Nanometer iron oxide/carbon sphere compound catalyst and preparation method and application thereof

A nano iron oxide, composite catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. and other problems, to achieve the effect of excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Weigh 1.6220g of ferrous sulfate into a beaker, and measure 49mL of distilled water into the beaker to make a solution.

[0017] (2) Weigh 3.5g of carbon spheres and add it to the ferrous sulfate aqueous solution prepared in step (1), sonicate for 30 minutes, and stir at 25°C for 30 minutes.

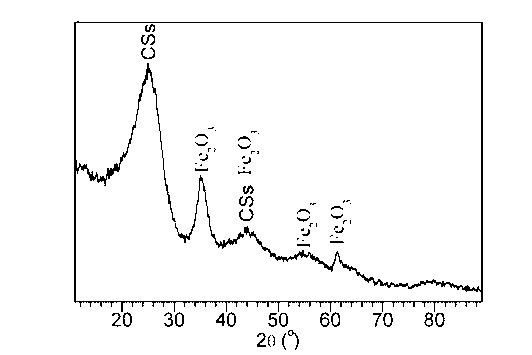

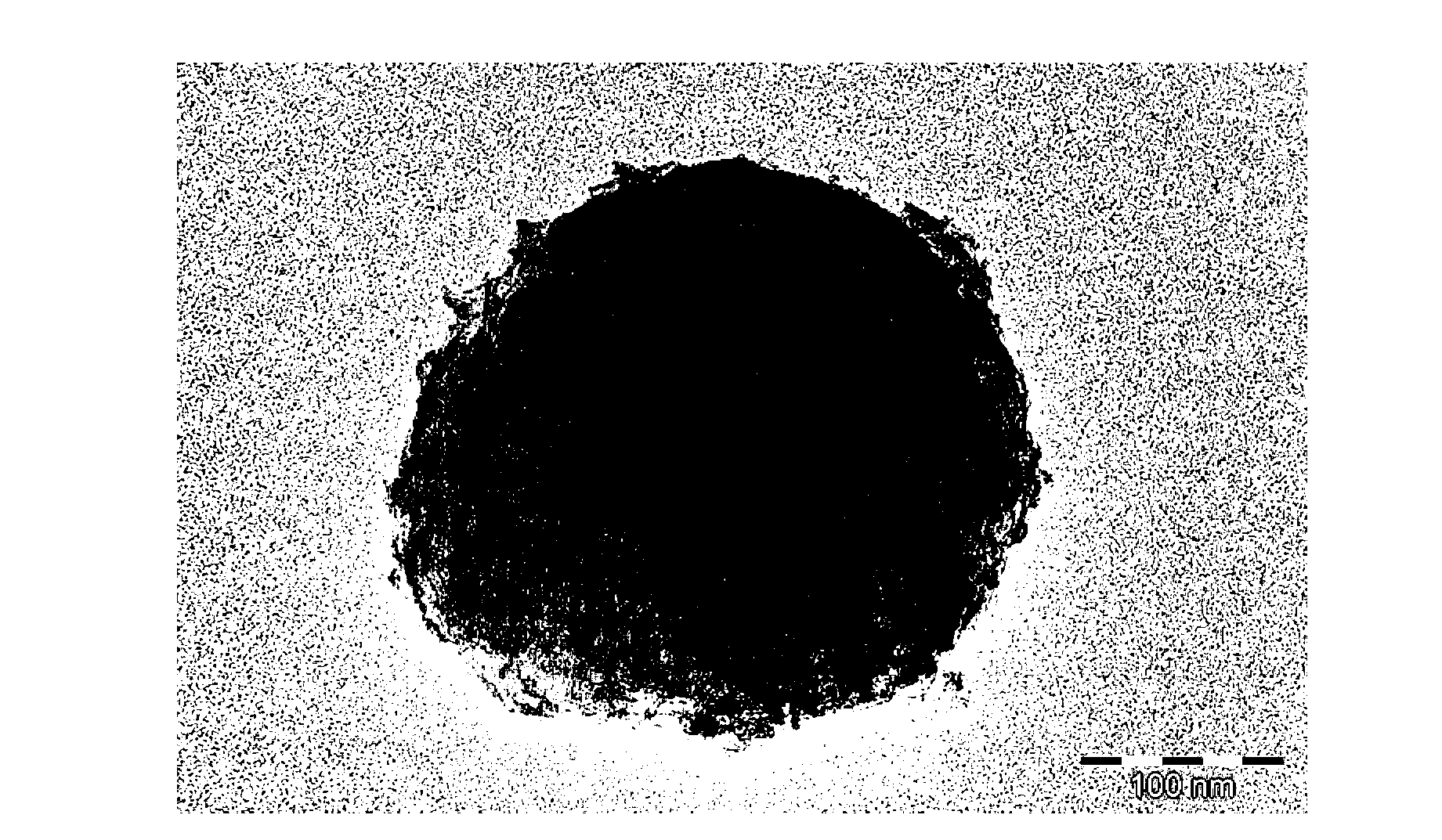

[0018] (3) Under the condition of stirring at 25°C, measure 200mL of hydrogen peroxide and add it dropwise to the mixture of carbon spheres and ferrous sulfate aqueous solution prepared in step (2), and continue to stir and react for 30 minutes after completion; then, suction filtration, The product is washed with distilled water and ethanol three times in sequence, and dried to obtain a nanometer iron oxide / carbon sphere composite catalyst. The transmission electron microscope photograph of gained nano-iron oxide / carbon sphere composite catalyst is shown in figure 1 , it can be seen from the transmission electron microscope photos that the diameter of the iron oxide nanopart...

Embodiment 2

[0020] (1) Weigh 1.6220g of ferrous sulfate into a beaker, and measure 49mL of distilled water into the beaker to make a solution.

[0021] (2) Weigh 0.5g of carbon spheres and add it to the ferrous sulfate aqueous solution prepared in step (1), ultrasonicate for 30 minutes, and stir at 25°C for 30 minutes.

[0022] (3) Under the condition of stirring at 25°C, measure 200mL of hydrogen peroxide and add it dropwise to the mixture of carbon spheres and ferrous sulfate aqueous solution prepared in step (2), and continue to stir and react for 30 minutes after completion; then, suction filtration, The product is washed with distilled water and ethanol three times in sequence, and dried to obtain a nanometer iron oxide / carbon sphere composite catalyst.

Embodiment 3

[0024] (1) Prepare 250mL reactive brilliant blue K-NR aqueous solution with a concentration of 20mg / L and place it in the photoreactor.

[0025] (2) Weigh 100 mg of the nano-iron oxide / carbon sphere composite catalyst prepared in Example 2 and add it to the methylene blue aqueous solution prepared in step (1), shake and stir overnight in a dark room.

[0026] (3) Under magnetic stirring, ultraviolet light (main wavelength is 365nm, power 300w) is used for catalytic degradation. After 60 minutes of light irradiation, the degradation rate of nano-iron oxide / carbon sphere composite catalyst on active brilliant blue K-NR is higher than that of pure iron oxide on active blue K-NR. The degradation rate of Brilliant Blue K-NR is higher than 15.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com