Gold/palladium alloy particle modified tin oxide composite material and preparation method and application thereof

A composite material and tin oxide technology, applied in the field of gas-sensitive sensing materials, can solve the problems of long detection time, expensive equipment, complicated operation process, etc., and achieve the effects of low cost of use, good gas sensitivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

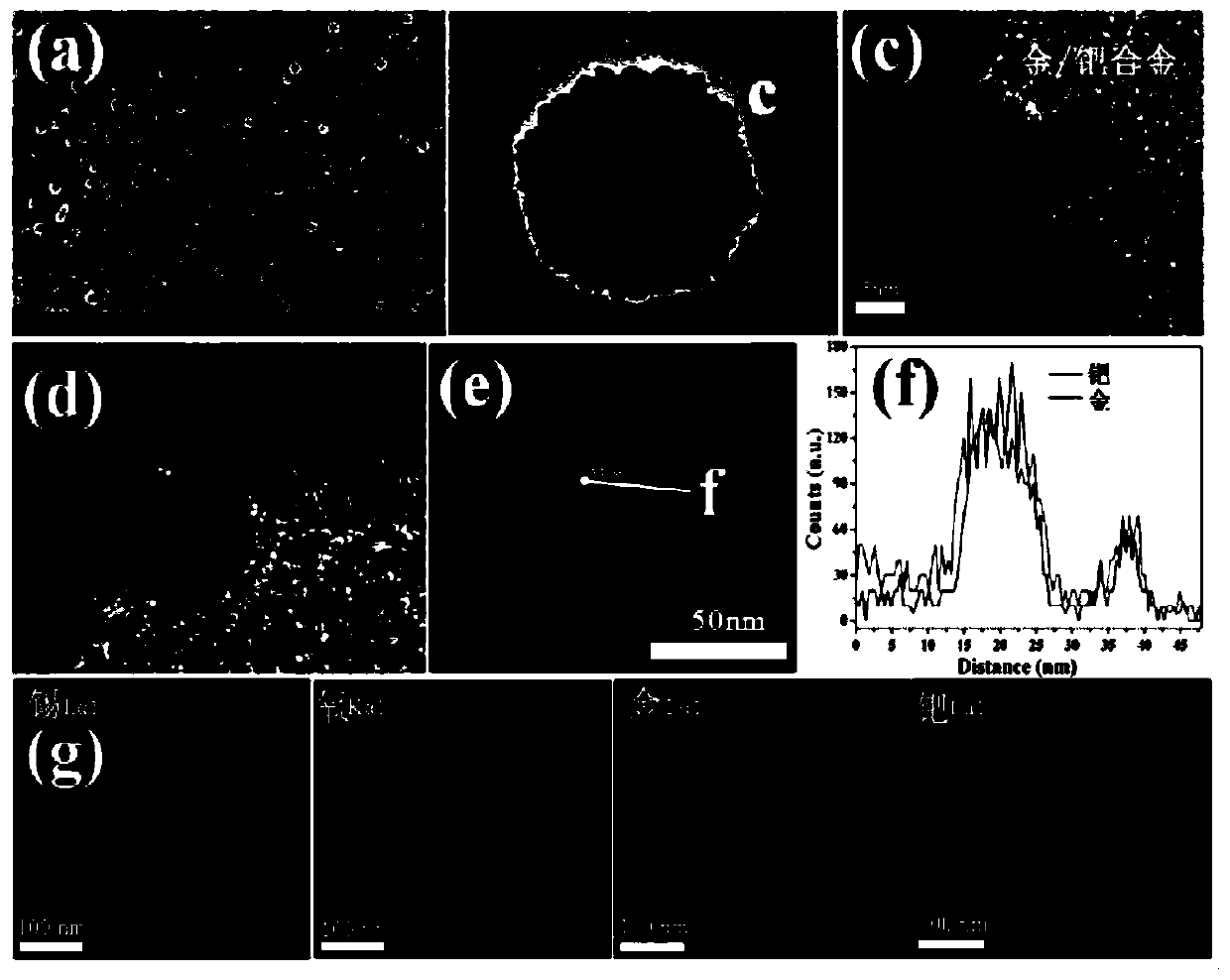

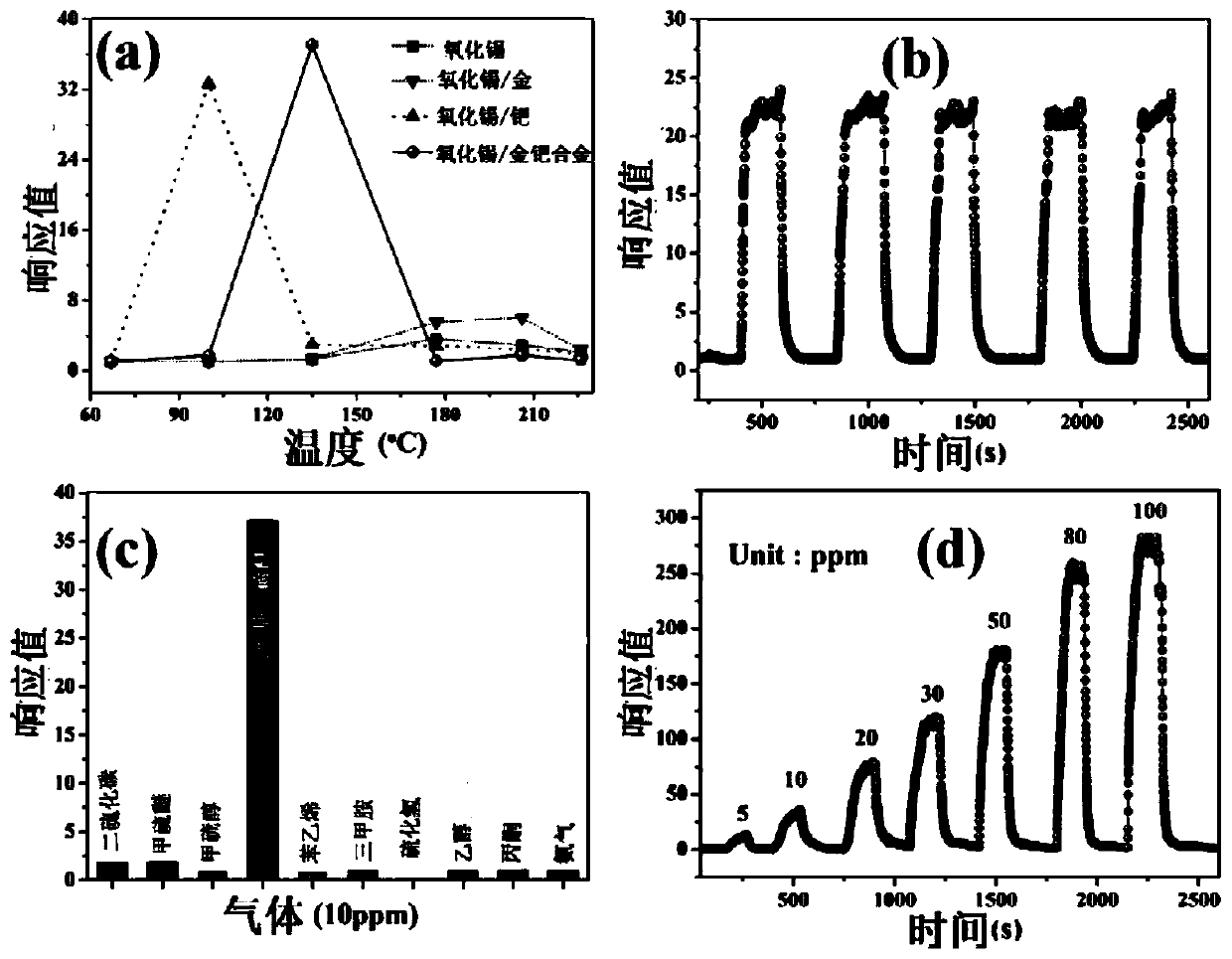

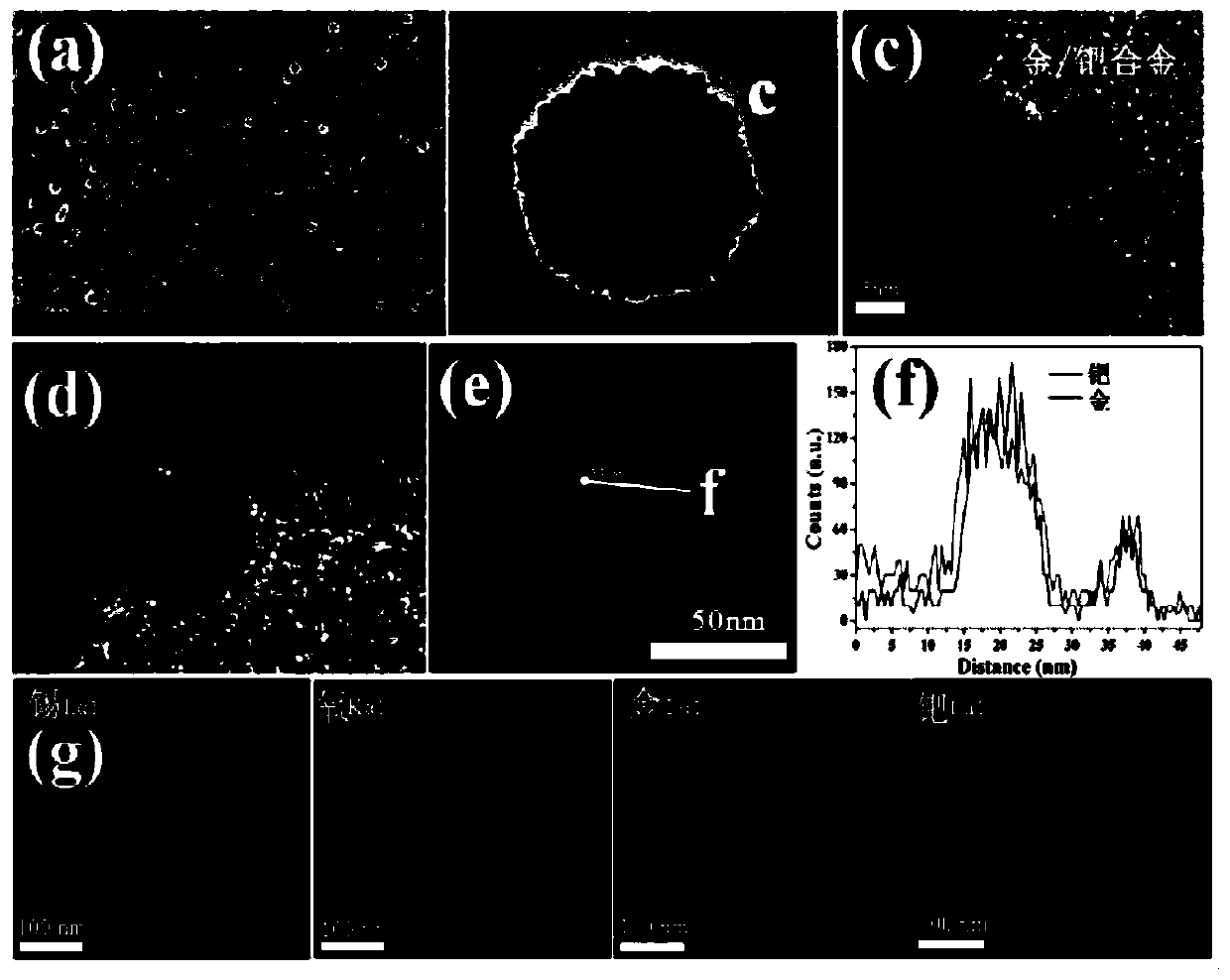

Image

Examples

preparation example Construction

[0018] The preparation method comprises steps:

[0019] The preparation method of the tin oxide composite material modified by gold / palladium alloy particles is characterized in that it comprises the steps:

[0020] Step A, according to tin tetrachloride pentahydrate: ethanol: concentration is the weight ratio of the hydrochloric acid solution=0.5~2:50~150:1 of 35~40wt%, adds tin tetrachloride pentahydrate in ethanol aqueous solution and stirs 10~ 30min, then add a hydrochloric acid solution with a concentration of 35-40wt%, and place it at 150-200°C for a closed reaction for 5-24h, then carry out solid-liquid separation and washing, so as to obtain tin oxide hollow spheres;

[0021] Step B. Disperse tin oxide into the ethanol / toluene mixture so that the concentration of tin oxide particles in the mixture is 0.1-3mg / mL, stir for 10-30min, and then add ammonia water and 3-aminopropyltriethoxy in sequence Silane, and stirred at 20-100°C for 10-48 hours, and then solid-liquid se...

Embodiment 1

[0036] A preparation method of a tin oxide composite material modified by gold / palladium alloy particles, the preparation method may include:

[0037] Step a1, according to the weight ratio of tin tetrachloride pentahydrate: ethanol: hydrochloric acid solution with a concentration of 35-40wt% = 0.5-2:50-150:1, add tin tetrachloride pentahydrate into the ethanol aqueous solution and stir for 30min, Then add a hydrochloric acid solution with a concentration of 35 to 40 wt%, and place it at 200° C. for closed reaction for 10 hours, and then carry out solid-liquid separation and washing, so as to obtain tin oxide hollow spheres.

[0038] Step b1, disperse 0.2g of tin oxide into 100mL of ethanol / toluene mixture (the volume ratio of ethanol to toluene is 1:2.5), stir magnetically for 30min, then add 3mL of ammonia water and 3mL of 3-aminopropyltriethoxy in sequence base silane, and stirred at 80° C. for 48 h, and then solid-liquid separation and washing were carried out to obtain am...

Embodiment 2

[0044] A preparation method of a tin oxide composite material modified by gold / palladium alloy particles, the preparation method may include:

[0045] Step a2, according to the weight ratio of tin tetrachloride pentahydrate: ethanol: hydrochloric acid solution with a concentration of 35-40wt% = 0.5-2:50-150:1, add tin tetrachloride pentahydrate into the ethanol aqueous solution and stir for 20min, Then add a hydrochloric acid solution with a concentration of 35 to 40 wt%, and place it at 180° C. for closed reaction for 10 hours, and then carry out solid-liquid separation and washing, so as to obtain tin oxide hollow spheres.

[0046] Step b2, disperse 0.3g of tin oxide into 100mL of ethanol / toluene mixture (the volume ratio of ethanol to toluene is 1:3), stir magnetically for 30min, then add 2mL of ammonia water and 3mL of 3-aminopropyltriethoxy in sequence base silane, and stirred at 80° C. for 24 hours, and then subjected to solid-liquid separation and washing to obtain amin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com