Copper chromite/carbon nanotube nano-composite catalyst, preparation method and application

A technology of carbon nanotubes and copper chromite, which is applied in the field of preparation of copper chromite/carbon nanotube nanocomposite catalysts and its preparation, can solve the problems of reducing catalyst catalytic efficiency and easy agglomeration, and achieve excellent catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at 90° C. for 3 hours, cool, filter, wash, and dry.

[0023] (2) Weigh 1.2765g of copper nitrate hexahydrate and 3.4564g of chromium nitrate nonahydrate into an in-situ flask, add deionized water and stir to dissolve. 1 g of multi-walled carbon nanotubes oxidized in step (1) was added, ultrasonicated for 30 minutes, stirred at 30° C. for 5 hours, and then left to stand for 12 hours. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

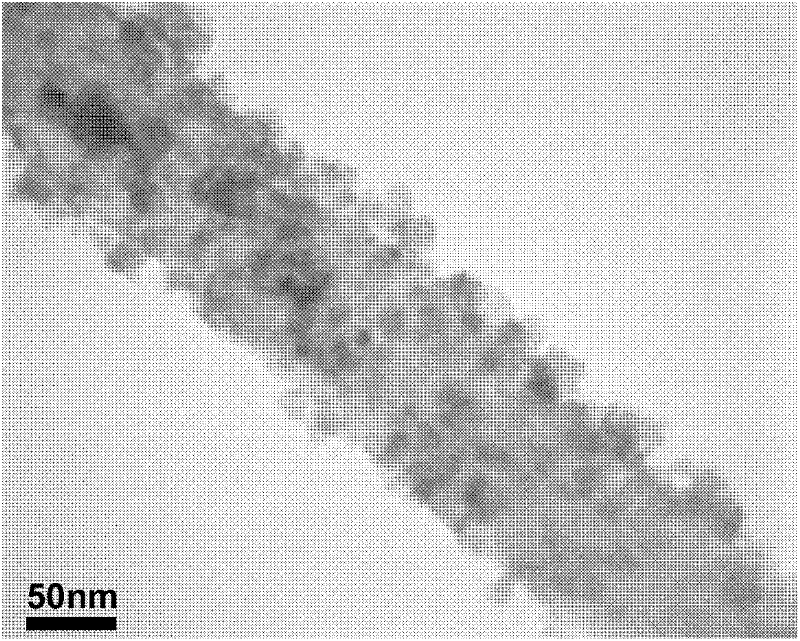

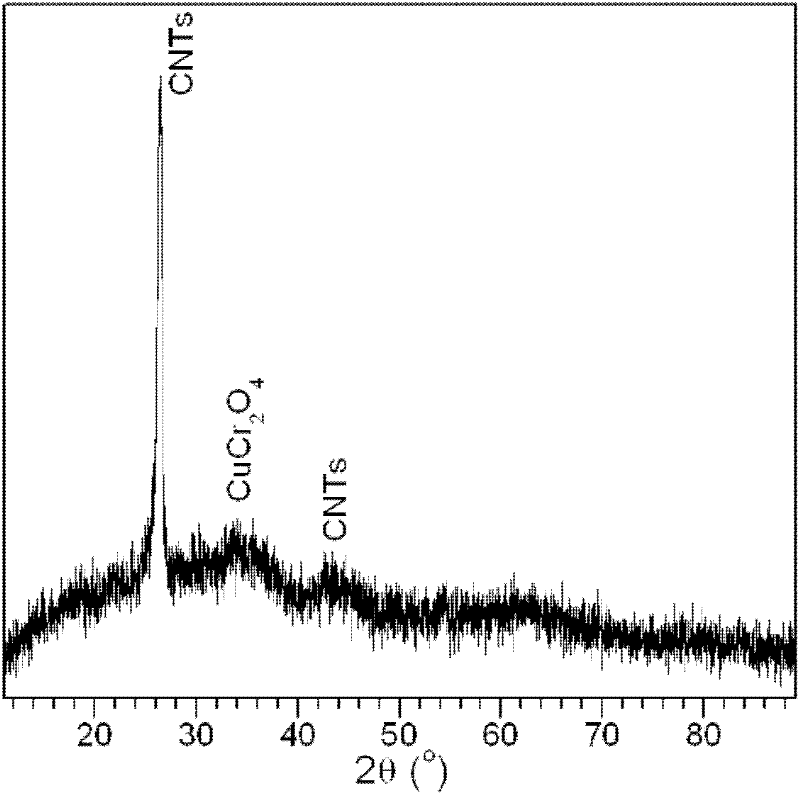

[0024] (3) Calcining at 280° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared. The transmission electron microscope photograph of gained copper chro...

Embodiment 2

[0026] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at 90° C. for 3 hours, cool, filter, wash, and dry.

[0027] (2) Take by weighing 1.9147g of copper nitrate hexahydrate and 5.1846g of chromium nitrate nonahydrate in a round bottom flask, add deionized water and stir to dissolve; then, add 1g of multi-walled carbon nanotubes through step (1) oxidation treatment , sonicated for 30 min, stirred at 30 °C for 5 h, and then allowed to stand for 12 h. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

[0028] (3) Calcining at 320° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared.

Embodiment 3

[0030] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at a temperature of 90° C. for 3 hours, cool, filter, wash, and dry.

[0031] (2) Weigh 0.3156g of copper chloride dihydrate and 1.4813g of chromium nitrate nonahydrate in a round bottom flask, add deionized water and stir to dissolve; then, add 1g of multi-walled carbon nanometer through step (1) oxidation treatment Tubes were sonicated for 30 min, stirred at 30 °C for 5 h, and then allowed to stand for 12 h. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

[0032] (3) Calcining at 320° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com