Tetra-beta-carboxyl phenoxy metal phthalocyanine/graphene composite material and method

A carboxylphenoxy copper phthalocyanine and carboxylphenoxy technology, which is applied in the field of tetra-β-carboxyphenoxy metal phthalocyanine/graphene composite materials, can solve the problem of high resistance value of phthalocyanine complexes and graphene selection. It can improve the gas sensing performance, improve the adsorption effect, and improve the conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

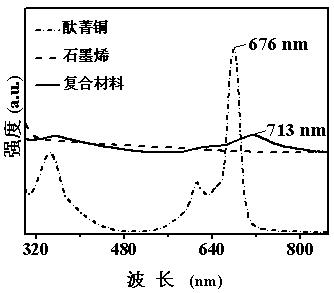

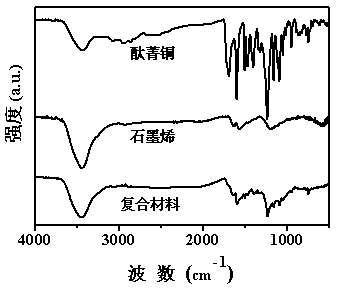

[0039] A kind of tetra-beta-carboxyphenoxy metal phthalocyanine / graphene composite material, described composite material comprises the four-beta-carboxyphenoxy metal phthalocyanine of 0.85%~1.69%, the graphite of 0.40%~0.56% Alkene, 80.1%~83.1% N,N dimethylformamide, 2.61%~3.05% hydrazine aqueous solution, 15.2%~17.1% ammonia water, the percentages are by weight.

Embodiment 2

[0041] According to the tetra-beta-carboxyphenoxy metal phthalocyanine / graphene composite material described in embodiment 1, the substituents in the tetra-beta-carboxy phenoxy metal phthalocyanine are carboxyphenoxy and 2-methyl Oxygen-4-carboxyphenoxy, the central metal is copper, cobalt, nickel, zinc, palladium or lead, and the graphene is reduced graphene oxide made by reducing graphene oxide.

Embodiment 3

[0043] The preparation method of the above-mentioned four-beta-carboxyphenoxy metal phthalocyanine / graphene composite material, the preparation method is carried out according to the following steps:

[0044] Step 1, preparing tetra-β-carboxyphenoxy metal phthalocyanine N,N dimethylformamide solution and graphene oxide DMF suspension respectively;

[0045] Step 2. Slowly add the tetra-β-carboxyphenoxy metal phthalocyanine solution into the graphene oxide DMF suspension, ultrasonically oscillate and react for 30-50 hours, add hydrazine hydrate and ammonia water, and continue heating and reacting at 80-110°C for 20 hours;

[0046] Step 3: Cool the reaction, filter with suction, wash with DMF and absolute ethanol in sequence, and dry at 60°C to obtain a tetra-β-carboxyphenoxy metal phthalocyanine / graphene composite product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com