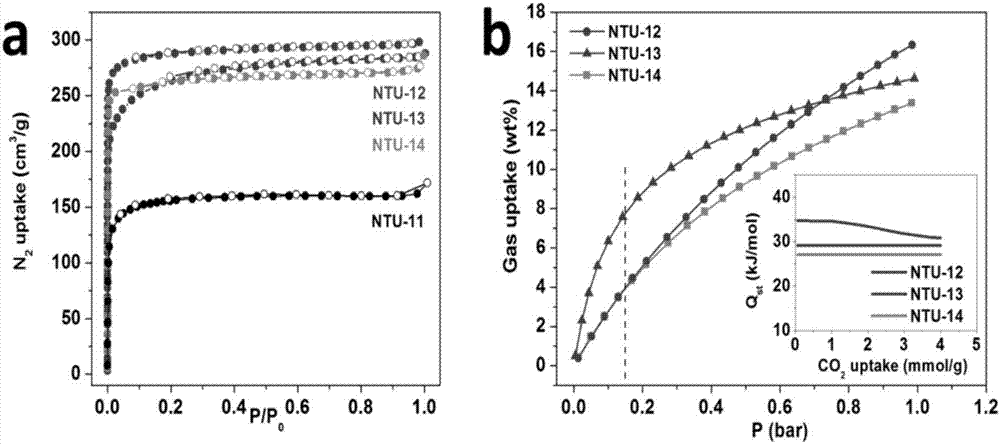

Metal organic framework material used for absorbing and separating CO2 and preparation method thereof

InactiveCN101816924ALarge specific surface areaImprove adsorption capacityProductsCarbon compoundsMetal-organic frameworkChemical measurement

The invention provides a metal organic framework material used for absorbing and separating CO2 and a preparation method thereof. The metal organic framework material is a rigid metal carboxyl compound cluster-like structure which is formed by transition metal ions and multidentate organic ligands through covalent bonds and intermolecular forces. An amine polymer is modified on the metal organic framework material; and the metal organic framework material used for absorbing and separating the CO2 has a specific surface area of 1,000 to 1,200 m<2> / g, and a pore volume of 0.4 to 0.6 cm<3> / g. The preparation method comprises the following steps of: respectively dissolving the nitrate, the chloride or the carbonate of copper or zinc and 1,3,5-trimesic acid together in a stoichiometric ratio in water or an organic solvent; mixing uniformly and sufficiently to react to obtain a BTC bridged complex crystal; and applying a product obtained by reacting an obtained BTC bridged complex crystal with the solution of polyethyleneimine to the metal organic framework material used for absorbing and separating the CO2. The material can realize selective absorption of a gas under a low pressure.

Owner:SOUTHEAST UNIV

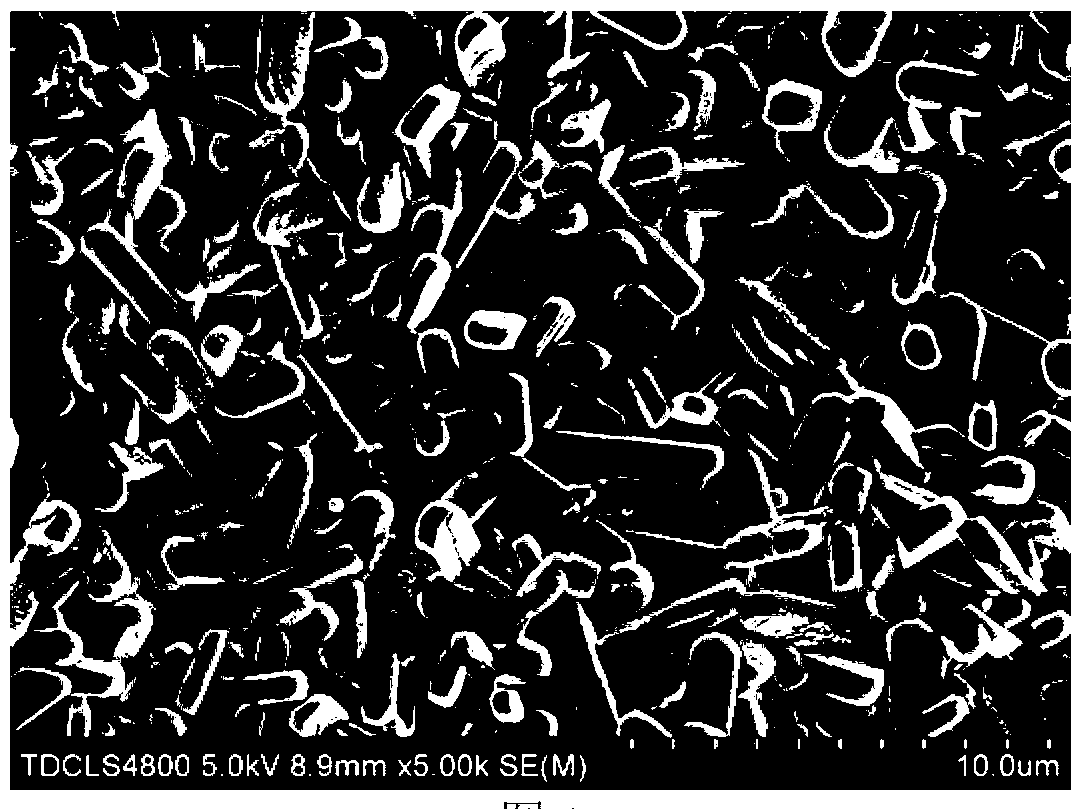

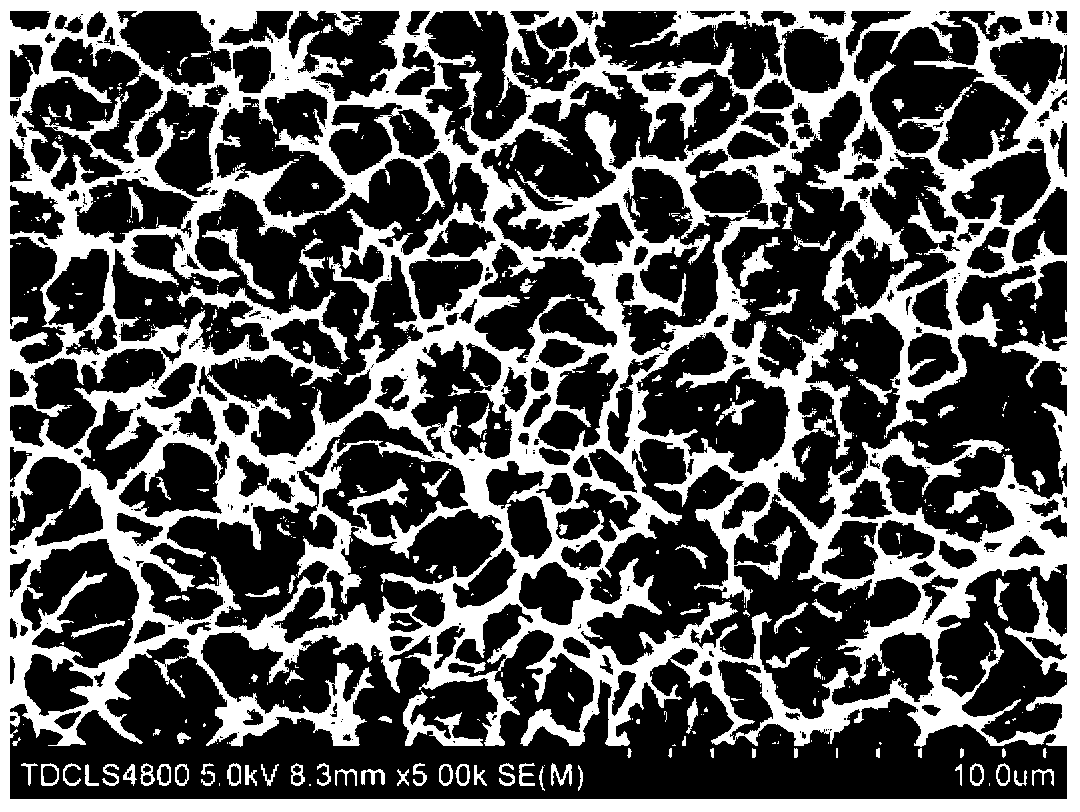

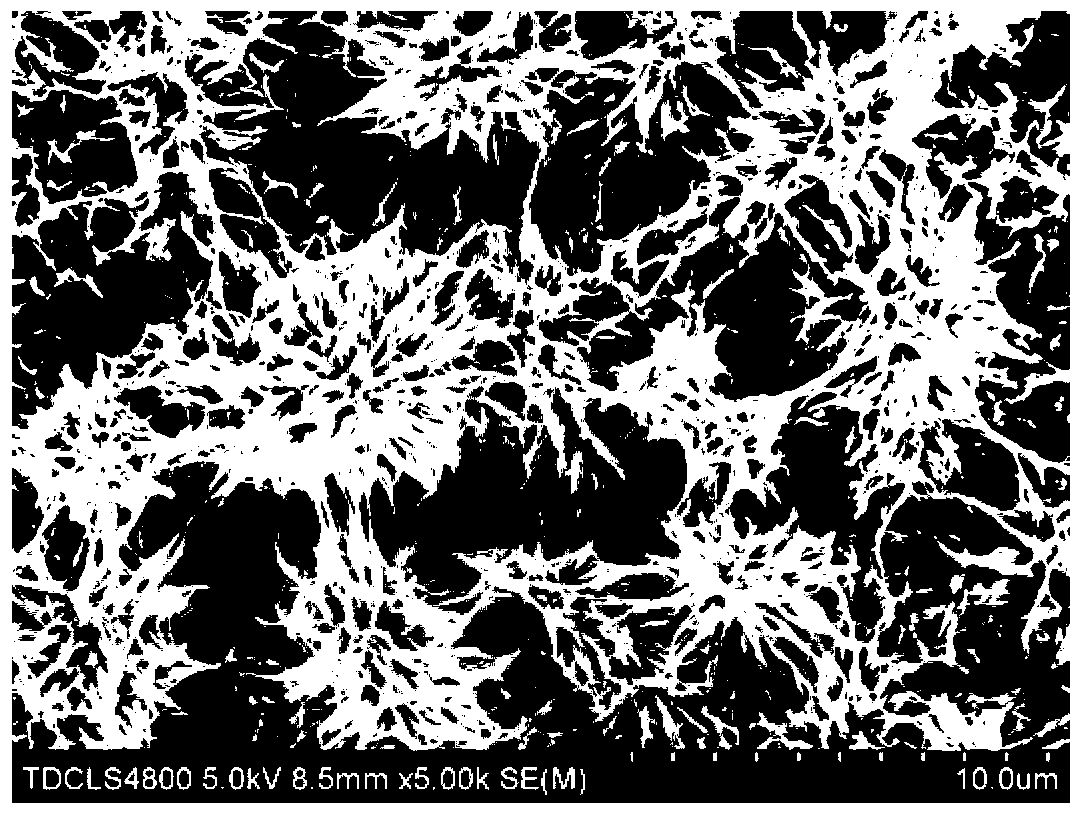

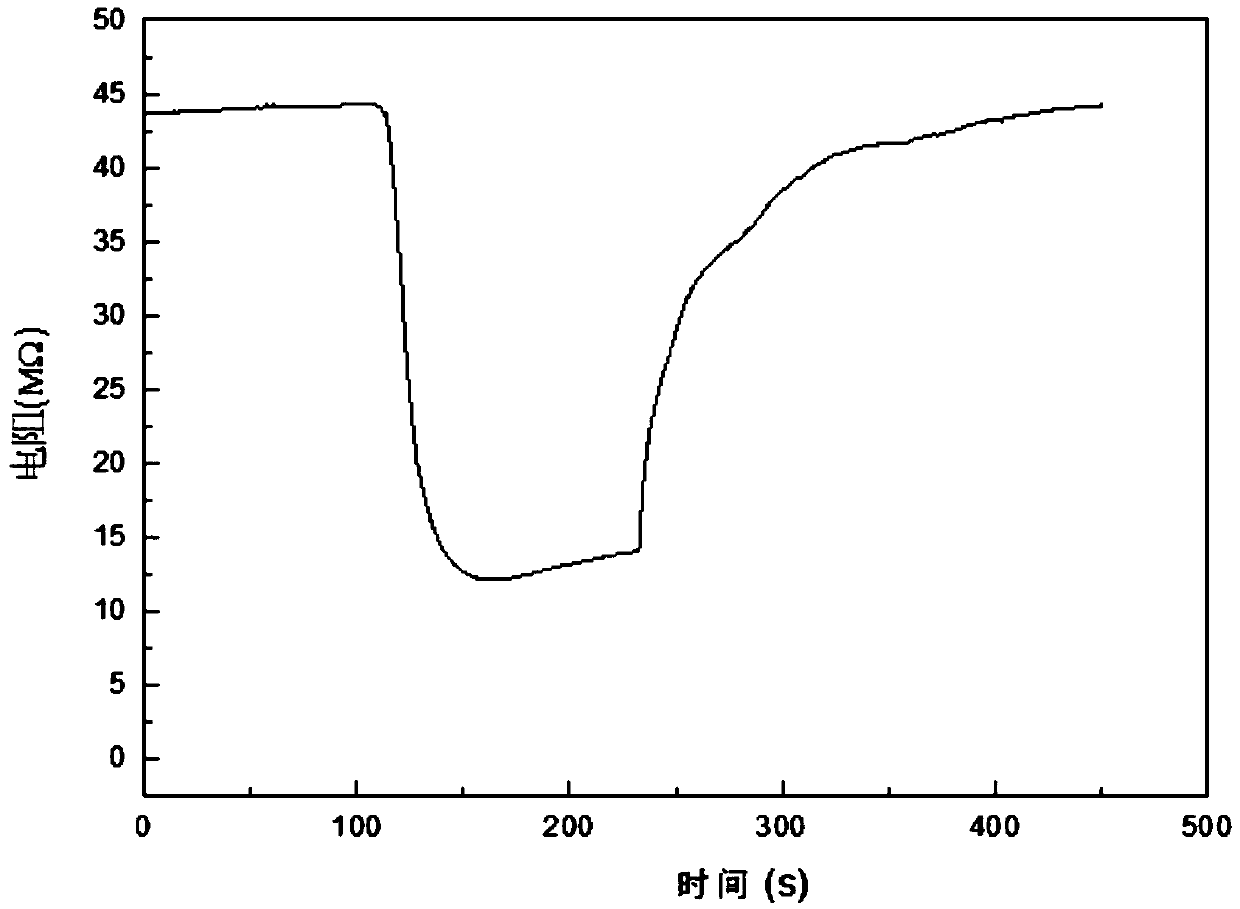

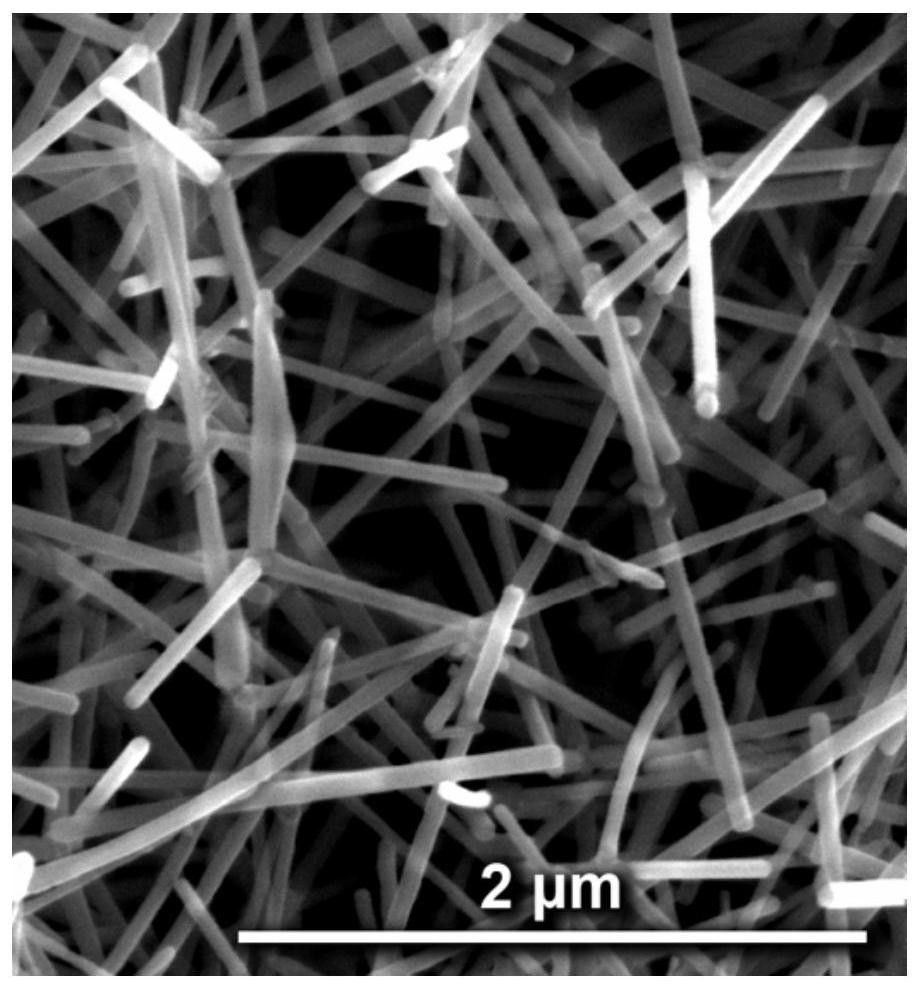

Preparation method for ethanol gas sensor based on vanadium pentoxide multilevel nanometer network structure

InactiveCN103267779AAvoid secondary transfer processReliable electrical contactMaterial resistanceMicro structureDual response

The present invention discloses a preparation method for an ethanol gas sensor based on a vanadium pentoxide multilevel nanometer network structure, wherein a seed layer induction growth approach is adopted to achieve direct in-situ assembly of a multilevel vanadium oxide nanometer network structure on the surface of a sensor substrate to form a high performance vanadium oxide base ethanol gas sensor element with a double work temperature characteristic so as to avoid a secondary transfer process of a gas sensitive material, the multilevel nanometer structure formed on the substrate in the in-situ manner presents a continuous, porous and loose-like micro-structure characteristic and has a significantly high specific surface area, and reliable electric contact is formed between a gas sensitive film and an electrode. The sensor element prepared by the preparation method provides double work temperature and dual response characteristics at a room temperature and a temperature of 250 DEG C for ethanol gas, and has advantages of simple equipment, easy operation, easy process parameter control, low cost and the like.

Owner:TIANJIN UNIV

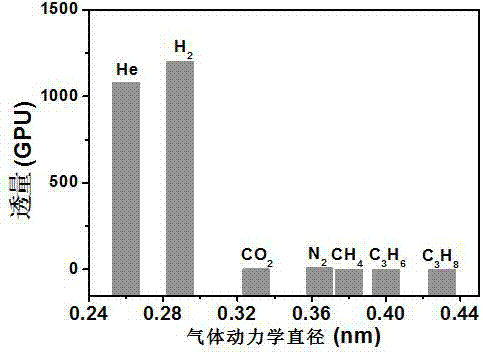

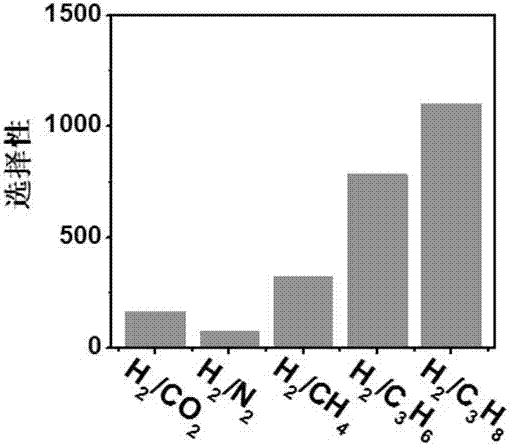

Application of two-dimensional MXene membrane in gas separation

ActiveCN107441892AImprove permeabilityImprove gas selectivitySemi-permeable membranesCarbon compoundsGas phaseTransmittance

The invention discloses application of a two-dimensional MXene membrane in gas separation. The application comprises the following steps: (1) placing the two-dimensional MXene membrane in a gas separation unit, and then, introducing a gas mixture required to be separated from a feed side; (2) introducing purge gas from a purge side; (3) introducing the purge gas to gas chromatography for detecting. The MXene membrane disclosed by the invention has ultrahigh H2 transmittance, ultrahigh H2 / CO2, H2 / N2, H2 / CH4, H2 / C3H6 and H2 / C3H8 separation selectivity and excellent mechanical properties; a preparation method of the two-dimensional MXene membrane is simple and easy in operation, low in energy consumption, low in cost and high in repeatability and is applicable to large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

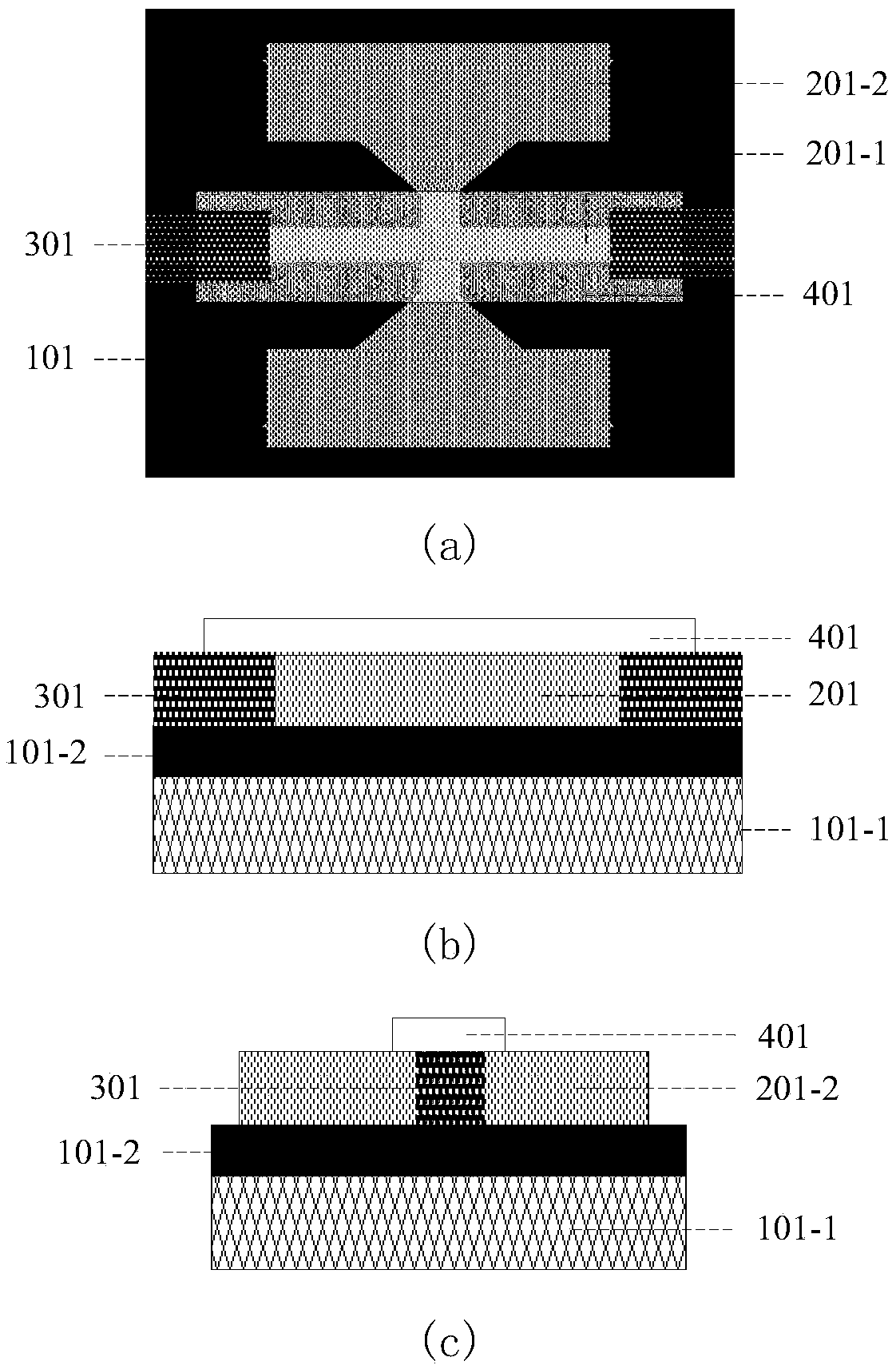

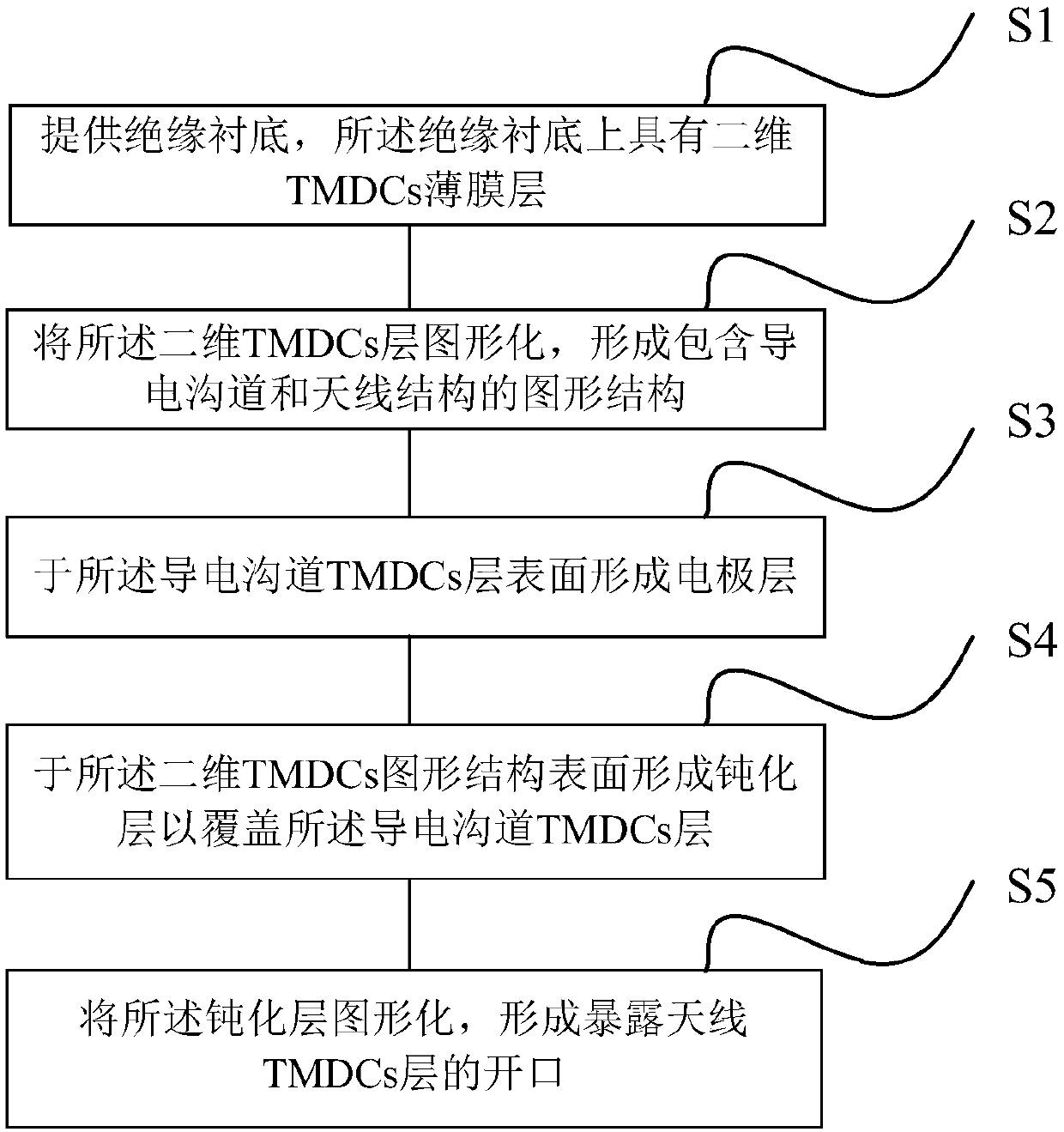

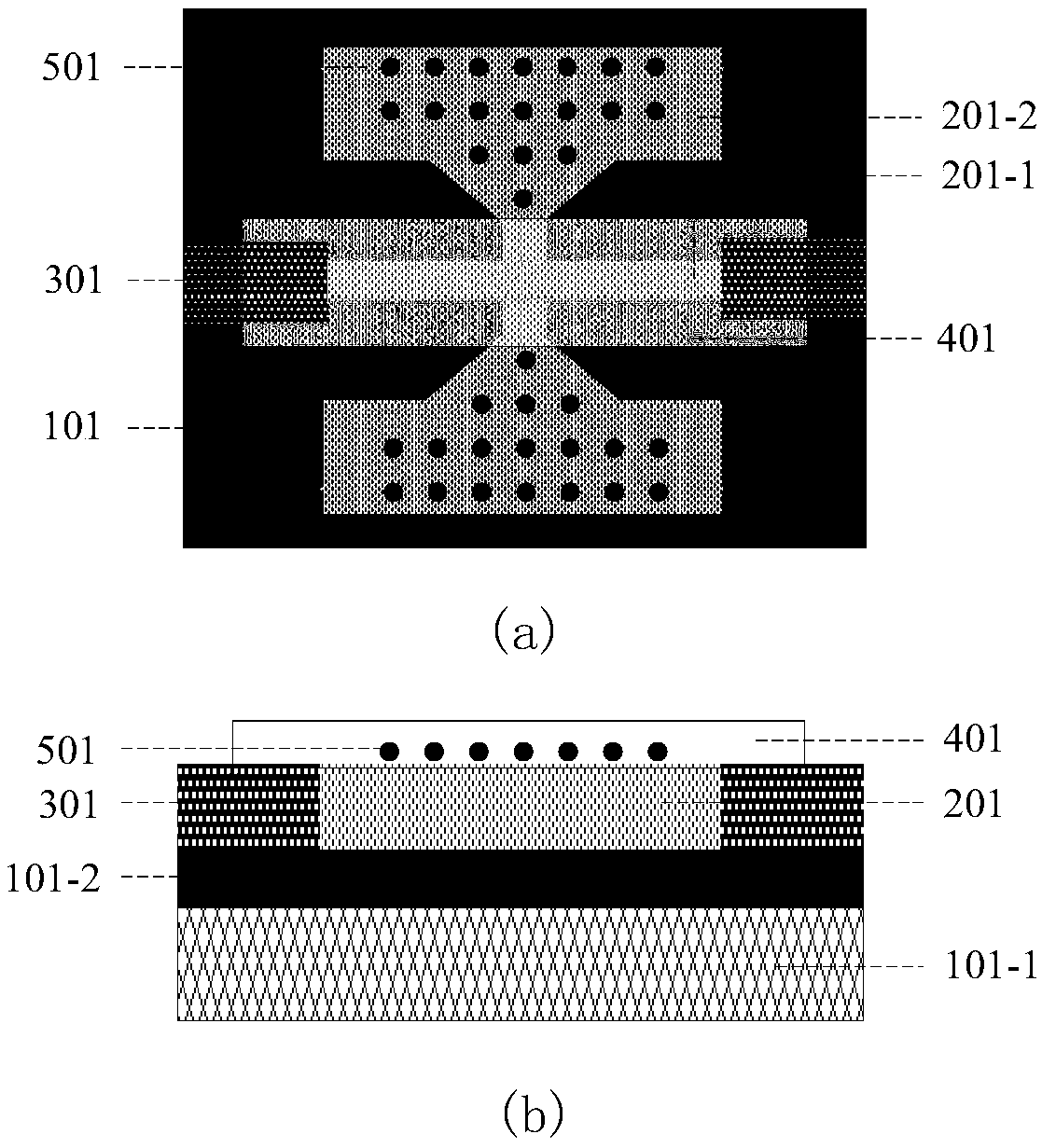

Two-dimensional transition metal sulfide gas sensor based on antenna structure, and preparation thereof

ActiveCN109580725AAdsorption/desorption temperature is lowAddress adverse effects of transport propertiesMaterial resistanceDiffusionElectrical resistance and conductance

The invention discloses a two-dimensional transition metal sulfide gas sensor based on an antenna structure, and preparation thereof. The gas sensor comprises a two-dimensional transition metal sulfide TMDCs film which is patterned into two connected parts of a conductive channel and an antenna structure, wherein the surface of the conductive channel is covered with a passivation layer; the antenna structure is used for adsorbing the gas to be tested as a gas sensitive layer; when molecules of the gas to be tested are adsorbed on the surface of the antenna structure and are performed with charge transfer, the concentration of carriers in the antenna structure changes to form a concentration gradient and induce the diffusion of the carriers, so that the concentration of the carriers in theconductive channel changes, and finally the resistance of the conductive channel is changed, thereby realizing the sensing of the gas to be tested by the gas sensor. The sensor, by distinguishing thegas sensitive layer and the conductive channel into two parts on the sensor structure, not only helps to increase the stability of the sensor, but also can improve the sensitivity of the gas sensor byutilizing the gain effect of the antenna structure.

Owner:HUAZHONG UNIV OF SCI & TECH +1

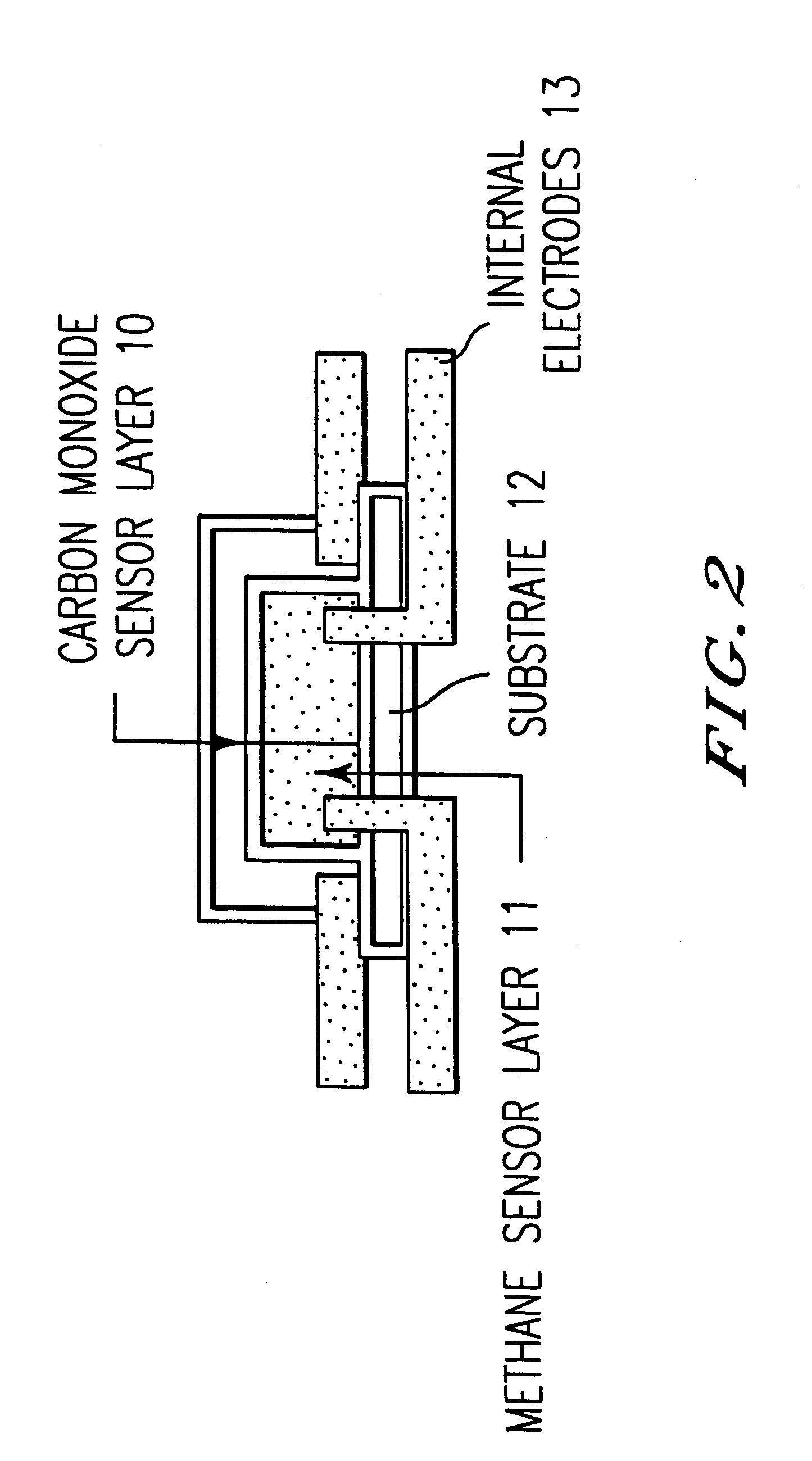

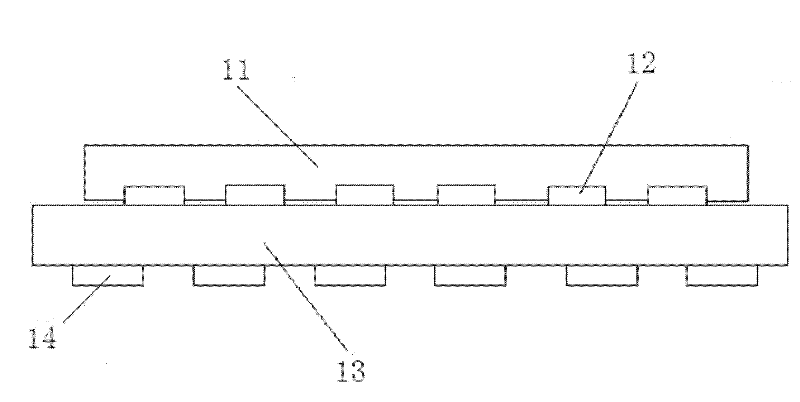

Multilayered gas sensor

InactiveUS6263723B1Improve gas selectivityGood choiceComponent separationSemiconductor/solid-state device manufacturingGas phaseProduct gas

The present invention provides a gas sensor element having properties capable of detecting methane and carbon monoxide selectively with 1 sensor by improving gas selectivity of the semiconductor gas sensor. The present invention relates to a gas sensor element, which has a carbon monoxide sensor layer with an ability to function as a catalyst film that blocks carbon monoxide, which impedes detection of methane at the underlying methane sensor, and has a layer-built structure where the surface of a methane sensor is covered with the carbon monoxide gas sensor which can be obtained by a gas-phase method.

Owner:TAKAO YASUMASA +2

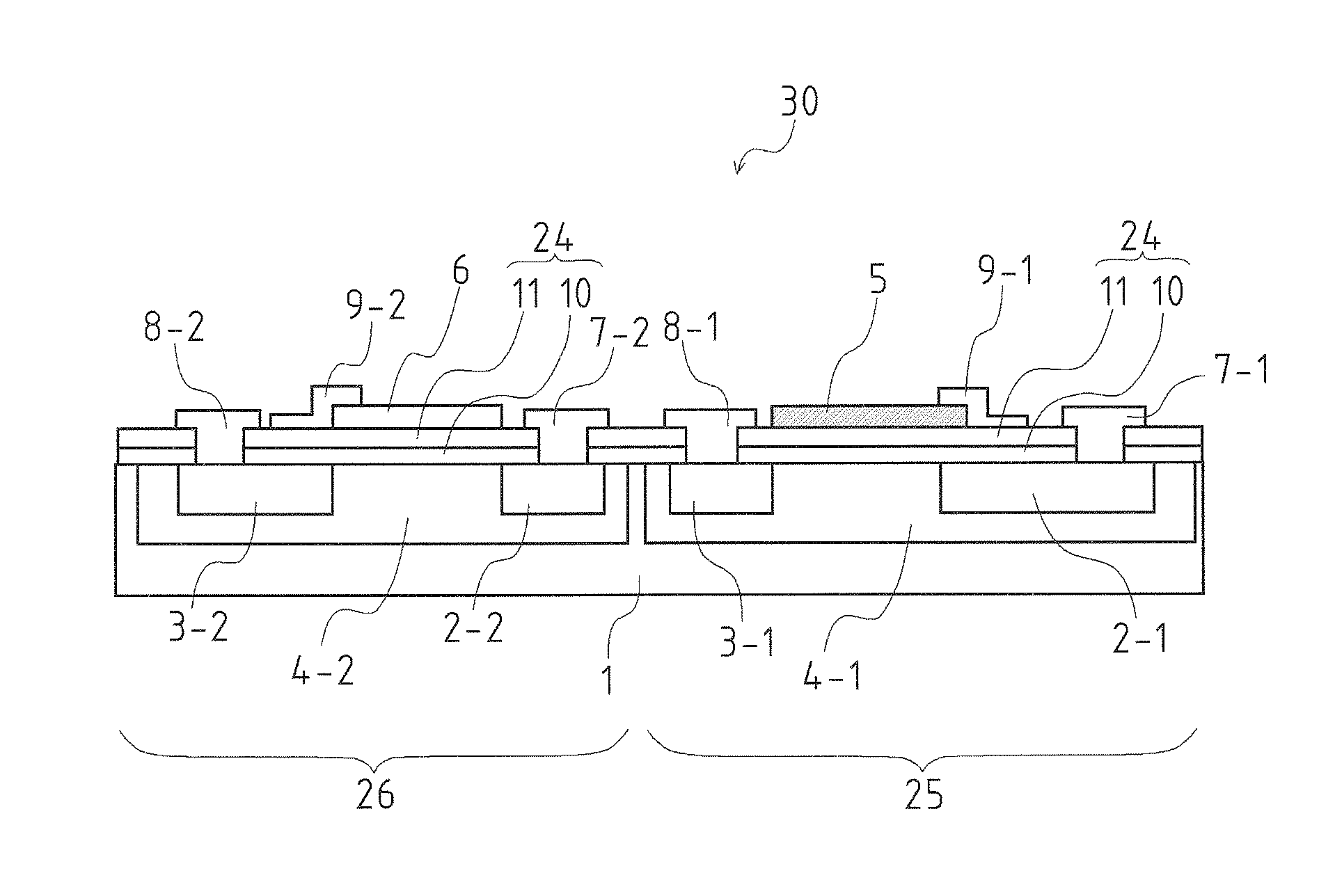

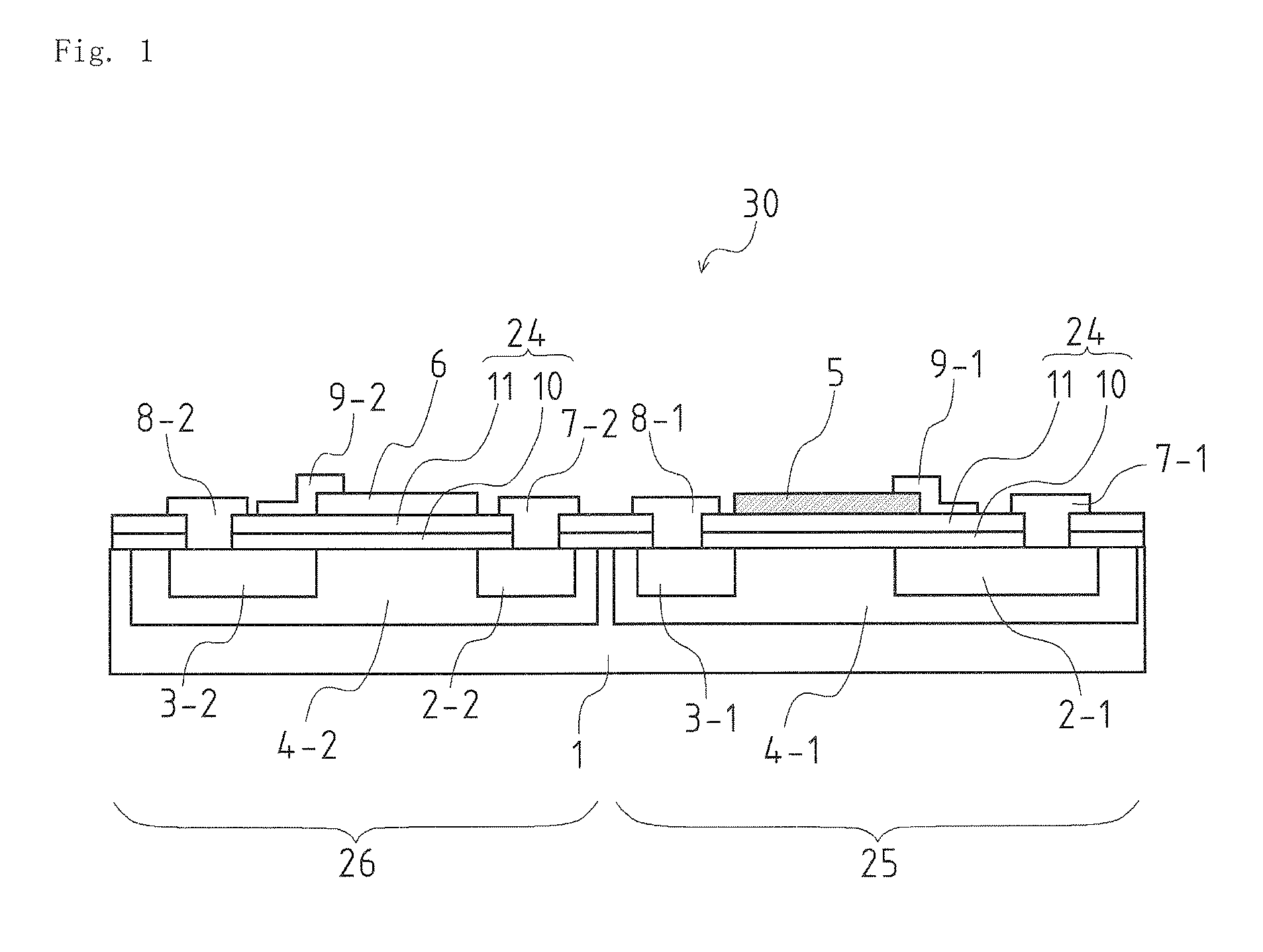

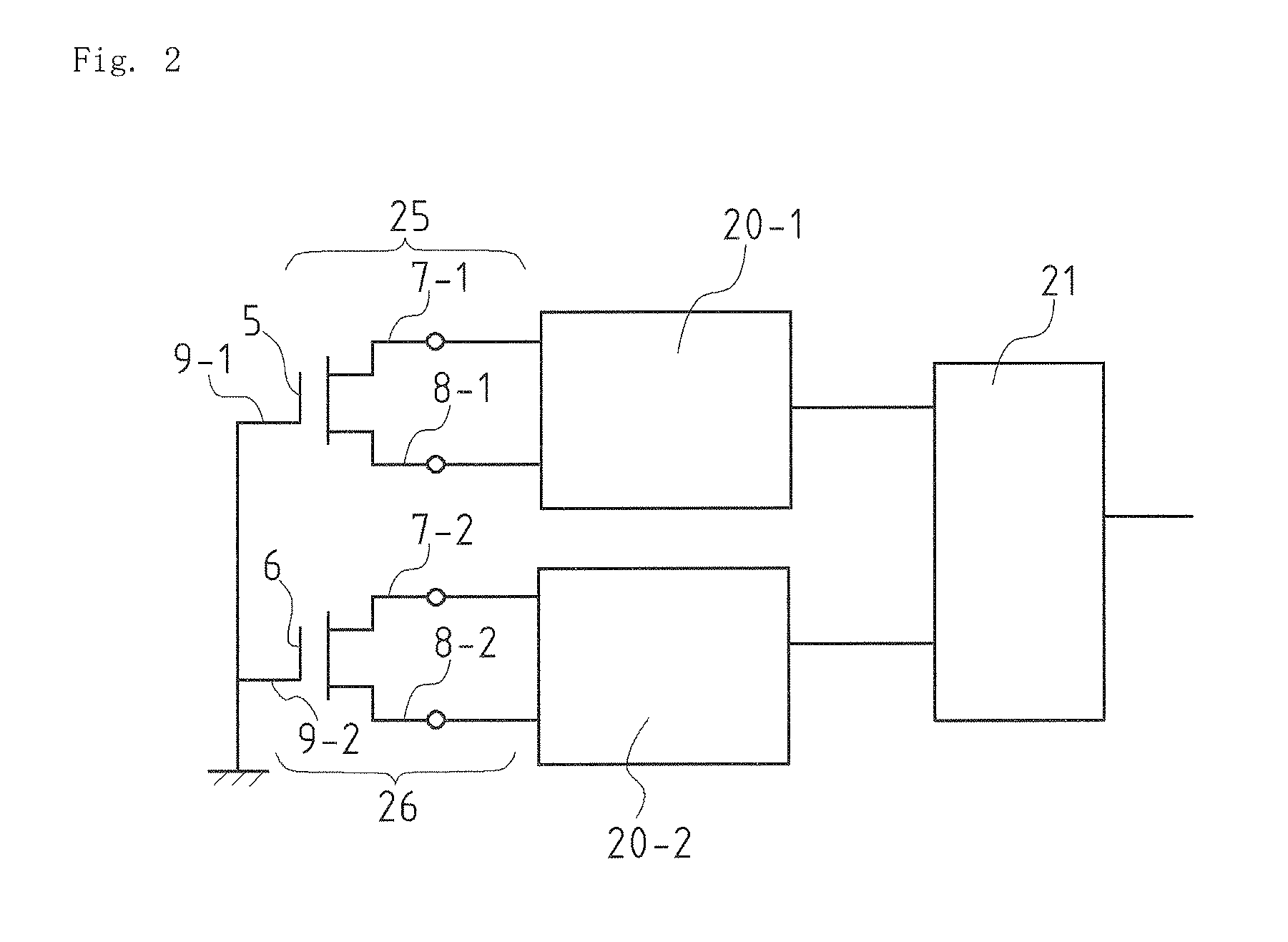

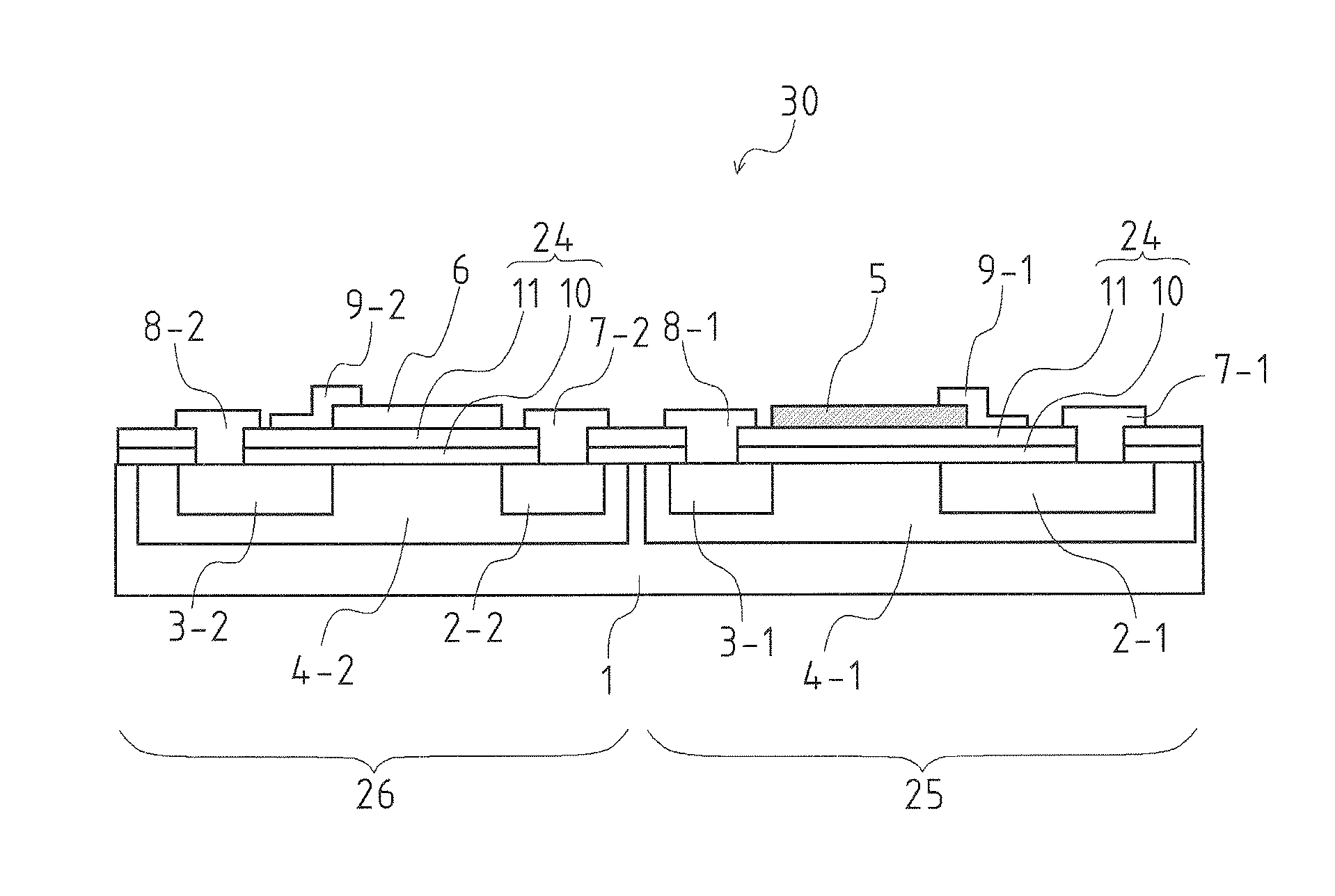

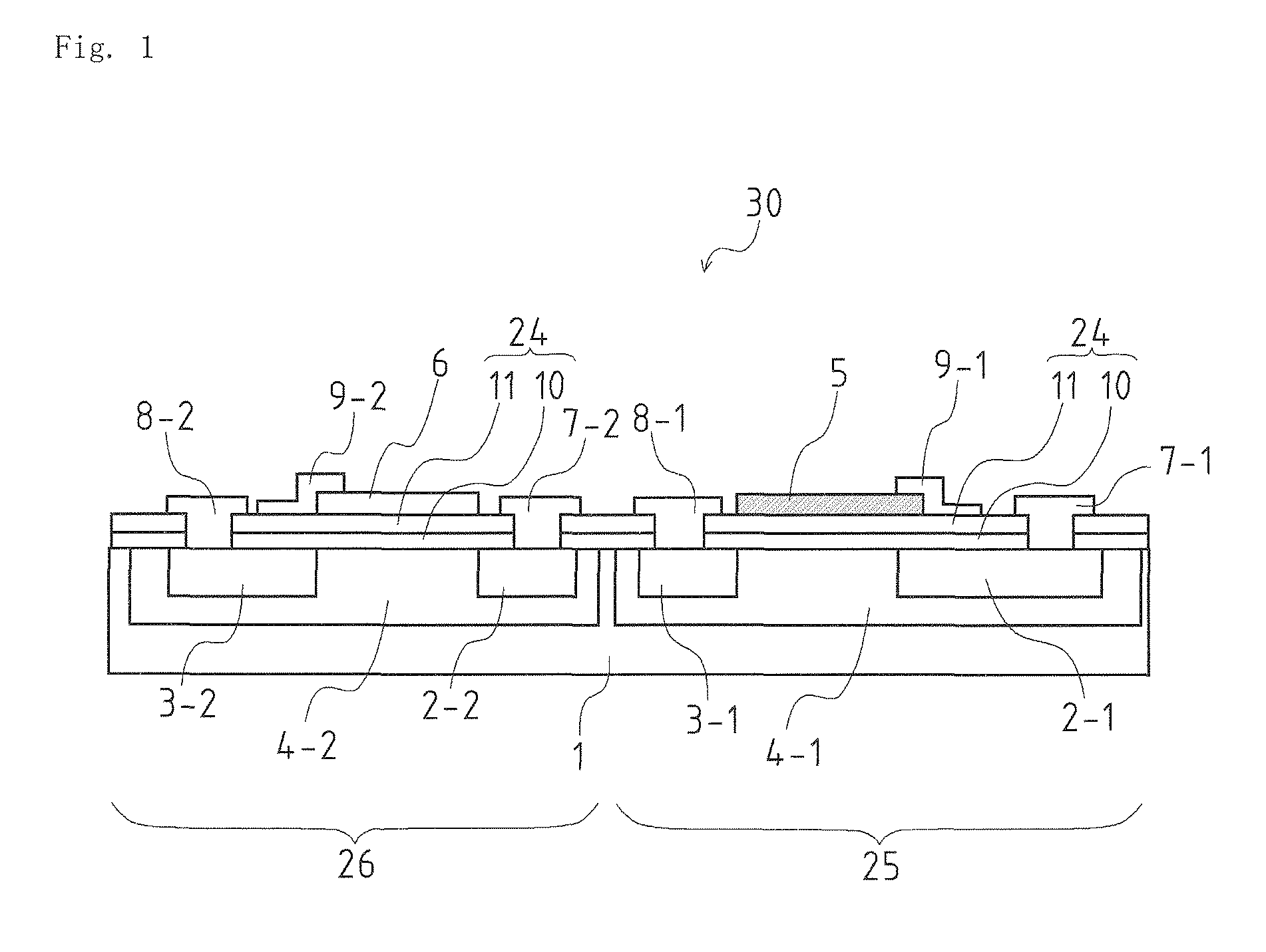

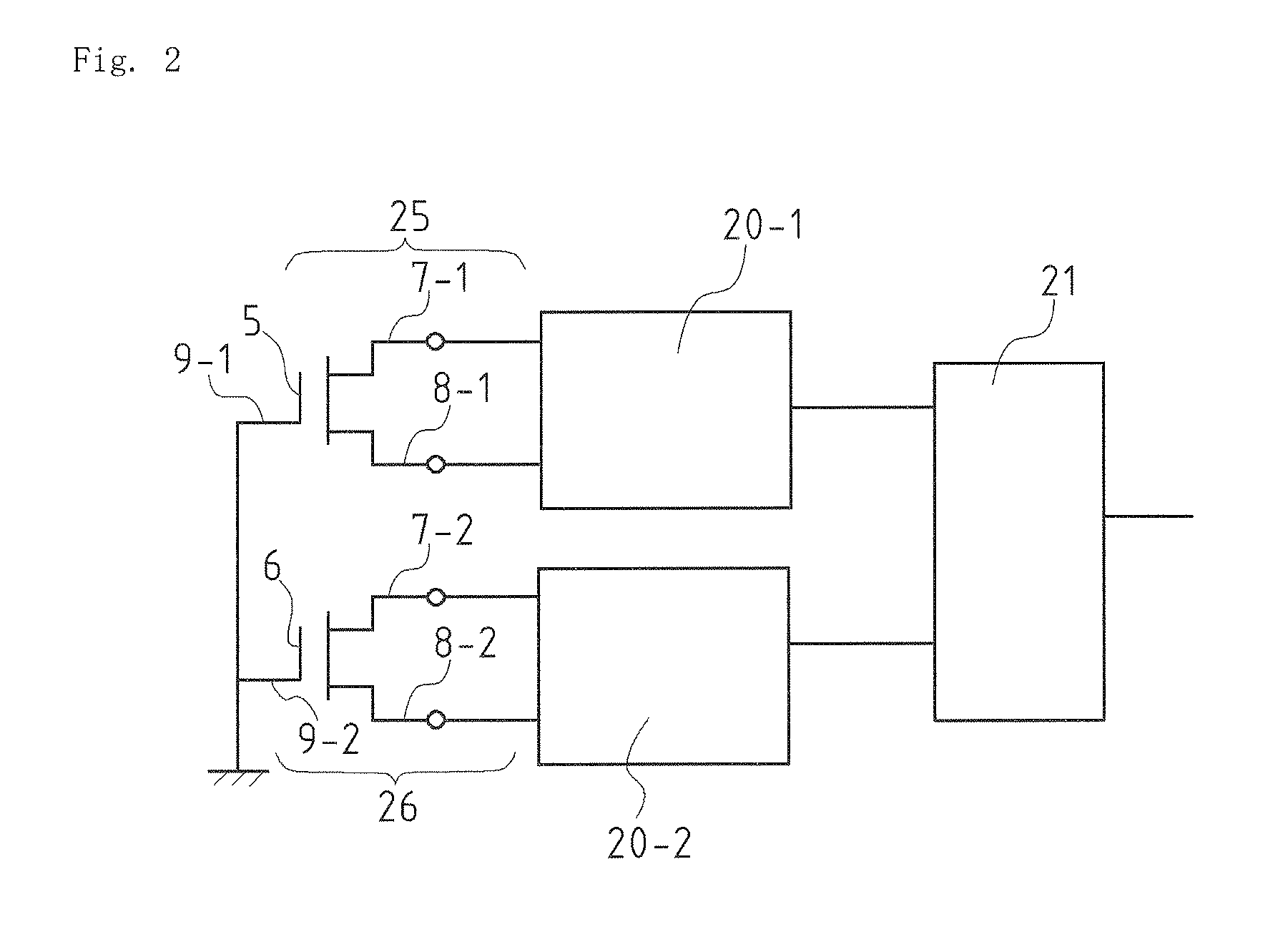

Gas Sensor

ActiveUS20110169057A1Different response propertyChange outputTransistorMaterial analysis by electric/magnetic meansEngineeringAlternating current

[Object] To provide a gas sensor having a self-diagnostic function with a simplified structure.[Means of Realizing the Object] A gas sensor (30) includes two field-effect transistors and gate electrodes on gate insulation films (24) of the two field-effect transistors to detect gas using the gate electrodes. The gas sensor (30) includes a first gate electrode (5), a second gate electrode (6), and voltage applying means. The first gate electrode (5) is provided on one of the field-effect transistors. The second gate electrode (6) is provided on another one of the field-effect transistors. The voltage applying means is for, with the first gate electrode (5) and the second gate electrode (6) coupled to one another by wiring, applying thereto one of a direct-current voltage and an alternating-current voltage having a same potential or a constant voltage difference. The first gate electrode (5) and the second gate electrode (6) are made of different metals. The one field-effect transistor and the other field-effect transistor have approximately the same structures.

Owner:UNIV OKAYAMA

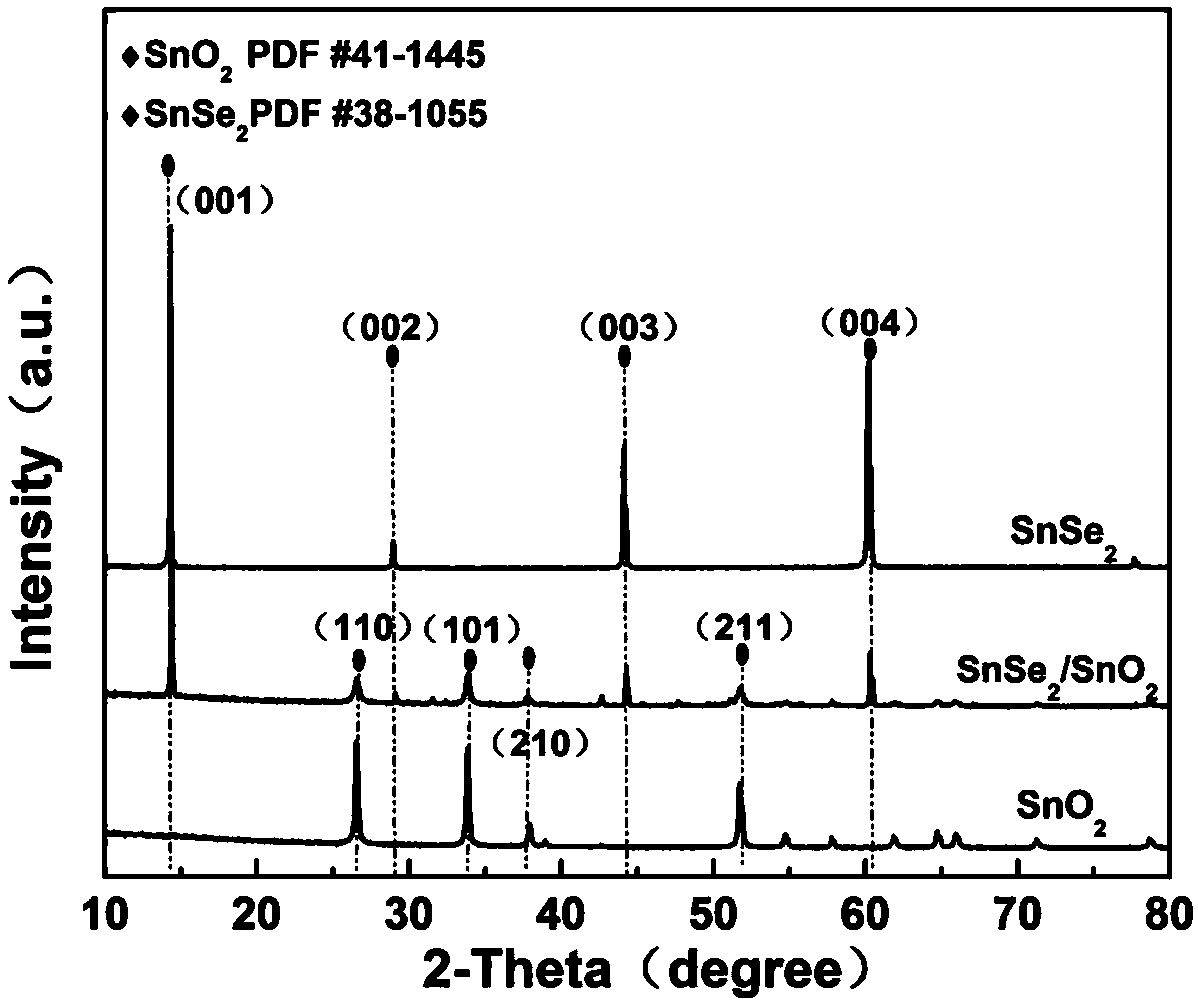

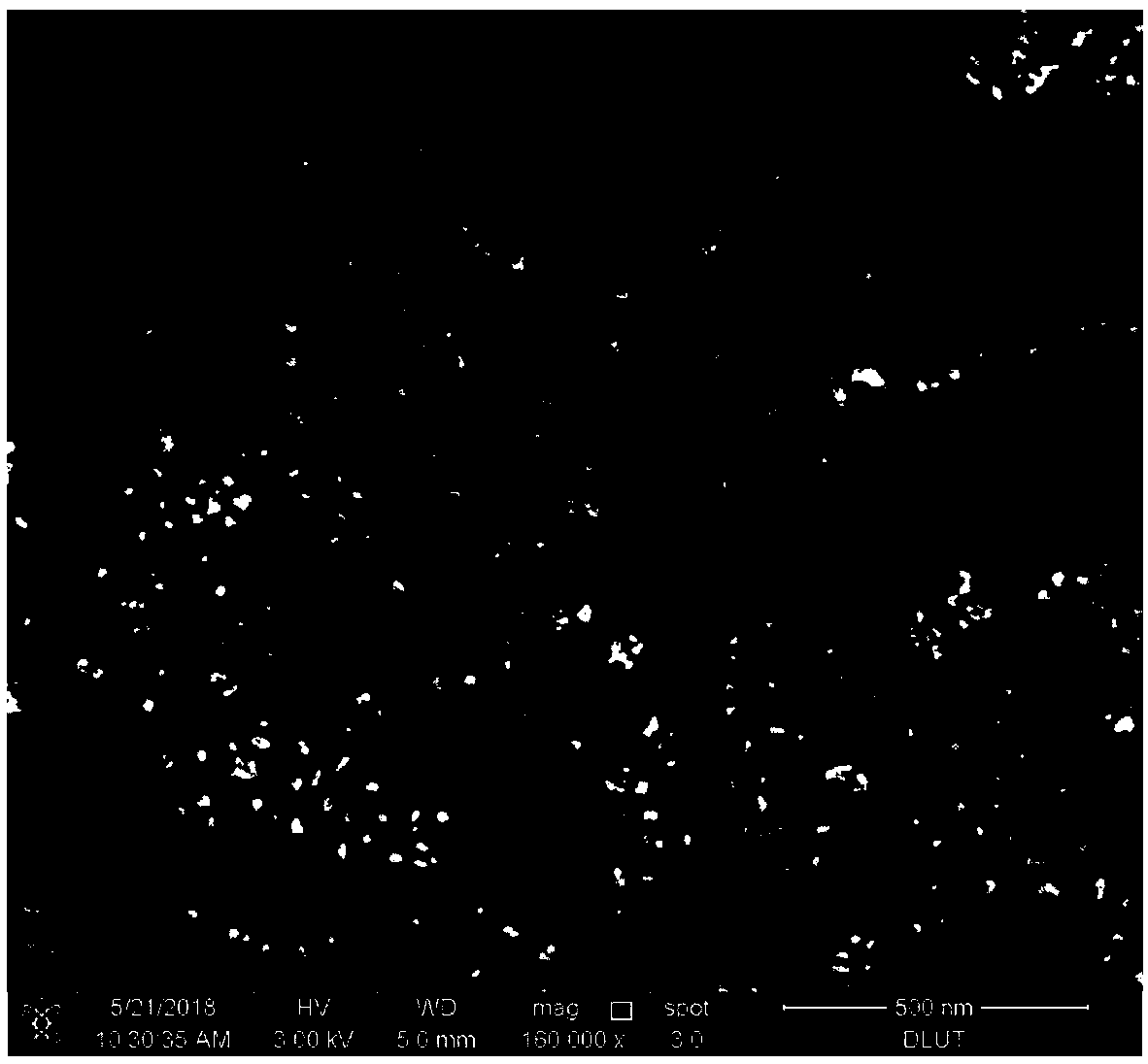

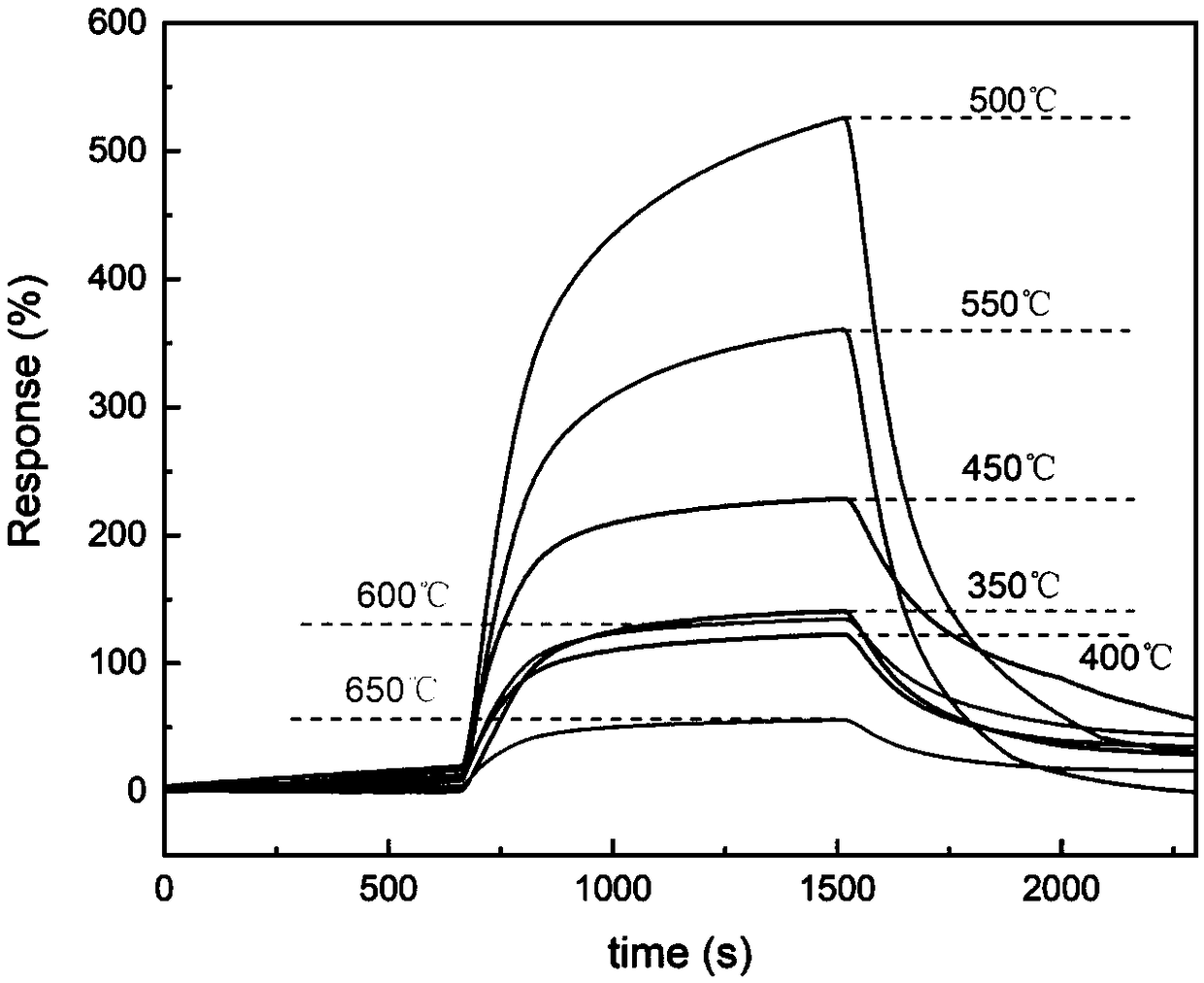

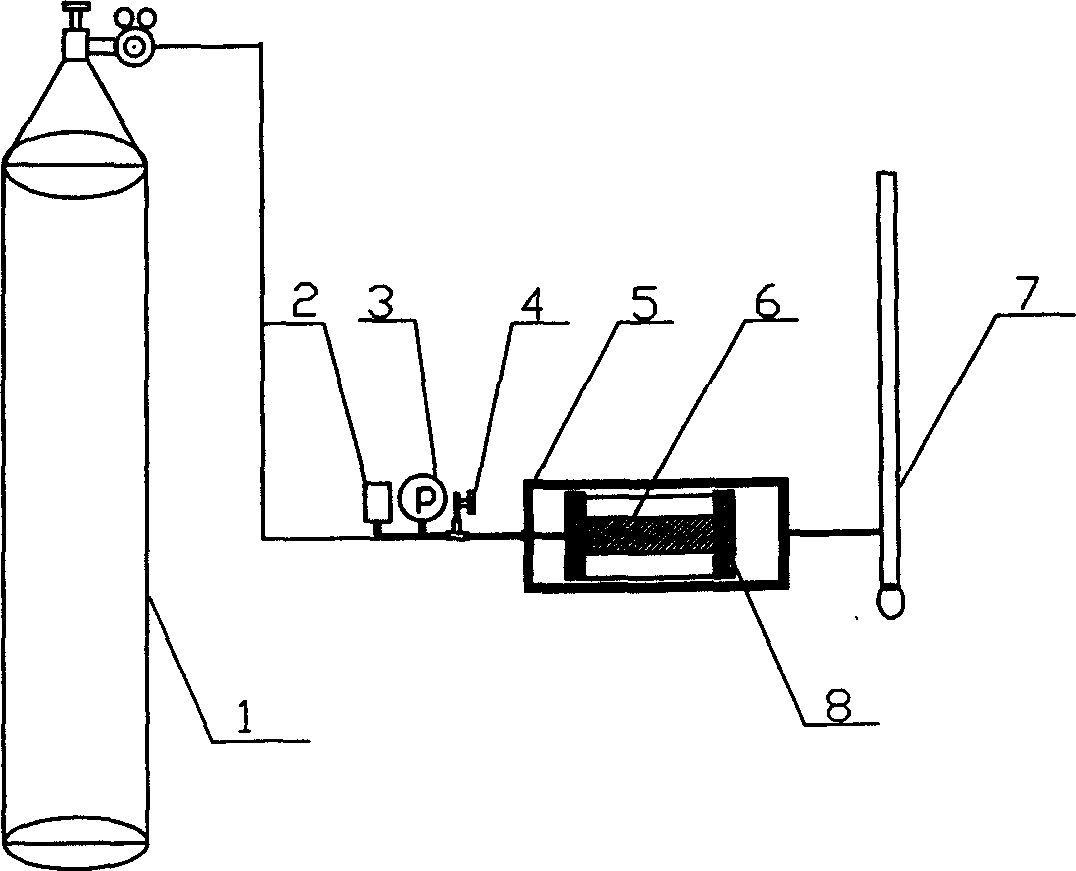

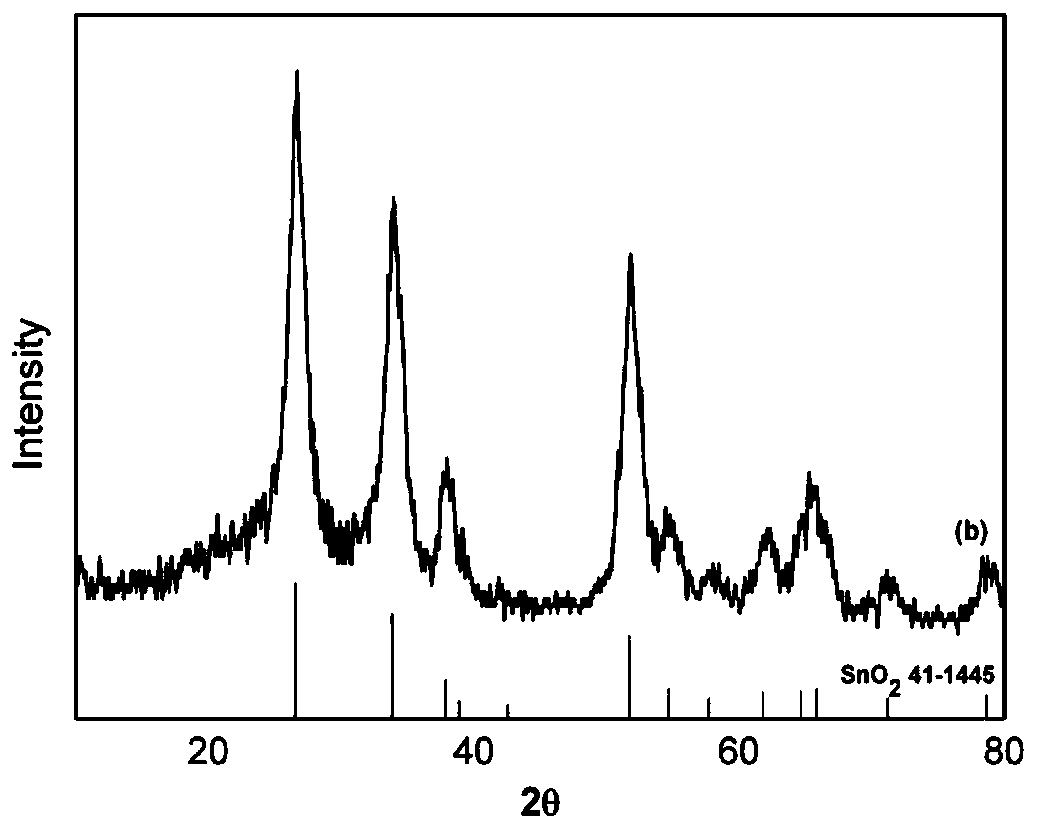

Nitrogen dioxide gas sensor based on SnSe2/SnO2 heterojunction as well as preparation process and application thereof

The invention belongs to the technical field of a nanometer material, and provides a nitrogen dioxide gas sensor based on a SnSe2 / SnO2 heterojunction as well as a preparation process and application thereof. The nitrogen dioxide gas sensor based on the SnSe2 / SnO2 heterojunction mainly consists of a gas sensitive material and a heating base plate, wherein the gas sensitive material is coated on thesurface of the heating base plate; the coating thickness is 1 mum to 100 mum; the gas sensitive material is a heterojunction composite nanometer material formed by ingredients of tin diselenide and tin dioxide. A hot oxidization method is used for obtaining the novel heterojunction composite nanometer material; the raw materials can be conveniently obtained; the price is low; the heterojunction preparation process is simple; the scheme beings to a two-dimensional semiconductor heterojunction preparation scheme with the advantages of low equipment investment and simple technical flow process.The work temperature of nitrogen dioxide made of the tin diselenide and tin dioxide heterojunction composite nanometer material is 120 DEG C; the material and silicon base microelectron phase integration can be realized.

Owner:DALIAN UNIV OF TECH

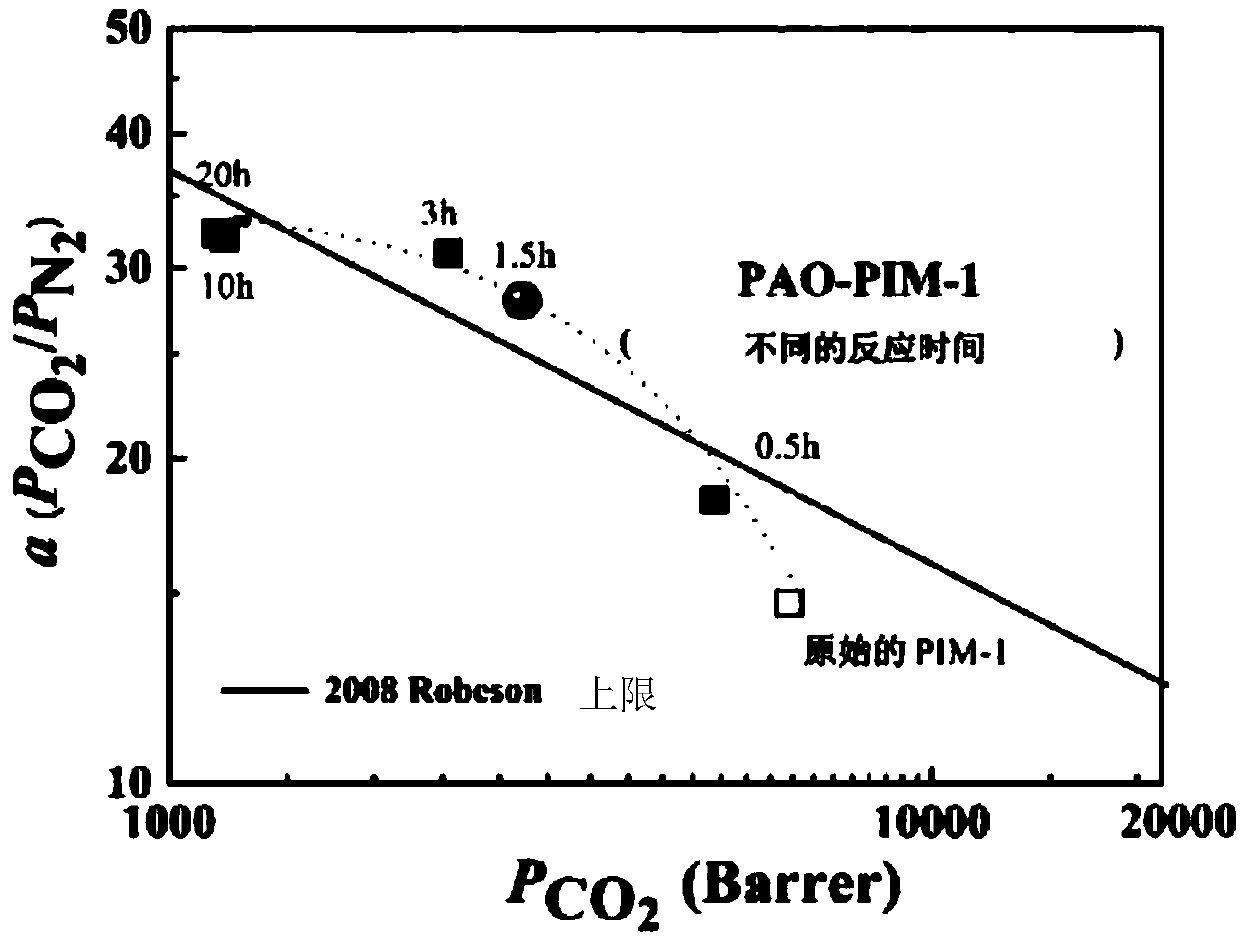

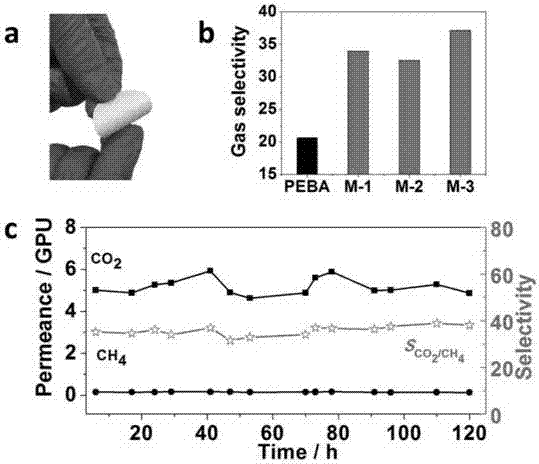

Macromolecular separation film as well as preparation method and application thereof

InactiveCN108854604AHigh selectivityImprove gas selectivitySemi-permeable membranesDispersed particle separationPolymer scienceSolvent

The invention discloses a macromolecular separation film as well as a preparation method and application thereof. The macromolecular separation film comprises a continuous phase of a polymer with a micropore structure, wherein the polymer comprises a microporous polymer and a dispersion phase containing inorganic materials; the microporous polymer comprises PIM-1 and / or PIM-1 derivatives. The preparation method comprises the following steps of uniformly mixing the microporous polymer and the inorganic materials into a solvent to obtain a blended solution; coating the blended solution onto a polymer support layer to obtain a macromolecular separation film. The composite gas separation film maintains good mechanical performance, thermal stability and processing performance of the polymer materials and good gas selection performance of inorganic materials, and has the advantages of high seepage performance and high selectivity during mixed gas separation, particularly oxygen gas and nitrogen gas separation; the preparation method is simple; the method is suitable for scaled industrial production; the potential application prospects are realized in the aspects of rich-oxygen, namely oxygen gas enriching application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Gas separation membrane and method of producing the same

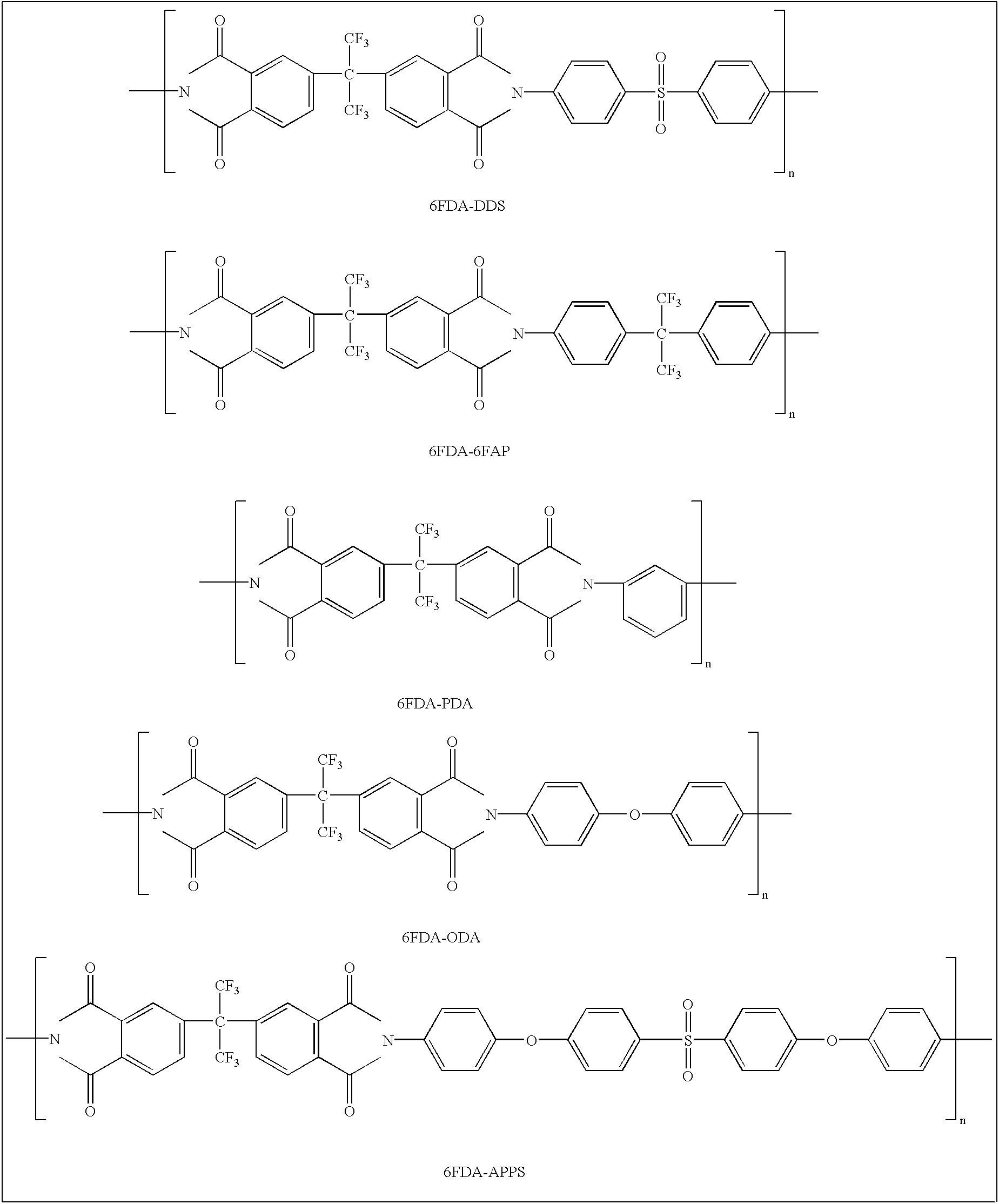

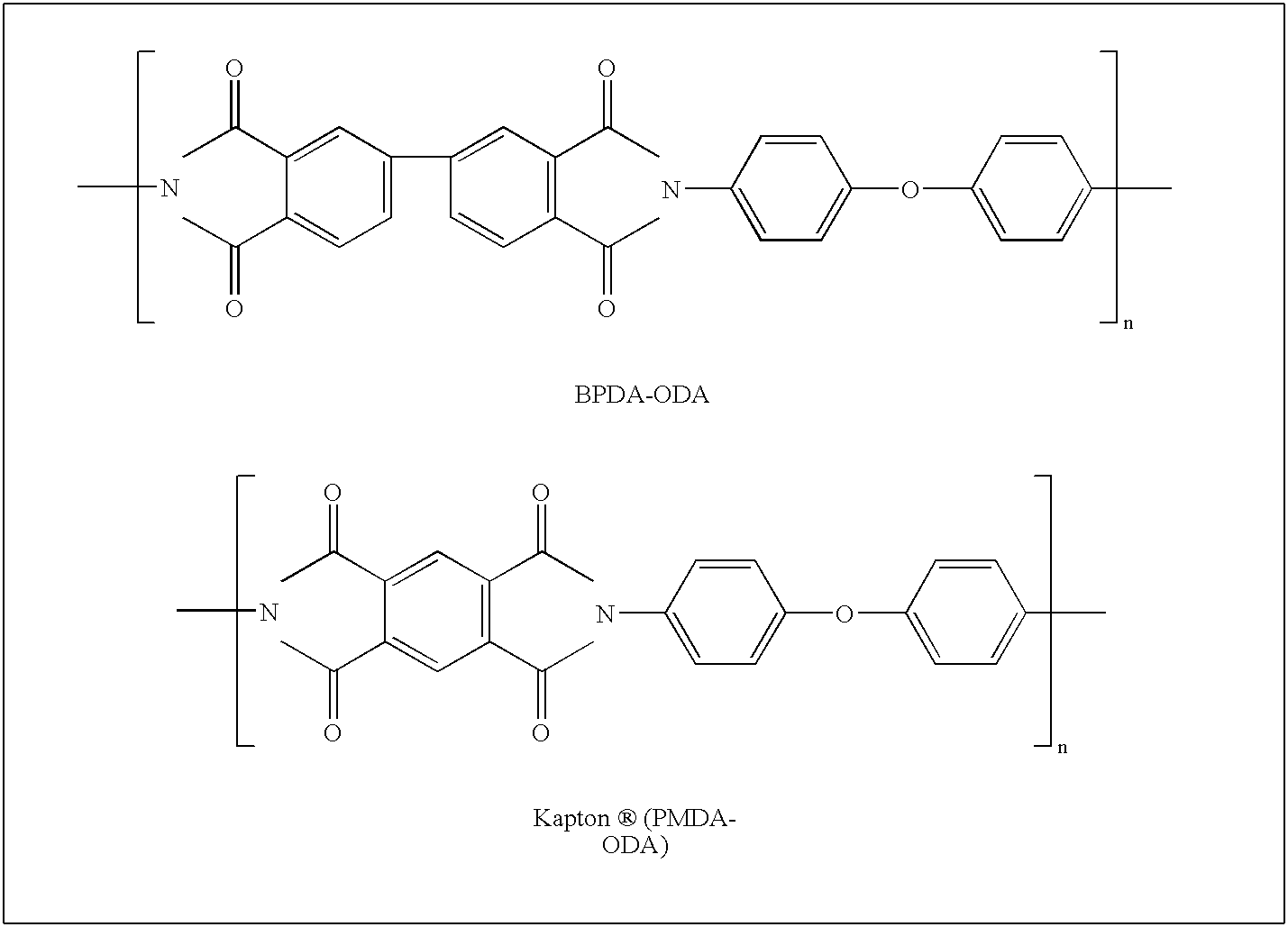

InactiveUS6709491B2Improve gas selectivitySave energyMembranesSemi-permeable membranesIon bombardmentOrganic solvent

The object of the present invention is to provide a novel gas separation membrane having a high gas permeability and a high gas selectivity, and a method of producing the same. The present invention provides a gas separation membrane comprising a polymeric material soluble in an organic solvent, wherein at least a part of the surface is modified by ion bombardment.

Owner:RIKEN

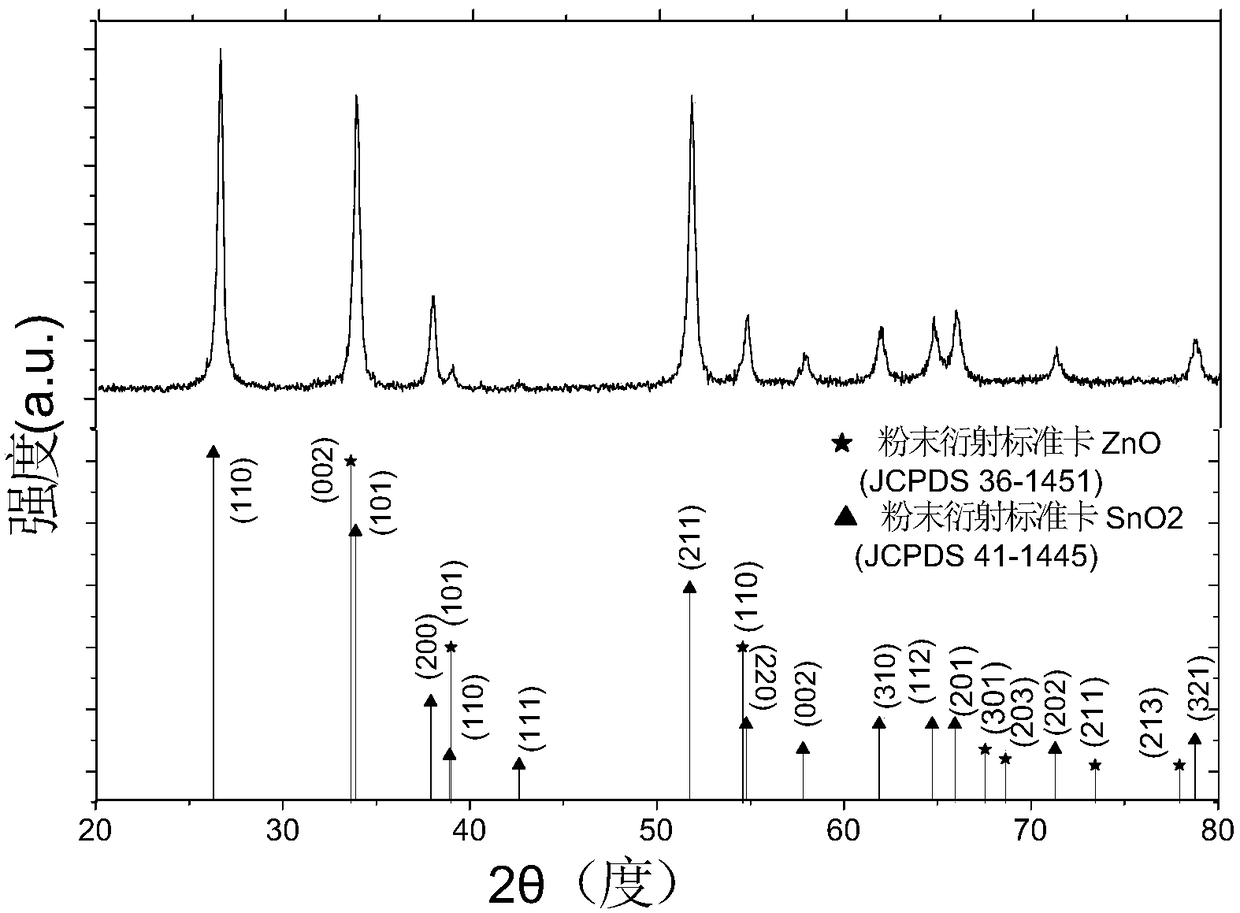

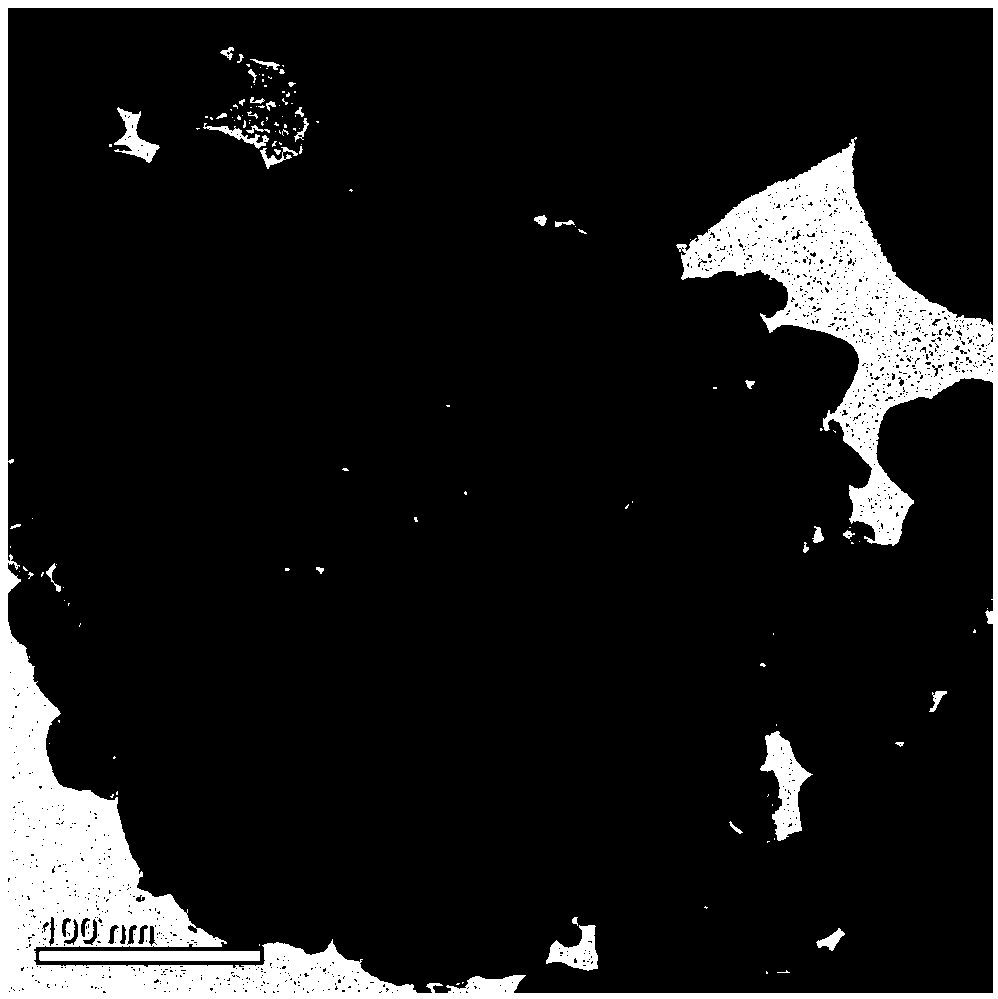

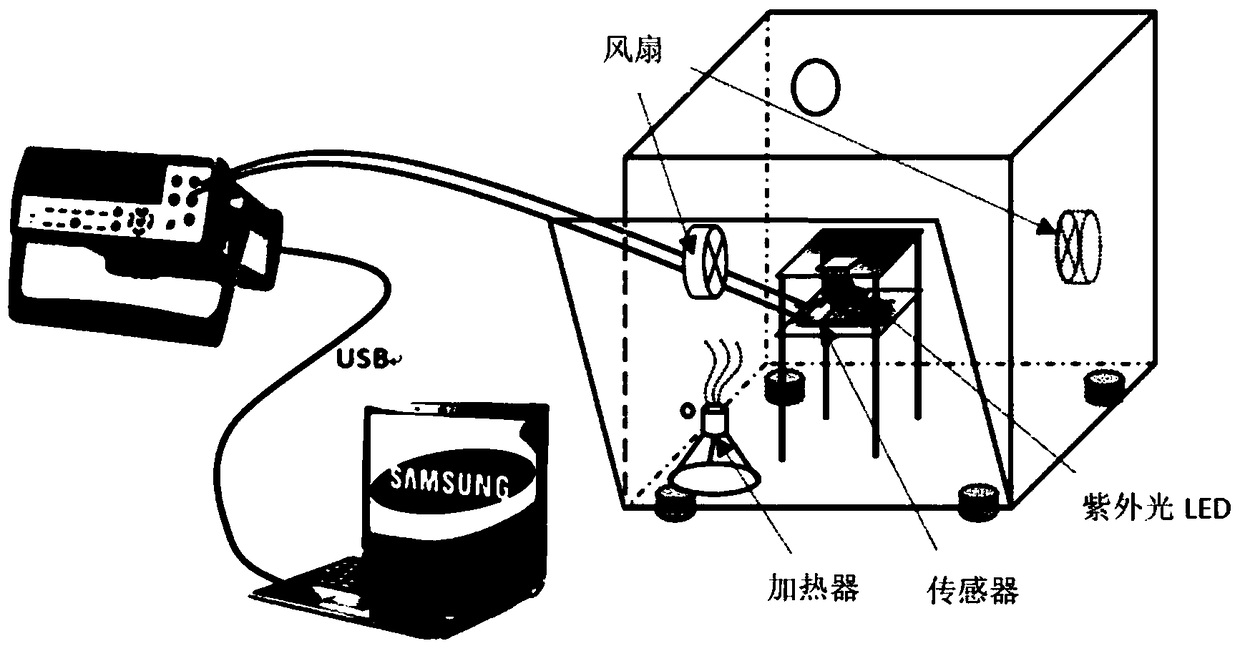

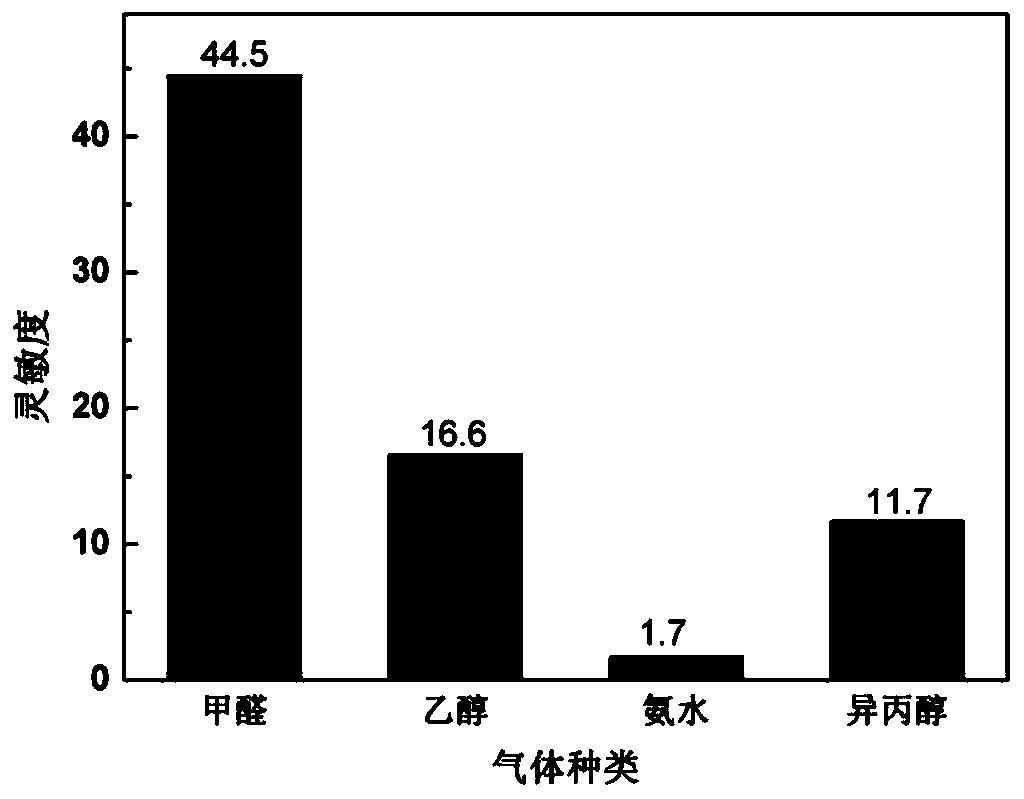

Light-excited formaldehyde gas sensor and preparation process thereof

InactiveCN108717072AHigh specific surface areaIncrease the reaction areaMaterial nanotechnologyZinc oxides/hydroxidesProduct gasZinc

The invention belongs to the technical field of sensors and provides a light-excited formaldehyde gas sensor and a preparation process thereof. The sensor comprises a light source, a gas-sensitive material and a substrate, wherein the gas-sensitive material is uniformly coated on the surface of the substrate; the component of the gas-sensitive material is a hollow microsphere zinc oxide and stannic oxide heterojunction composite nanometer material; the coating thickness of the gas-sensitive material is 1-100 microns; the service condition is that LED lamp bead irritation is performed at the band of 365nm. The formaldehyde sensor disclosed by the invention is high in response of formaldehyde gas, and also has the characteristics of being excellent in selectivity, sensitivity and stability and capable of working at a room temperature.

Owner:DALIAN UNIV OF TECH

Tubular supporting carbon molecular sieve membrance and its preparing method

InactiveCN1709560AGood effectPermeate flux decreaseSemi-permeable membranesMolecular sieveProduct gas

The present invention relates to char molecule sieve membrane and its method especially the cannular backstop char sieve membrane. It is a new Nami material -char sieve membrane filled Nami material in char sieve membrane. The preparation method is adding Nami material in no water ethanol of bakelite colophony. Nami materials are Nami nickel, Nami NaA molecule, Nami titanium dioxide. The ultrasonic makes Nano material decentralize in the membrane liquid and dip cannular backstop. Nami material has different adsorption ability to some gas. According this, char molecule can permeate or remain some gas. So it can increase or decrease the selectivity of the gas to other gas.

Owner:NANJING UNIV OF TECH

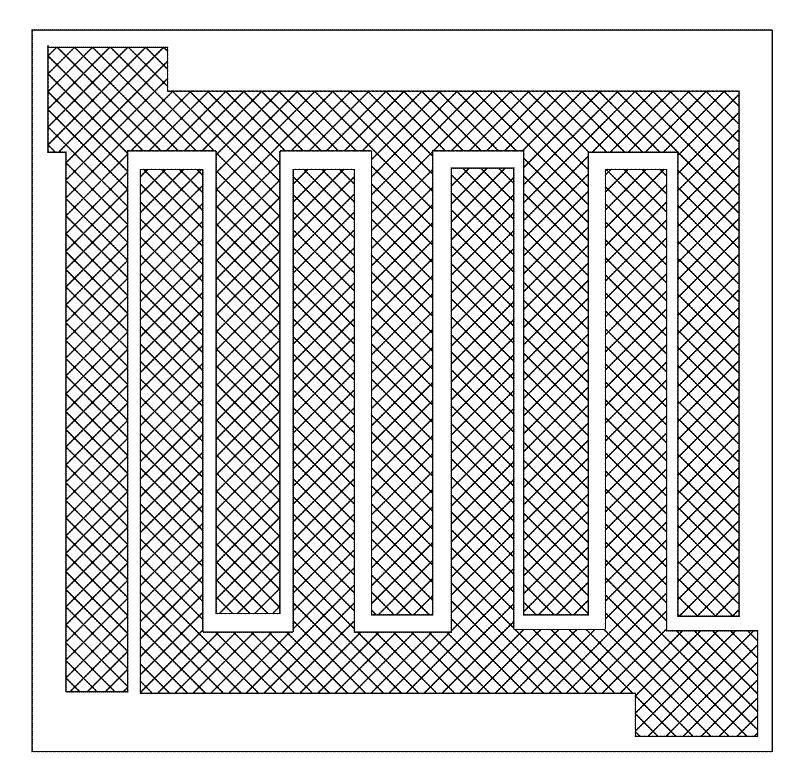

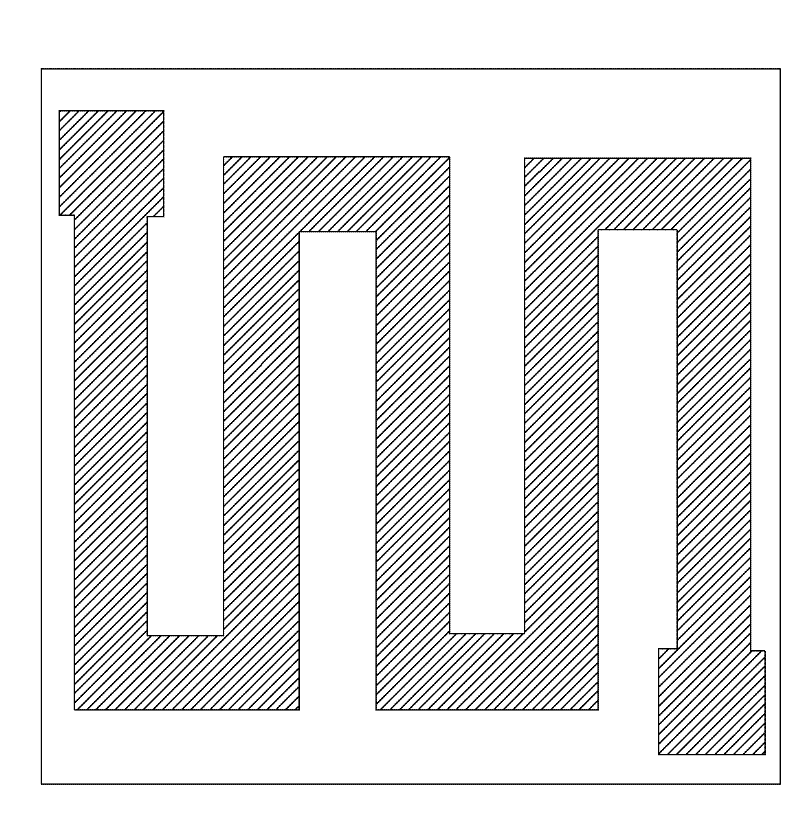

A resistance-type nitrogen dioxide gas sensor, and an apparatus manufactured with the sensor

InactiveCN102243195ASimple structureImprove gas selectivityMaterial resistanceElectrical resistance and conductancePlatinum

The invention discloses a resistance-type nitrogen dioxide gas sensor, and an apparatus manufactured with the sensor. The sensor comprises a gas-sensitive material layer with tungsten oxide as a main gas-sensitive material, and gold conductive electrode plates arranged with an interdigitated structure, wherein the gold conductive electrode plates contact the gas-sensitive material layer. The conductive electrode plates are printed on an alumina planar medium substrate. The back side of the medium substrate is provided with a platinum heating resistor. The sensor is arranged on a pedestal with a small hole. A cap with a ventilating central hole is covered on the pedestal. Platinum conductors are respectively led out from the platinum heating resistor and the interdigitated gold conductive electrodes. The conductors led out from the platinum heating resistor are connected with a heating controlling circuit, and the conductors led out from the interdigitated gold conductive electrodes are connected with a resistance calculating circuit. The apparatus provided by the invention has a simple structure, and employs a novel gas-sensitive material. With the apparatus, an accuracy of nitrogen dioxide volume concentration detection can be improved to a PPB (parts per billion) grade. The apparatus has advantages of good gas selectivity and short reaction time.

Owner:刘震国

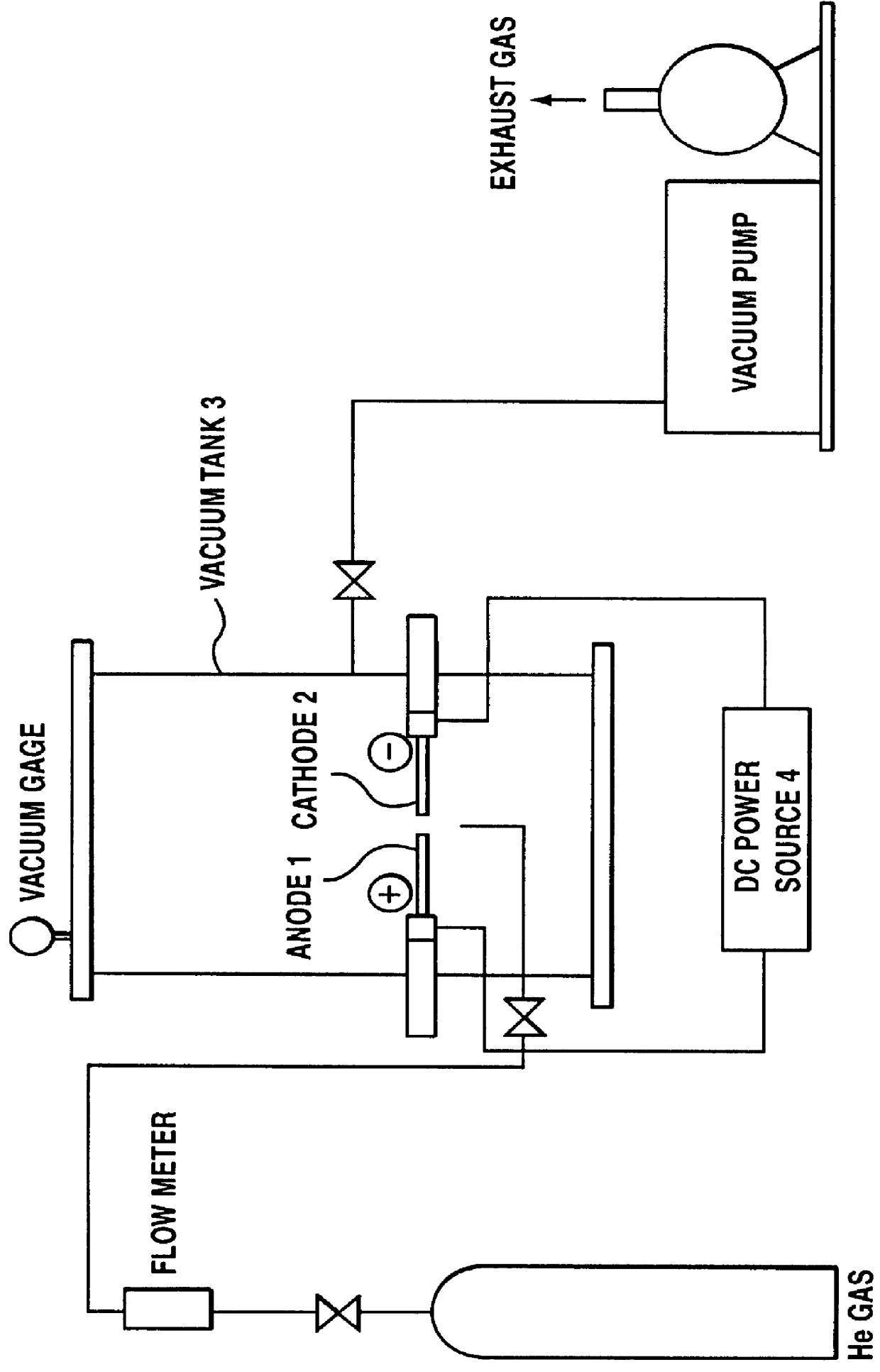

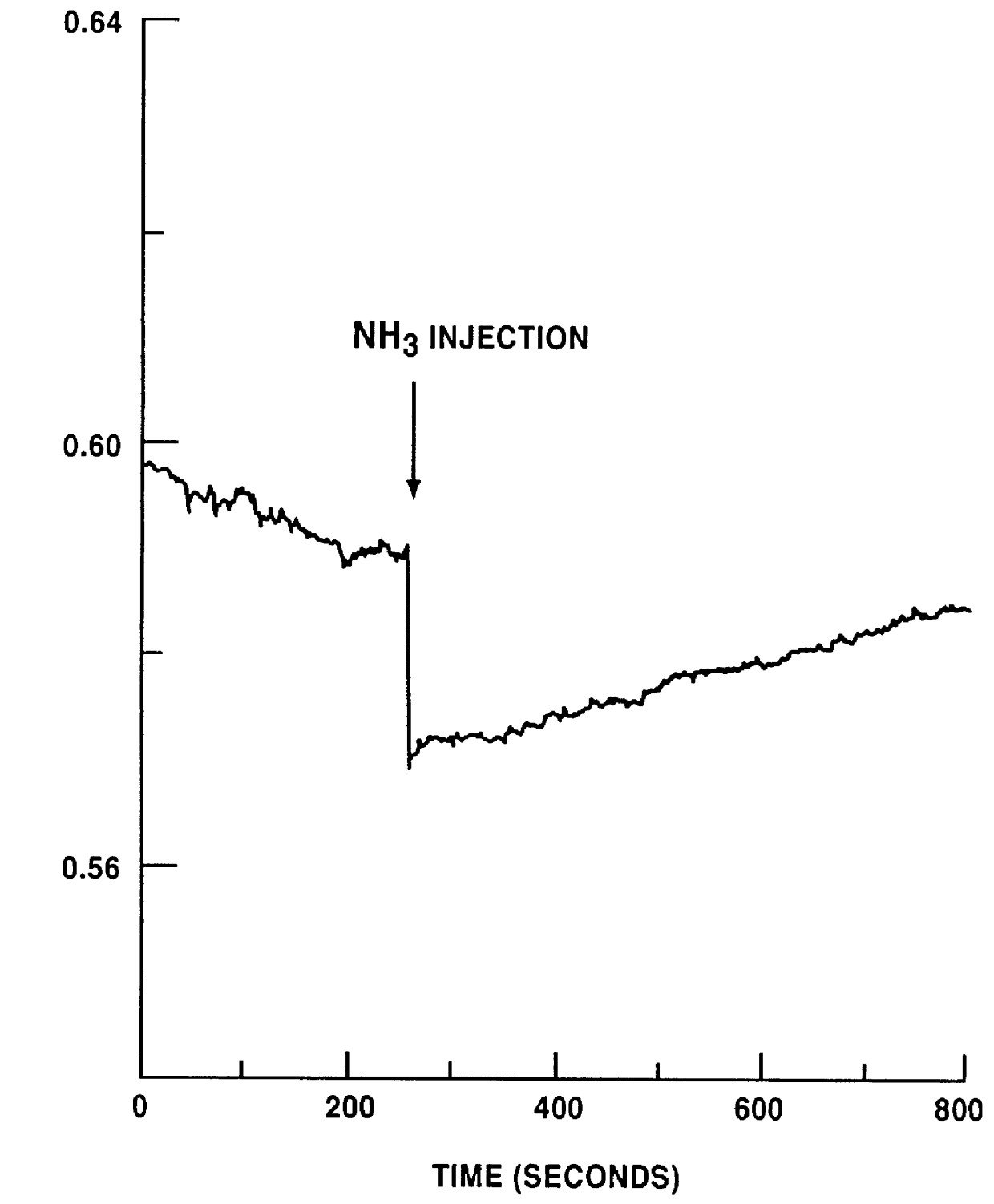

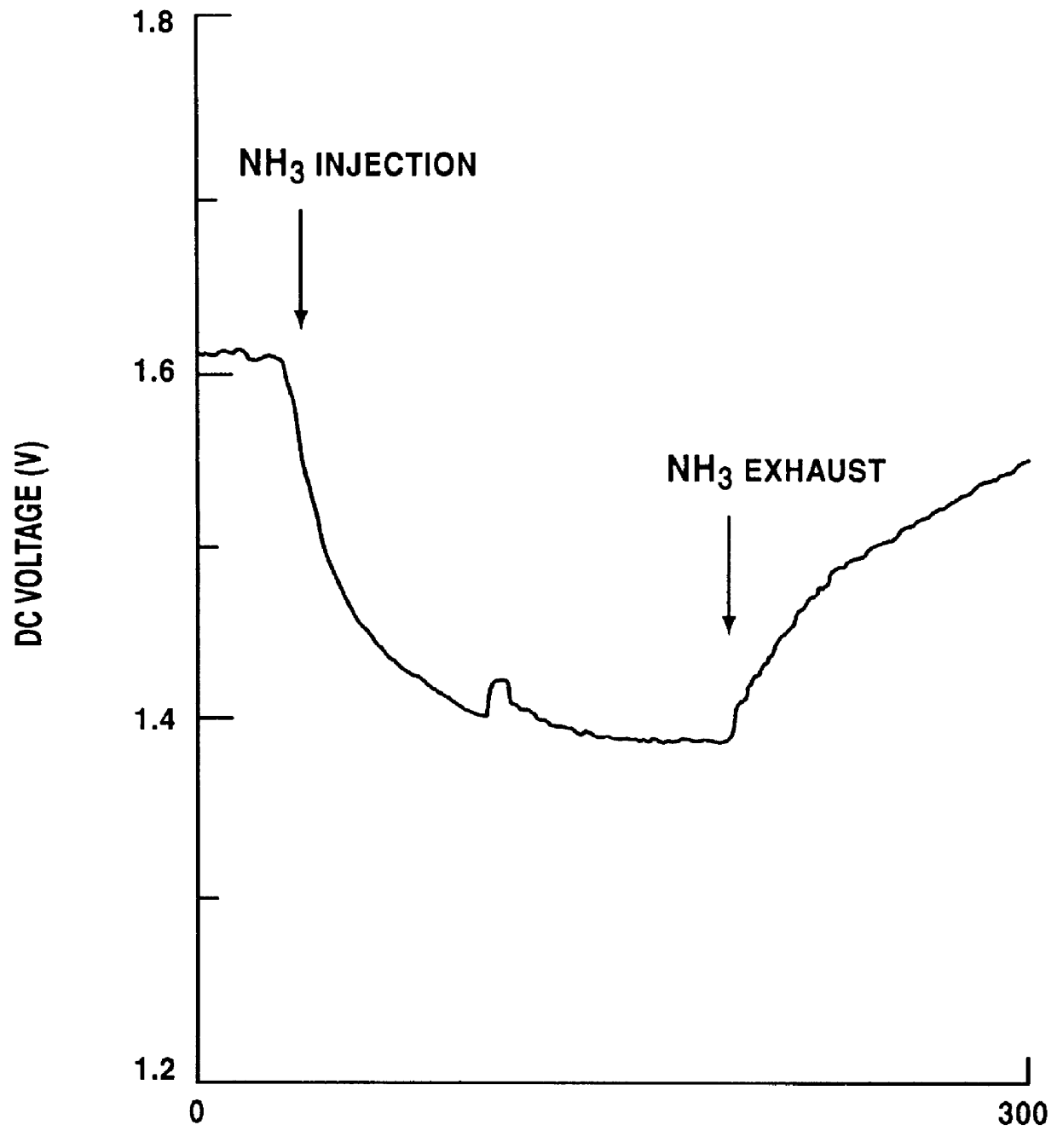

Gas sensor

InactiveUS6105417AIncrease the areaImprove gas selectivityComponent separationMaterial resistanceSensor materialsMaterials science

PCT No. PCT / JP97 / 03318 Sec. 371 Date Apr. 15, 1999 Sec. 102(e) Date Apr. 15, 1999 PCT Filed Sep. 19, 1997 PCT Pub. No. WO98 / 12548 PCT Pub. Date Mar. 26, 1998Gas sensor materials composed of carbon mixture or metal-containing carbon mixture obtained as evaporated matter by arc discharge which occurs by passing an alternating current or a direct current with electric current density of 0.8 to 3.5 A / mm2 on discharge surfaces of carbon electrodes or metal-containing carbon electrodes in an inert gas under a pressure of 0.1 to 600 torr.

Owner:AIR WATER INC +1

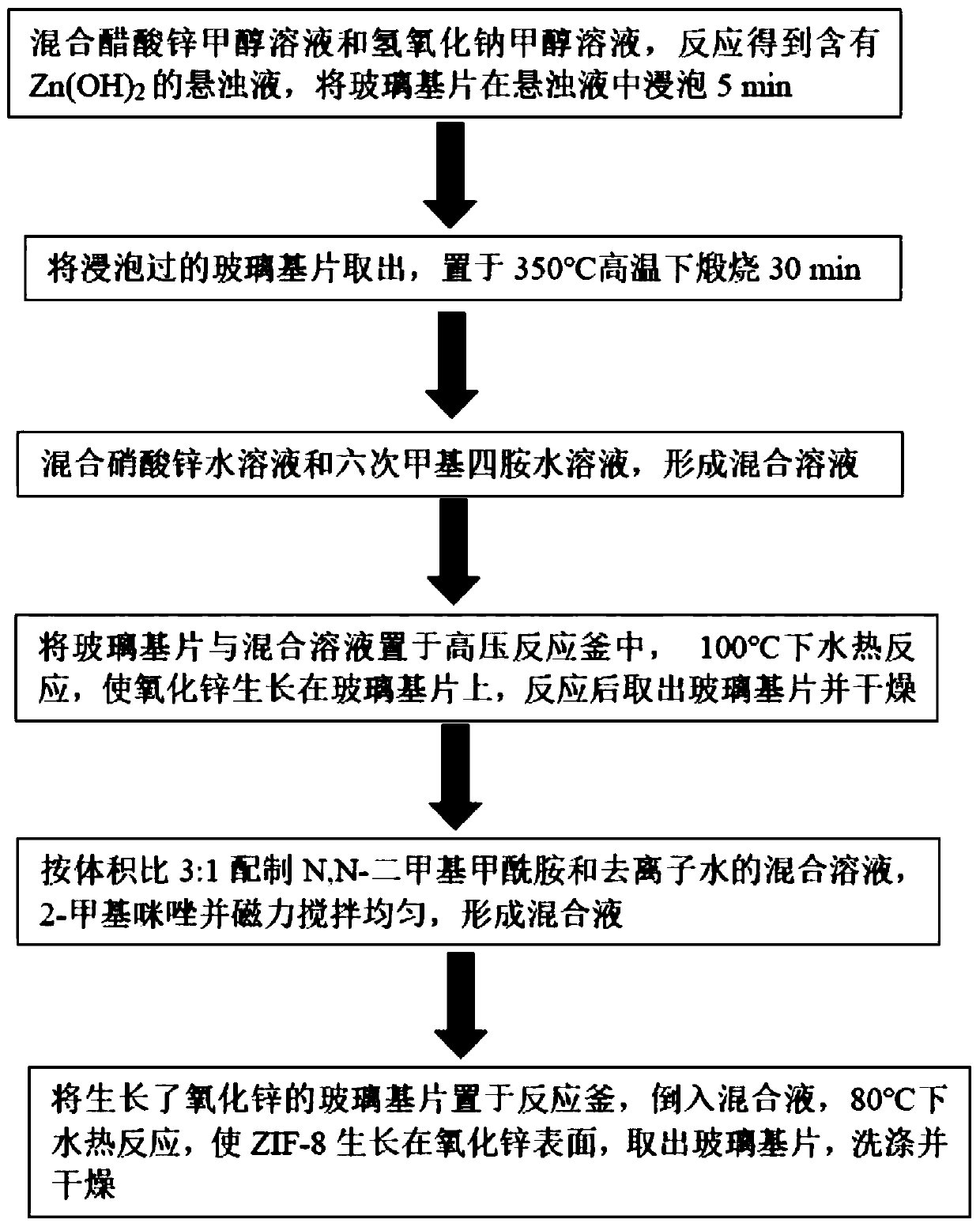

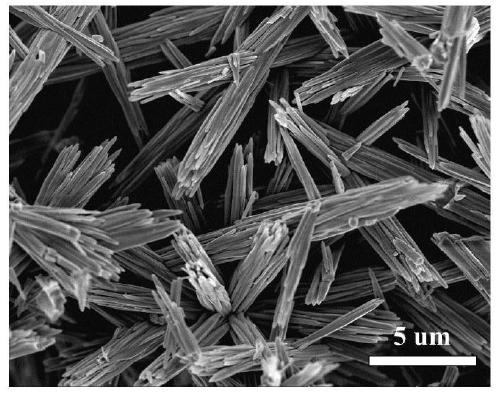

Method for preparing ZnO@ZIF-8 compound, ZnO@ZIF-8 compound and gas sensor

InactiveCN109970355AImprove gas selectivityImprove stabilityCoatingsMaterial resistanceN dimethylformamideGas detector

Provided is a method for preparing a ZnO@ZIF-8 compound. The method includes the steps that 1, a zinc acetatemethanol solution and a sodium hydroxidemethanol solution are mixed to obtain suspension liquid containing Zn(OH)2, and then a glass substrate is soaked in the suspension liquid containing Zn(OH)2 for 5 minutes; 2, the soaked glass substrate is taken out and then is subjected to annealing for 30 minutes at 350 DEG C; 3, a zinc nitrateaqueous solution and a hexamethylenetetramineaqueous solution are mixed to form a mixed solution; 4, the glass substrate processed in step 2 and the mixedsolution obtained in steps 3 are placed in a high-pressure reactor and are subjected to hydrothermal reaction at 100 DEG C, so that zinc oxide grows on the glass substrate ; 5, a mixed solution of N,N-dimethylformamide and deionized water is prepared, 2-methylimidazole is added, and the mixture is stirred to be uniform to form a mixed liquid; 6, the glass substrate in step 4 is placed into a linerof the reactor, the mixed liquid obtained in step 5 is poured into the liner, hydrothermal reaction is conducted at 80 DEG C for 3 hours so that ZIF-8 can grow on the surface of zinc oxide, and the ZnO@ZIF-8 compound is obtained.

Owner:CHONGQING UNIV +1

High selectivity composite gas sensitive material used for detection of acetic acid gas in air

ActiveCN108918600AHigh sensitivityHigh gas selectivityMaterial resistanceGas detectorWorking temperature

The invention discloses a high selectivity composite gas sensitive material used for detection of acetic acid gas in the air, and belongs to the technical field of gas sensitive material. The high selectivity composite gas sensitive material is C3N4-ZnO, the mass amount of C3N4 accounts for 5 to 20% of the total material mass; a side-heating gas-sensitive sensor is prepared from the high selectivity composite gas sensitive material, at 300 DEG C working temperature, the sensitivity on 0.1ppm acetic acid ranges from 1.2 to 1.4, the sensitivity on 1000ppm acetic acid ranges from 290 to 350, thesensitivity on 1000ppm acetone, formaldehyde, ethanol, acetaldehyde, and ammonia gas is lower than 31, it is shown that C3N4 is capable of increasing the sensitivity of zinc oxide on acetic acid gas,and increasing gas sensitive selectivity of zinc oxide on acetic acid gas, so that rapid detection of the concentration of acetic acid in the air is realized, and influences of acetone, formaldehyde,ethanol, acetaldehyde, and ammonia gas are eliminated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

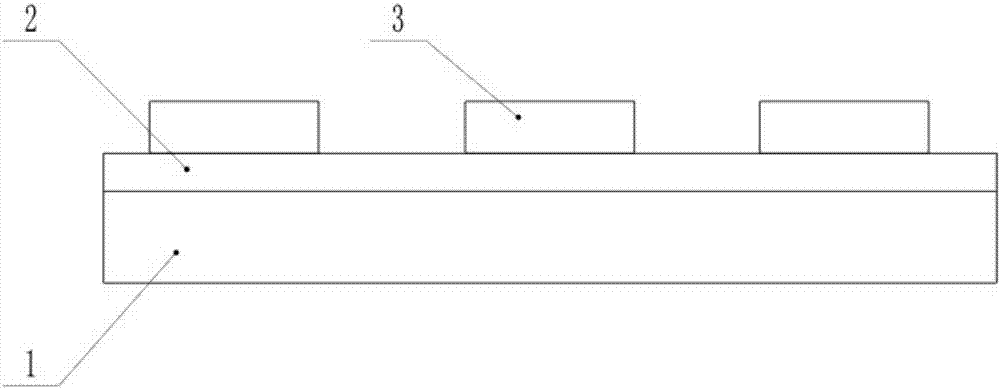

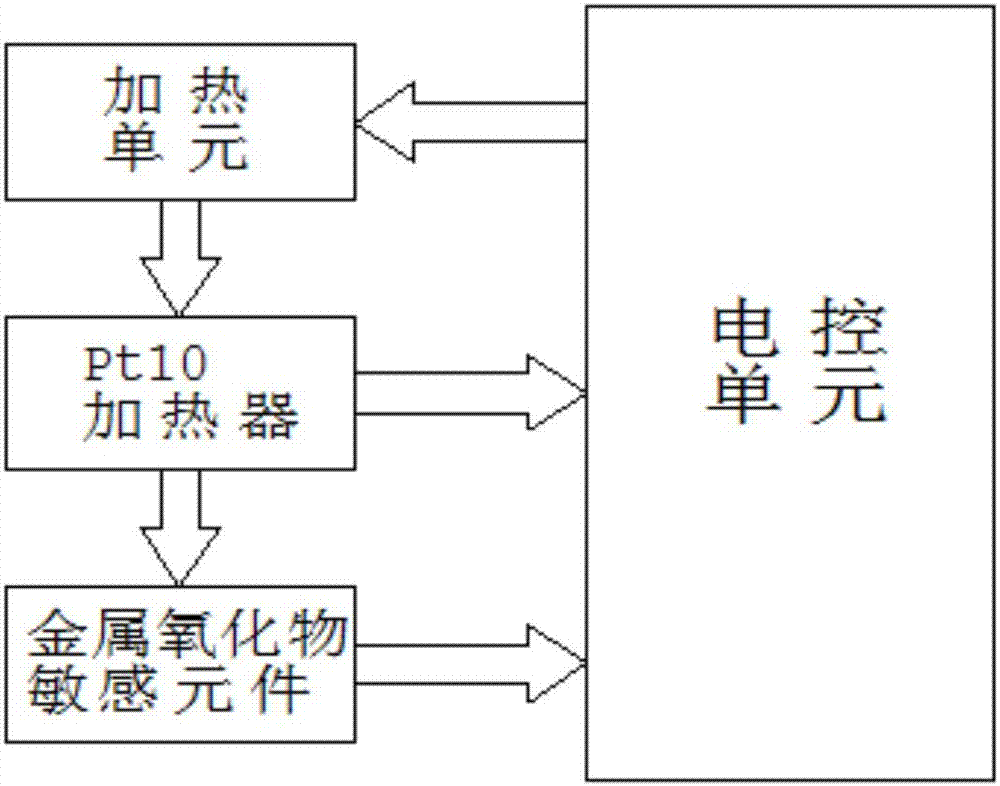

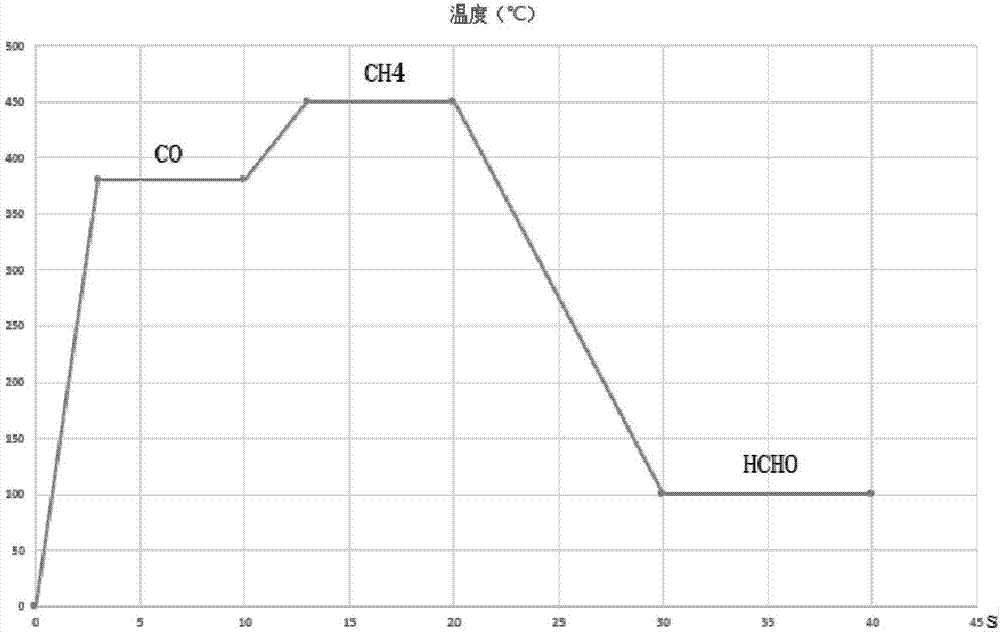

A multi-component gas sensor and a gas detection method

PendingCN107478687AReduced size and effective detection rateLow costMaterial resistanceElectronic control unitThermistor

A multi-component gas sensor is provided. The multi-component gas sensor includes an electronic control unit. The electronic control unit is connected to a heating unit, a Pt10 heater and metal oxide sensitive members. The heating unit is connected to the Pt10 heater. The metal oxide sensitive members are laid on a ceramic heating substrate, and the ceramic heating substrate is adhered to the Pt10 heater. The sensor includes a plurality of the metal sensitive members. In the structure, the Pt10 is adopted as a main part of the heater and is adopted as a thermistor, heating temperature values can be feed back in real time through resistance values of the thermistor, and then various components in gas to be detected are detected through the metal oxide sensitive members.

Owner:MULTI IR OPTOELECTRONICS

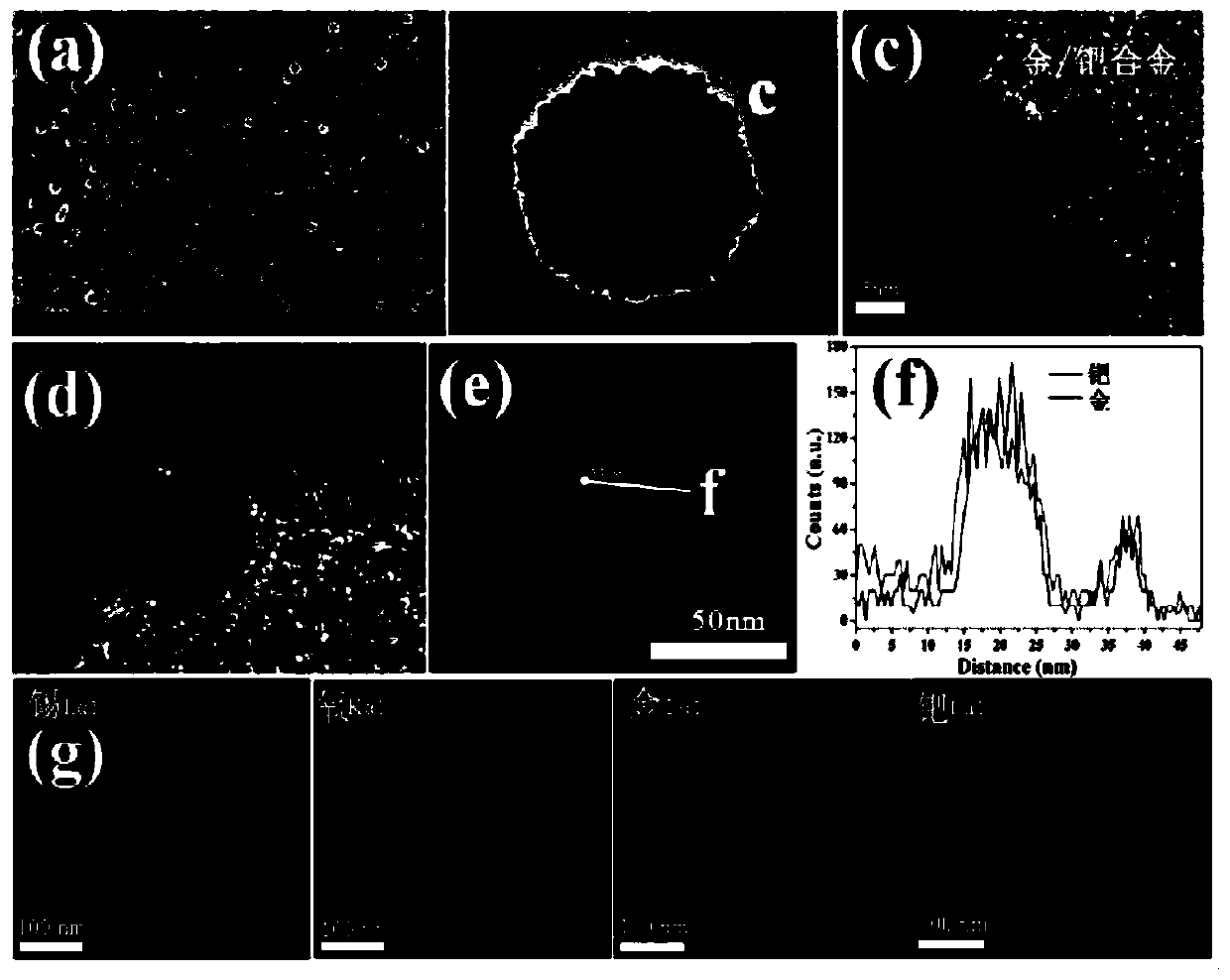

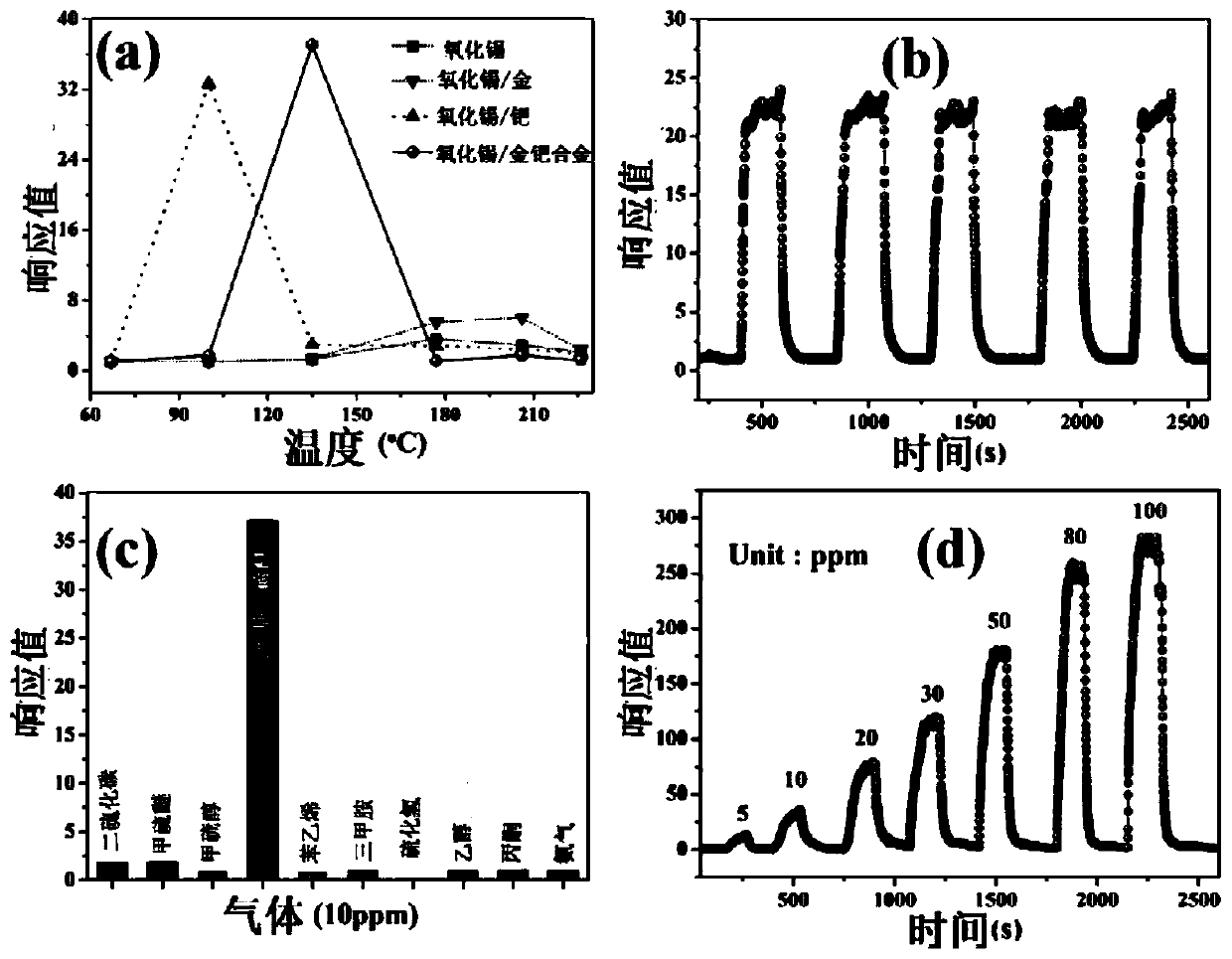

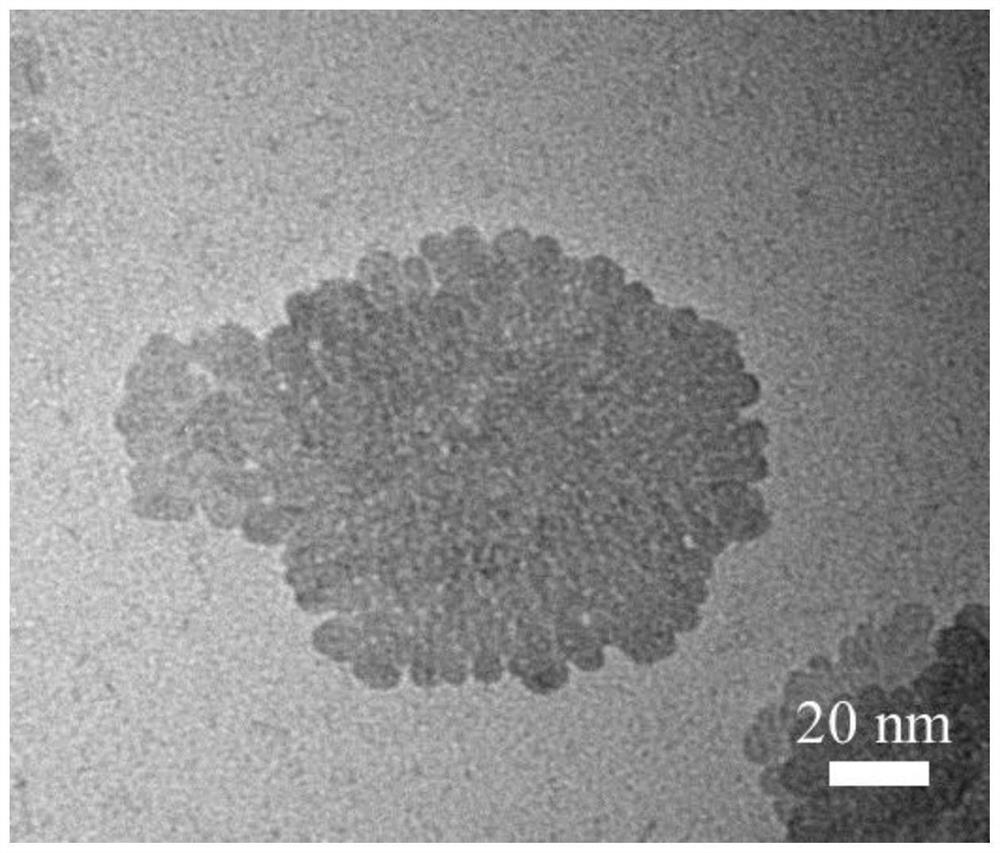

Gold/palladium alloy particle modified tin oxide composite material and preparation method and application thereof

ActiveCN109709161AGood catalyticLarge specific surface areaNanotechnologyMaterial resistanceMetalMaterials science

The invention discloses a gold / palladium alloy particle modified tin oxide composite material and a preparation method and application thereof. Tin oxide particles of hollow structure are prepared ina solvothermal method, gold / palladium alloy particle modified tin oxide composite particles in ultra small size are prepared in an in-situ reduction method, and the gold / palladium alloy particle modified tin oxide composite material is obtained via a gentle return process. The material is highly gas sensitive, can serve as a sensing layer of a resistive type metal oxide gas sensor, and can detectdimethyl disulfide gas with a superhigh selectivity; and expensive detection apparatuses are not needed, the detection cost is low, and operation is simple, rapid and efficient.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preparation method of PAA/AgNPs composite flexible ammonia gas sensor

ActiveCN109632890AReduce wasteLow production costMaterial nanotechnologyTransportation and packagingChemistryWorking temperature

The invention discloses a preparation method of a PAA / AgNPs composite flexible ammonia gas sensor. The method is characterized in that a sensitive material is prepared into an ink form suitable for being printed by a common ink-jet printer, the thickness and the shape of a deposited ammonia sensitive material layer can be conveniently controlled through an ink-jet printing method, the ammonia gassensor with good performance is prepared, and the ammonia sensitive material can be deposited as required through the ink-jet printing mode, the waste of raw materials can be effectively reduced, themanufacturing cost of the sensor is reduced, meanwhile, the large-scale manufacturing of the sensor is facilitated, and the industrial production is facilitated. According to the method, the process is simple, the production cost is low, the prepared ammonia gas sensor has relatively good response to ammonia gas at different concentrations at room temperature, the detecting range is wide, the response time is short, the stability is high, the gas selectivity is good, the ammonia gas sensor is suitable for high-sensitivity detection of ammonia gas at room temperature, good in flexibility and low in working temperature and can be applied to detection of ammonia gas around a human body by combining a wearable device.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Graphene-ZnGa2O4 compound gas-sensitive material with high selectivity on formaldehyde gas

InactiveCN109490376AImprove gas selectivityReduce sensitivityMaterial resistanceGas detectorWorking temperature

The invention discloses a graphene-ZnGa2O4 compound gas-sensitive material with high selectivity on a formaldehyde gas, and belongs to the technical field of gas-sensitive materials. The gas-sensitivematerial is prepared from graphene-ZnGa2O4, wherein the graphene is 0.08-0.20 percent of total mass of the material. A heater type gas-sensitive sensor prepared by using the material as a sensitive material has the lowest detection limit on formaldehyde being 1ppm, the sensitivity on 1ppm formaldehyde be 1.1-1.2, the sensitivity on 1000ppm formaldehyde being 29-33 and the response time and recovery time on 1-1000ppm formaldehyde being not more than 21 seconds and 25 seconds ; and the material has high gas-sensitive selectivity since the sensitivity on 1000ppm acetone, 1000ppm trimethylamine,1000ppm acetaldehyde, 1000ppm ammonia and the like is respectively less than 2.5 at the same working temperature.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Gas sensor

ActiveUS8283704B2Different response propertyChange outputMaterial analysis by electric/magnetic meansAlternating currentField-effect transistor

A gas sensor (30) includes two field-effect transistors and gate electrodes on gate insulation films (24) of the two field-effect transistors to detect gas using the gate electrodes. The gas sensor (30) includes a first gate electrode (5), a second gate electrode (6), and voltage applying means. The first gate electrode (5) is provided on one of the field-effect transistors. The second gate electrode (6) is provided on another one of the field-effect transistors. The voltage applying means is for, with the first gate electrode (5) and the second gate electrode (6) coupled to one another by wiring, applying thereto one of a direct-current voltage and an alternating-current voltage having a same potential or a constant voltage difference. The first gate electrode (5) and the second gate electrode (6) are made of different metals. The one field-effect transistor and the other field-effect transistor have approximately the same structures.

Owner:UNIV OKAYAMA

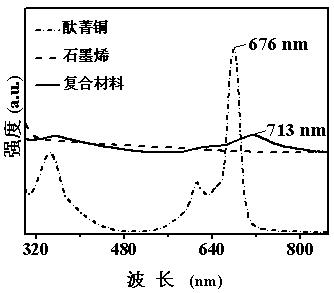

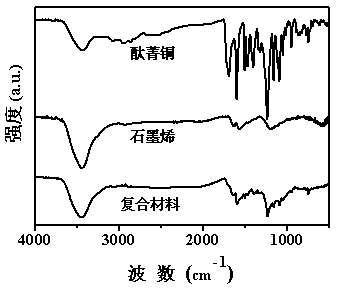

Tetra-beta-carboxyl phenoxy metal phthalocyanine/graphene composite material and method

ActiveCN109030589AImprove adsorption capacityGood dispersionMaterial electrochemical variablesSal ammoniacDispersity

Disclosed are a tetra-beta-carboxyl phenoxy metal phthalocyanine / graphene composite material and a method. Graphene is easy to agglomerate and has relative inert surface and poor dispersity, so that defects of poor selectivity and recovery capability, low sensitivity and the like occur when graphene is used as a gas-sensitive material. Further application of a phthalocyanine complex is hindered due to an overhigh resistance value in practical application. The effect between the phthalocyanine complex and graphene is still unclear, and the distribution of the phthalocyanine complex on the surface of graphene is still not uniform. The compositions of the composite material comprise the following components: 0.85%-1.69% of tetra-beta-carboxyl phenoxy metal phthalocyanine, 0.40%-0.56% of graphene, 80.1%-83.1% of N, N-dimethylformamide, 2.61%-3.05% of hydrazine aqueous solution, and 15.2%-17.1% of ammonia water, wherein the percentage is weight percentage. The composite material is appliedto gas sensitive materials.

Owner:HEILONGJIANG INST OF TECH

Fruit and vegetable fresh-keeping packaging film and preparation method thereof

ActiveCN114656665AHas antibacterial propertiesExtended shelf lifeBio-packagingPolyether coatingsPolyvinyl alcoholPolyethylene glycol

The invention provides a fruit and vegetable fresh-keeping packaging film and a preparation method thereof, the packaging film comprises a base film and a coating liquid coating the base film, the coating liquid comprises, by weight, 5-10 parts of a polyvinyl alcohol aqueous solution, 1-2 parts of a polyethylene glycol aqueous solution, 0.5-2 parts of modified sodium lignin sulfonate and 0.1-0.3 part of a glutaraldehyde aqueous solution; the modified sodium lignin sulfonate is obtained by modifying an amino reagent. On the basis of a transmission promoting mechanism, amido groups which have interaction or reversible reaction with CO2 gas molecules are introduced into a polymer aiming at the phenomenon of fruit and vegetable rot caused by the change of a gas environment in a package in the middle and later periods of fruit and vegetable package storage, so that the dissolution coefficient and the diffusion coefficient of specific gas in a film are increased; therefore, the permeation rate of CO2 gas can be increased, so that the gas selectivity of the mixed film is improved, the rotting phenomenon caused by over-high CO2 concentration of the environment in a package and vigorous oxygen-free respiration of fruits and vegetables is avoided, and the shelf life of the fruits and vegetables is prolonged.

Owner:JIANGYIN CITY DEHUI HEAT SHRINKABLE PACKING MATERIAL

Tungsten oxide composite gas sensitive material used for detecting low concentration acetone gas

ActiveCN108918601AImprove gas sensitivityHigh sensitivityMaterial resistanceNitrogen and non-metal compoundsProduct gasOperating temperature

The invention discloses a tungsten oxide composite gas sensitive material used for detecting low concentration acetone gas, and belongs to the field of gas sensitive material. The tungsten oxide composite gas sensitive material used for detecting low concentration acetone gas is composed of WO3 and C3N4; the mass amount of C3N4 accounts for 1 to 5% of the total material mass; C3N4 in the tungstenoxide composite gas sensitive material is capable of increasing the sensitivity of tungsten oxide on acetone gas, reducing sensitivity of tungsten oxide on interface gas such as formaldehyde, and improving the gas sensitivity of the tungsten oxide composite gas sensitive material on acetone. A side-heating gas-sensitive element is prepared from the tungsten oxide composite gas sensitive material,at a working temperature of 310 DEG C, the sensitivity of the element on 1000ppm acetone ranges from 61 to 83, the sensitivity on 0.1ppm acetone gas ranges from 1.2 to 1.6, the response time and the recovery time on 0.1 to 1000ppm acetone gas are shorter than 60s, and the response time on 0.1ppm acetone is shorter than 10s. At a same working temperature, the sensitivity of the side-heating gas-sensitive element on 1000ppm formaldehyde is lower than 7, so that it is confirmed that the side-heating gas-sensitive element is high in gas sensitivity on acetone.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High porosity porous coordination polymer, preparation method, application and preparation method of film thereof

ActiveCN107022087APromote absorptionIncrease surface areaSemi-permeable membranesGas treatmentPorosityPolymer science

Belonging to inorganic materials, the invention discloses a high porosity porous coordination polymer, a preparation method, application and a preparation method of a film thereof. Through the strategy of introducing two shortest alkyl groups or changing the positions, preparation of the porous coordination polymer with comprehensive performance can be realized. The prepared skeleton has one-dimensional pore channel, and has excellent water stability, thermal stability and acid-alkali stability simultaneously. Mixed gas adsorption based on the material indicates that the porous coordination polymer shows excellent methane / ethylene selective adsorption capacity at room temperature. In addition, through mixing of the porous coordination polymer with an organic polymer, a flexible film can be prepared, and the film has continuous, high efficiency and low energy consumption methane purification ability. The polymer is expected to be used for separation and purification of CH4 in natural gas, biogas, oil field gas and coal mine tunnel gas, and also can be used for purification of CH4 in hydrogen, carbon dioxide, carbon monoxide, ethylene, nitrogen and other mixed gases.

Owner:NANJING UNIV OF TECH

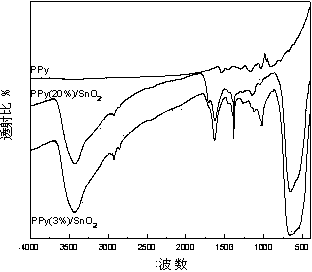

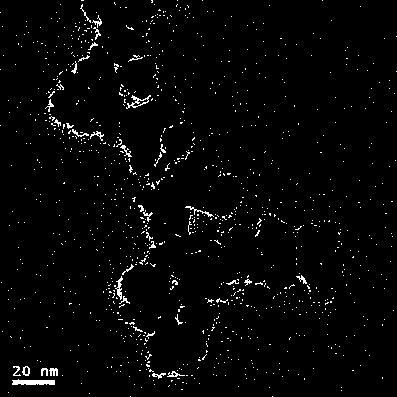

Preparation method for acetone gas sensor

InactiveCN103675078BEasy to purifyImprove gas selectivityMaterial analysis by electric/magnetic meansTin dioxidePolypyrrole

The invention discloses a preparation method for an acetone gas sensor. According to the preparation method, a series of tin dioxide and polypyrrole hybrid materials with different polypyrrole mass percents are prepared by using a simultaneous reaction of a hydrothermal method and a polymer in-situ generation method; the tin dioxide and polypyrrole hybrid materials are used for coating a heater-type device structure and an aluminum oxide ceramic tube is used as a carrier to prepare the acetone gas sensor; a noble metal electrode lead wire is a platinum wire and a sensing element tube core is the aluminum oxide ceramic tube. The method disclosed by the invention is good for finishing a reaction in one step and easily purifying a product. The gas sensor prepared by the method has good gas sensing selectivity on acetone gas under a low working environment; the recovery time can be rapidly responded; meanwhile, the interferences caused by hydrogen, carbon monoxide and ammonia gas can also be eliminated.

Owner:中国人民解放军白求恩医务士官学校

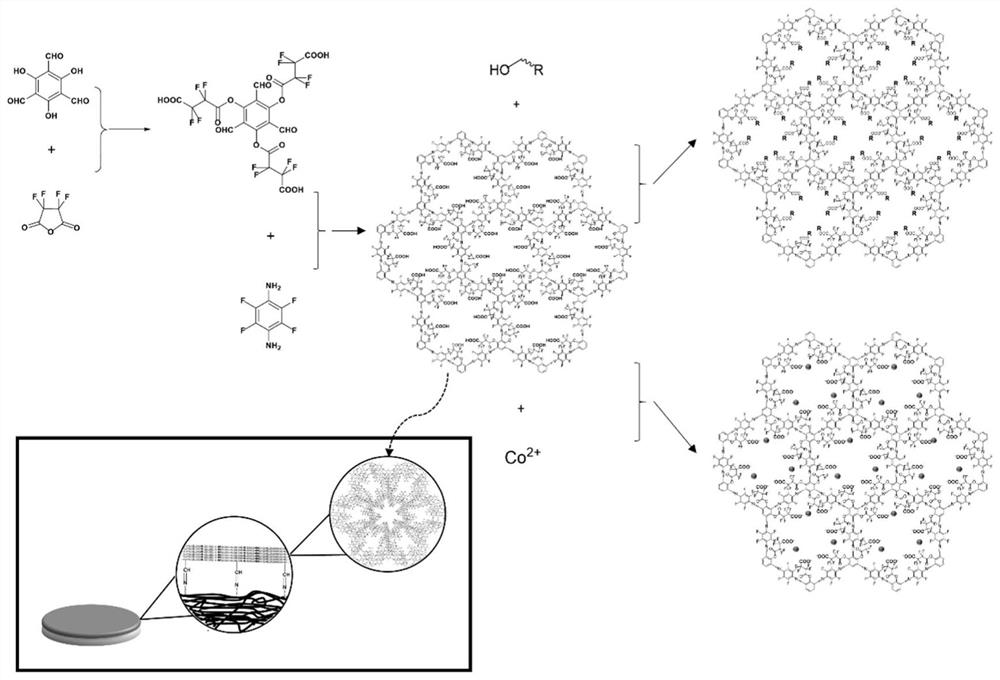

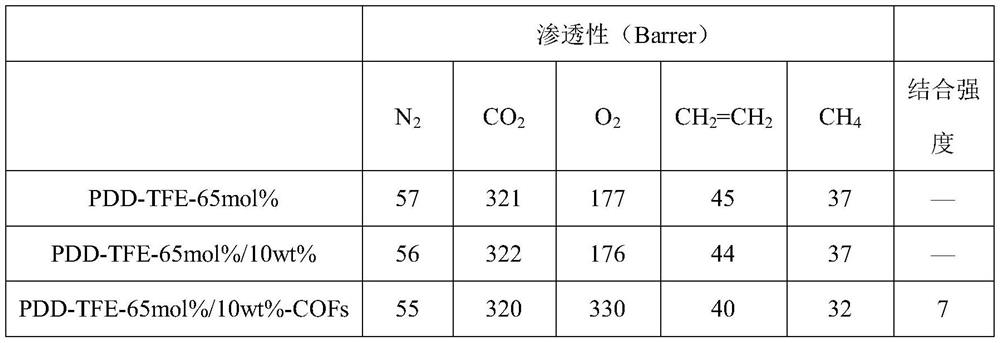

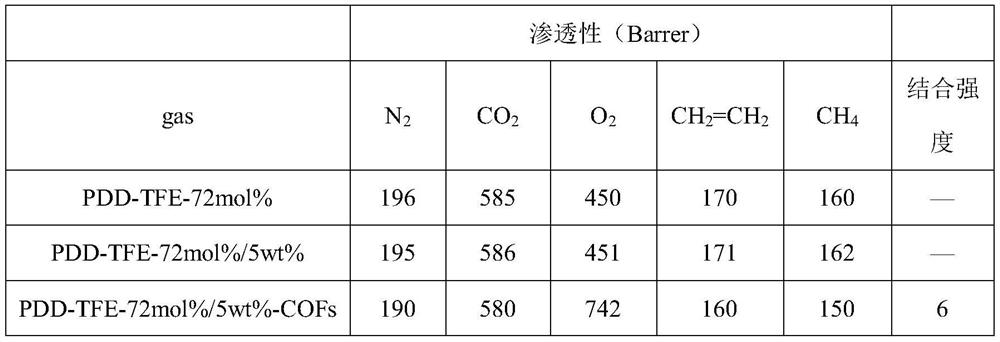

Composite separation membrane based on fluorine-containing copolymer and having in-situ grown organic framework structure and preparation method and application of composite separation membrane

ActiveCN113209836AGood compatibilityAperture size adjustableSemi-permeable membranesDispersed particle separationTetrafluoroethyleneAlkene

The invention discloses a composite separation membrane based on a fluorine-containing copolymer and having an in-situ grown organic framework and a preparation method and application of the composite separation membrane. The preparation method comprises the following steps: randomly copolymerizing perfluoro-2,2-dimethyl-1,3-dioxole (PDD), tetrafluoroethylene (TFE) and amine-terminated olefin according to a certain ratio to prepare a fluorine-containing copolymer which can be further subjected to reaction modification; mixing the fluorine-containing copolymer with a PDD-co-TFE binary copolymer according to different ratios to prepare a membrane; and performing Schiff base reaction to grow a covalent organic frame structure sheet layer in situ on the surface of a membrane matrix and introducing a functional group into a frame structure to form a coordination structure so as to obtain the fluorine-containing copolymer composite separation membrane. According to the composite separation membrane prepared by the method disclosed by the invention, binding force between a fluorine-containing copolymer layer and an organic framework structure layer is remarkably enhanced through amino bridging, and the adjustability of an internal pore size is realized through the modification of the internal structure of the pore channel of the organic framework structure layer, so organic gas and inorganic gas (oxygen, carbon dioxide and the like) can be efficiently and selectively separated; and the method has extremely high practical value.

Owner:ZHEJIANG UNIV +1

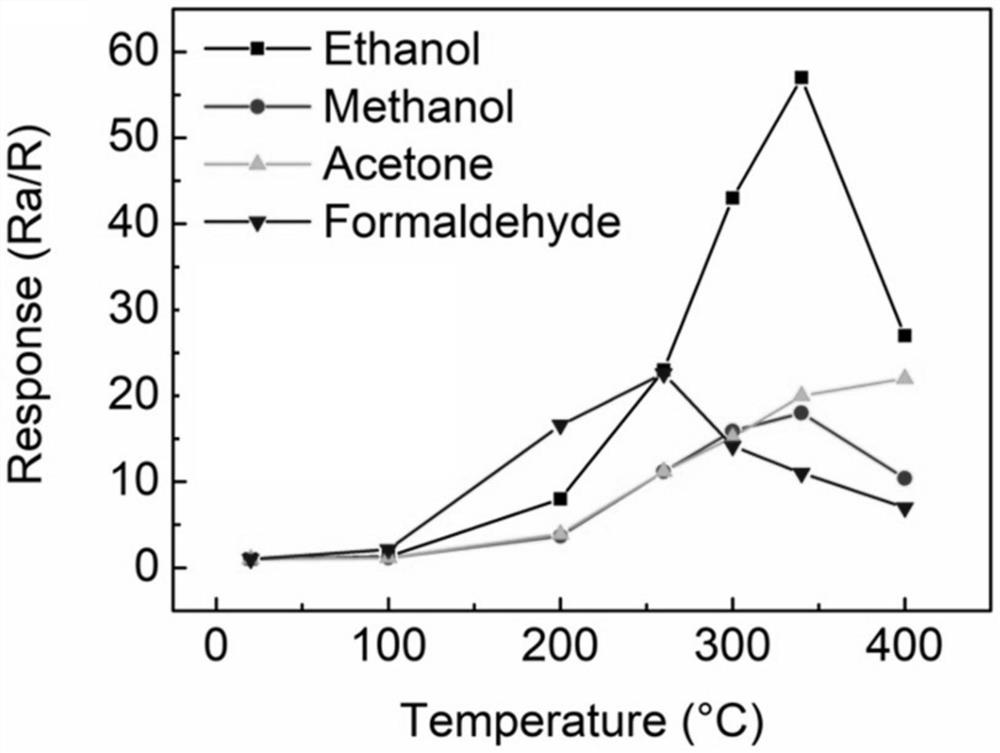

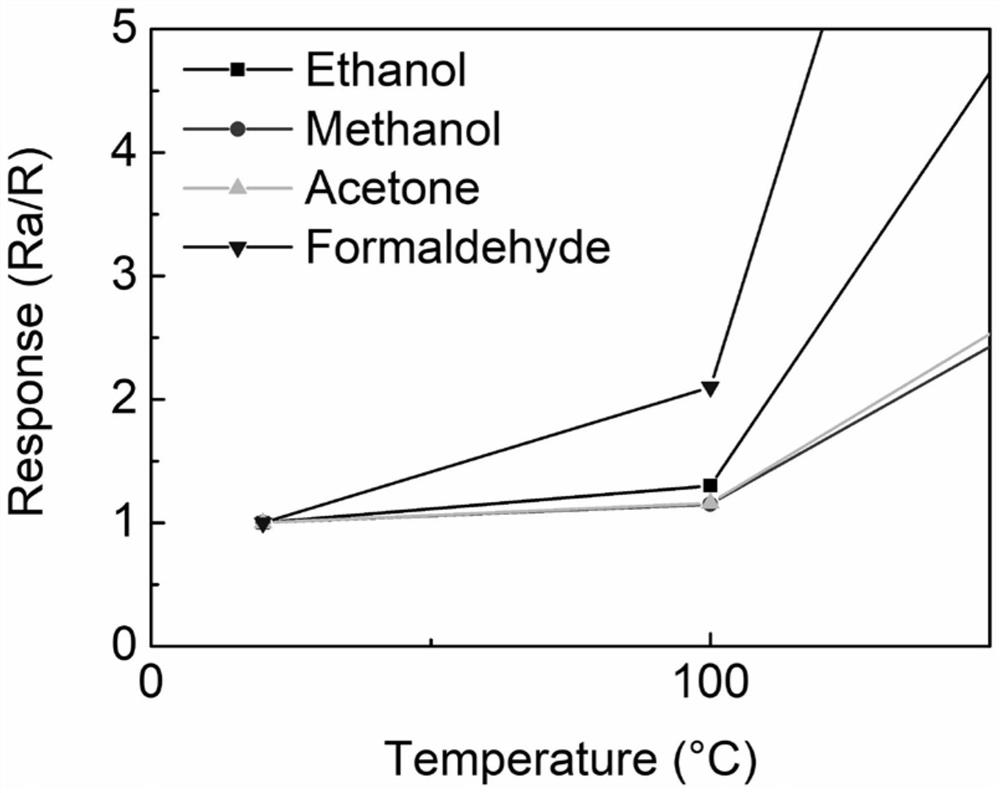

Method for adding gas selection function of multifunctional gas sensor and gas sensor

ActiveCN113252736AImprove gas selectivityIncrease varietyMaterial resistanceChemical physicsPhysical chemistry

The invention discloses a method for adding a gas selection function of a multifunctional gas sensor and the gas sensor. The method for adding the gas selection function of the multifunctional gas sensitive sensor comprises the step of forming a nano noble metal particle modification layer on the surface of a semiconductor gas sensitive material layer of a probe of the gas sensitive sensor, so that the single probe of the gas sensitive sensor can realize selective detection on at least three gases in a working temperature range of 0-400 DEG C. According to the method for adding the gas selection function of the multifunctional gas sensitive sensor, the surface of the semiconductor gas sensitive material layer is modified by using the nano noble metal particles, so that the gas selectivity of the gas sensitive sensor is improved, the types of selected gases are expanded, and selective detection of at least three gases within the working temperature range of 0-400 DEG C can be realized; and a new scheme and a new way are provided for preparing the multifunctional gas sensitive sensor with more gas selection functions.

Owner:SHENZHEN TECH UNIV

Cerium fluoride porous nanosheet regulated mixed matrix membrane, preparation method and application thereof

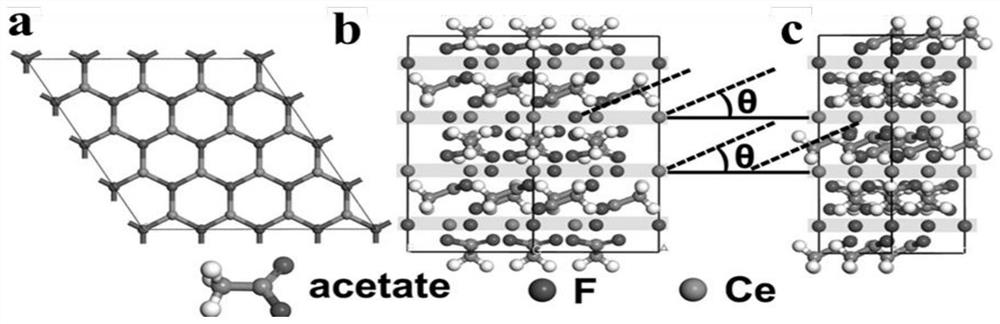

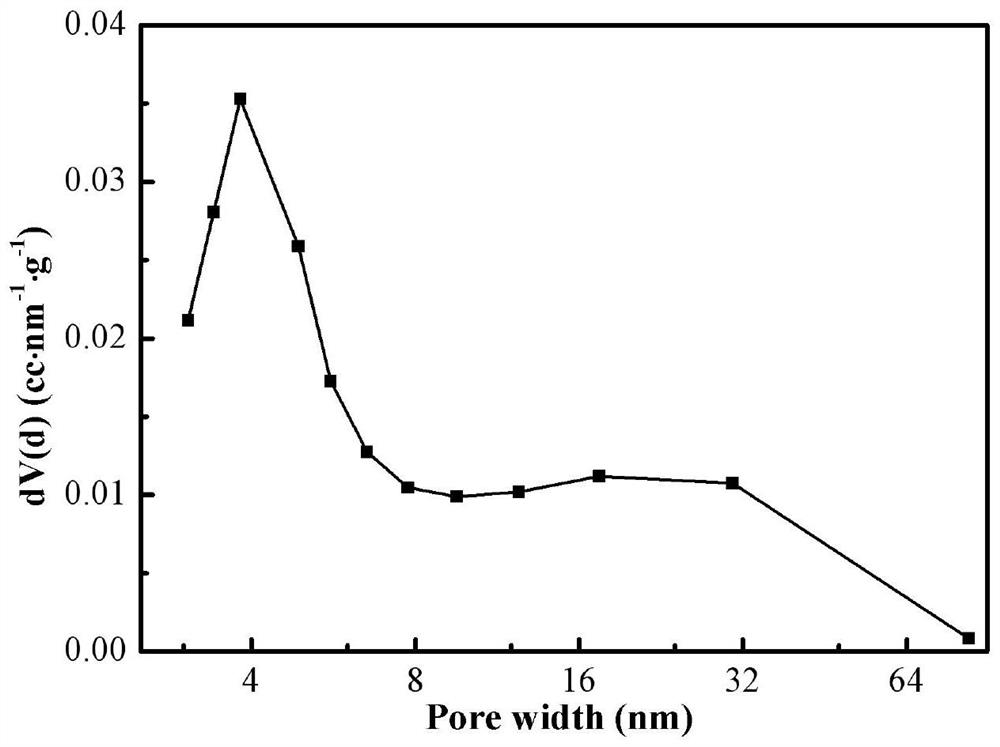

ActiveCN113896220AHigh selectivityImprove permeabilityMaterial nanotechnologySemi-permeable membranesPhysical chemistryMaterials science

The invention discloses a cerium fluoride porous nanosheet regulated mixed matrix membrane, a preparation method and application thereof, and belongs to the technical field of gas separation membranes. Specifically, the invention discloses a cerium fluoride porous nanosheet, which is formed by arranging fluorine-cerium monatomic layers and acetate radicals which are alternately stacked between the layers, wherein the fluorine-cerium monatomic layers are formed by arranging fluorine atoms and cerium atoms in a six-membered ring honeycomb form. The invention further provides a cerium fluoride porous nanosheet regulated mixed matrix membrane composed of the cerium fluoride porous nanosheet and a polymer matrix. The invention also provides a preparation method of the cerium fluoride porous nanosheet and a preparation method of the cerium fluoride porous nanosheet regulated mixed matrix membrane, wherein the preparation method is simple to operate. According to the invention, the cerium fluoride porous nanosheet filled polymer matrix membrane is applied to gas dehumidification / humidification, water vapor is permeated preferentially, and the high separation performance on water vapor is achieved.

Owner:TIANJIN POLYTECHNIC UNIV

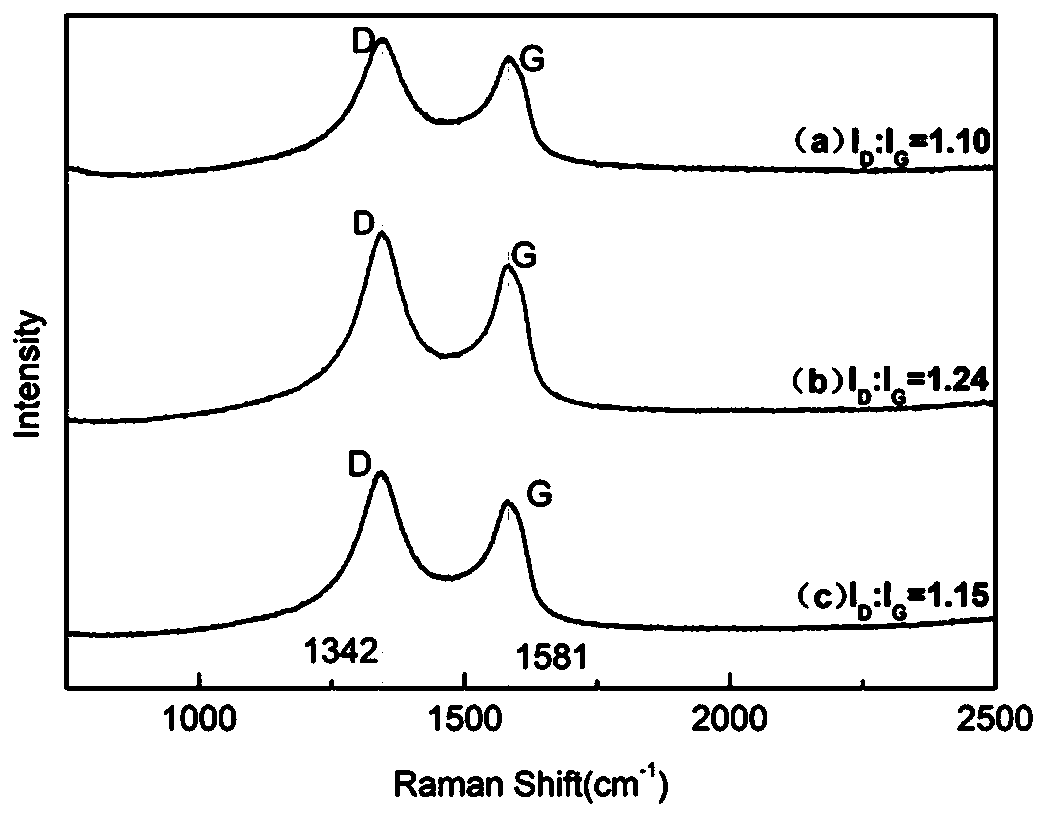

Preparation method of sensitive material with specificity to formaldehyde gas

InactiveCN110887875AFacilitate carrier separation and transferImprove sensitivity and response speedMaterial resistanceTin oxidesPyrroleMixed solution

The invention relates to a preparation method of a sensitive material with specificity to formaldehyde gas. The method comprises the following steps: mixing a graphene oxide suspension with a solutioncontaining citric acid, glucose and SnCl2.2H2O, and adding urea and ammonia water to obtain a mixed solution; and carrying out microwave hydrothermal reaction on the mixed solution in a microwave / ultraviolet / ultrasonic three-in-one reaction instrument in a pressure control mode, and carrying out ultrasonic treatment; and then obtaining a formaldehyde gas sensitive material after microwave hydrothermal reaction. According to the invention, the SnO2 and NG are compounded and the concentrations and distribution states of pyridine nitrogen, graphite nitrogen and pyrrole nitrogen in NG are controlled by adjusting reaction medium compositions and the microwave hydrothermal preparation process, so that specific binding of formaldehyde molecules and the composite material is facilitated and thusa strong response mechanism is generated. With the heterojunction formed by SnO2 and NG, the carrier separation and transferring are promoted, the sensitivity and the response speed of the material are effectively improved, and the prepared composite material has high selectivity to formaldehyde gas.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com