Copper chromite/carbon nanotube nano-composite catalyst, preparation method and application

A carbon nanotube and copper chromite technology is applied in the preparation of copper chromite/carbon nanotube nanocomposite catalyst and the field of preparation thereof, which can solve the problems of reducing the catalytic efficiency of the catalyst, easy agglomeration and the like, and achieve the effect of excellent catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at 90° C. for 3 hours, cool, filter, wash, and dry.

[0023] (2) Weigh 1.2765g of copper nitrate hexahydrate and 3.4564g of chromium nitrate nonahydrate into an in-situ flask, add deionized water and stir to dissolve. 1 g of multi-walled carbon nanotubes oxidized in step (1) was added, ultrasonicated for 30 minutes, stirred at 30° C. for 5 hours, and then left to stand for 12 hours. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

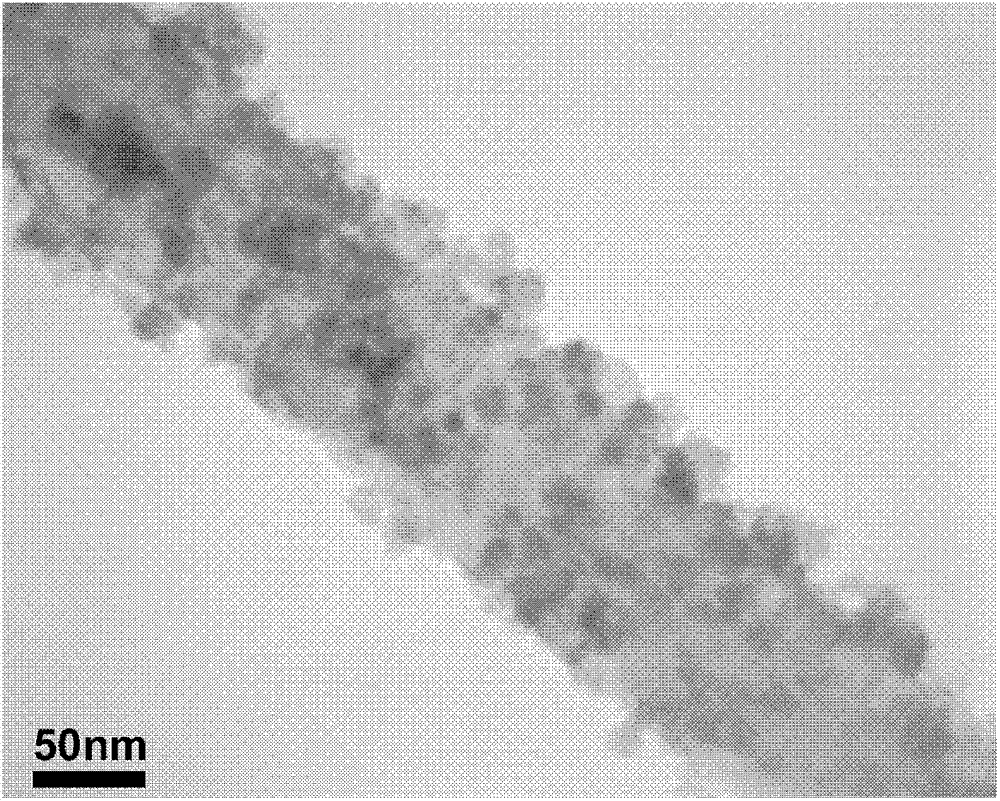

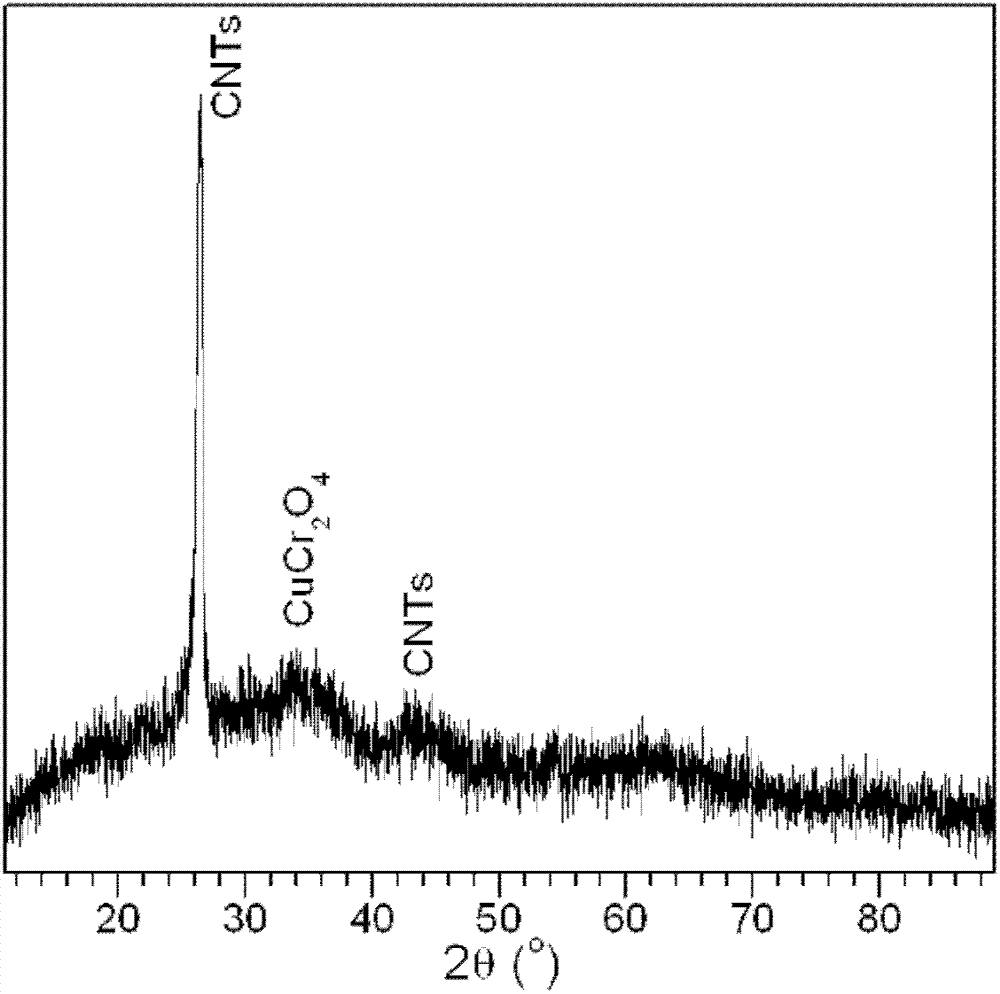

[0024] (3) Calcining at 280° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared. The transmission electron microscope photograph of gained copper chro...

Embodiment 2

[0026] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at 90° C. for 3 hours, cool, filter, wash, and dry.

[0027] (2) Take by weighing 1.9147g of copper nitrate hexahydrate and 5.1846g of chromium nitrate nonahydrate in a round bottom flask, add deionized water and stir to dissolve; then, add 1g of multi-walled carbon nanotubes through step (1) oxidation treatment , sonicated for 30 min, stirred at 30 °C for 5 h, and then allowed to stand for 12 h. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

[0028] (3) Calcining at 320° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared.

Embodiment 3

[0030] (1) Weigh 1 g of multi-walled carbon nanotubes into a round bottom flask, add concentrated nitric acid, ultrasonicate for 30 minutes, reflux at 90° C. for 3 hours, cool, filter, wash, and dry.

[0031] (2) Weigh 0.3156g of copper chloride dihydrate and 1.4813g of chromium nitrate nonahydrate in a round bottom flask, add deionized water and stir to dissolve; then, add 1g of multi-walled carbon nanometer through step (1) oxidation treatment Tubes were sonicated for 30 min, stirred at 30 °C for 5 h, and then allowed to stand for 12 h. Concentrated aqueous ammonia was added dropwise under stirring at 30°C until the pH value was 8.5, and then stood still for 4 hours. Filter with suction, wash the product three times with distilled water and ethanol successively, and dry.

[0032] (3) Calcining at 320° C. for 2 hours under an air atmosphere, the copper chromite / carbon nanotube nanocomposite catalyst can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com